化工学报 ›› 2025, Vol. 76 ›› Issue (5): 1909-1926.DOI: 10.11949/0438-1157.20241467

• 综述与专论 •

何燎( ), 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮(

), 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮( ), 高金森, 徐春明

), 高金森, 徐春明

收稿日期:2024-12-18

修回日期:2025-01-29

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

赵亮

作者简介:何燎(1995—),女,博士研究生,heliao@zgsydxbj.wecom.work

基金资助:

Liao HE( ), Jun LI, Mengshu GAO, Dongyang LIU, Yuhao ZHANG, Liang ZHAO(

), Jun LI, Mengshu GAO, Dongyang LIU, Yuhao ZHANG, Liang ZHAO( ), Jinsen GAO, Chunming XU

), Jinsen GAO, Chunming XU

Received:2024-12-18

Revised:2025-01-29

Online:2025-05-25

Published:2025-06-13

Contact:

Liang ZHAO

摘要:

在“双碳”目标推动下,精细化加工和节能降耗成为新趋势,“分子炼油”技术是炼油行业绿色创新和高质量发展的关键。从石油烃中高效分离芳烃,为芳烃按需加工提供优质原料,是实现“分子炼油”理念的重要技术途径。详细介绍了芳烃与非芳烃及芳烃组分间分离技术研究现状,进一步总结了芳烃分离技术选型策略,并提出了芳烃分离低碳工业化主要发展方向,从而实现芳烃高值化利用和化工行业可持续发展。

中图分类号:

何燎, 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮, 高金森, 徐春明. 石油烃中芳烃分离技术研究进展[J]. 化工学报, 2025, 76(5): 1909-1926.

Liao HE, Jun LI, Mengshu GAO, Dongyang LIU, Yuhao ZHANG, Liang ZHAO, Jinsen GAO, Chunming XU. Research progress on aromatic hydrocarbons separation from petroleum hydrocarbons[J]. CIESC Journal, 2025, 76(5): 1909-1926.

| 原料 | 溶剂 | 萃取温度/℃ | 萃取时间/min | 剂油比 | 芳烃纯度/% | 芳烃收率/% | 文献 |

|---|---|---|---|---|---|---|---|

| 糠醛抽出油 | 糠醛 | 70 | — | 3 | 76.8 | 58.6 | [ |

| 减二线糠醛抽出油 | 糠醛 | 60 | — | 2 | 80.6 | 52.3 | [ |

| 减四线糠醛抽出油 | 糠醛 | 70 | — | 3 | 76.8 | 55.1 | [ |

| 重质馏分糠醛抽出油 | 糠醛 | 60~90 | — | 1.5~2 | 78.7~84.8 | — | [ |

| 重质馏分糠醛抽出油 | 环丁砜 | 70 | — | 3 | 45.7 | — | [ |

| FCC柴油 | 环丁砜 | 50 | 5 | 1.5 | 93.71 | 29.29 | [ |

| FCC柴油 | 环丁砜 | 45 | 5 | 1.4 | 99.07 | 29.87 | [ |

表1 芳烃与非芳烃体系中单一有机溶剂萃取效果

Table 1 Extraction efficiency of aromatic and non-aromatic hydrocarbons with single organic solvent

