化工学报 ›› 2024, Vol. 75 ›› Issue (10): 3464-3476.DOI: 10.11949/0438-1157.20240472

收稿日期:2024-04-28

修回日期:2024-05-27

出版日期:2024-10-25

发布日期:2024-11-04

通讯作者:

林梅

作者简介:赵浩然(2000—),男,硕士研究生,1401178775@qq.com

Haoran ZHAO1( ), Siluo HUANG2, Mei LIN1(

), Siluo HUANG2, Mei LIN1( )

)

Received:2024-04-28

Revised:2024-05-27

Online:2024-10-25

Published:2024-11-04

Contact:

Mei LIN

摘要:

采用计算流体力学软件,基于Euler-Lagrange方法,对一种余热锅炉入口管箱底面沉积特性进行数值模拟,详细研究了质量流量(0.002~0.010 kg·s-1)、入口速度(1.5~3.5 m·s-1)以及颗粒直径(20~60

中图分类号:

赵浩然, 黄嗣罗, 林梅. 余热锅炉入口管箱底面沉积特性[J]. 化工学报, 2024, 75(10): 3464-3476.

Haoran ZHAO, Siluo HUANG, Mei LIN. Sedimentation characteristics of the bottom surface of the inlet pipe box of a waste heat boiler[J]. CIESC Journal, 2024, 75(10): 3464-3476.

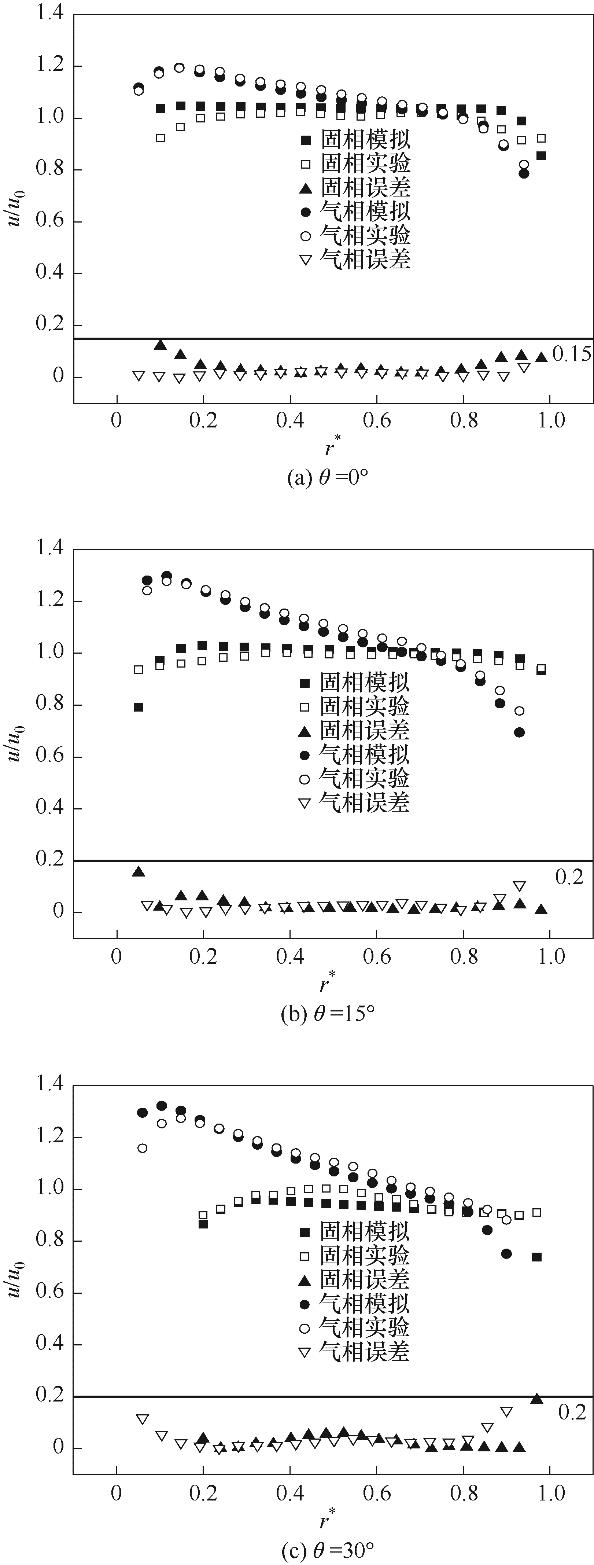

图4 弯管内不同偏转角度处气固流动的速度分布和实验数据的比较

Fig.4 Comparison of velocity distribution and experimental data of gas-solid flow at different deflection angles inside a curved pipe

