化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2363-2373.DOI: 10.11949/0438-1157.20230301

于源1( ), 陈薇薇1, 付俊杰1, 刘家祥2, 焦志伟1(

), 陈薇薇1, 付俊杰1, 刘家祥2, 焦志伟1( )

)

收稿日期:2023-03-28

修回日期:2023-05-16

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

焦志伟

作者简介:于源(1976—),女,博士,副教授,tougao_20192019@163.com

基金资助:

Yuan YU1( ), Weiwei CHEN1, Junjie FU1, Jiaxiang LIU2, Zhiwei JIAO1(

), Weiwei CHEN1, Junjie FU1, Jiaxiang LIU2, Zhiwei JIAO1( )

)

Received:2023-03-28

Revised:2023-05-16

Online:2023-06-05

Published:2023-07-27

Contact:

Zhiwei JIAO

摘要:

为探究几何相似涡流空气分级机环形区流场的分布特性,建立不同尺寸的涡流空气分级机模型,提取关键结构的几何参数,通过数值模拟分析尺寸比例因数对分级机环形区流场分布的影响。模拟结果表明,在相同进口风速下,几何相似分级机模型环形区内切向速度呈准自由涡的分布。模型尺寸增大,环形区内柱面面积加权平均切向速度增大,环形区切向速度分布不均匀。转笼内外缘切向速度越接近,环形区内近转笼外缘处切向速度产生的波动越小。几何相似分级机模型环形区内径向速度分布符合点汇流动的规律,除了在靠近转笼外缘处径向速度数值有较大差异外,环形区其余位置柱面面积加权平均径向速度不随比例因数变化而变化。以几何相似分级机模型数值模拟数据作为训练样本拟合分级机环形区内柱面面积加权平均切向速度和径向速度预测公式,并建立测试样本分级机模型对预测公式进行验证。柱面面积加权平均切向速度和径向速度预测值与模拟值的最大误差分别为3.5%和1.8%。此外,通过对几何相似涡流空气分级机模型环形区流场运动相似和动力相似分析,得出几何相似分级机模型流场具有相似性。

中图分类号:

于源, 陈薇薇, 付俊杰, 刘家祥, 焦志伟. 几何相似涡流空气分级机环形区流场变化规律研究及预测[J]. 化工学报, 2023, 74(6): 2363-2373.

Yuan YU, Weiwei CHEN, Junjie FU, Jiaxiang LIU, Zhiwei JIAO. Study and prediction of flow field in the annular region of geometrically similar turbo air classifier[J]. CIESC Journal, 2023, 74(6): 2363-2373.

| 尺寸比例因数k1 | Dv | Dzn | Dzw | Ddn | b | a |

|---|---|---|---|---|---|---|

| 1 | 219 | 70 | 100 | 132 | 48 | 31 |

| 2 | 438 | 140 | 200 | 264 | 96 | 62 |

| 4 | 876 | 280 | 400 | 528 | 192 | 124 |

| 8 | 1752 | 560 | 800 | 1056 | 384 | 248 |

表1 几何相似涡流空气分级机模型主要结构尺寸

Table 1 Main structural dimensions of geometrically similar turbo air classifier models

| 尺寸比例因数k1 | Dv | Dzn | Dzw | Ddn | b | a |

|---|---|---|---|---|---|---|

| 1 | 219 | 70 | 100 | 132 | 48 | 31 |

| 2 | 438 | 140 | 200 | 264 | 96 | 62 |

| 4 | 876 | 280 | 400 | 528 | 192 | 124 |

| 8 | 1752 | 560 | 800 | 1056 | 384 | 248 |

图3 几何相似涡流空气分级机模型环形区柱面面积加权平均切向速度曲线

Fig.3 Area weighted average tangential velocity curves of the cylinder surface in the annular region of geometrically similar turbo air classifier models