| 原料 | 溶剂 | 萃取温度/℃ | 萃取时间/min | 剂油比 | 芳烃纯度/% | 芳烃收率/% | 文献 |

|---|---|---|---|---|---|---|---|

| 糠醛抽出油 | 糠醛 | 70 | — | 3 | 76.8 | 58.6 | [ |

| 减二线糠醛抽出油 | 糠醛 | 60 | — | 2 | 80.6 | 52.3 | [ |

| 减四线糠醛抽出油 | 糠醛 | 70 | — | 3 | 76.8 | 55.1 | [ |

| 重质馏分糠醛抽出油 | 糠醛 | 60~90 | — | 1.5~2 | 78.7~84.8 | — | [ |

| 重质馏分糠醛抽出油 | 环丁砜 | 70 | — | 3 | 45.7 | — | [ |

| FCC柴油 | 环丁砜 | 50 | 5 | 1.5 | 93.71 | 29.29 | [ |

| FCC柴油 | 环丁砜 | 45 | 5 | 1.4 | 99.07 | 29.87 | [ |

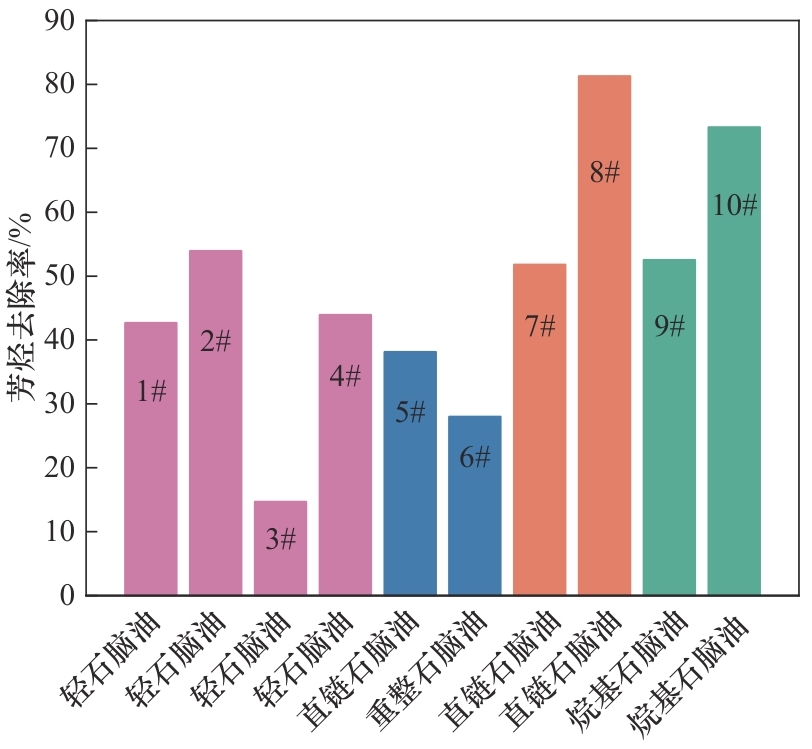

图2 芳烃与非芳烃体系中复配有机溶剂的芳烃去除率1#—环丁砜[37]; 2#—环丁砜/10%(质量分数)异丙醇[37]; 3#—环丁砜/10%(质量分数)乙二醇[37]; 4#—环丁砜/10%(质量分数)水[37]; 5#—二甲基甲酰胺[38]; 6#—二甲基甲酰胺/乙二醇[39]; 7#—N-甲基吡咯烷酮[38]; 8#—N-甲基吡咯烷酮/N,N-二甲基甲酰胺[38]; 9#—二甲基亚砜[40]; 10#—二甲基亚砜/10%N,N-二甲基甲酰胺[40]

Fig.2 Removal efficiency of aromatic and non-aromatic hydrocarbons by compounded organic solvents

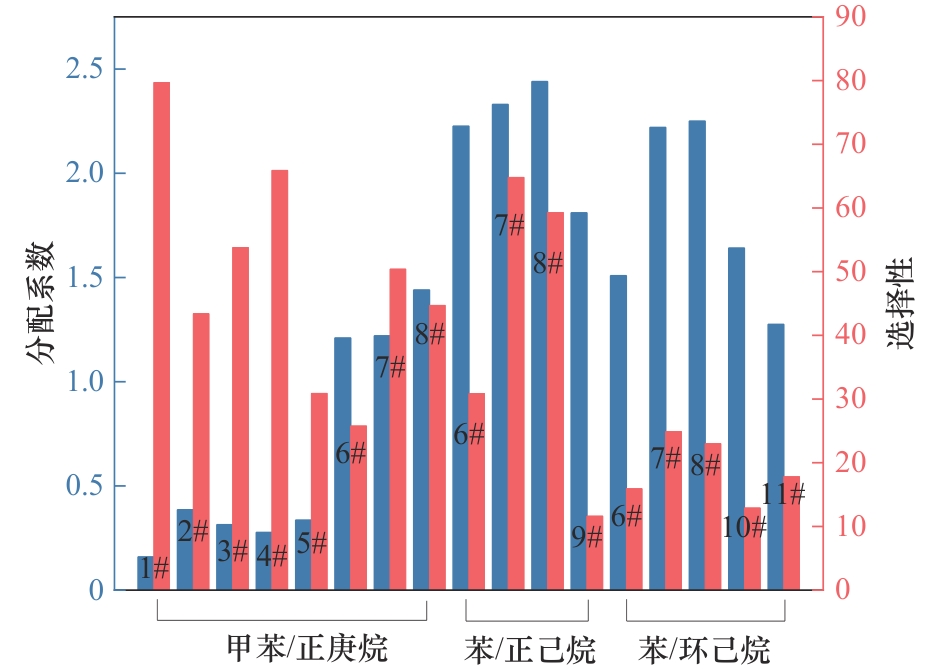

图4 芳烃与非芳烃体系中咪唑类离子液体分离性能1#—1-ethyl-3-methylimidazolium methylsulfonate[47]; 2#—1-ethyl-3-methylimidazolium trifluoromethanesulfonate[47]; 3#—1-ethyl-3-methylimidazolium 1,1,2,2-tetrafluoroethanesulfonate[47]; 4#—1-butyl-3-methylimidazolium dicyanamide[48]; 5#—1-butyl-3-methylimidazolium thiocyanate[49]; 6#—N-benzyl-N-methylimidazoium bis(trifluoromethylsulfonyl)mide[50]; 7#—[C5(MIM)2][NTf2]2[51]; 8#—[C6(MIM)2][NTf2]2[51]; 9#—1-butyl-3-methylimidazolium tetrachloroferrate[52]; 10#—1-benzyl-3-vinylimidazolium bis(trifluoromethylsulfonyl)imide[51]; 11#—1-hexyl-3-methylimidazolium hexafluorophosphate[53]

Fig.4 Separation performance of imidazole ionic liquids with different aromatic and non-aromatic separation systems

| 原料 | 离子液体 | 温度/℃ | 芳烃分离性能 | 文献 | |

|---|---|---|---|---|---|

| 分配系数 | 选择性 | ||||

| 苯/正己烷 | methylpridinium ethylsulphate | 25 | 0.90 | 26.12 | [ |

| 正丁基苯/正癸烷 | 1-己基-4-甲基吡啶四氟硼酸盐 | 40 | 0.45 | 49.36 | [ |

| 四氢萘/正癸烷 | 1-己基-4-甲基吡啶四氟硼酸盐 | 40 | 0.75 | 90.03 | [ |

| 萘/正癸烷 | 1-己基-4-甲基吡啶四氟硼酸盐 | 40 | 5.08 | 778.50 | [ |

表2 芳烃与非芳烃体系中吡啶类离子液体萃取效果

Table 2 Extraction efficiency of pyridine ionic liquids for aromatic and non-aromatic hydrocarbons