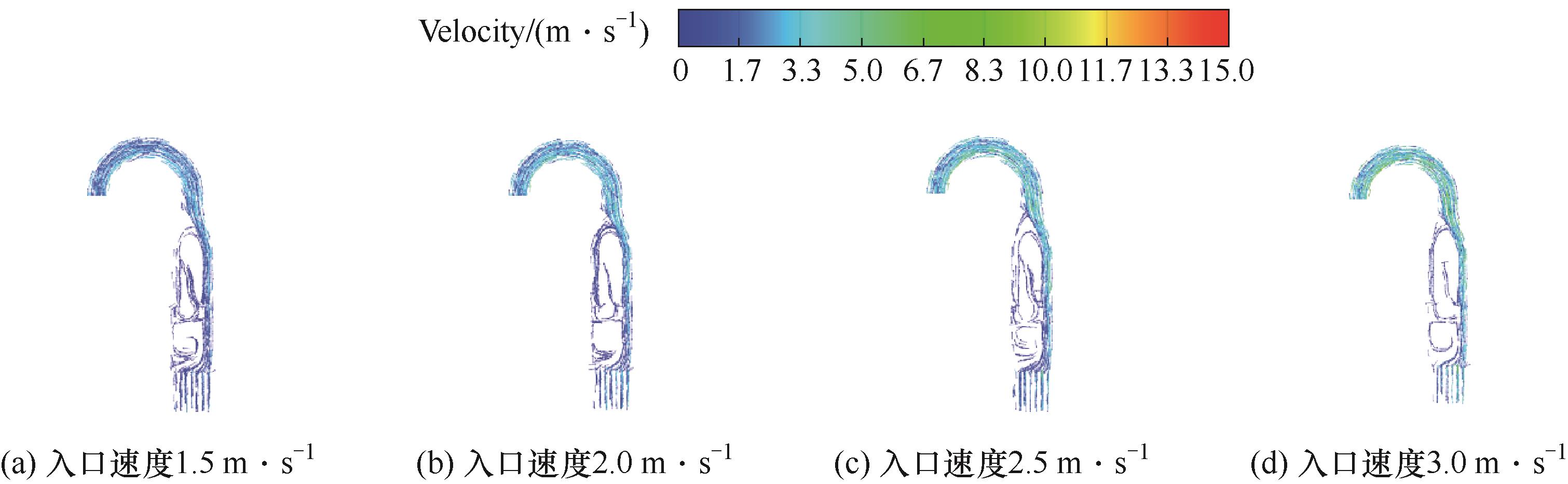

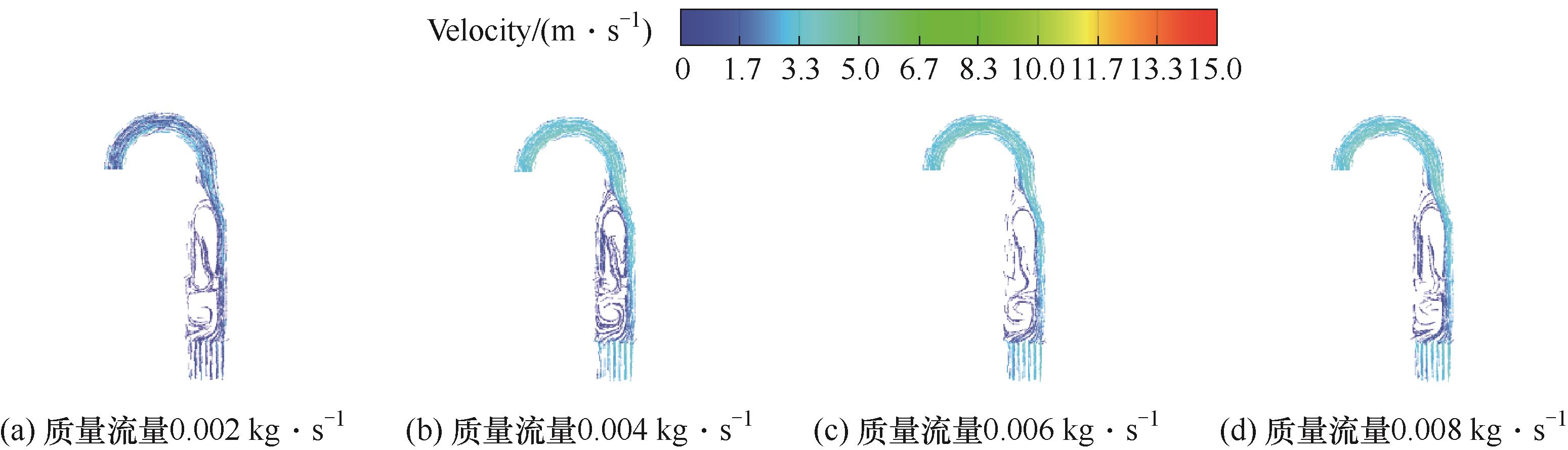

图7 颗粒质量流量为0.002 kg·s-1的入口管箱对称面固相速度矢量图

Fig.7 Solid phase velocity vector diagram on the symmetrical plane of the inlet pipe box with a particle mass flow rate of 0.002 kg·s-1

