化工学报 ›› 2023, Vol. 74 ›› Issue (1): 449-458.DOI: 10.11949/0438-1157.20221196

陈余1,2( ), 郑晓妍1,3, 赵辉1, 王二强2, 李杰1,4(

), 郑晓妍1,3, 赵辉1, 王二强2, 李杰1,4( ), 李春山1,2(

), 李春山1,2( )

)

收稿日期:2022-09-01

修回日期:2022-10-27

出版日期:2023-01-05

发布日期:2023-03-20

通讯作者:

李杰,李春山

作者简介:陈余(1997—),女,博士研究生,yuchen@ipe.ac.cn

基金资助:

Yu CHEN1,2( ), Xiaoyan ZHENG1,3, Hui ZHAO1, Erqiang WANG2, Jie LI1,4(

), Xiaoyan ZHENG1,3, Hui ZHAO1, Erqiang WANG2, Jie LI1,4( ), Chunshan LI1,2(

), Chunshan LI1,2( )

)

Received:2022-09-01

Revised:2022-10-27

Online:2023-01-05

Published:2023-03-20

Contact:

Jie LI, Chunshan LI

摘要:

近年来,煤基合成甲基丙烯酸甲酯(MMA)工艺获得广泛关注,但甲醛、丙醛羟醛缩合反应存在反应过程不连续、分离回收过程复杂等瓶颈问题。本文以表面改性的二氧化硅(SiO2)纳米球为乳化剂,乳化剂颗粒交联进一步“加固”,在液滴周围形成了致密SiO2壳层,构筑了强化型油包水(W/O)Pickering乳液。该Pickering乳液催化体系不仅实现了催化剂的“固载”和羟醛缩合温和反应过程的非均相转化,也为其他均相催化反应体系提供了机遇。

中图分类号:

陈余, 郑晓妍, 赵辉, 王二强, 李杰, 李春山. Pickering乳液催化非均相羟醛缩合反应研究[J]. 化工学报, 2023, 74(1): 449-458.

Yu CHEN, Xiaoyan ZHENG, Hui ZHAO, Erqiang WANG, Jie LI, Chunshan LI. Heterogeneous aldol condensation catalyzed with Pickering emulsion[J]. CIESC Journal, 2023, 74(1): 449-458.

图3 不同MTMS用量改性SiO2颗粒的接触角及其稳定的Pickering乳液显微镜图

Fig.3 The contact angle of SiO2 particles modified with various MTMS contents and the microscope image of Pickering emulsions stabilized by different amounts of MTMS-modified SiO2

