化工学报 ›› 2024, Vol. 75 ›› Issue (10): 3498-3506.DOI: 10.11949/0438-1157.20240488

收稿日期:2024-05-06

修回日期:2024-06-12

出版日期:2024-10-25

发布日期:2024-11-04

通讯作者:

谷德银

作者简介:谷德银(1989—),男,博士,副教授,gdy0811@126.com

基金资助:

Deyin GU1( ), Changshu LI1, Hao YANG1, Zuohua LIU2

), Changshu LI1, Hao YANG1, Zuohua LIU2

Received:2024-05-06

Revised:2024-06-12

Online:2024-10-25

Published:2024-11-04

Contact:

Deyin GU

摘要:

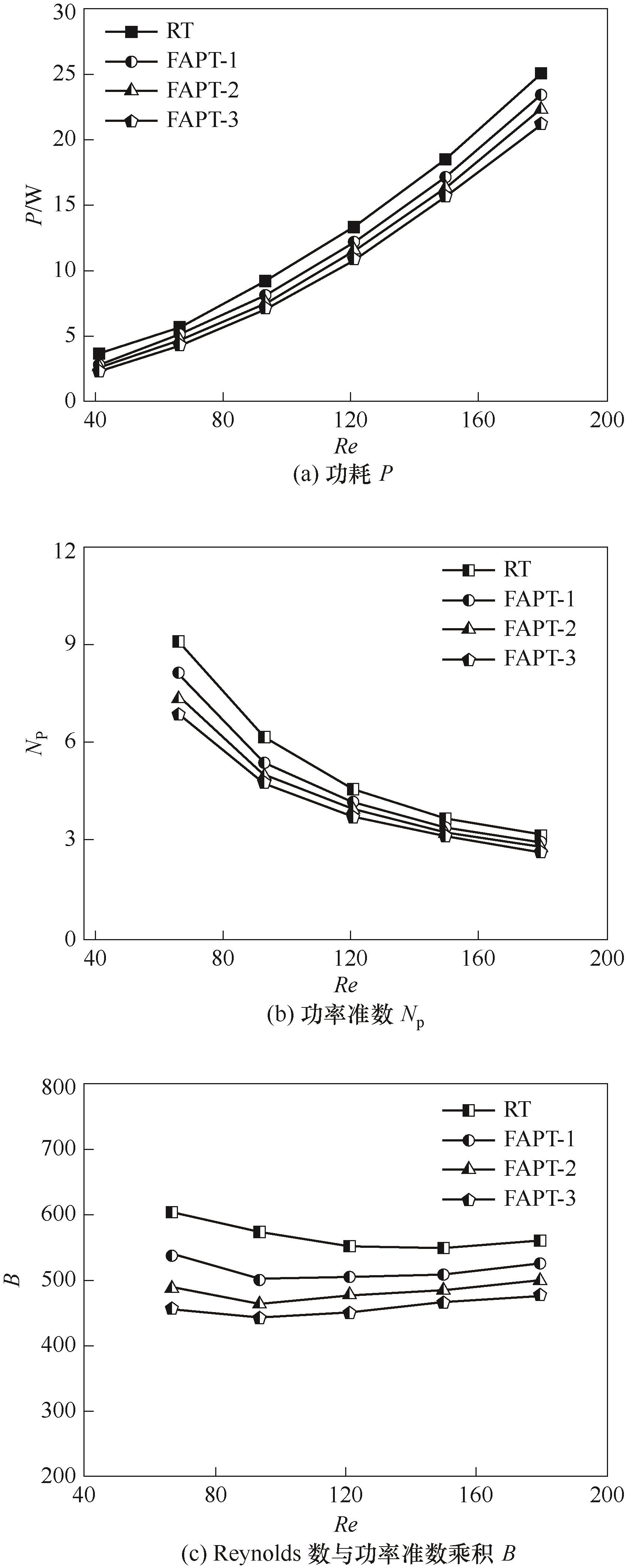

为减小混合隔离区、增大混沌混合区、强化流体的混沌混合过程,基于分形理论的自相似特性提出一种具有分形排布式穿流孔的搅拌桨强化流体的混沌混合行为。采用计算流体力学(CFD)和实验相结合的方法探究了流体混合过程中的功耗特性、速度分布、剪切应变率分布、隔离区结构以及Poincare截面。研究结果表明,在相同Reynolds数下,与Rushton桨相比,分形排布式穿流搅拌桨(FAPT)能够有效降低搅拌功耗和功率准数,而且随着穿流孔分形迭代次数的增加,搅拌功耗和功率准数进一步降低。其中,FAPT-1体系的功率准数降低6.57%~12.50%,FAPT-2体系的功率准数降低10.95%~19.32%,FAPT-3体系的功率准数降低15.25%~24.66%。在相同功耗下,与Rushton桨相比,FAPT桨能够增强对流体的剪切作用,增大剪切应变率,减小混合隔离区,缩短流体的混合时间,提高流体的混合效率,而且随着穿流孔分形迭代次数的增加这一效果更为明显。

中图分类号:

谷德银, 李昌树, 杨豪, 刘作华. 分形排布式穿流搅拌桨强化流体混沌混合行为[J]. 化工学报, 2024, 75(10): 3498-3506.

Deyin GU, Changshu LI, Hao YANG, Zuohua LIU. Fluid chaotic mixing behavior intensified by fractal-arranged perforated impeller[J]. CIESC Journal, 2024, 75(10): 3498-3506.

图6 不同搅拌桨体系中功耗、功率准数、Reynolds数与功率准数乘积随Reynolds数的变化

Fig.6 Variation of power consumption and power number with Reynolds number in different impeller systems

| 1 | Dusting J, Sheridan J, Hourigan K. A fluid dynamics approach to bioreactor design for cell and tissue culture[J]. Biotechnology and Bioengineering, 2006, 94(6): 1196-1208. |

| 2 | Alvarez M M, Guzman A, Elias M. Experimental visualization of mixing pathologies in laminar stirred tank bioreactor[J]. Chemical Engineering Science, 2005, 60(8/9): 2449-2457. |

| 3 | Kang Q Q, Liu J F, Feng X, et al. Isolated mixing regions and mixing enhancement in a high-viscosity laminar stirred tank[J]. Chinese Journal of Chemical Engineering, 2022, 41: 176-192. |