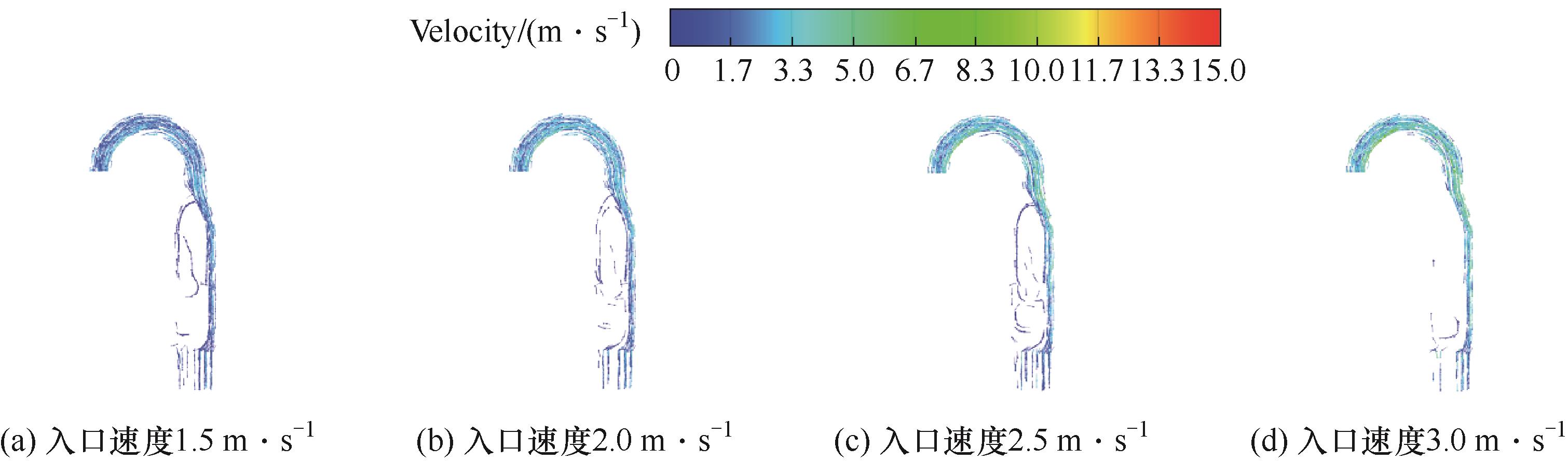

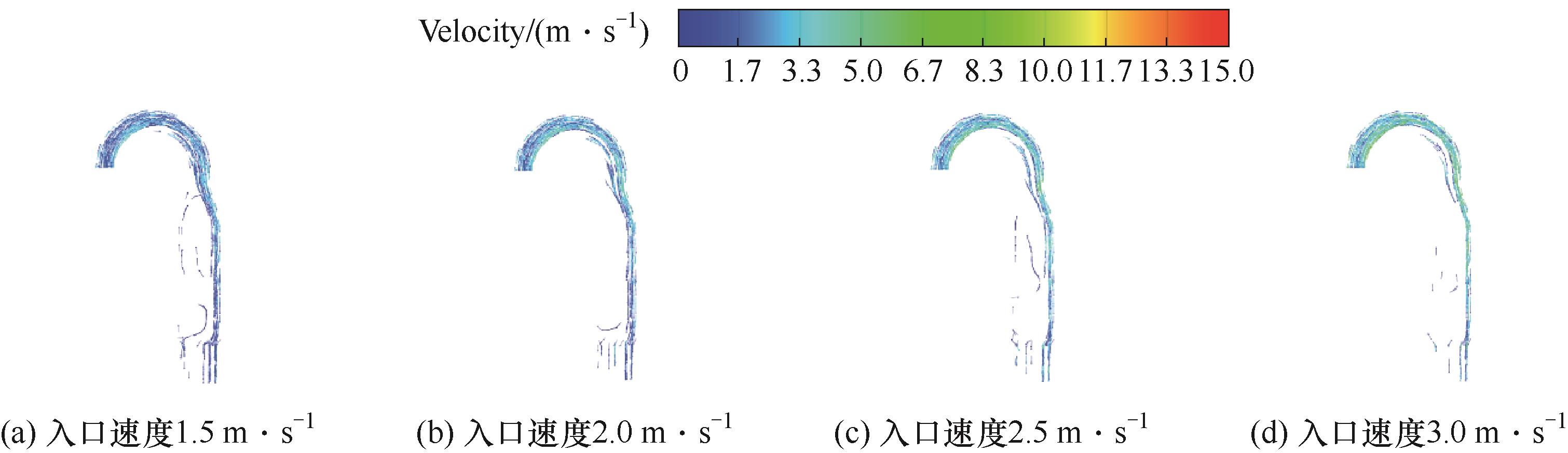

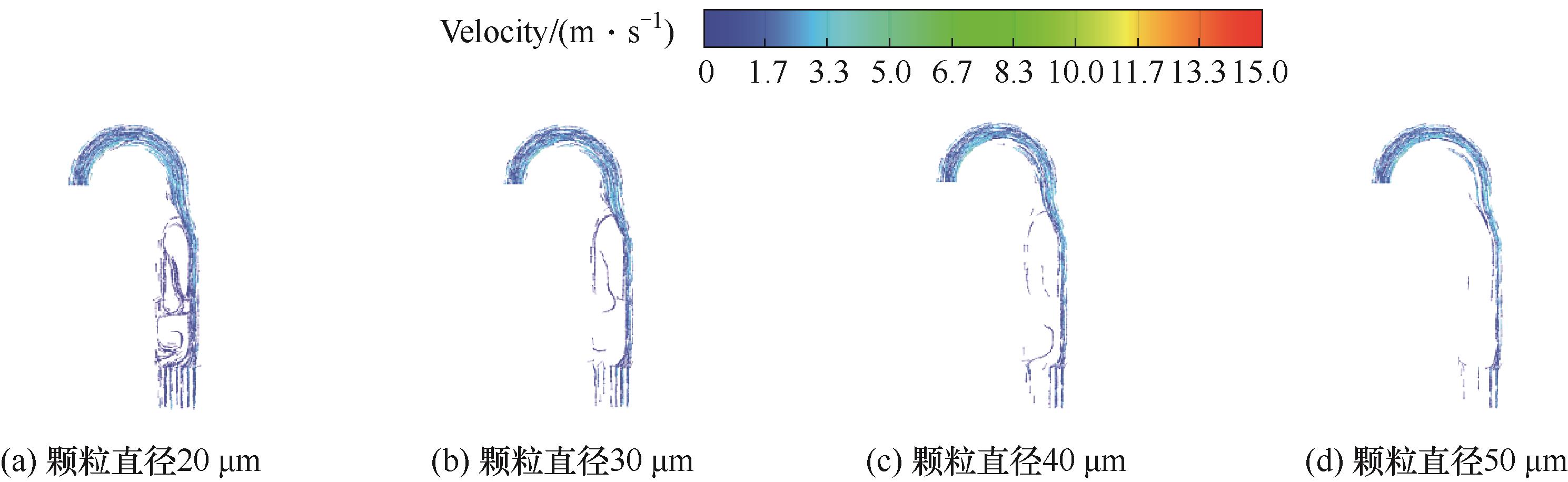

图9 颗粒入口速度为1.5 m·s-1的入口管箱对称面固相速度矢量图

Fig.9 Solid phase velocity vector diagram on the symmetrical plane of the inlet pipe box with a particle inlet velocity of 1.5 m·s-1

图12 颗粒直径为30 μm的入口管箱对称面固相速度矢量图

Fig.12 Solid phase velocity vector diagram on the symmetrical plane of the inlet pipe box with a particle diameter of 30 μm

图14 颗粒直径为40 μm的入口管箱对称面固相速度矢量图

Fig.14 Solid phase velocity vector diagram on the symmetrical plane of the inlet pipe box with a particle diameter of 40 μm

