化工学报 ›› 2023, Vol. 74 ›› Issue (12): 4968-4978.DOI: 10.11949/0438-1157.20231196

刘世君1( ), 郑安庆1,2, 陈晓丽1, 付娟1(

), 郑安庆1,2, 陈晓丽1, 付娟1( ), 苏秋成1

), 苏秋成1

收稿日期:2023-11-20

修回日期:2023-12-14

出版日期:2023-12-25

发布日期:2024-02-19

通讯作者:

付娟

作者简介:刘世君(1990—),男,硕士研究生,实验师,liusj@ms.giec.ac.cn

基金资助:

Shijun LIU1( ), Anqing ZHENG1,2, Xiaoli CHEN1, Juan FU1(

), Anqing ZHENG1,2, Xiaoli CHEN1, Juan FU1( ), Qiucheng SU1

), Qiucheng SU1

Received:2023-11-20

Revised:2023-12-14

Online:2023-12-25

Published:2024-02-19

Contact:

Juan FU

摘要:

天然纤维在许多领域可取代合成纤维应用于增强式复合材料中,在保证了一定强度与刚度的同时具有成本低、质量轻、降解易等优点,但目前对于天然复合材料热解回收方面的研究匮乏。鉴于此,本文通过热重分析仪(TG)和热裂解气相色谱质谱联用仪(Py-GC/MS)研究天然纤维素增强式环氧树脂复合材料热解反应动力学和产物生产特性。结果表明,在复合材料中,纤维素和环氧树脂的协同效应降低了复合材料的热稳定性,同时极大程度地降低了焦的残余量,最终显著降低了复合材料的热解活化能;另一方面,协同效应对快速热解产物的种类影响不明显,但能够显著影响产物产量和分布。

中图分类号:

刘世君, 郑安庆, 陈晓丽, 付娟, 苏秋成. 纤维素增强环氧树脂复合材料热解特性研究[J]. 化工学报, 2023, 74(12): 4968-4978.

Shijun LIU, Anqing ZHENG, Xiaoli CHEN, Juan FU, Qiucheng SU. Study on pyrolysis characteristics of cellulose-enhanced epoxy resin composites[J]. CIESC Journal, 2023, 74(12): 4968-4978.

| 样品编号 | 原料配比/%(质量分数) | 固化温度与时间 | |

|---|---|---|---|

| DGEBA+DDM | 纤维素 | ||

| EP | 100 | 0 | 100℃ 2 h+ 150℃ 2 h |

| EP-10Cell | 90 | 10 | |

| EP-20Cell | 80 | 20 | |

| EP-30Cell | 70 | 30 | |

表1 固化比例与实验条件

Table 1 Curing ratio and experimental conditions

| 样品编号 | 原料配比/%(质量分数) | 固化温度与时间 | |

|---|---|---|---|

| DGEBA+DDM | 纤维素 | ||

| EP | 100 | 0 | 100℃ 2 h+ 150℃ 2 h |

| EP-10Cell | 90 | 10 | |

| EP-20Cell | 80 | 20 | |

| EP-30Cell | 70 | 30 | |

| 步骤 | Starink积分法 |

|---|---|

| 1 | 获得至少在三种加热速率下转化率α与温度T的关系 |

| 2 | 在不同加热速率下选定α值时计算ln(β/T1.92)的值 |

| 3 | 绘制在选定α值下ln(β/T1.92)与1/T的关系,并确定活化能E |

表2 Starink积分法计算活化能流程

Table 2 The activation energy calculation flow of Starink integral method

| 步骤 | Starink积分法 |

|---|---|

| 1 | 获得至少在三种加热速率下转化率α与温度T的关系 |

| 2 | 在不同加热速率下选定α值时计算ln(β/T1.92)的值 |

| 3 | 绘制在选定α值下ln(β/T1.92)与1/T的关系,并确定活化能E |

图1 不同升温速率下EP-10Cell、EP-20Cell和EP-30Cell的TGA/DTG实验(exp.)和预测(pred.)曲线

Fig.1 TGA/DTG experimental (exp.) and predicted (pred.) curves of EP-10Cell, EP-20Cell and EP-30Cell at different heating rates