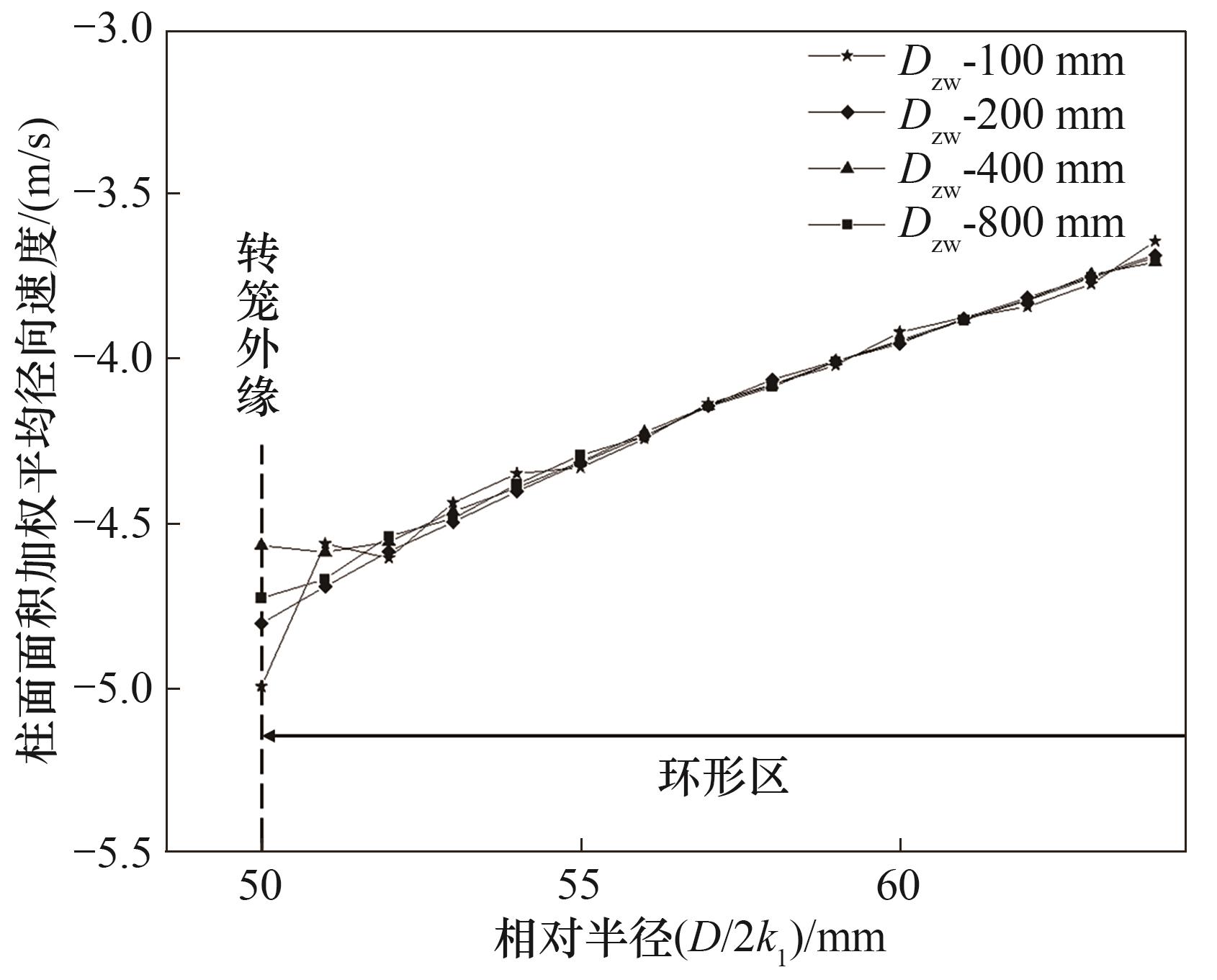

图5 几何相似涡流空气分级机模型环形区柱面面积加权平均径向速度曲线

Fig.5 Area weighted average radial velocity curves of the cylinder surface in the annular region of geometrically similar turbo air classifier models