| 原料 | 离子液体 | 温度/℃ | 芳烃分离性能 | 文献 | |

|---|---|---|---|---|---|

| 分配系数 | 选择性 | ||||

| 苯/正己烷 | methylpridinium ethylsulphate | 25 | 0.90 | 26.12 | [ |

| 正丁基苯/正癸烷 | 1-己基-4-甲基吡啶四氟硼酸盐 | 40 | 0.45 | 49.36 | [ |

| 四氢萘/正癸烷 | 1-己基-4-甲基吡啶四氟硼酸盐 | 40 | 0.75 | 90.03 | [ |

| 萘/正癸烷 | 1-己基-4-甲基吡啶四氟硼酸盐 | 40 | 5.08 | 778.50 | [ |

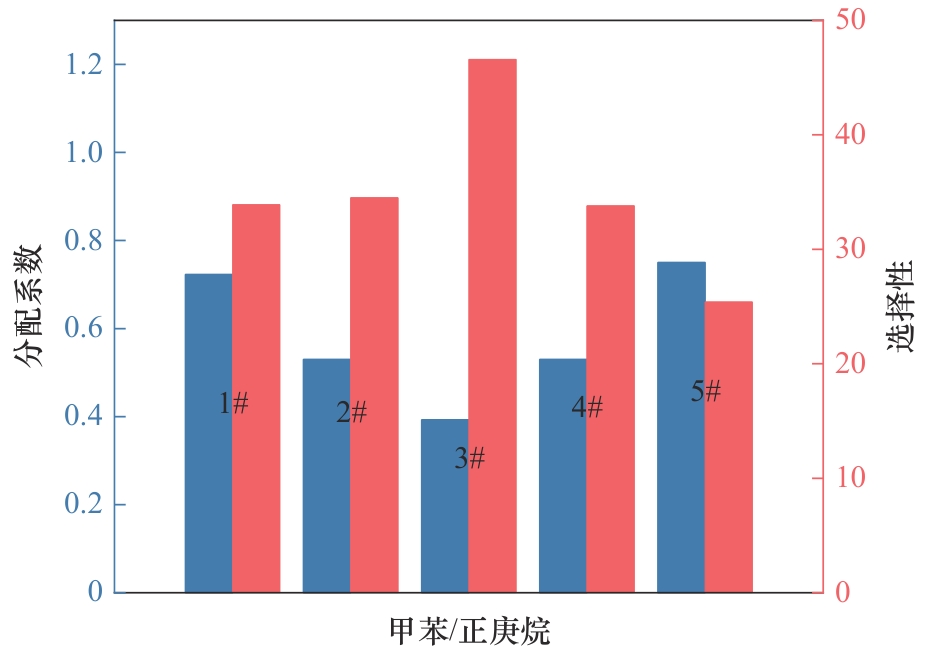

图5 甲苯/正庚烷体系中复配离子液体的分离性能1#—[bpy][BF4]/[4bpy][Tf2N][56]; 2#—[bpy][BF4] (0.7)/[4bmpy][Tf2N] (0.3)[57]; 3#—[emim][TCM] (0.8)/[emim][DCA] (0.2)[58]; 4#—[4bmpy][Tf2N](0.3)/[emim][CHF2CF2SO3](0.7)[59]; 5#—[4bmpy][Tf2N](0.5)/[emim][C2H5SO4](0.5)[60]

Fig.5 Separation performance of compounded ionic liquids in toluene/n-heptane system

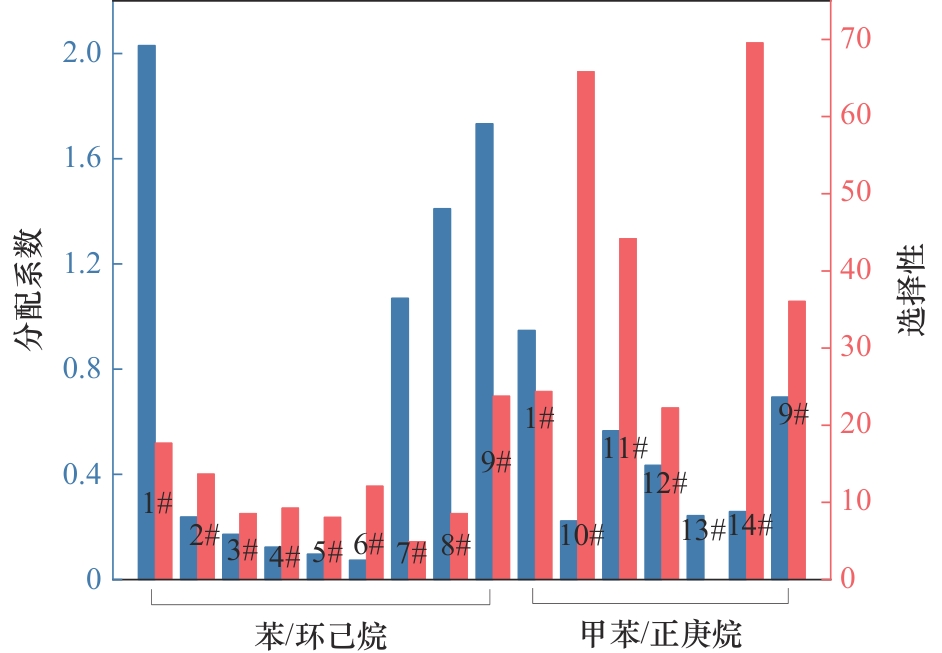

图6 芳烃与非芳烃体系中低共熔溶剂分离性能1#—1-butyl-3-methylimidazolium bromide/N-formylmorpholine[68]; 2#—tetrabutylammonium bromide/sulfolane[69]; 3#—tetrabutylammonium bromide/triethylene glycol[69]; 4#—methyltriphenylphosphonium bromide/tetraethylene glycol[69]; 5#—methyltriphenylphosphonium bromide/1,2 propanediol[69]; 6#—choline chloride/triethylene glycol[69]; 7#—tetrahexylammonium bromide/ethylene glycol l[70]; 8#—tetrahexylammonium bromide/glycerol[70]; 9#—N-ethylpyridinium bromide/ N-formyl morpholin[71]; 10#—ethyltriphenylphosphonium iodide/ethylene glycol[72]; 11#—ethyltriphenylphosphonium iodide/sulfolane[72]; 12#—tetrabutylphosphonium bromide/ethylene glycol[73]; 13#—tetrabutylphosphonium bromide/sulfolane[73]; 14#—pyridine based ionic liquid/acetylpropionic acid[74]