| 4 | Gu D Y, Liu Z H, Li J, et al. Intensification of chaotic mixing in a stirred tank with a punched rigid-flexible impeller and a chaotic motor[J]. Chemical Engineering & Processing: Process Intensification, 2017, 122: 1-9. |

| 5 | Wang S, Wu J, Bong E. Reduced IMRs in a mixing tank via agitation improvement[J]. Chemical Engineering Research and Design, 2013, 91(6): 1009-1017. |

| 6 | Arratia P E, Lacombe J P, Shinbrot T, et al. Segregated regions in continuous laminar stirred tank reactors[J]. Chemical Engineering Science, 2004, 59(7): 1481-1490. |

| 7 | Lamberto D J, Muzzio F J, Swanson P D, et al. Using time-dependent RPM to enhance mixing in stirred vessels[J]. Chemical Engineering Science, 1996, 51(5): 733-741. |

| 8 | Lamberto D J, Alvarez M M, Muzzio F J. Computational analysis of regular and chaotic mixing in a stirred tank reactor[J]. Chemical Engineering Science, 2001, 56(16): 4887-4899. |

| 9 | Nomura T, Uchida T, Takahashi K. Enhancement of mixing by unsteady agitation of an impeller in an agitated vessel[J]. Journal of Chemical Engineering of Japan, 1997, 30(5): 875-879. |

| 10 | Masiuk S. Mixing time for a reciprocating plate agitator with flapping blades[J]. Chemical Engineering Journal, 2000, 79(1): 23-30. |

| 11 | 杨锋苓, 周慎杰, 王贵超. 双层涡轮桨偏心搅拌槽内的宏观不稳定性研究[J]. 高校化学工程学报, 2013, 27(4): 585-590. |

| Yang F L, Zhou S J, Wang G C. Study on the macro-instability in a stirred tank equipped with double eccentrically located Rushton impellers[J]. Journal of Chemical Engineering of Chinese Universities, 2013, 27(4): 585-590. | |

| 12 | Karcz J, Cudak M, Szoplik J. Stirring of a liquid in a stirred tank with an eccentrically located impeller[J]. Chemical Engineering Science, 2005, 60(8/9): 2369-2380. |