| (D/2k1)/mm | 平均切向速度/(m/s) | |||

|---|---|---|---|---|

| k1=1 | k1=2 | k1=4 | k1=8 | |

| 51 | 21.70 | 22.89 | 23.33 | 25.09 |

| 52 | 21.40 | 22.57 | 23.02 | 24.57 |

| 53 | 20.97 | 22.19 | 22.70 | 24.32 |

| 54 | 20.57 | 21.78 | 22.36 | 23.82 |

| 55 | 20.45 | 21.38 | 21.97 | 23.34 |

| 56 | 20.05 | 20.97 | 21.55 | 23.00 |

| 57 | 19.61 | 20.57 | 21.14 | 22.44 |

| 58 | 19.29 | 20.19 | 20.74 | 22.03 |

| 59 | 19.01 | 19.87 | 20.31 | 21.46 |

| 60 | 18.61 | 19.53 | 19.87 | 20.93 |

| 61 | 18.22 | 19.19 | 19.46 | 20.41 |

| 62 | 18.00 | 18.68 | 18.98 | 19.78 |

| 63 | 17.60 | 18.27 | 18.49 | 19.06 |

| 64 | 17.28 | 18.00 | 18.08 | 18.70 |

表2 分级机模型环形区柱面面积加权平均切向速度

Table 2 Area weighted average tangential velocity of the cylinder surface in the annular region of classifier models

| (D/2k1)/mm | 平均切向速度/(m/s) | |||

|---|---|---|---|---|

| k1=1 | k1=2 | k1=4 | k1=8 | |

| 51 | 21.70 | 22.89 | 23.33 | 25.09 |

| 52 | 21.40 | 22.57 | 23.02 | 24.57 |

| 53 | 20.97 | 22.19 | 22.70 | 24.32 |

| 54 | 20.57 | 21.78 | 22.36 | 23.82 |

| 55 | 20.45 | 21.38 | 21.97 | 23.34 |

| 56 | 20.05 | 20.97 | 21.55 | 23.00 |

| 57 | 19.61 | 20.57 | 21.14 | 22.44 |

| 58 | 19.29 | 20.19 | 20.74 | 22.03 |

| 59 | 19.01 | 19.87 | 20.31 | 21.46 |

| 60 | 18.61 | 19.53 | 19.87 | 20.93 |

| 61 | 18.22 | 19.19 | 19.46 | 20.41 |

| 62 | 18.00 | 18.68 | 18.98 | 19.78 |

| 63 | 17.60 | 18.27 | 18.49 | 19.06 |

| 64 | 17.28 | 18.00 | 18.08 | 18.70 |

| 模型 | 尺寸比例因数k1 | C1 | C2 |

|---|---|---|---|

| Dzw=100 mm | 1 | 1165 | -1.010 |

| Dzw=200 mm | 2 | 1480 | -1.059 |

| Dzw=400 mm | 4 | 2151 | -1.145 |

| Dzw=800 mm | 8 | 3793 | -1.272 |

表3 分级机模型环形区柱面面积加权平均切向速度预测公式的系数C1和C2

Table 3 Coefficients C1 and C2 of the prediction formula for area weighted average tangential velocity of the cylinder surface in annular region of classifier models