Fig.6 Separation performance of low eutectic solvents for aromatic and non-aromatic hydrocarbons

图7 芳烃与非芳烃体系中萃取精馏的分离效果1#—N-甲基-2-吡咯烷酮[82]; 2#—苯酚[82]; 3#—环丁砜[82]; 4#— N-甲基吡咯烷酮[83]; 5#—二甲基亚砜[84]; 6#—85%(质量分数)环丁砜/15%(质量分数)甲基磺酰乙烷[85]

Fig.7 Effect of extractive distillation on the separation of aromatic and non-aromatic hydrocarbons

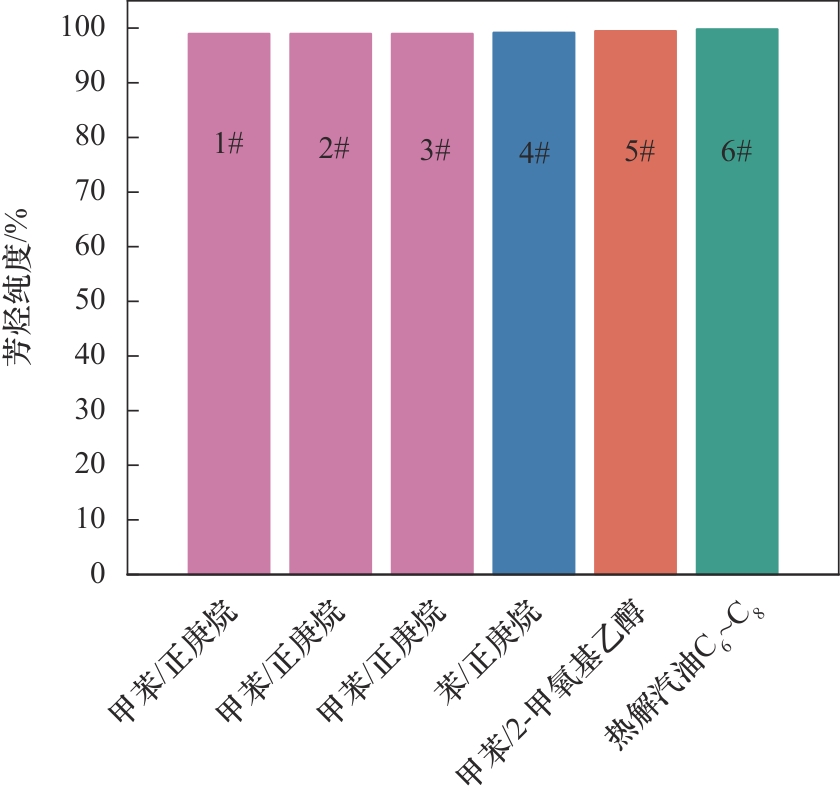

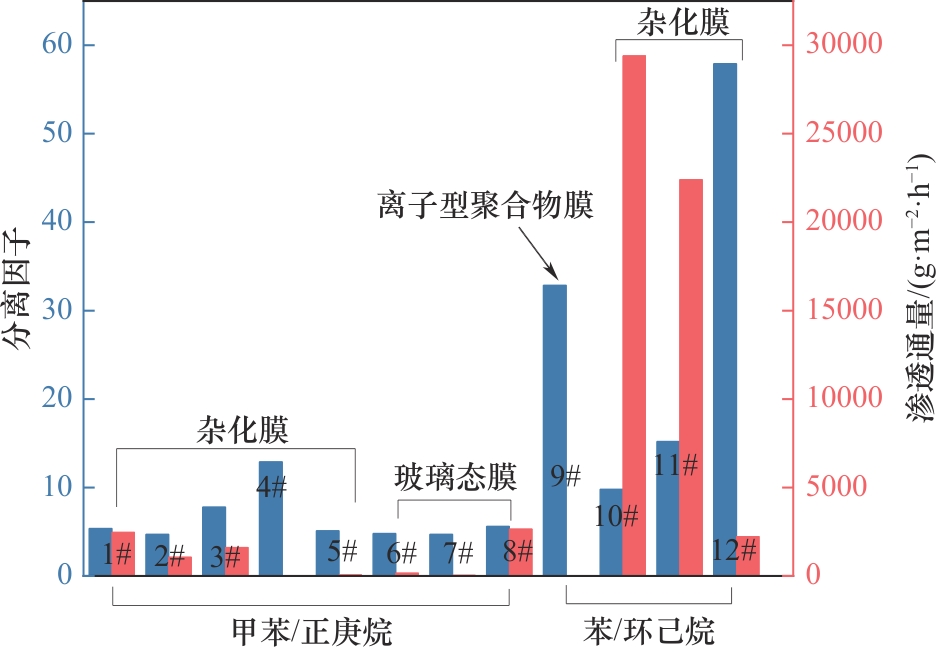

图9 芳烃与非芳烃体系中膜材料的分离性能1#—非对称聚丙烯腈/苯甲酮/聚乙二醇甲醚甲基丙烯酸酯接枝复合膜[96]; 2#—聚丙烯腈/甲基丙烯酸甲酯-甲基丙烯酸钾盐/十二烷基二甲基苄基氯化铵膜[102]; 3#—聚丙烯腈/聚乙二醇甲基丙烯酸酯接枝复合膜[103]; 4#—不对称聚丙烯腈/聚乙烯醇-氧化石墨烯[104]; 5#—Boltorn W3000“孔填充”陶瓷复合膜[105]; 6#—聚酰亚胺膜[106]; 7#—芳香族聚酰亚胺和聚苯并𫫇唑膜[107]; 8#—杂萘联苯聚芳醚腈酮/聚乙二醇甲基丙烯酸酯接枝复合膜[108]; 9#—[3-Mebupy][BF4]聚偏二氟乙烯支撑液膜[109]; 10#—聚己二酸乙二醇酯/聚氨酯脲膜[98]; 11#—聚己二酸乙二醇酯/聚氨酯酰亚胺膜[98]; 12#—海藻酸钠/羧甲基纤维素钠共混膜[110]