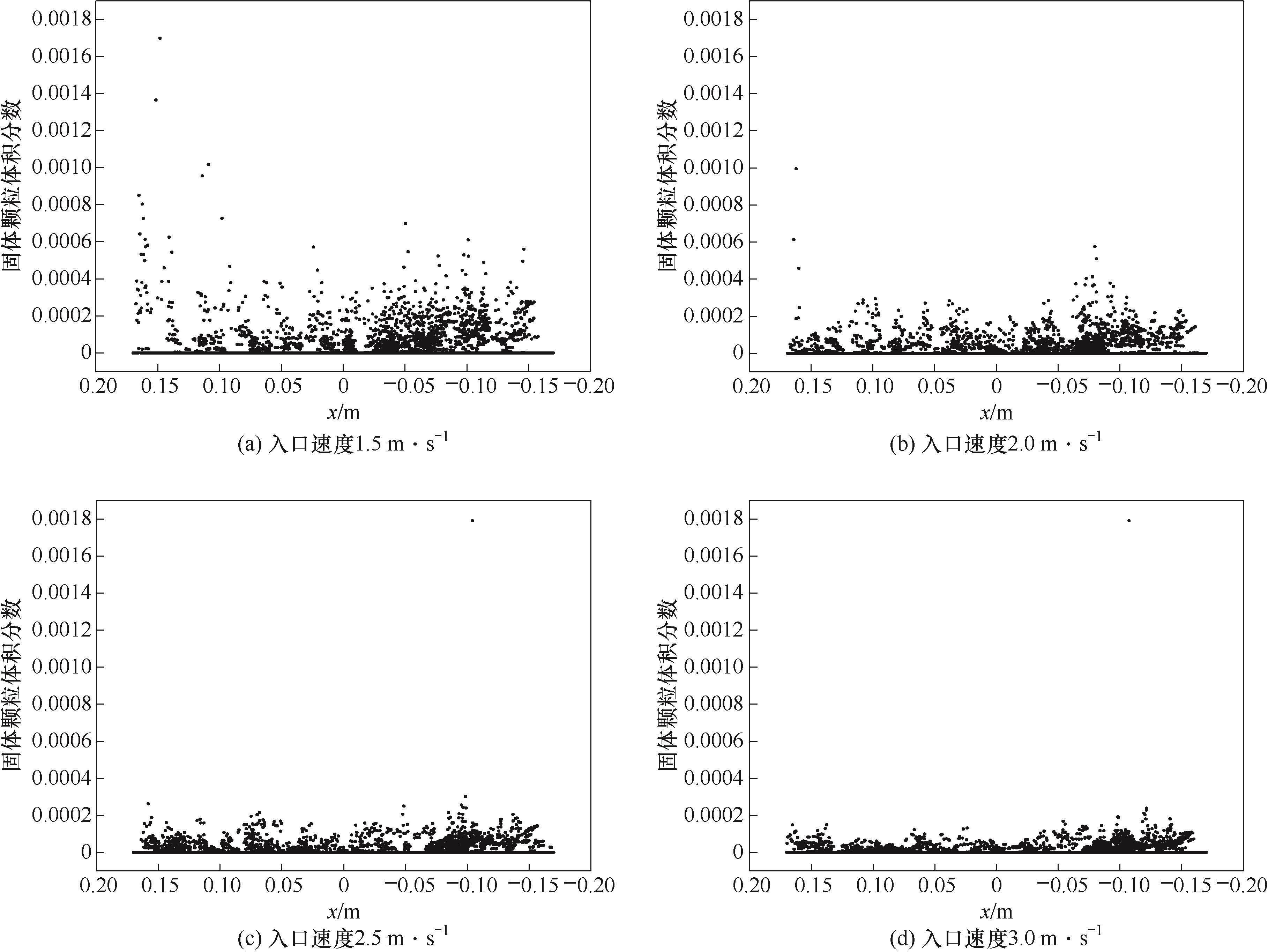

图15 颗粒直径为40 μm的管箱底面固体颗粒体积分数的径向分布

Fig.15 Radial distribution of solid particle volume fraction on the bottom surface of the pipe box with a particle diameter of 40 μm

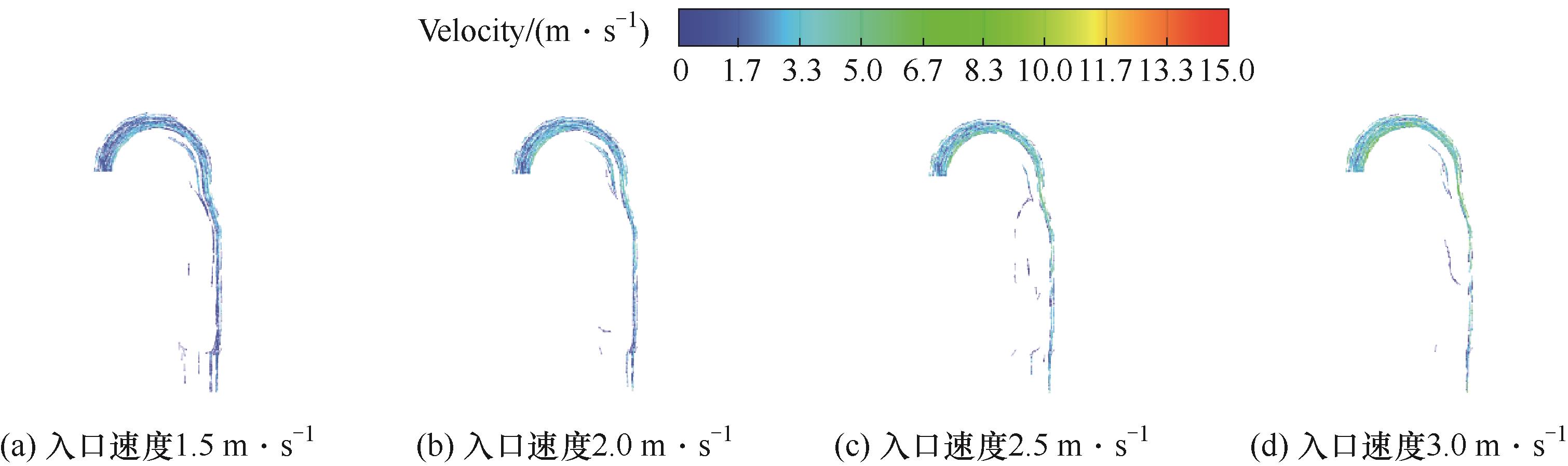

图17 颗粒直径为50 μm的入口管箱对称面固相速度矢量图

Fig.17 Solid phase velocity vector diagram on the symmetrical plane of the inlet pipe box with a particle diameter of 50 μm