| 模型 | 尺寸比例因数k1 | C1 | C2 |

|---|---|---|---|

| Dzw=100 mm | 1 | 1165 | -1.010 |

| Dzw=200 mm | 2 | 1480 | -1.059 |

| Dzw=400 mm | 4 | 2151 | -1.145 |

| Dzw=800 mm | 8 | 3793 | -1.272 |

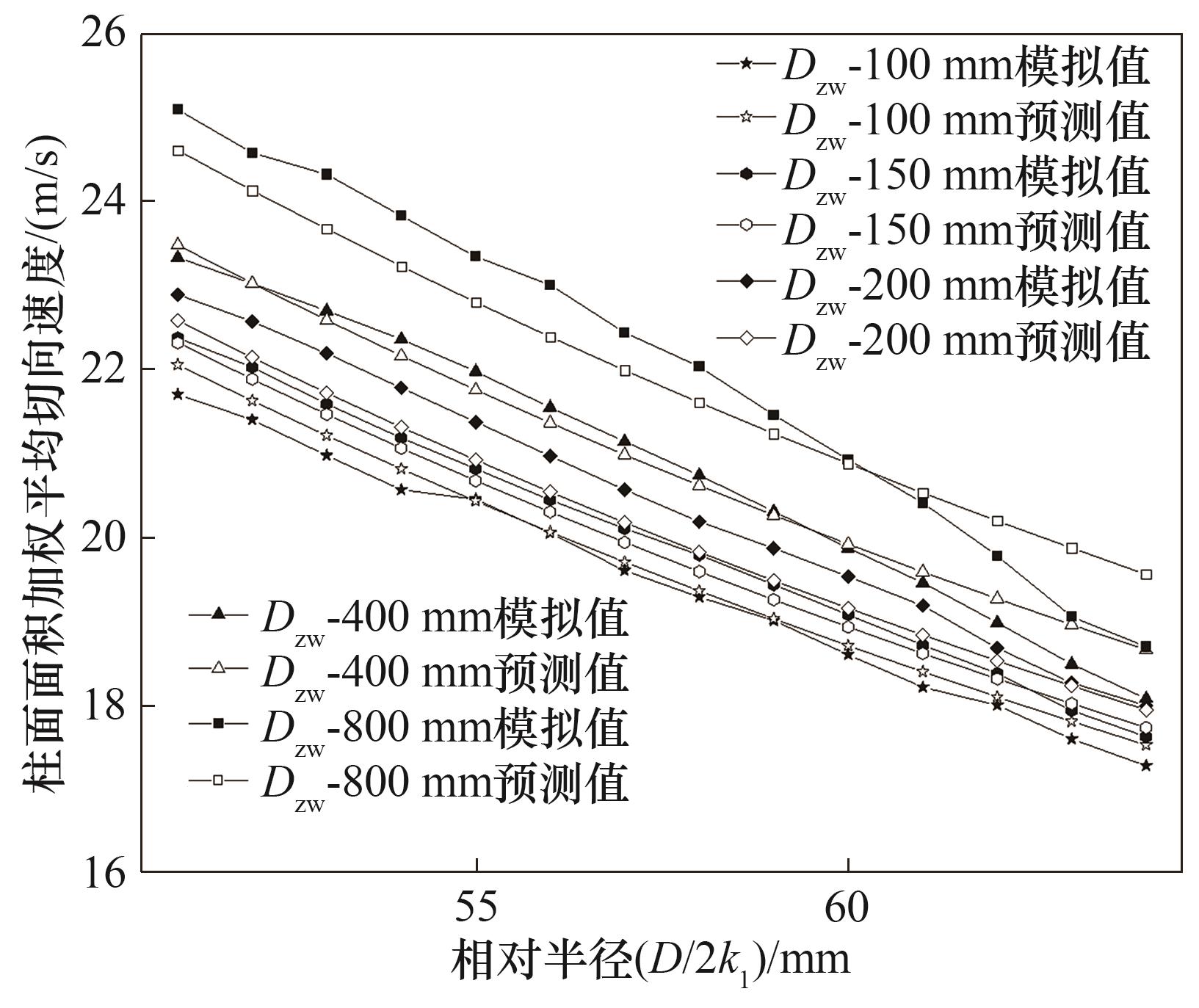

图6 几何相似分级机模型环形区柱面面积加权平均切向速度预测值与模拟值

Fig.6 Predicted and simulated area weighted average tangential velocity of the cylinder surface in the annular region of geometrically similar classifier models