Fig.9 Membrane separation performance of different aromatic and non-aromatic separation systems

| 芳烃碳数 | 原料 | 分离技术 | 分离效率 | 文献 |

|---|---|---|---|---|

| C8 | 间/对二甲苯 | 常压低温结晶法 | 98%对二甲苯 | [ |

| 混合二甲苯 | 吸附分离 | 99.5%对二甲苯 | [ | |

| 间/对二甲苯 | 加压结晶法 | 99.5%对二甲苯 | [ | |

| 混合二甲苯 | 蒸馏冷冻结晶法 | 99.9%对二甲苯 | [ | |

| 对二甲苯/甲苯 | 熔融结晶 | 99.52%对二甲苯 | [ | |

| 混合二甲苯 | MFI沸石膜分离 | 对二甲苯/邻二甲苯分离因子为600 | [ | |

| C8芳烃异构体 | MIL-160膜分离 | 对二甲苯/邻二甲苯分离因子为38.5 | [ | |

| C8芳烃异构体 | 环糊精纳米薄膜分离 | 对二甲苯/邻二甲苯分离因子为6.1 | [ | |

| C8芳烃异构体 | 分子印迹聚合物膜分离 | 对二甲苯/邻二甲苯分离因子为4.24 | [ | |

| C8芳烃异构体 | MOF-5膜分离 | 对二甲苯/邻二甲苯分离因子为1.95 | [ | |

| C9 | 重整C9芳烃 | 偏三甲苯异构化-精馏 | >95%均三甲苯 | [ |

| 富集均三甲苯 | 烷基化-精馏 | >99%均三甲苯 | [ | |

| C9芳烃 | 烷基化-常规精馏 | >98%均三甲苯 | [ | |

| C9芳烃 | 萃取精馏-催促精馏 | >98%(质量分数)均三甲苯 | [ | |

| 重整C9芳烃 | 精馏 | >99%偏三甲苯 | [ | |

| 重整C9芳烃 | 精密分馏 | 98.5%偏三甲苯 | [ | |

| C9芳烃 | 双塔双效热集成精馏 | 98.51%(质量分数)偏三甲苯 | [ | |

| 重整C9芳烃 | 差压热耦合精馏 | 99%(质量分数)偏三甲苯 | [ | |

| C9芳烃 | 精密精馏-深冷结晶 | >91%连三甲苯 | [ | |

| C9芳烃 | 萃取精馏 | 99%(质量分数)连三甲苯 | [ | |

| C9芳烃 | 精密精馏-深冷结晶 | >96%茚满 | [ | |

| 重整C9芳烃 | 精密分馏 | >95%间/邻/对甲乙苯 | [ | |

| C10 | C10芳烃 | 精馏-萃取精馏 | ≥95%(质量分数)间二乙苯 | [ |

| C10芳烃 | 精馏-萃取精馏 | ≥90%(质量分数)对二乙苯 | [ | |

| C10芳烃 | 熔融结晶 | 99.06%(质量分数)均四甲苯 | [ | |

| 均四甲苯粗产品 | 熔融结晶 | 99%均四甲苯 | [ |

表3 C8、C9、C10单环芳烃分离研究

Table 3 Separation studies of C8, C9, C10 monocyclic aromatic hydrocarbons

| 芳烃碳数 | 原料 | 分离技术 | 分离效率 | 文献 |

|---|---|---|---|---|

| C8 | 间/对二甲苯 | 常压低温结晶法 | 98%对二甲苯 | [ |

| 混合二甲苯 | 吸附分离 | 99.5%对二甲苯 | [ | |

| 间/对二甲苯 | 加压结晶法 | 99.5%对二甲苯 | [ | |

| 混合二甲苯 | 蒸馏冷冻结晶法 | 99.9%对二甲苯 | [ | |

| 对二甲苯/甲苯 | 熔融结晶 | 99.52%对二甲苯 | [ | |

| 混合二甲苯 | MFI沸石膜分离 | 对二甲苯/邻二甲苯分离因子为600 | [ | |

| C8芳烃异构体 | MIL-160膜分离 | 对二甲苯/邻二甲苯分离因子为38.5 | [ | |

| C8芳烃异构体 | 环糊精纳米薄膜分离 | 对二甲苯/邻二甲苯分离因子为6.1 | [ | |

| C8芳烃异构体 | 分子印迹聚合物膜分离 | 对二甲苯/邻二甲苯分离因子为4.24 | [ | |

| C8芳烃异构体 | MOF-5膜分离 | 对二甲苯/邻二甲苯分离因子为1.95 | [ | |

| C9 | 重整C9芳烃 | 偏三甲苯异构化-精馏 | >95%均三甲苯 | [ |

| 富集均三甲苯 | 烷基化-精馏 | >99%均三甲苯 | [ | |

| C9芳烃 | 烷基化-常规精馏 | >98%均三甲苯 | [ | |

| C9芳烃 | 萃取精馏-催促精馏 | >98%(质量分数)均三甲苯 | [ | |

| 重整C9芳烃 | 精馏 | >99%偏三甲苯 | [ | |

| 重整C9芳烃 | 精密分馏 | 98.5%偏三甲苯 | [ | |

| C9芳烃 | 双塔双效热集成精馏 | 98.51%(质量分数)偏三甲苯 | [ | |

| 重整C9芳烃 | 差压热耦合精馏 | 99%(质量分数)偏三甲苯 | [ | |

| C9芳烃 | 精密精馏-深冷结晶 | >91%连三甲苯 | [ | |

| C9芳烃 | 萃取精馏 | 99%(质量分数)连三甲苯 | [ | |

| C9芳烃 | 精密精馏-深冷结晶 | >96%茚满 | [ | |

| 重整C9芳烃 | 精密分馏 | >95%间/邻/对甲乙苯 | [ | |

| C10 | C10芳烃 | 精馏-萃取精馏 | ≥95%(质量分数)间二乙苯 | [ |

| C10芳烃 | 精馏-萃取精馏 | ≥90%(质量分数)对二乙苯 | [ | |

| C10芳烃 | 熔融结晶 | 99.06%(质量分数)均四甲苯 | [ | |

| 均四甲苯粗产品 | 熔融结晶 | 99%均四甲苯 | [ |

| 分离技术 | 分离原理 | 分离效率 | 能耗 | 环境 影响 | 优点 | 缺点 |

|---|---|---|---|---|---|---|