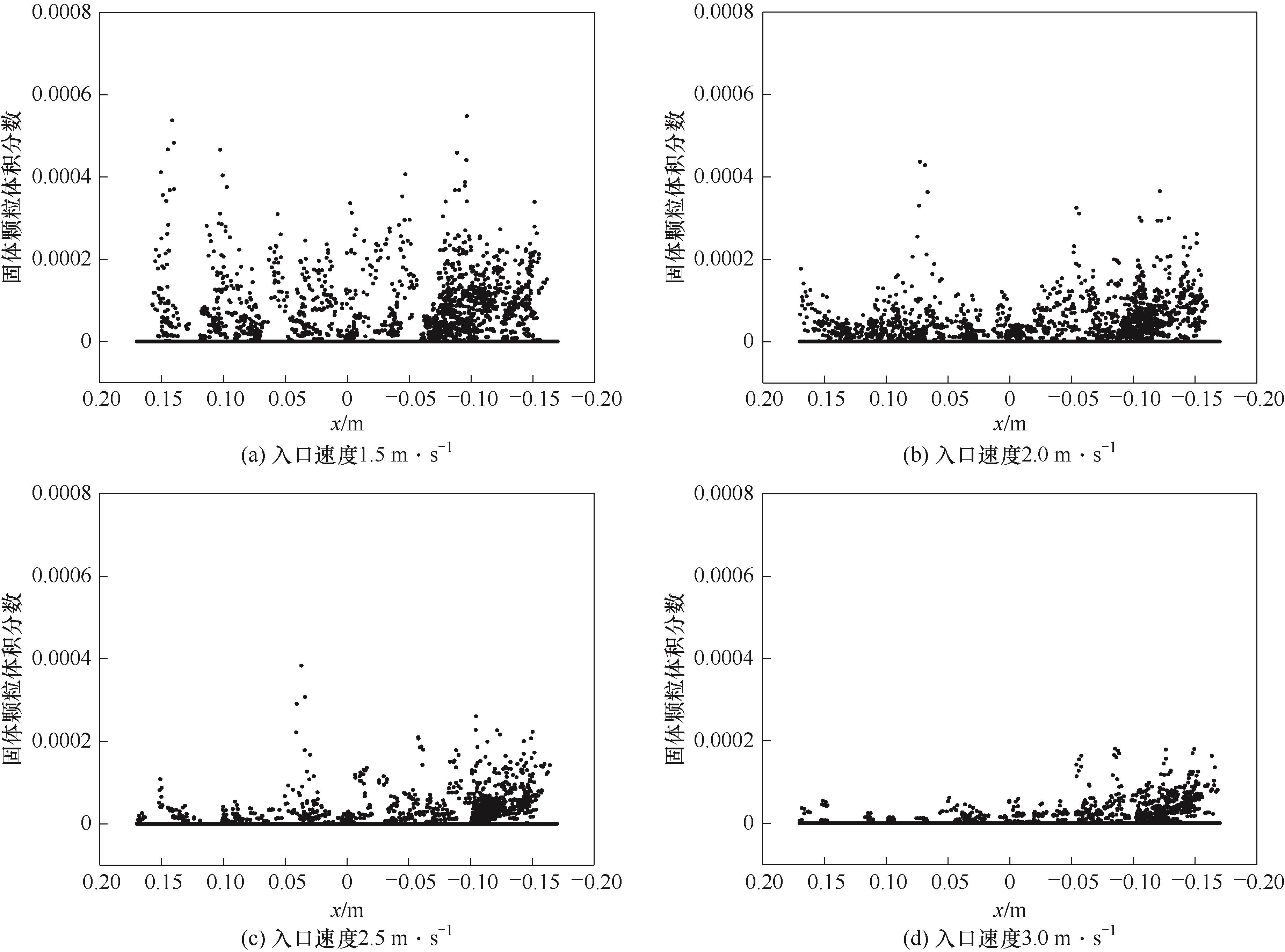

图18 颗粒直径为50 μm的管箱底面固体颗粒体积分数的径向分布

Fig.18 Radial distribution of solid particle volume fraction on the bottom surface of the pipe box with a particle diameter of 50 μm

图22 颗粒质量流量为0.002 kg·s-1的入口管箱对称面固相速度矢量图

Fig.22 Solid phase velocity vector diagram on the symmetrical plane of the inlet pipe box with a particle mass flow rate of 0.002 kg·s-1

| 1 | 董其伍, 张垚. 换热器: 石油化工设备设计选用手册[M]. 北京: 化学工业出版社, 2009. |

| Dong Q W, Zhang Y. Heat Exchanger: Handbook for Design and Selection of Petrochemical Equipment[M]. Beijing: Chemical Industry Press, 2009. | |

| 2 | 赵广锐. 特殊结构急冷锅炉应力分析和强度设计[D]. 北京: 北京化工大学, 2023. |

| Zhao G R. Stress analysis and strength design of quench boiler with special structure[D]. Beijing: Beijing University of Chemical Technology, 2023. | |

| 3 | Zhao X G, Jiang G W, Li A, et al. Technology, cost, a performance of waste-to-energy incineration industry in China[J]. Renewable and Sustainable Energy Reviews, 2016, 55: 115-130. |

| 4 | Lombardi L, Carnevale E, Corti A. A review of technologies and performances of thermal treatment systems for energy recovery from waste[J]. Waste Management, 2015, 37: 26-44. |

| 5 | 李少强. 焦化炉废气余热回收利用的技术研究[J]. 山西化工, 2024, 44(2): 248-250. |

| Li S Q. Technical research on the recovery and utilization of waste heat from coking furnace exhaust gas[J]. Shanxi Chemical Industry, 2024, 44(2): 248-250. | |

| 6 | 金志浩, 龚斌, 金文, 等. 管壳式换热器原理与设计[M]. 沈阳: 辽宁科学技术出版社, 2001. |

| Jin Z H, Gong B, Jin W, et al. Principle and Design of Shell and Tube Heat Exchanger[M]. Shenyang: Liaoning Science and Technology Publishing House, 2001. | |

| 7 | 邱剑勇, 郭庆华, 许建良, 等. 气流床气化辐射废锅单面受热水冷壁数值模拟[J]. 高校化学工程学报, 2019, 33(1): 48-54. |

| Qiu J Y, Guo Q H, Xu J L, et al. Numerical simulation of one-side heating membrane wall in radiant syngas cooler of entrained flow gasification[J]. Journal of Chemical Engineering of Chinese Universities, 2019, 33(1): 48-54. | |

| 8 | Zbogar A, Frandsen F, Jensen P A, et al. Shedding of ash deposits[J]. Progress in Energy and Combustion Science, 2009, 35(1): 31-56. |