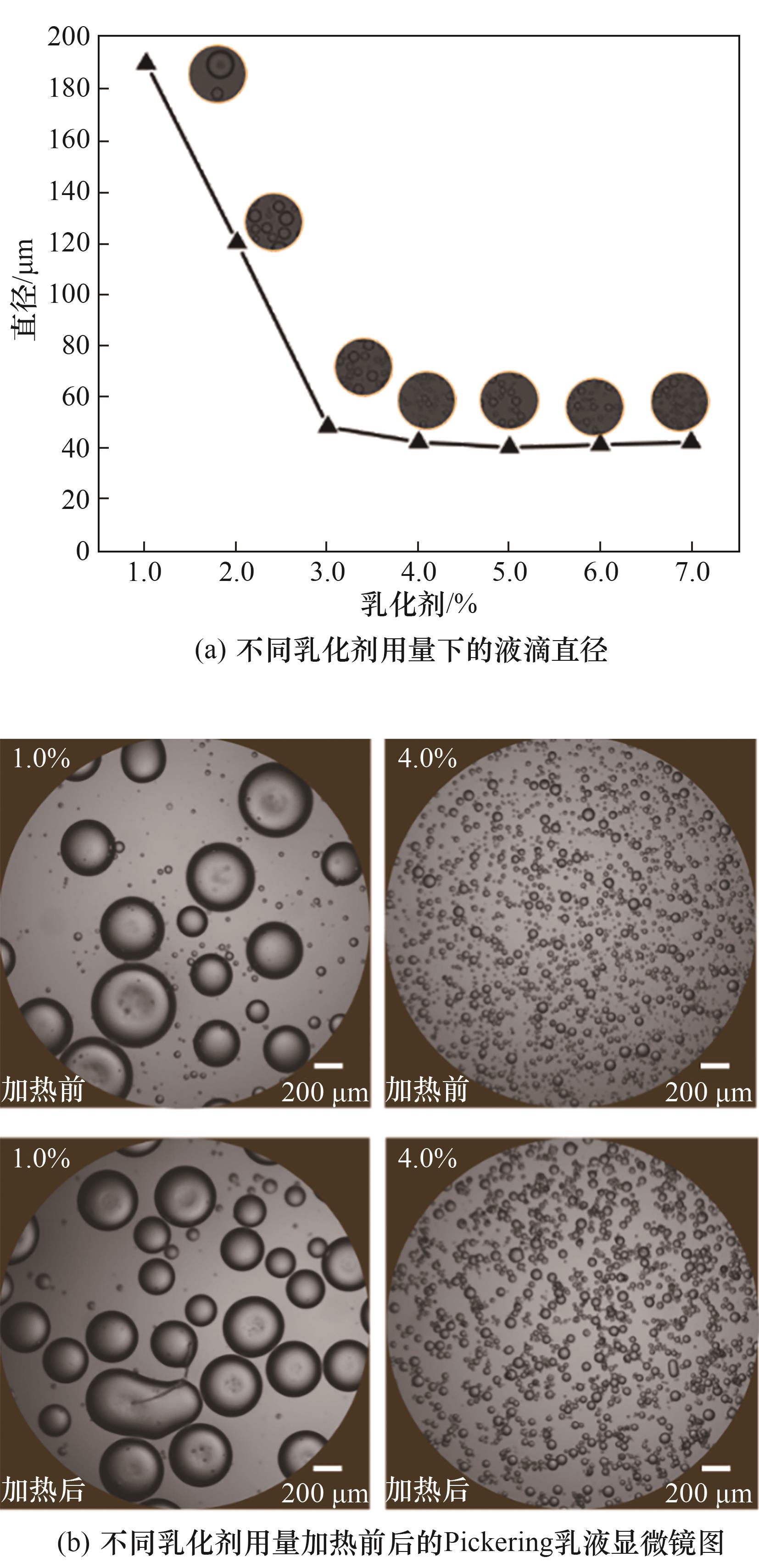

图5 不同乳化剂用量下的液滴直径及加热前后Pickering乳液显微镜图

Fig.5 The diameter of droplets with the different stabilizer content and the optical microscope images of Pickering emulsions with varied stabilizer contents

图6 不同交联剂及交联方式制备的强化Pickering乳液显微镜图像

Fig.6 Optical microscope images of the reinforced Pickering emulsion prepared by different crosslinking agents and various cross-linking methods

| 样品 | BET表面积/ (m²·g-1) | 孔径/nm | 孔体积/ (cm3·g-1) |

|---|---|---|---|

| P2 | 290 | 10.6 | 0.66 |

| P4 | 280 | 8.7 | 0.66 |

| P8 | 291 | 9.3 | 0.66 |

| P10 | 449 | 8.9 | 0.82 |

表1 不同交联剂用量合成多孔微球孔结构表征

Table 1 Characterization of the pore structure of porous microspheres with different crosslinker contents