| 13 | Ameur H. 3D hydrodynamics involving multiple eccentric impellers in unbaffled cylindrical tank[J]. Chinese Journal of Chemical Engineering, 2016, 24(5): 572-580. |

| 14 | 李挺, 贾卓泰, 张庆华, 等. 几种单层桨搅拌槽内宏观混合特性的比较[J]. 化工学报, 2019, 70(1): 32-38. |

| Li T, Jia Z T, Zhang Q H, et al. Comparison of macro-mixing characteristics of a stirred tank with different impellers[J]. CIESC Journal, 2019, 70(1): 32-38. | |

| 15 | 栾德玉, 周慎杰, 陈颂英, 等. 错位六弯叶桨在假塑性流体中的混沌搅拌特性[J]. 化学工程, 2011, 39(9): 41-46. |

| Luan D Y, Zhou S J, Chen S Y, et al. Chaotic agitation characteristics of shifted 6-bent-blade impeller in pseudoplastic fluid[J]. Chemical Engineering (China), 2011, 39(9): 41-46. | |

| 16 | Gu D Y, Li C S. Mixing characteristics of high-viscosity fluids with laminar flow in a stirred tank with a fractal arranged perforated impeller[J]. Chemical Engineering and Processing - Process Intensification, 2024, 197: 109706. |

| 17 | Hashimoto S, Osaka R, Kawamata M. Analysis on laminar chaotic mixing based on configuration of streak lobes in an impeller-agitated vessel[J]. Industrial & Engineering Chemistry Research, 2012, 51(19): 6939-6947. |

| 18 | Takahashi K, Takeno Y, Takahata Y. Comparison of mixing performances among several spatial chaotic mixing methods[J]. Journal of Chemical Engineering of Japan, 2015, 48(7): 518-522. |

| 19 | Ameur H. Newly modified curved-bladed impellers for process intensification: energy saving in the agitation of Hershel-Bulkley fluids[J]. Chemical Engineering and Processing - Process Intensification, 2020, 154: 108009. |

| 20 | 邹晨, 谢明辉, 周国忠, 等. 穿流式搅拌器槽内流场的数值模拟[J]. 机械设计与制造, 2012(4): 239-241. |

| Zou C, Xie M H, Zhou G Z, et al. Numerical simulation for flow field in stirred tank of punched impeller[J]. Machinery Design & Manufacture, 2012(4): 239-241. | |

| 21 | 徐阳, 杨其洲, 潘跃跃, 等. 穿流-四斜叶组合桨搅拌槽内的流场特性[J]. 化工进展, DOI: 10.16085/j.issn.1000-6613.2023-2214 . |

| Xu Y, Yang Q Z, Pan Y Y, et al. Flow field characteristics in stirred tank equipped with punched and four pitched blade combined impeller [J]. Chemical Industry and Engineering Progress, DOI: 10.16085/j.issn.1000-6613.2023-2214 . | |

| 22 | Başbuğ S, Papadakis G, Vassilicos J C. Reduced power consumption in stirred vessels by means of fractal impellers[J]. AIChE Journal, 2018, 64(4): 1485-1499. |

| 23 | Steiros K, Bruce P J K, Buxton O R H, et al. Effect of blade modifications on the torque and flow field of radial impellers in stirred tanks[J]. Physical Review Fluids, 2017, 2(9): 094802. |

| 24 | Steiros K, Bruce P J K, Buxton O R H, et al. Power consumption and form drag of regular and fractal-shaped turbines in a stirred tank[J]. AIChE Journal, 2017, 63(2): 843-854. |

| 25 | Gu D Y, Chen J J, Song Y H, et al. Modification of impeller blades for the efficient mixing of particulate suspensions in a stirred tank[J]. Advanced Powder Technology, 2024, 35(5): 104444. |

| 26 | Kulkarni A A, Jha N, Singh A, et al. Fractal impeller for stirred tank reactors[J]. Industrial & Engineering Chemistry Research, 2011, 50(12): 7667-7676. |

| 27 | Buwa V, Dewan A, Nassar A F, et al. Fluid dynamics and mixing of single-phase flow in a stirred vessel with a grid disc impeller: experimental and numerical investigations[J]. Chemical Engineering Science, 2006, 61(9): 2815-2822. |