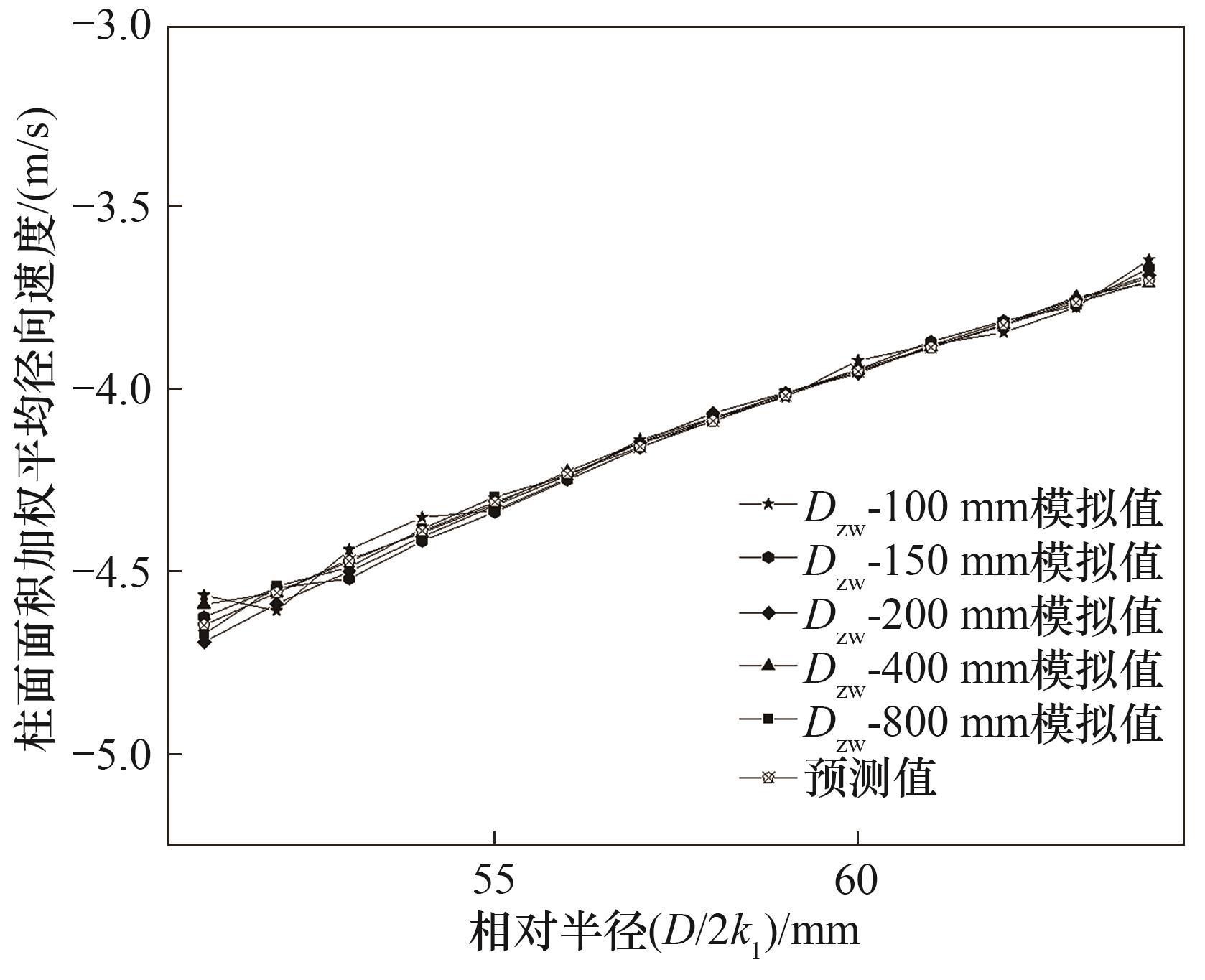

图7 几何相似分级机模型环形区柱面面积加权平均径向速度预测值与模拟值

Fig.7 Predicted and simulated area weighted average radial velocity of the cylinder surface in the annular region of geometrically similar classifier models