| 样品 | BET表面积/ (m²·g-1) | 孔径/nm | 孔体积/ (cm3·g-1) |

|---|---|---|---|

| P2 | 290 | 10.6 | 0.66 |

| P4 | 280 | 8.7 | 0.66 |

| P8 | 291 | 9.3 | 0.66 |

| P10 | 449 | 8.9 | 0.82 |

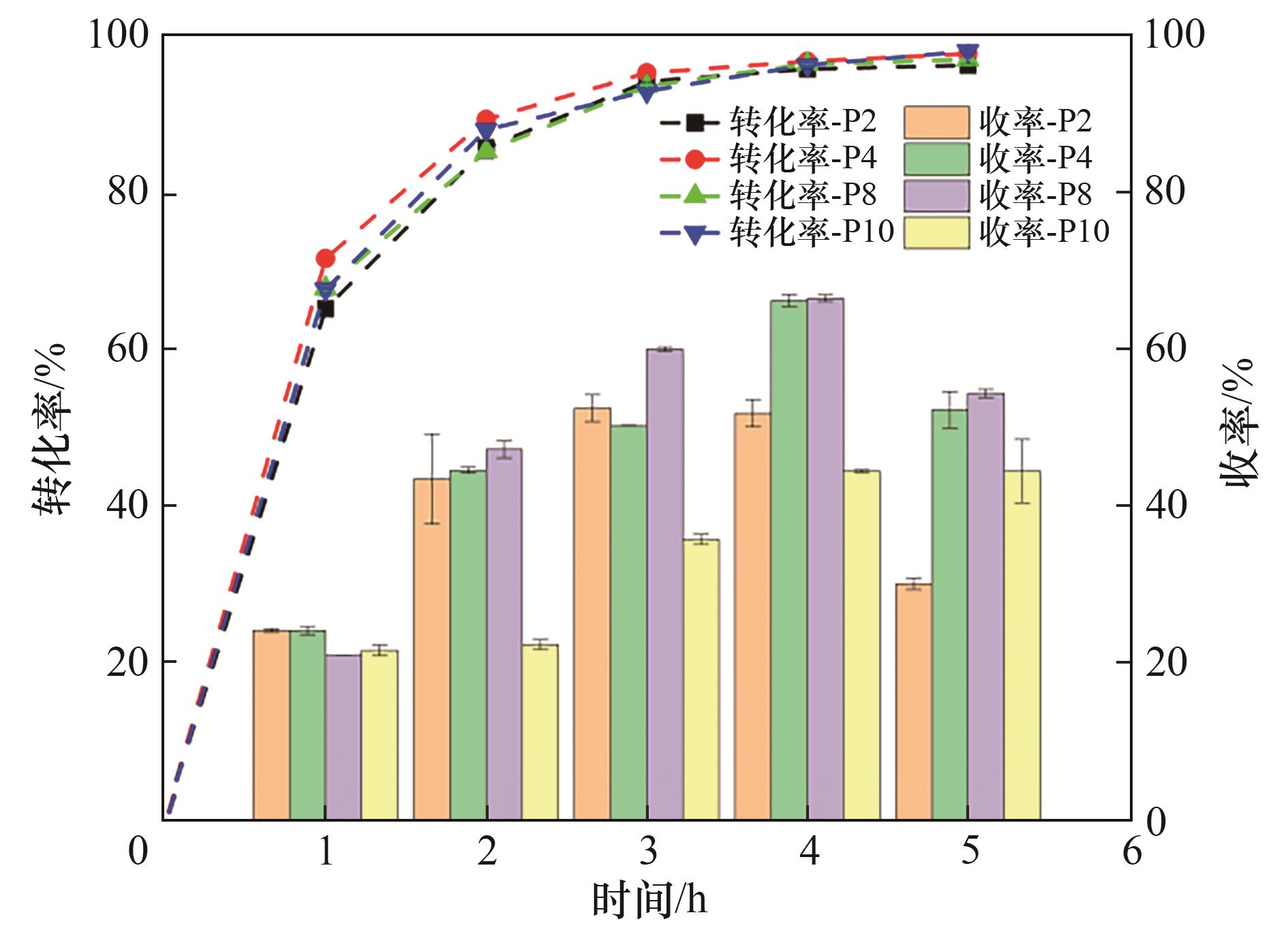

图10 间歇反应过程中不同交联剂用量下强化Pickering乳液的反应性能

Fig.10 Reaction performance of reinforced Pickering emulsions with different crosslinker amounts during batch reactions

| 文献 | 催化剂 | FA∶PA(摩尔比) | 温度/℃ | 压力/MPa | 收率/% | 反应过程 | 催化剂分离 |

|---|---|---|---|---|---|---|---|

| [ | 二乙胺+乙酸水溶液 | 1.05∶1 | 132 | 5.0 | 99 | 连续 | 是 |

| [ | 二乙胺乙酸盐 | 1∶1 | 40 | 常压 | 97 | 间歇 | 是 |

| [ | 层状双氢氧化物 | 1∶1 | 60 | 常压 | 30 | 间歇 | 否 |

| [ | 羟脯氨酸 | 1∶1 | 43 | 常压 | 45 | 间歇 | 否 |

| [ | 仲胺接枝D301树脂 | 2∶1 | 80 | 常压 | 40 | 连续 | 否 |

| 本工作 | L-脯氨酸 | 1.1∶1 | 45 | 常压 | 45 | 连续 | 否 |

表2 本工作中的操作条件和结果与文献的比较

Table 2 Comparison of the operating conditions and results in this work with literatures

| 文献 | 催化剂 | FA∶PA(摩尔比) | 温度/℃ | 压力/MPa | 收率/% | 反应过程 | 催化剂分离 |

|---|---|---|---|---|---|---|---|

| [ | 二乙胺+乙酸水溶液 | 1.05∶1 | 132 | 5.0 | 99 | 连续 | 是 |

| [ | 二乙胺乙酸盐 | 1∶1 | 40 | 常压 | 97 | 间歇 | 是 |

| [ | 层状双氢氧化物 | 1∶1 | 60 | 常压 | 30 | 间歇 | 否 |

| [ | 羟脯氨酸 | 1∶1 | 43 | 常压 | 45 | 间歇 | 否 |

| [ | 仲胺接枝D301树脂 | 2∶1 | 80 | 常压 | 40 | 连续 | 否 |

| 本工作 | L-脯氨酸 | 1.1∶1 | 45 | 常压 | 45 | 连续 | 否 |

| 1 | 王刚, 李增喜, 李春山. 温和条件下丙酸甲酯和甲醇一步合成甲基丙烯酸甲酯[J]. 中国科学: 化学, 2021, 51(2): 235-241. |