溶剂 萃取 | 溶剂对组分选择溶解性差异 | 高,尤其适用于不同极性的混合物 | 低 | 中等 | 操作简便,适用范围广,可选择性强 | 溶剂回收成本高 |

| 精馏 | 组分挥发度差异 | 中等,适用于沸点差异明显的混合物 | 高 | 中等 | 技术成熟,操作简单,适用范围广 | 设备投资高,能耗高,对热敏性物质不适用 |

萃取 蒸馏 | 增加组分间相对挥发度 | 高,适用于沸点相近的混合物 | 中等 | 中等 | 投资少,能耗低 | 溶剂回收成本高 |

萃取 精馏 | 增加组分间相对挥发度 | 高,适用于沸点相近的混合物和共沸物 | 中等 | 中等 | 操作灵活,能耗较低 | 溶剂回收成本高 |

吸附 分离 | 吸附剂对组分的吸附能力差异 | 高,尤其适用于气体和液体混合物 | 高 | 中等 | 操作简单,适用范围广,可选择性强 | 吸附剂再生困难,成本高,吸附容量有限 |

| 膜分离 | 膜的选择渗透性 | 中等,尤其适用于热敏感物质 | 低 | 低 | 低能耗,设备简单,操作灵活 | 膜成本高,易污染,需定期更换 |

结晶 分离 | 组分的凝固点差异 | 低,尤其适用于同分异构体和共沸物 | 低 | 低 | 工艺简单,能耗低 | 回收率低,连续工业化生产难 |

表4 不同芳烃分离技术对比

Table 4 Comparison of various aromatics separation technologies

| 分离技术 | 分离原理 | 分离效率 | 能耗 | 环境 影响 | 优点 | 缺点 |

|---|---|---|---|---|---|---|

溶剂 萃取 | 溶剂对组分选择溶解性差异 | 高,尤其适用于不同极性的混合物 | 低 | 中等 | 操作简便,适用范围广,可选择性强 | 溶剂回收成本高 |

| 精馏 | 组分挥发度差异 | 中等,适用于沸点差异明显的混合物 | 高 | 中等 | 技术成熟,操作简单,适用范围广 | 设备投资高,能耗高,对热敏性物质不适用 |

萃取 蒸馏 | 增加组分间相对挥发度 | 高,适用于沸点相近的混合物 | 中等 | 中等 | 投资少,能耗低 | 溶剂回收成本高 |

萃取 精馏 | 增加组分间相对挥发度 | 高,适用于沸点相近的混合物和共沸物 | 中等 | 中等 | 操作灵活,能耗较低 | 溶剂回收成本高 |

吸附 分离 | 吸附剂对组分的吸附能力差异 | 高,尤其适用于气体和液体混合物 | 高 | 中等 | 操作简单,适用范围广,可选择性强 | 吸附剂再生困难,成本高,吸附容量有限 |

| 膜分离 | 膜的选择渗透性 | 中等,尤其适用于热敏感物质 | 低 | 低 | 低能耗,设备简单,操作灵活 | 膜成本高,易污染,需定期更换 |

结晶 分离 | 组分的凝固点差异 | 低,尤其适用于同分异构体和共沸物 | 低 | 低 | 工艺简单,能耗低 | 回收率低,连续工业化生产难 |

| 1 | 马力. 石化芳烃生产技术环境保护分析[J]. 中国资源综合利用, 2018, 36(3): 140-142. |

| Ma L. Environmental protection analysis of petrochemical aromatic hydrocarbon production technology[J]. China Resources Comprehensive Utilization, 2018, 36(3): 140-142. | |

| 2 | 米多, 王琦, 刘利国, 等. 芳烃主要产品生产及市场分析[J]. 化学工业, 2022, 40(4): 71-82. |

| Mi D, Wang Q, Liu L G, et al. Production and market analysis of major aromatic products[J]. Chemical Industry, 2022, 40(4): 71-82. | |

| 3 | Mochida I, Shimizu K, Korai Y, et al. Mesophase pitch catalytically prepared from anthracene with HF/BF3 [J]. Carbon, 1992, 30(1): 55-61. |

| 4 | 贾智杰, 林伯强. 国有企业、价格管制与经济稳定: 来自中国特色汽柴油市场的视角[J]. 中国人口·资源与环境, 2022, 32(7): 173-185. |

| Jia Z J, Lin B Q. State-owned enterprises, price regulation, and economic stability: from the perspective of gasoline and diesel markets with Chinese characteristics[J]. China Population, Resources and Environment, 2022, 32(7): 173-185. | |

| 5 | 王尤佳, 赵亮, 高金森, 等. 柴油烃类族组成分离技术研究进展[J]. 化工学报, 2024, 75(1): 20-32. |

| Wang Y J, Zhao L, Gao J S, et al. Research progress on separation technology of diesel hydrocarbon components[J]. CIESC Journal, 2024, 75(1): 20-32. | |

| 6 | 陈浩. 芳烃产业发展现状及趋势分析[J]. 炼油技术与工程, 2020, 50(7): 1-4. |

| Chen H. Analysis on the development status and trend of aromatics industry[J]. Petroleum Refinery Engineering, 2020, 50(7): 1-4. | |