| 16 | Zeng Y, Huang B W, Qin D X, et al. Numerical and experiment investigation on novel guide vane structures of turbo air classifier[J]. Processes, 2022, 10(5): 844. |

| 17 | 任文静. 涡流空气分级机流场分析及结构优化[D]. 北京: 北京化工大学, 2016. |

| Ren W J. Flow field analyses and structure optimization for turbo air classifiers[D]. Beijing: Beijing University of Chemical Technology, 2016. | |

| 18 | Sun Z P, Liang L L, Liu C Y, et al. Structural optimization of vortex finder for a centrifugal air classifier[J]. Chemical Engineering Research and Design, 2021, 166: 220-226. |

| 19 | Zeng Y, Zhang S, Zhou Y, et al. Numerical simulation of a flow field in a turbo air classifier and optimization of the process parameters[J]. Processes, 2020, 8(2): 237. |

| 20 | Denmud N, Baite K, Plookphol T, et al. Effects of operating parameters on the cut size of turbo air classifier for particle size classification of SAC305 lead-free solder powder[J]. Processes, 2019, 7(7): 427. |

| 21 | Adamčík M, Svěrák T, Peciar P. Parameters effecting forced vortex formation in blade passageway of dynamic air classifier[J]. Acta Polytechnica, 2017, 57(5): 304. |

| 22 | Peng S H, Wu Y, Tao J, et al. Airflow velocity designing for air classifier of manufactured sand based on CPFD method[J]. Minerals, 2022, 12(1): 90. |

| 23 | Shi C L, Chen S H, Ma J, et al. Experimental and theoretical study on strengthening mechanism of coarse coal slime classification process with cone wall structure[J]. Fuel, 2022, 309: 122127. |

| 24 | Akimochkina G V, Rogovenko E S, Gareeva A S, et al. Aerodynamic separation of dispersed microspheres PM2.5, PM10 from fly ash of lignite combustion for production of new materials[J]. Journal of Siberian Federal University-Chemistry, 2022, 15(3): 387-397. |

| 25 | Li H, He Y Q, Shi F N, et al. Performance of the static air classifier in a vertical spindle mill[J]. Fuel, 2016, 177: 8-14. |

| 26 | 邹鹏程, 张明星, 黄生龙, 等. 膨化黑米粉的粉碎分级实验[J]. 化工进展, 2018, 37(5): 1664-1669. |

| Zou P C, Zhang M X, Huang S L, et al. Experimental study on crushing and grading of expanded black rice flour[J]. Chemical Industry and Engineering Progress, 2018, 37(5): 1664-1669. | |

| 27 | Barimani M, Green S, Rogak S. Particulate concentration distribution in centrifugal air classifiers[J]. Minerals Engineering, 2018, 126: 44-51. |

| 28 | Yu Y, Liu J X, Zhang K. Establishment of a prediction model for the cut size of turbo air classifiers[J]. Powder Technology, 2014, 254: 274-280. |

| 29 | 刘家祥, 何廷树, 夏靖波. 涡流分级机流场特性分析及分级过程[J]. 硅酸盐学报, 2003, 31(5): 485-489. |

| Liu J X, He T S, Xia J B. Air flow field characteristics analyzing and classification process of the turbo classifier[J]. Journal of the Chinese Ceramic Society, 2003, 31(5): 485-489. | |

| 30 | 阎超, 于剑, 徐晶磊, 等. CFD模拟方法的发展成就与展望[J]. 力学进展, 2011, 41(5): 562-589. |

| Yan C, Yu J, Xu J L, et al. On the achievements and prospects for the methods of computational fluid dynamics[J]. Advances in Mechanics, 2011, 41(5): 562-589. | |