| Wang G, Li Z X, Li C S. One-step synthesis of methyl methacrylate from methyl propionate and methanol under mild condition[J]. Scientia Sinica Chimica, 2021, 51(2): 235-241. | |

| 2 | Ran R, Li J, Wang G, et al. Esterification of methacrylic acid with methanol: process optimization, kinetic modeling, and reactive distillation[J]. Industrial & Engineering Chemistry Research, 2019, 58(6): 2135-2145. |

| 3 | Wang G, Li Z X, Li C S, et al. In-situ generated ionic liquid catalyzed aldol condensation of trioxane with ester in mild homogeneous system[J]. Green Energy & Environment, 2019, 4(3): 293-299. |

| 4 | 董海峰, 李增喜, 王正平, 等. Pd-Pb/Al2O3催化剂上甲基丙烯醛氧化酯化合成甲基丙烯酸甲酯[J]. 化工学报, 2006, 57(6): 1346-1350. |

| Dong H F, Li Z X, Wang Z P, et al. Oxidative esterification of methacrolein to methyl methacrylate over Pd-Pb/Al2O3 catalysts[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(6): 1346-1350. | |

| 5 | Yu J Y, Yang Y Q, Chen Y, et al. Selective methacrolein oxidation catalyzed with heteropoly compounds: effect of the oxidation state modulated with hydrogen pretreatment[J]. Industrial & Engineering Chemistry Research, 2022, 61(28): 10014-10023. |

| 6 | Deng S L, Yan T T, Ran R, et al. Influence of Al oxides on Cs-SiO2 catalysts for vapor phase aldol condensation of methyl acetate and formaldehyde[J]. Industrial & Engineering Chemistry Research, 2022, 61(17): 5766-5777. |

| 7 | Mahboub M J D, Dubois J L, Cavani F, et al. Catalysis for the synthesis of methacrylic acid and methyl methacrylate[J]. Chemical Society Reviews, 2018, 47(20): 7703-7738. |

| 8 | Moraru M D, Bildea C S, Kiss A A. Novel eco-efficient process for methyl methacrylate production[J]. Industrial & Engineering Chemistry Research, 2021, 60(3): 1290-1301. |

| 9 | Fan L, Xu B H, Li J, et al. Kinetic studies on both synthesis of methacrolein catalyzed by an ionic liquid and catalyst deactivation[J]. Industrial & Engineering Chemistry Research, 2021, 60(15): 5411-5420. |

| 10 | Zhao H, Ran R, Wang L, et al. Novel continuous process for methacrolein production in numerous droplet reactors[J]. AIChE Journal, 2020, 66(7): 16239. |

| 11 | Yan H W, Huo F, Li P, et al. Mild catalytic mechanism of the mannich reaction for synthesizing methylacrolein by sec-amine short-chain aliphatic acid ionic liquid catalysts[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(20): 6687-6698. |

| 12 | Yu J Y, Jensen A D, Wang L, et al. Catalytic synthesis of methacrolein via the condensation of formaldehyde and propionaldehyde with L-proline[J]. Green Chemistry, 2020, 22(13): 4222-4230. |

| 13 | 李玉超, 闫瑞一, 王蕾, 等. 甲醛和丙醛缩合制备甲基丙烯醛反应动力学[J]. 过程工程学报, 2012, 12(4): 602-607. |

| Li Y C, Yan R Y, Wang L, et al. Reaction kinetics for preparation of methacrolein by condensation of formaldehyde with propionaldehyde[J]. The Chinese Journal of Process Engineering, 2012, 12(4): 602-607. | |

| 14 | Chong S Y, Wang T T, Zhong H J, et al. A bifunctional and recyclable catalyst: amine and ionic liquid grafting on MOFs for the one-pot synthesis of N-aryl oxazolidin-2-ones[J]. Green Energy & Environment, 2020, 5(2): 154-165. |

| 15 | Wang G, Li Z X, Fan L, et al. Sec-amine grafted D301 resin catalyzed fixed-bed process for continuous preparation of methacrolein via Mannich reaction[J]. Chemical Engineering Journal, 2019, 370: 625-636. |

| 16 | Yu S J, Zhang D Y, Jiang J Z, et al. Biphasic biocatalysis using a CO2-switchable Pickering emulsion[J]. Green Chemistry, 2019, 21(15): 4062-4068. |