| 7 | 田璐瑶, 王梓豪, 粟杨, 等. 基于深度学习的溶剂定量构效关系建模研究进展[J]. 化工学报, 2020, 71(10): 4462-4472. |

| Tian L Y, Wang Z H, Su Y, et al. Research advances in deep learning based quantitative structure-property relationship modeling of solvents[J]. CIESC Journal, 2020, 71(10): 4462-4472. | |

| 8 | 张旭东, 刘彦花, 申峻, 等. COSMO-RS模型在离子液体/低共熔溶剂筛选中的应用研究进展[J]. 化工学报, 2023, 74(11):4383-4396. |

| Zhang X D, Liu Y H, Shen J, et al. Recent progress on application of COSMO-RS model in screening of ionic liquids/deep eutectic solvents[J]. CIESC Journal, 2023, 74(11): 4383-4396. | |

| 9 | 张宇豪, 赵亮, 高金森, 等. 溶剂结构对萃取分离直馏柴油中不同环数芳烃的影响[J]. 中国科学(化学), 2023, 53(9): 1781-1791. |

| Zhang Y H, Zhao L, Gao J S, et al. Effect of solvent structure on separation of different ring aromatics from straight-run diesel[J]. Scientia Sinica Chimica, 2023, 53(9): 1781-1791. | |

| 10 | Liu Q H, Zhu R S, Zhao F, et al. Solute structure effect on polycyclic aromatics separation from fuel oil: molecular mechanism and experimental insights[J]. AIChE Journal, 2024, 70(11): e18574. |

| 11 | Bei P Z, Rajendran A, Feng J, et al. Deciphering the intermolecular interactions for separating bicyclic and tricyclic aromatics via different naphthalene-based solvents[J]. Frontiers of Chemical Science and Engineering, 2024, 18(10): 111. |

| 12 | 唐坤, 刘奇磊, 张磊, 等. 基于高阶基团贡献法与COSMO-SAC模型的溶剂设计方法[J]. 化工进展, 2021, 40(S2): 48-55. |

| Tang K, Liu Q L, Zhang L, et al. Solvent design method based on higher-order group contribution method and COSMO-SAC model[J]. Chemical Industry and Engineering Progress, 2021, 40(S2): 48-55. | |

| 13 | 庄志海, 张建强, 刘殿华. 聚甲氧基二甲醚+水+正己烷三元体系的液液相平衡[J]. 化工学报, 2016, 67(9): 3545-3551. |

| Zhuang Z H, Zhang J Q, Liu D H. Liquid-liquid equilibria for ternary systems polyoxymethylene dimethyl ethers + water + n-hexane[J]. CIESC Journal, 2016, 67(9): 3545-3551. | |

| 14 | Hadj-Kali M K, Salleh Z, Ali E, et al. Separation of aromatic and aliphatic hydrocarbons using deep eutectic solvents: a critical review[J]. Fluid Phase Equilibria, 2017, 448: 152-167. |

| 15 | Liu Q H, Li G X, Gui C M, et al. Solvents evaluation for extraction of polycyclic aromatics from FCC diesel: experimental and computational thermodynamics[J]. Chemical Engineering Science, 2022, 264: 118205. |

| 16 | Brijmohan N, Moodley K, Narasigadu C. Identification and screening of potential organic solvents for the liquid-liquid extraction of aromatics[J]. Organic Process Research & Development, 2021, 25(10): 2230-2248. |

| 17 | 陈利维, 张天嵌. 芳烃抽提技术研究进展和应用现状[J]. 石油化工应用, 2017, 36(1): 7-10. |

| Chen L W, Zhang T Q. Research progress and application status of aromatics extraction technology[J]. Petrochemical Industry Application, 2017, 36(1): 7-10. | |

| 18 | 霍月洋. 芳烃抽提技术应用进展[J]. 山东化工, 2015, 44(4): 41-43, 46. |

| Huo Y Y. Application progress of aromatics extraction technologies[J]. Shandong Chemical Industry, 2015, 44(4): 41-43, 46. | |

| 19 | 赛买提江·艾山. 几种芳烃抽提工艺对比[J]. 建筑工程技术与设计, 2016(22): 2855. |

| Smtjiang A. Comparison of several aromatics extraction processes[J]. Architectural Engineering Technology and Design, 2016(22): 2855. | |

| 20 | 黄灏, 郑军, 朱士荣. 糠醛精制工艺过程用能分析和节能优化[J]. 石油学报(石油加工), 2010, 26(S1): 66-70. |

| Huang H, Zheng J, Zhu S R. Analysis and optimization about energy of furfural refining process[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2010, 26(S1): 66-70. | |

| 21 | 李东胜, 张毅, 宋毅, 等. 润滑油基础油糠醛精制工艺加助剂脱氮小试研究[J]. 石油化工高等学校学报, 2011, 24(1): 41-43, 92. |

| Li D S, Zhang Y, Song Y, et al. Denitrogeneration of furfural refining process of lube base oil into which the assistant is added [J]. Journal of Petrochemical Universities, 2011, 24(1): 41-43, 92. | |

| 22 | 韩镇, 杨鹏. 润滑油糠醛精制装置工艺参数优化对能耗的影响[J]. 润滑油, 2020, 35(2): 62-64. |

| Han Z, Yang P. Effect of process parameter optimization on energy consumption of lubricating oil furfural refining unit[J]. Lubricating Oil, 2020, 35(2): 62-64. | |

| 23 | 苏玉忠, 杨海兰, 李军, 等. 阿曼渣油丙烷脱沥青试验研究[J]. 厦门大学学报(自然科学版), 2004, 43(1): 84-88. |

| Su Y Z, Yang H L, Li J, et al. Study on deasphalting by propane for Oman residue oil[J]. Journal of Xiamen University (Natural Science), 2004, 43(1): 84-88. | |