| 参数 | 升温速率/ (℃/min) | 纤维素 | EP | EP-10Cell | EP-20Cell | EP-30Cell | |||

|---|---|---|---|---|---|---|---|---|---|

| Exp. | Pred. | Exp. | Pred. | Exp. | Pred. | ||||

| Ychar /% | 5 | 0.37 | 17.63 | 7.93 | 15.53 | 5.89 | 13.43 | 9.38 | 11.33 |

| 15 | 2.39 | 16.67 | 6.16 | 15.24 | 7.49 | 13.82 | 6.45 | 12.39 | |

| 30 | 5.41 | 15.43 | 7.90 | 14.43 | 7.08 | 13.43 | 10.61 | 12.42 | |

| T0 /℃ | 5 | 293.69 | 349.40 | 300.57 | 339.47 | 291.48 | 315.46 | 293.92 | 296.42 |

| 15 | 308.45 | 370.71 | 322.75 | 367.43 | 312.82 | 348.60 | 314.78 | 313.23 | |

| 30 | 320.11 | 382.04 | 335.20 | 367.98 | 323.84 | 333.22 | 328.39 | 326.60 | |

| Tmax /℃ | 5 | 322.50 | 375.00 | 365.00 | 375.00 | 362.50 | 375.00 | 365.00 | 375.00 |

| 15 | 342.50 | 395.00 | 390 | 395.00 | 387.50 | 395.00 | 390 | 395.00 | |

| 30 | 360 | 407.50 | 407.50 | 407.50 | 405.00 | 407.50 | 407.50 | 407.50 | |

| Tf /℃ | 5 | 349.66 | 432.55 | 428.58 | 432.84 | 426.32 | 433.19 | 422.65 | 433.64 |

| 15 | 370.83 | 454.20 | 452.43 | 454.45 | 450.27 | 454.77 | 446.96 | 455.21 | |

| 30 | 388.88 | 472.79 | 468.40 | 473.30 | 465.17 | 473.92 | 462.39 | 474.69 | |

| (dm/dTmax)/(%/℃) | 5 | -3.10 | -1.90 | -1.50 | -1.71 | -1.36 | -1.53 | -1.38 | -1.34 |

| 15 | -2.67 | -1.97 | -1.53 | -1.78 | -1.34 | -1.59 | -1.43 | -1.39 | |

| 30 | -2.35 | -1.84 | -1.47 | -1.66 | -1.34 | -1.48 | -1.35 | -1.31 | |

表3 EP-10Cell、EP-20Cell和EP-30Cell的热解特征参数

Table 3 Characteristic parameters of TGA/DTG curves of EP-10Cell, EP-20Cell and EP-30Cell

| 参数 | 升温速率/ (℃/min) | 纤维素 | EP | EP-10Cell | EP-20Cell | EP-30Cell | |||

|---|---|---|---|---|---|---|---|---|---|

| Exp. | Pred. | Exp. | Pred. | Exp. | Pred. | ||||

| Ychar /% | 5 | 0.37 | 17.63 | 7.93 | 15.53 | 5.89 | 13.43 | 9.38 | 11.33 |

| 15 | 2.39 | 16.67 | 6.16 | 15.24 | 7.49 | 13.82 | 6.45 | 12.39 | |

| 30 | 5.41 | 15.43 | 7.90 | 14.43 | 7.08 | 13.43 | 10.61 | 12.42 | |

| T0 /℃ | 5 | 293.69 | 349.40 | 300.57 | 339.47 | 291.48 | 315.46 | 293.92 | 296.42 |

| 15 | 308.45 | 370.71 | 322.75 | 367.43 | 312.82 | 348.60 | 314.78 | 313.23 | |

| 30 | 320.11 | 382.04 | 335.20 | 367.98 | 323.84 | 333.22 | 328.39 | 326.60 | |

| Tmax /℃ | 5 | 322.50 | 375.00 | 365.00 | 375.00 | 362.50 | 375.00 | 365.00 | 375.00 |

| 15 | 342.50 | 395.00 | 390 | 395.00 | 387.50 | 395.00 | 390 | 395.00 | |

| 30 | 360 | 407.50 | 407.50 | 407.50 | 405.00 | 407.50 | 407.50 | 407.50 | |

| Tf /℃ | 5 | 349.66 | 432.55 | 428.58 | 432.84 | 426.32 | 433.19 | 422.65 | 433.64 |

| 15 | 370.83 | 454.20 | 452.43 | 454.45 | 450.27 | 454.77 | 446.96 | 455.21 | |

| 30 | 388.88 | 472.79 | 468.40 | 473.30 | 465.17 | 473.92 | 462.39 | 474.69 | |

| (dm/dTmax)/(%/℃) | 5 | -3.10 | -1.90 | -1.50 | -1.71 | -1.36 | -1.53 | -1.38 | -1.34 |