| 17 | 王伟浩, 杨鑫, 李飞, 等. 载酶海藻酸钙复合微球稳定水包油型Pickering乳液及其强化界面酶催化反应[J]. 化工学报, 2019, 70(12): 4777-4786. |

| Wang W H, Yang X, Li F, et al. E@Alg@s-TiO2 microsphere stabilized O/W Pickering emulsion and the enhancement of interfacial enzymatic catalysis[J]. CIESC Journal, 2019, 70(12): 4777-4786. | |

| 18 | Röllig R, Plikat C, Ansorge-Schumacher M B. Efficient and selective carboligation with whole-cell biocatalysts in Pickering emulsion[J]. Angewandte Chemie, 2019, 58(37): 12960-12963. |

| 19 | Zhao Y, Zhang M, Wen X, et al. Microfluidic interface boosted synthesis of covalent organic polymer capsule[J]. Green Chemical Engineering, 2020, 1(1): 63-69. |

| 20 | Zhang M, Ettelaie R, Dong L L, et al. Pickering emulsion droplet-based biomimetic microreactors for continuous flow cascade reactions[J]. Nature Communications, 2022, 13: 475. |

| 21 | Wu J, Ma G H. Pickering emulsions: recent studies of Pickering emulsions: particles make the difference[J]. Small, 2016, 12(34): 4582. |

| 22 | Zhao H, Yang Y Q, Chen Y, et al. A review of multiple Pickering emulsions: solid stabilization, preparation, particle effect, and application[J]. Chemical Engineering Science, 2022, 248: 117085. |

| 23 | Zhao P P, Hu Z H, Cheng P, et al. Coalescence-induced bubble departure: effects of dynamic contact angles[J]. Langmuir, 2022, 38(34): 10558-10567. |

| 24 | 罗东琴, 孙宁, 李秋红, 等. 非共价改性纳米颗粒稳定Pickering乳液的制备及可逆调控[J]. 化工学报, 2020, 71(4): 1859-1870. |

| Luo D Q, Sun N, Li Q H, et al. Preparation and modulation of Pickering emulsion stabilized by non-covalent hydrophobic modified nanoparticles[J]. CIESC Journal, 2020, 71(4): 1859-1870. | |

| 25 | Zhao H, Li J, Wang L, et al. Pickering emulsion stabilized by dual stabilizer: a novel reaction/separation system for methacrolein synthesis[J]. Chemical Engineering Science, 2021, 229: 116038. |

| 26 | Zhang Y B, Bai P L, Zhang M, et al. Pickering droplet-derived silica microreactors with a biomimetic aqueous environment for continuous-flow enzymatic reactions[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(1): 662-670. |

| 27 | Zhang X M, Hou Y T, Ettelaie R, et al. Pickering emulsion-derived liquid-solid hybrid catalyst for bridging homogeneous and heterogeneous catalysis[J]. Journal of the American Chemical Society, 2019, 141(13): 5220-5230. |

| 28 | Lei L, Tao R, Shi J M, et al. Rapid and continuous synthesis of methacrolein with high selectivity by condensation of propanal with formaldehyde in laboratory[J]. The Canadian Journal of Chemical Engineering, 2017, 95(10): 1985-1992. |

| 29 | Yan R Y, Lv Z P, Tang H G, et al. Mechanistic insight into methacrolein formation from formaldehyde and propionaldehyde[J]. Catalysis Letters, 2022, 152: 799-805. |

| 30 | Ju L X, Li G, Luo H X. Catalytic synthesis of methacrolein via the condensation of formaldehyde and propionaldehyde with L-proline intercalated layered double hydroxides[J]. Catalysts, 2021, 12(1): 42. |

| 31 | Deshpande R M, Diwakar M M, Mahajan A N, et al. Biphasic catalysis for a selective oxo-Mannich tandem synthesis of methacrolein[J]. Journal of Molecular Catalysis A: Chemical, 2004, 211(1/2): 49-53. |

| 32 | Wei W, Ettelaie R, Zhang X M, et al. Co-compartmentalization of enzymes and cofactors within Pickering emulsion droplets for continuous-flow catalysis[J]. Angewandte Chemie, 2022,61(45):e202211912. |

| [1] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [2] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [3] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [4] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [5] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [6] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [7] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [8] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [9] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [10] | 陈雅鑫, 袁航, 刘冠章, 毛磊, 杨纯, 张瑞芳, 张光亚. 蛋白质纳米笼介导的酶自固定化研究进展[J]. 化工学报, 2023, 74(7): 2773-2782. |

| [11] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [12] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [13] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [14] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [15] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号