| 9 | 张志超, 郭英毅, 巴文君. 浅谈炭素余热锅炉结焦、积灰的处理方法[J]. 轻金属, 2009(4): 61-64. |

| Zhang Z C, Guo Y Y, Ba W J. Treating methods of coking and deposition dust on waste heat boiler in carbon production[J]. Light Metals, 2009(4): 61-64. | |

| 10 | 周朋. DCC装置余热锅炉优化改造[J]. 设备管理与维修, 2024(2): 182-184. |

| Zhou P. Optimization and reconstruction of waste heat boiler in DCC plant[J]. Plant Maintenance Engineering, 2024(2): 182-184. | |

| 11 | 刘栋. 余热锅炉上蒸发器管穿孔泄漏原因分析[J]. 中国特种设备安全, 2022, 38(4): 60-64, 69. |

| Liu D. Failure analysis on perforation leakage of upper evaporator tube of heat recovery boiler[J]. China Special Equipment Safety, 2022, 38(4): 60-64, 69. | |

| 12 | 马玺坤, 武春青, 柏慧. 浅谈管壳式换热器的泄漏与预防措施[J]. 中国特种设备安全, 2017, 33(12): 63-65. |

| Ma X K, Wu C Q, Bai H. Analysis and precautionary measures of shell-and-tube heat exchanger leakage[J]. China Special Equipment Safety, 2017, 33(12): 63-65. | |

| 13 | 李圣君. 壳牌煤气化装置合成气冷却器积灰原因分析及解决措施[J]. 化肥设计, 2012, 50(4): 40-41. |

| Li S J. Reason analysis for ash accumulation in synthetic gas cooler and its solution measures[J]. Chemical Fertilizer Design, 2012, 50(4): 40-41. | |

| 14 | 钱飞舟, 魏召强. 立式火管锅炉煤气降温过程中的积灰特性[J]. 锅炉制造, 2021(4): 19-24. |

| Qian F Z, Wei Z Q. Characteristics of ash deposition of vertical fire-tube boiler gas during cooling[J]. Boiler Manufacturing, 2021(4): 19-24. | |

| 15 | 杨震, 刘忠楼, 郭琴琴, 等. 余热锅炉入口烟道数值模拟[J]. 锅炉技术, 2007, 38(3): 1-3, 42. |

| Yang Z, Liu Z L, Guo Q Q, et al. Numerical simulation of HRSG inlet duct[J]. Boiler Technology, 2007, 38(3): 1-3, 42. | |

| 16 | 聂宇宏, 任祥翔, 聂德云, 等. 余热锅炉通流结构的三维数值模拟及结构优化[J]. 锅炉技术, 2014, 45(6): 7-11. |

| Nie Y H, Ren X X, Nie D Y, et al. Three-dimensional numerical simulation of the waste heat boiler flow structure and structural optimization[J]. Boiler Technology, 2014, 45(6): 7-11. | |

| 17 | 蔡兴瑞, 王跃凤, 杜雨佳, 等. Cl/S与Na相互作用对Shell气化炉合成气冷却器入口积灰机制的影响[J]. 煤炭学报, 2024, 49(5): 2498-2506. |

| Cai X R, Wang Y F, Du Y J, et al. Effect of Cl/S and Na interaction on ash deposition mechanism at the inlet of Shell gasifier syngas cooler[J]. Journal of China Coal Society, 2024, 49(5): 2498-2506. | |

| 18 | 许明磊, 严建华, 马增益, 等. 垃圾焚烧炉受热面的积灰腐蚀机理分析[J]. 中国电机工程学报, 2007, 27(23): 32-37. |

| Xu M L, Yan J H, Ma Z Y, et al. Mechanism analysis of ash deposits corrosion in waste incinerator[J]. Proceedings of the CSEE, 2007, 27(23): 32-37. | |

| 19 | Phongphiphat A, Ryu C, Yang Y B, et al. Investigation into high-temperature corrosion in a large-scale municipal waste-to-energy plant[J]. Corrosion Science, 2010, 52(12): 3861-3874. |

| 20 | Nielsen H P, Frandsen F J, Dam-Johansen K, et al. The implications of chlorine-associated corrosion on the operation of biomass-fired boilers[J]. Progress in Energy and Combustion Science, 2000, 26(3): 283-298. |

| 21 | 常秀华. Shell粉煤气化装置合成气冷却器积灰结垢的分析与对策[J]. 山西化工, 2017, 37(3): 97-99. |

| Chang X H. Analysis and countermeasure for ash accumulation and fouling of synthetic gas cooler for Shell pulverized coal gasification device[J]. Shanxi Chemical Industry, 2017, 37(3): 97-99. | |

| 22 | 穆林, 赵亮, 尹洪超. 废液焚烧余热锅炉内气固两相流动与飞灰沉积的数值模拟[J]. 中国电机工程学报, 2012, 32(29): 30-37, 15. |

| Mu L, Zhao L, Yin H C. Numerical simulation of gas-solid two-phase flows and ash deposition in a wastewater incineration heat recovery steam generator[J]. Proceedings of the CSEE, 2012, 32(29): 30-37, 15. | |