| 31 | 赵海朋, 任成, 张来龙, 等. 涡流空气分级机转笼底盘结构对分级性能的影响[J]. 北京化工大学学报(自然科学版), 2018, 45(6): 73-78. |

| Zhao H P, Ren C, Zhang L L, et al. Influence of the rotor cage underpan on the classification performance of a turbo air classifier[J]. Journal of Beijing University of Chemical Technology (Natural Science Edition), 2018, 45(6): 73-78. | |

| 32 | Zambrano H, Di G Sigalotti L, Peña-Polo F, et al. Turbulent models of oil flow in a circular pipe with sudden enlargement[J]. Applied Mathematical Modelling, 2015, 39(21): 6711-6724. |

| 33 | Yu Y, Wang L, Liu J. Analysis of numerical simulation models for the turbo air classifier[J]. Materialwissenschaft Und Werkstofftechnik, 2022, 53(5): 644-657. |

| 34 | 刘蓉蓉, 刘家祥, 于源. 涡流空气分级机进口风速和转笼转速匹配研究[J]. 化学工程, 2015, 43(3): 41-45. |

| Liu R R, Liu J X, Yu Y. Matching of air inlet velocity and rotor cage’s rotating speed of turbo air classifier[J]. Chemical Engineering (China), 2015, 43(3): 41-45. | |

| 35 | 袁惠新, 李新, 刘麟, 等. 液-液水力旋流器准自由涡的数值模拟研究[J]. 矿山机械, 2012, 40(4): 84-87. |

| 1 | Brar L S, Kumar A. CFD simulations of cyclone separators with different diameters: analysis of gas cyclones with different cylinder diameters[C]//2015 International Conference on Futuristic Trends on Computational Analysis and Knowledge Management (ABLAZE). Greater Noida, India: IEEE, 2015: 180-185. |

| 2 | Ghasemi A, Shams M, Heyhat M M. A numerical scheme for optimizing gas liquid cylindrical cyclone separator[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2017, 231(4): 836-848. |

| 3 | Erol H I, Turgut O, Unal R. Experimental and numerical study of Stairmand cyclone separators: a comparison of the results of small-scale and large-scale cyclones[J]. Heat and Mass Transfer, 2019, 55(8): 2341-2354. |

| 4 | Shang L, Wang N. Design of increasing capacity of centrifugal pump without changing overall dimensions[C]//Proc. SPIE 12079, Second IYSF Academic Symposium on Artificial Intelligence and Computer Engineering, 2021, 12079: 452-455. |

| 5 | Zhang Z. Streamline similarity method for flow distributions and shock losses at the impeller inlet of the centrifugal pump[J]. Journal of Hydrodynamics, 2018, 30(1): 140-152. |

| 6 | 柏静远, 于永海. 基于相似理论的单级双吸离心泵选型新方法[J]. 中国农村水利水电, 2018, 425(3): 96-98, 104. |

| Bai J Y, Yu Y H. New method of selection of single-stage and double-acting centrifugal pump based on similarity theory[J]. China Rural Water and Hydropower, 2018, 425(3): 96-98, 104. | |

| 7 | 司乔瑞, 崔强磊, 袁寿其, 等. 气液两相条件下进口含气率对离心泵相似定律的影响[J]. 农业机械学报, 2018, 49(2): 107-112, 268. |

| Si Q R, Cui Q L, Yuan S Q, et al. Influence of inlet gas volume fraction on similarity law in centrifugal pumps under gas-liquid two-phase condition[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 107-112, 268. | |

| 8 | Zhao X Y, Ao Q, Yang L W, et al. Application of superfine pulverization technology in biomaterial industry[J]. Journal of the Taiwan Institute of Chemical Engineers, 2009, 40(3): 337-343. |