| 28 | Kazemzadeh A, Ein-Mozaffari F, Lohi A, et al. Investigation of hydrodynamic performances of coaxial mixers in agitation of yield-pseudoplasitc fluids: single and double central impellers in combination with the anchor[J]. Chemical Engineering Journal, 2016, 294: 417-430. |

| 29 | Luan D Y, Wang Z R, Wang H, et al. Determination method of the cavern boundary viscosity in a stirred tank with pseudoplastic fluid[J]. AIChE Journal, 2020, 66(5): e16941. |

| 30 | Khapre A, Munshi B. Numerical investigation of hydrodynamic behavior of shear thinning fluids in stirred tank[J]. Journal of the Taiwan Institute of Chemical Engineers, 2015, 56: 16-27. |

| 31 | Bao Y Y, Lu Y, Liang Q Q, et al. Power demand and mixing performance of coaxial mixers in a stirred tank with CMC solution[J]. Chinese Journal of Chemical Engineering, 2015, 23(4): 623-632. |

| 32 | Buffo M M, Corrêa L J, Esperança M N, et al. Influence of dual-impeller type and configuration on oxygen transfer, power consumption, and shear rate in a stirred tank bioreactor[J]. Biochemical Engineering Journal, 2016, 114: 130-139. |

| 33 | Zhang Z, Chen G R. Liquid mixing enhancement by chaotic perturbations in stirred tanks[J]. Chaos, Solitons & Fractals, 2008, 36(1): 144-149. |

| 34 | Rutherford K, Lee K C, Mahmoudi S M S, et al. Hydrodynamic characteristics of dual Rushton impeller stirred vessels[J]. AIChE Journal, 1996, 42(2): 332-346. |

| [1] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [2] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [3] | 李倩, 张蓉民, 林子杰, 战琪, 蔡伟华. 基于机器学习的印刷电路板式换热器流动换热预测与仿真[J]. 化工学报, 2024, 75(8): 2852-2864. |

| [4] | 曹佳蕾, 孙立岩, 曾德望, 尹凡, 高子翔, 肖睿. 双流化床化学链制氢反应器的数值模拟[J]. 化工学报, 2024, 75(8): 2865-2874. |

| [5] | 金虎, 杨帆, 戴梦瑶. 基于格子Boltzmann方法的液滴在圆柱壁面上运动过程研究[J]. 化工学报, 2024, 75(8): 2897-2908. |

| [6] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [7] | 周文轩, 刘珍, 张福建, 张忠强. 高通量-高截留率时间维度膜法水处理机理研究[J]. 化工学报, 2024, 75(7): 2583-2593. |

| [8] | 张香港, 常玉龙, 汪华林, 江霞. 废弃秸秆等生物质低能耗非相变秒级干燥[J]. 化工学报, 2024, 75(7): 2433-2445. |

| [9] | 胡军勇, 胡亚丽, 谭学诣, 黄佳欣, 张乐炜, 曾俊立, 刘晓奕, 陶源. 基于LiCl-NH4Cl水溶液多级逆电渗析性能的实验研究[J]. 化工学报, 2024, 75(7): 2670-2679. |

| [10] | 王芝安, 兰忠, 马学虎. 喷嘴参数对超临界水热燃烧特性影响的模拟[J]. 化工学报, 2024, 75(6): 2190-2200. |

| [11] | 徐嘉宇, 陈飞国, 徐骥, 葛蔚. 颗粒体系的多尺度混合指数[J]. 化工学报, 2024, 75(6): 2214-2221. |

| [12] | 黎宏陶, 王振雷, 王昕. 基于即时学习的改进条件高斯回归软测量[J]. 化工学报, 2024, 75(6): 2299-2312. |

| [13] | 苏彬, 董浩伟, 罗振敏, 邓军, 王涛, 程方明. 气粉两相体系爆炸动力学特性及机理研究进展[J]. 化工学报, 2024, 75(6): 2109-2122. |

| [14] | 师毓辉, 邢继远, 姜雪晗, 叶爽, 黄伟光. 基于PBM的离心式叶轮内气泡破碎合并数值模拟[J]. 化工学报, 2024, 75(5): 1816-1829. |

| [15] | 刘帆, 张芫通, 陶成, 胡成玉, 杨小平, 魏进家. 歧管式射流微通道液冷散热性能[J]. 化工学报, 2024, 75(5): 1777-1786. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号