| 23 | 汪杰. 烧结余热回收锅炉烟气流场数值模拟研究[J]. 工业锅炉, 2018(6): 5-10. |

| Wang J. Numerical simulation of flue gas flow field in sintering heat recovery boiler[J]. Industrial Boiler, 2018(6): 5-10. | |

| 24 | 阳自霖, 闫友, 陈坤, 等. 铅冶炼富氧侧吹炉余热锅炉积灰结焦分析及预防[J]. 绿色矿冶, 2023, 39(6): 53-57. |

| Yang Z L, Yan Y, Chen K, et al. Analysis and prevention of ash deposition and coking in waste heat boiler of oxygen-enriched side-blown furnace in lead smelting[J]. Sustainable Mining and Metallurgy, 2023, 39(6): 53-57. | |

| 25 | 郭纪伟. 基于气固两相流的弯管内颗粒沉积及冲蚀特性的研究[D]. 天津: 河北工业大学, 2020. |

| Guo J W. Study on particle deposition and erosion characteristics in bend based on gas-solid two-phase flow[D]. Tianjin: Hebei University of Technology, 2020. | |

| 26 | 屈子尧, 陈敏, 姚啸林. 分离器转速对中速磨煤机风粉分配的影响[J]. 热力发电, 2024, 53(4): 141-149. |

| Qu Z Y, Chen M, Yao X L. Influence of separator rotation speed on air-powder distribution in medium-speed coal pulverizer[J]. Thermal Power Generation, 2024, 53(4): 141-149. | |

| 27 | ANSYS, Inc. Ansys Fluent Theory Guide[M]. Pennsylvania: ANSYS, Inc., 2024: 493. |

| 28 | Deen N G, van Sint Annaland M, van der Hoef M A, et al. Review of discrete particle modeling of fluidized beds[J]. Chemical Engineering Science, 2007, 62(1/2): 28-44. |

| 29 | Zhu H P, Zhou Z Y, Yang R Y, et al. Discrete particle simulation of particulate systems: a review of major applications and findings[J]. Chemical Engineering Science, 2008, 63(23): 5728-5770. |

| 30 | Zhu H P, Zhou Z Y, Yang R Y, et al. Discrete particle simulation of particulate systems: theoretical developments[J]. Chemical Engineering Science, 2007, 62(13): 3378-3396. |

| 31 | Kliafas Y, Holt M. LDV measurements of a turbulent air-solid two-phase flow in a 90° bend[J]. Experiments in Fluids, 1987, 5(2): 73-85. |

| 32 | 李铭坤. 基于DPM的地热汽轮机导向叶片表面颗粒沉积特性及改型模拟研究[D]. 哈尔滨: 哈尔滨理工大学, 2020. |

| Li M K. Study on particle deposition characteristics and modification simulation of guide vane surface of geothermal turbine based on DPM[D]. Harbin: Harbin University of Science and Technology, 2020. |

| [1] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 基于CPFD方法的U3O8氢还原流化床反应器数值模拟[J]. 化工学报, 2024, 75(9): 3133-3151. |

| [2] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [3] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [4] | 豆少军, 郝亮. PEMFC催化层耦合气体电荷传输过程的介观模拟[J]. 化工学报, 2024, 75(8): 3002-3010. |

| [5] | 钱啸宇, 阮璇, 李水清. 外加电场下电介质颗粒层结构重构与悬浮[J]. 化工学报, 2024, 75(8): 2756-2762. |

| [6] | 朱子良, 王爽, 姜宇昂, 林梅, 王秋旺. 欧拉-拉格朗日迭代固-液相变算法[J]. 化工学报, 2024, 75(8): 2763-2776. |

| [7] | 邓爱明, 何玉荣, 唐天琪, 胡彦伟. 导流板对喷雾流化床内颗粒生长过程影响的模拟[J]. 化工学报, 2024, 75(8): 2787-2799. |

| [8] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [9] | 李倩, 张蓉民, 林子杰, 战琪, 蔡伟华. 基于机器学习的印刷电路板式换热器流动换热预测与仿真[J]. 化工学报, 2024, 75(8): 2852-2864. |

| [10] | 曹佳蕾, 孙立岩, 曾德望, 尹凡, 高子翔, 肖睿. 双流化床化学链制氢反应器的数值模拟[J]. 化工学报, 2024, 75(8): 2865-2874. |

| [11] | 金虎, 杨帆, 戴梦瑶. 基于格子Boltzmann方法的液滴在圆柱壁面上运动过程研究[J]. 化工学报, 2024, 75(8): 2897-2908. |

| [12] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [13] | 韩志敏, 李江, 陈则齐, 刘威, 徐志明. 脉动流通道内不同纵向涡发生器的颗粒污垢特性[J]. 化工学报, 2024, 75(7): 2486-2496. |

| [14] | 方立昌, 李梓龙, 陈博, 苏政, 贾莉斯, 王智彬, 陈颖. 基于相变微胶囊悬浮液的芯片阵列冷却特性研究[J]. 化工学报, 2024, 75(7): 2455-2464. |

| [15] | 周文轩, 刘珍, 张福建, 张忠强. 高通量-高截留率时间维度膜法水处理机理研究[J]. 化工学报, 2024, 75(7): 2583-2593. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号