| 15 | -2.67 | -1.97 | -1.53 | -1.78 | -1.34 | -1.59 | -1.43 | -1.39 | |

| 30 | -2.35 | -1.84 | -1.47 | -1.66 | -1.34 | -1.48 | -1.35 | -1.31 | |

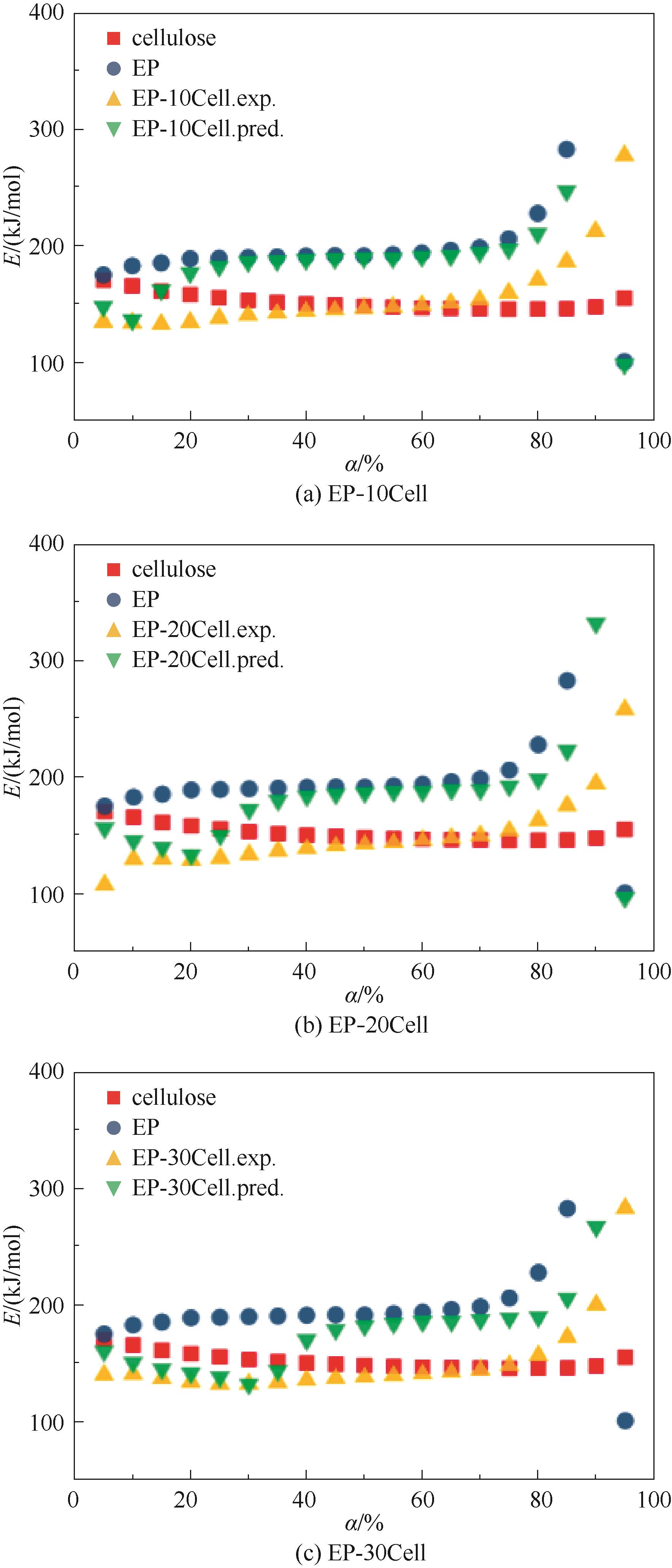

图2 EP-10Cell、EP-20Cell和EP-30Cell实验(exp.)与预测(pred.)的活化能E与转化率α关系

Fig.2 The experimental and predicted relationship between the activation energy E and conversion α of EP-10Cell, EP-20Cell and EP-30Cell

| 样品 | E0/(kJ/mol) |

|---|---|

| 纤维素 | 152.4 |

| EP | 192.4 |

| EP-10Cell | 145.1 |

| EP-20Cell | 140.5 |

| EP-30Cell | 137.8 |

表4 活化能在稳定区域(α=20%~70%)的平均值

Table 4 The average activation energy in the stable region (α=20%—70%)