| 9 | Jia F C, Mou X L, Fang Y, et al. A new rotor-type dynamic classifier: structural optimization and industrial applications[J]. Processes, 2021, 9(6): 1033. |

| 10 | Petit H A, Irassar E F, Barbosa M R. Evaluation of the performance of the cross-flow air classifier in manufactured sand processing via CFD-DEM simulations[J]. Computational Particle Mechanics, 2018, 5(1): 87-102. |

| 11 | Sun Z P, Liu C Y, Yang G, et al. Orthogonal vortices characteristic, performance evaluation and classification mechanism of a horizontal classifier with three rotor cages[J]. Powder Technology, 2022, 404: 117438. |

| 12 | Galletti C, Rum A, Turchi V, et al. Numerical analysis of flow field and particle motion in a dynamic cyclonic selector[J]. Advanced Powder Technology, 2020, 31(3): 1264-1273. |

| 13 | Mou X L, Jia F C, Fang Y, et al. CFD-based structural optimization of rotor cage for high-efficiency rotor classifier[J]. Processes, 2021, 9(7): 1148. |

| 14 | Yu Y, Kong X, Ren C, et al. Effect of the rotor cage chassis on inner flow field of a turbo air classifier[J]. Materialwissenschaft Und Werkstofftechnik, 2021, 52(7): 772-780. |

| 15 | Wu S B, Liu J X, Yu Y. Design of a new double layer spreading plate for a turbo air classifier[J]. Powder Technology, 2017, 312: 277-286. |

| 35 | Yuan H X, Li X, Liu L, et al. Study on numerical simulation of Rankine vortex in hydrocyclones for liquid-liquid separation[J]. Mining & Processing Equipment, 2012, 40(4): 84-87. |

| 36 | 张涛. 喷射式液体输送泵内部流场的数值模拟与优化研究[D]. 北京: 中国农业科学院, 2011. |

| Zhang T. Simulation and optimization research of the jet pump internal flow field[D]. Beijing: Chinese Academy of Agricultural Sciences, 2011. | |

| 37 | 张翔禹. 超细粉体气固旋流分级的流场特性与分离行为研究[D]. 徐州: 中国矿业大学, 2021. |

| Zhang X Y. Study on flow field characteristics and separation behavior of ultrafine powders gas-solid swirling classification[D]. Xuzhou: China University of Mining and Technology, 2021. | |

| 38 | 宋健斐, 杨光福, 陈建义, 等. 旋风分离器内气相流场的相似模化分析(Ⅱ): 尺寸参数[J]. 化工学报, 2010, 61(9): 2274-2279. |

| Song J F, Yang G F, Chen J Y, et al. Similarity analysis of modeling of gas phase flow field in cyclone separator (Ⅱ): Size parameters[J]. CIESC Journal, 2010, 61(9): 2274-2279. | |

| 39 | 王冠. 脉冲袋式除尘器内部流场的研究[D]. 北京: 中冶集团建筑研究总院, 2007. |

| Wang G. A study on flow field in the impulse bag-type dust filter[D]. Beijing: Central Research Institute of Building and Construction Co., Ltd., MCC Group, 2007. | |

| 40 | 宫泽, 董智, 王德喜, 等. 基于相似理论的轻烧氧化镁闪速炉实验装置研究[J]. 节能, 2022, 41(1): 56-58. |

| Gong Z, Dong Z, Wang D X, et al. Research on experimental device of light burning magnesium oxide flash furnace based on similarity theory[J]. Energy Conservation, 2022, 41(1): 56-58. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [7] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [8] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [9] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [10] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [11] | 尹刚, 李伊惠, 何飞, 曹文琦, 王民, 颜非亚, 向禹, 卢剑, 罗斌, 卢润廷. 基于KPCA和SVM的铝电解槽漏槽事故预警方法[J]. 化工学报, 2023, 74(8): 3419-3428. |

| [12] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [13] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [14] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [15] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号