| 样品 | E0/(kJ/mol) |

|---|---|

| 纤维素 | 152.4 |

| EP | 192.4 |

| EP-10Cell | 145.1 |

| EP-20Cell | 140.5 |

| EP-30Cell | 137.8 |

| 种类编号 | 定义 |

|---|---|

| LMW | 低分子量物种 |

| 1-B | 化合物具有一个没有氧或氮的单一苯环 |

| 1-B-O | 含有一个含有氧的单个苯环的化合物 |

| 1-B-N | 具有单一苯环和氮气特征的化合物 |

| 2-B | 具有两个苯环而含氧或氮的化合物 |

| 2-B-O | 具有两个苯环的化合物 |

| 2-B-N | 具有两个苯环和氮的化合物 |

| 其他 | 未识别或杂质 |

表5 环氧树脂热解产物分类方法

Table 5 Classification method of epoxy resin pyrolysis products

| 种类编号 | 定义 |

|---|---|

| LMW | 低分子量物种 |

| 1-B | 化合物具有一个没有氧或氮的单一苯环 |

| 1-B-O | 含有一个含有氧的单个苯环的化合物 |

| 1-B-N | 具有单一苯环和氮气特征的化合物 |

| 2-B | 具有两个苯环而含氧或氮的化合物 |

| 2-B-O | 具有两个苯环的化合物 |

| 2-B-N | 具有两个苯环和氮的化合物 |

| 其他 | 未识别或杂质 |

图3 EP、EP-10Cell、EP-20Cell和EP-30Cell快速热解过程中EP产物的类别分布

Fig.3 Class distribution of EP products during fast pyrolysis of EP, EP-10cell, EP-20cell and EP-30cell

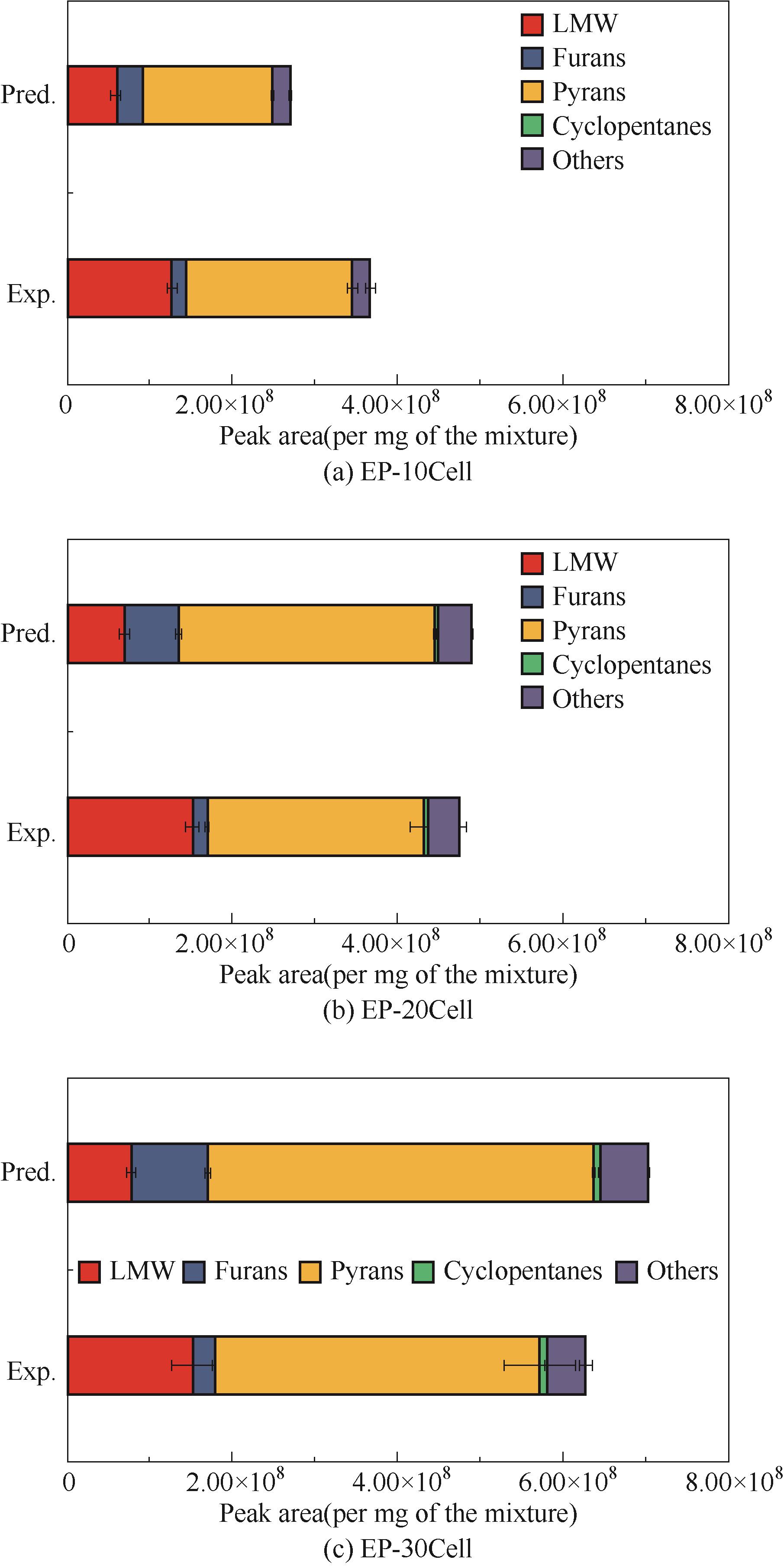

图5 纤维素组分EP-10Cell、EP-20Cell、EP-30Cell快速热解中产物的实验和预测类别分布

Fig.5 Experimental and predicted class distribution of products from fast pyrolysis of cellulose in EP-10Cell, EP-20Cell and EP-30Cell

| 产物类别 | 占比/% | |||||||

|---|---|---|---|---|---|---|---|---|

| LMS | 1-B | 1-B-O | 1-B-N | 2-B | 2-B-O | 2-B-N | Others | |

| EP | 1.52 | 0.49 | 9.71 | 0.42 | 0.14 | 66.36 | 15.34 | 6.01 |

| EP-10Cell | 1.45 | 0.47 | 10.20 | 0.30 | 0.18 | 68.42 | 14.60 | 4.38 |

| EP-20Cell | 1.65 | 0.50 | 13.34 | 0.35 | 0.16 | 68.15 | 11.70 | 4.16 |

| EP-30Cell | 1.27 | 0.41 | 11.00 | 0.32 | 0.14 | 70.53 | 12.45 | 3.88 |

表6 环氧树脂快速热解产物中各类产物的占比

Table 6 Class distribution during fast pyrolysis of epoxy resin

| 产物类别 | 占比/% | |||||||

|---|---|---|---|---|---|---|---|---|

| LMS | 1-B | 1-B-O | 1-B-N | 2-B | 2-B-O | 2-B-N | Others | |

| EP | 1.52 | 0.49 | 9.71 | 0.42 | 0.14 | 66.36 | 15.34 | 6.01 |

| EP-10Cell | 1.45 | 0.47 | 10.20 | 0.30 | 0.18 | 68.42 | 14.60 | 4.38 |

| EP-20Cell | 1.65 | 0.50 | 13.34 | 0.35 | 0.16 | 68.15 | 11.70 | 4.16 |

| EP-30Cell | 1.27 | 0.41 | 11.00 | 0.32 | 0.14 | 70.53 | 12.45 | 3.88 |

| 产物类别 | 含量/% | ||||

|---|---|---|---|---|---|

| p-Isopropenylphenol | Phenol | p-Cumenol | Phenol, 2-methyl- | p-Cresol | |

| EP | 41.49 | 30.00 | 16.54 | 8.44 | 3.53 |

| EP-10Cell | 39.54 | 30.90 | 16.47 | 9.13 | 3.96 |

| EP-20Cell | 40.84 | 32.04 | 16.26 | 8.14 | 2.71 |

| EP-30Cell | 40.92 | 31.77 | 16.40 | 7.84 | 3.06 |

表7 1-B-O中主要产物的百分含量

Table 7 Percentages of the main product in class 1-B-O

| 产物类别 | 含量/% | ||||

|---|---|---|---|---|---|

| p-Isopropenylphenol | Phenol | p-Cumenol | Phenol, 2-methyl- | p-Cresol | |

| EP | 41.49 | 30.00 | 16.54 | 8.44 | 3.53 |

| EP-10Cell | 39.54 | 30.90 | 16.47 | 9.13 | 3.96 |

| EP-20Cell | 40.84 | 32.04 | 16.26 | 8.14 | 2.71 |

| EP-30Cell | 40.92 | 31.77 | 16.40 | 7.84 | 3.06 |

| 产物类别 | 含量/% | ||||

|---|---|---|---|---|---|

| Phenol, 4,4′-(1-methylethylidene)bis- | 2-(4′-Hydroxyphenyl)-2-(4′-methoxyphenyl)propane | 4-(2-(4-(Ethynyloxy)phenyl)propan-2-yl)phenol | 4-(2-(4-(2-Hydroxyethoxy)phenyl)propan-2-yl)phenol | 4-(2-(4-(2-Hydroxypropoxy)phenyl)propan-2-yl)phenol | |

| EP | 63.79 | 13.09 | 12.15 | 6.59 | 4.39 |

| EP-10Cell | 69.45 | 16.32 | 9.38 | 1.70 | 3.15 |

| EP-20Cell | 73.52 | 14.36 | 7.22 | 1.72 | 3.18 |

| EP-30Cell | 72.49 | 14.77 | 7.86 | 1.80 | 3.08 |

表8 2-B-O中主要产物的百分含量

Table 8 Percentages of the main product in class 2-B-O

| 产物类别 | 含量/% | ||||

|---|---|---|---|---|---|

| Phenol, 4,4′-(1-methylethylidene)bis- | 2-(4′-Hydroxyphenyl)-2-(4′-methoxyphenyl)propane | 4-(2-(4-(Ethynyloxy)phenyl)propan-2-yl)phenol | 4-(2-(4-(2-Hydroxyethoxy)phenyl)propan-2-yl)phenol | 4-(2-(4-(2-Hydroxypropoxy)phenyl)propan-2-yl)phenol | |

| EP | 63.79 | 13.09 | 12.15 | 6.59 | 4.39 |

| EP-10Cell | 69.45 | 16.32 | 9.38 | 1.70 | 3.15 |

| EP-20Cell | 73.52 | 14.36 | 7.22 | 1.72 | 3.18 |

| EP-30Cell | 72.49 | 14.77 | 7.86 | 1.80 | 3.08 |

| 产物类别 | 含量/% | ||||

|---|---|---|---|---|---|

| 4,4′-Methylenebis(N-methylaniline) | Benzenamine, 4,4′- methylenebis(N,N-dimethyl-) | N,N-Dimethyl-4-(4-(methylamino)benzyl)aniline | Benzenamine, 4,4′-methylenebis- | Oxazole, 2-(4-methoxyphenyl)-5-phenyl- | |

| EP | 30.53 | 24.76 | 22.95 | 17.50 | 4.27 |

| EP-10Cell | 31.15 | 32.04 | 22.81 | 8.17 | 5.83 |

| EP-20Cell | 21.51 | 39.60 | 18.18 | 11.95 | 8.76 |

| EP-30Cell | 24.16 | 35.14 | 22.71 | 10.47 | 7.52 |

表9 2-B-N中主要产物的百分含量

Table 9 Percentages of the main product in class 2-B-N

| 产物类别 | 含量/% | ||||

|---|---|---|---|---|---|

| 4,4′-Methylenebis(N-methylaniline) | Benzenamine, 4,4′- methylenebis(N,N-dimethyl-) | N,N-Dimethyl-4-(4-(methylamino)benzyl)aniline | Benzenamine, 4,4′-methylenebis- | Oxazole, 2-(4-methoxyphenyl)-5-phenyl- | |

| EP | 30.53 | 24.76 | 22.95 | 17.50 | 4.27 |

| EP-10Cell | 31.15 | 32.04 | 22.81 | 8.17 | 5.83 |

| EP-20Cell | 21.51 | 39.60 | 18.18 | 11.95 | 8.76 |

| EP-30Cell | 24.16 | 35.14 | 22.71 | 10.47 | 7.52 |

| 1 | Ma C, Sánchez-Rodríguez D, Kamo T. A comprehensive study on the oxidative pyrolysis of epoxy resin from fiber/epoxy composites: product characteristics and kinetics[J]. Journal of Hazardous Materials, 2021, 412: 125329. |

| 2 | 纪荣彬, 陈婷, 彭超华, 等. 有机磷/硼杂化小分子阻燃改性环氧树脂[J]. 化工学报, 2021, 72(7): 3856-3868. |

| Ji R B, Chen T, Peng C H, et al. Flame retardant epoxy resin composites modified with organophosphorus and boron hybrid molecules[J]. CIESC Journal, 2021, 72(7): 3856-3868. | |

| 3 | 田秀娟, 王忠卫, 于青, 等. 含磷阻燃剂阻燃环氧树脂热降解动力学[J]. 化工学报, 2014, 65(12): 5082-5089. |

| Tian X J, Wang Z W, Yu Q, et al. Kinetics of thermal decomposition of epoxy resins modified with phosphorus-containing flame retardant[J]. CIESC Journal, 2014, 65(12): 5082-5089. | |

| 4 | Das S, Yokozeki T. A brief review of modified conductive carbon/glass fibre reinforced composites for structural applications: lightning strike protection, electromagnetic shielding, and strain sensing[J]. Composites Part C: Open Access, 2021, 5: 100162. |

| 5 | 邹祺, 叶逸云, 焦俊科, 等. 碳纤维增强热固性复合材料-钛合金激光连接接头性能分析[J]. 航空学报, 2022, 43(2): 625037. |

| Zou Q, Ye Y Y, Jiao J K, et al. Performance analysis of carbon fiber reinforced thermalsetting composite-titanium alloy laser joint[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(2): 625037. | |

| 6 | 张灵静, 陈桦, 蒋建军, 等. 碳纤维增强热固性复合材料回收再利用技术研究进展[J]. 工程塑料应用, 2019, 47(7): 134-140, 150. |

| Zhang L J, Chen H, Jiang J J, et al. Research progress on recycling and reuse technology of carbon fiber reinforced thermosetting composites[J]. Engineering Plastics Application, 2019, 47(7): 134-140, 150. | |

| 7 | 王琪, 罗胜利, 王强, 等. 电子废弃物中环氧树脂的无害化和资源化处置现状和对策研究[J]. 环境工程, 2011, 29(S1): 357-359, 367. |

| Wang Q, Luo S L, Wang Q, et al. Study on the present situation and countermeasures of harmless and resource disposal of epoxy resin in electronic waste[J]. Environmental Engineering, 2011, 29(S1): 357-359, 367. | |

| 8 | 王芳, 刘玉卿, 海热提. 防溴型环氧树脂电路板热解动力学分析[J]. 化工学报, 2011, 62(10): 2945-2950. |

| Wang F, Liu Y Q, Hai R T. Pyrolysis kinetics of anti-Br printed circuit boards made epoxy resin[J]. CIESC Journal, 2011, 62(10): 2945-2950. | |

| 9 | 董卿, 尤飞, 蒋军成, 等. 废弃FR4环氧树脂覆铜板热解特性及固体残余物组成[J]. 安全与环境学报, 2016, 16(5): 265-269. |

| Dong Q, You F, Jiang J C, et al. Pyrolysis properties and the composition of the solid residues of the waste FR4 epoxy copper clad panels[J]. Journal of Safety and Environment, 2016, 16(5): 265-269. | |

| 10 | Anuar Sharuddin S D, Abnisa F, Wan Daud W M A, et al. A review on pyrolysis of plastic wastes[J]. Energy Conversion and Management, 2016, 115: 308-326. |

| 11 | Kim K W, Jeong J S, An K H, et al. A low energy recycling technique of carbon fibers-reinforced epoxy matrix composites[J]. Industrial & Engineering Chemistry Research, 2019, 58(2): 618-624. |

| 12 | Park H S, Han Y S, Park J H. Massive recycling of waste mobile phones: pyrolysis, physical treatment, and pyrometallurgical processing of insoluble residue[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(16): 14119-14125. |

| 13 | 陈瑞哲, 程磊磊, 顾菁, 等. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| Chen R Z, Cheng L L, Gu J, et al. Research progress in chemical recovery technology of fiber-reinforced polymer composites[J]. CIESC Journal, 2023, 74(3): 981-994. | |

| 14 | 李传强, 刘思媛, 王东升, 等. 压力反应釜中低温热裂解废旧LLDPE塑料制备PE蜡[J]. 化工学报, 2019, 70(12): 4856-4863. |

| Li C Q, Liu S Y, Wang D S, et al. Preparation of PE wax by pyrolysis of LLDPE waste plastic in a pressure reactor under low temperature[J]. CIESC Journal, 2019, 70(12): 4856-4863. | |

| 15 | Engamba Esso S B, Zhe X, Chaiwat W, et al. Review on synergistic effects during co-pyrolysis of biomass and plastic waste: significance of operating conditions and interaction mechanism[J]. Biomass and Bioenergy, 2022, 159: 106415. |

| 16 | Huang S X, Qin J, Chen T, et al. Co-pyrolysis of different torrefied Chinese herb residues and low-density polyethylene: kinetic and products distribution[J]. Science of the Total Environment, 2022, 802: 149752. |

| 17 | Xie T, Zhao L X, Yao Z L, et al. Co-pyrolysis of biomass and polyethylene: insights into characteristics, kinetic and evolution paths of the reaction process[J]. Science of the Total Environment, 2023, 897: 165443. |

| 18 | 王润涛, 罗泽军, 王储, 等. 生物油蒸馏残渣与废弃塑料催化共热解协同作用的研究[J]. 化工学报, 2022, 73(11): 5088-5097. |

| Wang R T, Luo Z J, Wang C, et al. Synergistic effect during catalytic co-pyrolysis of bio-oil distillation residue and waste plastic[J]. CIESC Journal, 2022, 73(11): 5088-5097. | |

| 19 | Chattopadhyay J, Pathak T, Srivastava R, et al. Catalytic co-pyrolysis of paper biomass and plastic mixtures (HDPE (high density polyethylene), PP (polypropylene) and PET (polyethylene terephthalate)) and product analysis[J]. Energy, 2016, 103: 513-521. |

| 20 | Wang Z W, Burra K G, Lei T Z, et al. Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals—a review[J]. Progress in Energy and Combustion Science, 2021, 84: 100899. |

| 21 | 王佳, 张助坤, 蒋剑春. 生物质与废塑料/橡胶共热解研究进展[J]. 林业工程学报, 2023, 8(2): 10-20. |

| Wang J, Zhang Z K, Jiang J C. A review on co-pyrolysis of biomass and waste plastics/rubbers[J]. Journal of Forestry Engineering, 2023, 8(2): 10-20. | |

| 22 | 王志伟, 郭帅华, 吴梦鸽, 等. 生物质与塑料催化共热解技术研究进展[J]. 化工进展, 2023, 42(5): 2655-2665. |

| Wang Z W, Guo S H, Wu M G, et al. Recent advances on catalytic co-pyrolysis of biomass and plastic[J]. Chemical Industry and Engineering Progress, 2023, 42(5): 2655-2665. | |

| 23 | 马中青, 丁紫霞, 李逍然, 等. 纤维素生物质与废塑料共催化热解制取富烃液体燃料的研究进展[J]. 燃料化学学报, 2023. DOI: 10.19906/j.cnki.JFCT.2023070 . |

| Ma Z Q, Ding Z X, Li X R, et al. Recent progress on co-catalytic fast pyrolysis of biomass and waste plastics to produce hydrocarbon-rich liquid fuels[J]. Journal of Fuel Chemistry and Technology, 2023. DOI: 10.19906/j.cnki.JFCT.2023070 . | |

| 24 | 李晓娜, 潘超, 宋洋, 等. 典型塑料与生物质废弃物的共热解技术及高值化利用[J]. 环境科学研究, 2023, 36(9): 1765-1778. |

| Li X N, Pan C, Song Y, et al. Review of co-pyrolysis technologies of typical plastic and biomass waste for value-added products[J]. Research of Environmental Sciences, 2023, 36(9): 1765-1778. | |

| 25 | 何冠宇, 赫玉欣, 张丽, 等. 天然纤维混杂增强树脂基复合材料的研究现状及应用[J]. 化工新型材料, 2023. DOI: 10.19817/j.cnki.issn.1006-3536.2024.01.032 . |

| He G Y, He Y X, Zhang L, et al. Research and application status of natural fiber hybrid reinforced resin matrix composites[J]. New Chemical Materials, 2023. DOI: 10.19817/j.cnki.issn.1006-3536.2024.01.032 . | |

| 26 | Dong C S. Review of natural fibre-reinforced hybrid composites[J]. Journal of Reinforced Plastics and Composites, 2018, 37(5): 331-348. |

| 27 | 李允锋, 申世杰, 王静. 纤维增强树脂/木材复合材料的研究进展[J]. 林业机械与木工设备, 2009, 37(5): 10-12. |

| Li Y F, Shen S J, Wang J. Research progress of fiber reinforced polymer/wood composites[J]. Forestry Machinery & Woodworking Equipment, 2009, 37(5): 10-12. | |

| 28 | 张萌, 冯冰涛, 王晓珂, 等. 天然纤维增强热塑性复合材料制备与应用研究进展[J]. 工程塑料应用, 2023, 51(10): 179-185. |

| Zhang M, Feng B T, Wang X K, et al. Research progress in preparation and application of natural fiber reinforced thermoplastic composites[J]. Engineering Plastics Application, 2023, 51(10): 179-185. | |

| 29 | Karimah A, Ridho M R, Munawar S S, et al. A review on natural fibers for development of eco-friendly bio-composite: characteristics, and utilizations[J]. Journal of Materials Research and Technology, 2021, 13: 2442-2458. |

| 30 | Huang J L, Guo W W, Wang X, et al. Intrinsically flame retardant cardanol-based epoxy monomer for high-performance thermosets[J]. Polymer Degradation and Stability, 2021, 186: 109519. |

| 31 | Vyazovkin S, Burnham A K, Criado J M, et al. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data[J]. Thermochimica Acta, 2011, 520(1/2): 1-19. |

| 32 | Starink M J. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods[J]. Thermochimica Acta, 2003, 404(1/2): 163-176. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [3] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [4] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [5] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [6] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [7] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [8] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [9] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [10] | 张蒙蒙, 颜冬, 沈永峰, 李文翠. 电解液类型对双离子电池阴阳离子储存行为的影响[J]. 化工学报, 2023, 74(7): 3116-3126. |

| [11] | 赵婧, 顾程文, 蹇锡高, 翁志焕. 厚朴酚基环氧树脂防腐涂层的制备及性能评价[J]. 化工学报, 2023, 74(7): 3010-3017. |

| [12] | 邵伟明, 韩文学, 宋伟, 杨勇, 陈灿, 赵东亚. 基于分布式贝叶斯隐马尔可夫回归的动态软测量建模方法[J]. 化工学报, 2023, 74(6): 2495-2502. |

| [13] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [14] | 郑志航, 马郡男, 闫子涵, 卢春喜. 提升管射流影响区内压力脉动特性研究[J]. 化工学报, 2023, 74(6): 2335-2350. |

| [15] | 董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号