| 24 | 彭乔毅, 王公炎, 刘晓伟. 丙烷脱沥青装置溶剂脱硫系统改造及运行效果分析[J]. 山东化工, 2019, 48(12): 86-88. |

| Peng Q Y, Wang G Y, Liu X W. Modification of solvent desulfurization system in propane deasphalting unit and analysis of operation effect[J]. Shandong Chemical Industry, 2019, 48(12): 86-88. | |

| 25 | 李俊, 赵亮, 高金森, 等. 不同馏分油分级分质加工中萃取技术研究进展[J]. 化工学报, 2024, 75(4): 1065-1080. |

| Li J, Zhao L, Gao J S, et al. Research progress of extraction technology in processing different distillate by grade and composition[J]. CIESC Journal, 2024, 75(4): 1065-1080. | |

| 26 | 姜华, 郑英峨, 时钧. 二甲基甲酰胺-苯-正庚烷三元体系的液液平衡[J]. 高校化学工程学报, 1993, 7(2): 96-100. |

| Jiang H, Zheng Y E, Shi J. Liquid-liquid equilibrium of DMF∶ benzene: n-heptane ternary system[J]. Journal of Chemical Engineering of Chinese Universities, 1993, 7(2): 96-100. | |

| 27 | 李永锐. DMF+NH4SCN液液萃取分离苯和正庚烷[D]. 哈尔滨: 哈尔滨工程大学, 2013. |

| Li Y R. Separation of benzene and n-heptane by DMF+NH4SCN liquid-liquid extraction[D]. Harbin: Harbin Engineering University, 2013. | |

| 28 | 王峰, 赵德智, 宋荣君. 催化裂化油浆糠醛分离及应用[J]. 辽宁石油化工大学学报, 2005, 25(1): 40-44. |

| Wang F, Zhao D Z, Song R J. Separation of catalytic cracking slurry oil with furfural and application[J]. Journal of Liaoning Petrochemical University, 2005, 25(1): 40-44. | |

| 29 | 袁萍, 翁惠新. 溶剂抽提偏三甲苯-正辛烷三元体系液-液相平衡的对比分析[J]. 上海化工, 2006, 31(12): 14-18. |

| Yuan P, Weng H X. Contrasting analysis on liquid-liquid equilibrium data of solvents extracting ternary systems 1,2,4-trimethylebenzene-n-octane[J]. Shanghai Chemical Industry, 2006, 31(12): 14-18. | |

| 30 | 袁倩, 陈冰, 公茂柱, 等. 重石脑油萃取脱芳烃技术基础研究[J]. 应用化工, 2015, 44(S1): 69-72. |

| Yuan Q, Chen B, Gong M Z, et al. Basic research on extraction and dearomatization of heavy naphtha[J]. Applied Chemical Industry, 2015, 44(S1): 69-72. | |

| 31 | 曹群, 陈海丽, 刘井杰, 等. 润滑油抽出油糠醛精制生产橡胶填充油的研究[J]. 当代化工, 2010, 39(4): 363-365, 368. |

| Cao Q, Chen H L, Liu J J, et al. Preparation of rubber packing oil from extract oil of lubricating oil by furfural refining technique[J]. Contemporary Chemical Industry, 2010, 39(4): 363-365, 368. | |

| 32 | 刘井杰, 王海超, 刘玲爽, 等. 糠醛抽出油生产芳烃溶剂油的研究[J]. 石油与天然气化工, 2010, 39(1): 43-46, 97. |

| Liu J J, Wang H C, Liu L S, et al. Study on aromatic solvent naphtha refined from furfural extract oil[J]. Chemical Engineering of Oil & Gas, 2010, 39(1): 43-46, 97. | |

| 33 | 熊良铨, 吕贞, 刘亚娟, 等. 溶剂萃取脱除橡胶油中多环芳烃试验探讨[J]. 润滑油, 2011, 26(1): 56-60. |

| Xiong L Q, Lyu Z, Liu Y J, et al. Study on the removal of polycyclic aromatic hydrocarbon from rubber oil with solvent extraction[J]. Lubricating Oil, 2011, 26(1): 56-60. | |

| 34 | 唐晓东, 杨谨, 仝保田, 等. 催化裂化柴油萃取脱芳烃技术研究[J]. 石油炼制与化工, 2020, 51(8): 12-18. |

| Tang X D, Yang J, Tong B T, et al. Study on aromatics removal from FCC diesel by extraction[J]. Petroleum Processing and Petrochemicals, 2020, 51(8): 12-18. | |

| 35 | 唐晓东, 李小雨, 杨谨, 等. 分离多环芳烃用于超稠油掺稀降黏的研究[J]. 石油炼制与化工, 2024, 55(3): 55-60. |

| Tang X D, Li X Y, Yang J, et al. Study on separated polycyclic aromatic hydrocarbons for thinning and viscosity reduction of ultra- heavy oil[J]. Petroleum Processing and Petrochemicals, 2024, 55(3): 55-60. | |

| 36 | Gaile A A, Zalishchevskii G D, Erzhenkov A S, et al. Extraction of aromatic hydrocarbons from reformates with mixtures of triethylene glycol and sulfolane[J]. Russian Journal of Applied Chemistry, 2007, 80(4): 591-594. |

| 37 | Mahmoudi J, Lotfollahi M N. Extraction of benzene from a narrow cut of naphtha via liquid-liquid extraction using pure-sulfolane and 2-propanol-sulfolane-mixed solvents[J]. Korean Journal of Chemical Engineering, 2010, 27(1): 214-217. |

| 38 | 史云鹤, 李长明, 周金波, 等. 离心萃取法优选直馏石脑油脱芳烃萃取剂[J]. 应用化工, 2015, 44(5): 899-902. |

| Shi Y H, Li C M, Zhou J B, et al. Dearomatization effect study of composite extractant NMP-DMF to straight-run naphtha[J]. Applied Chemical Industry, 2015, 44(5): 899-902. | |

| 39 | Radwan G M, Al-Muhtaseb S A, Fahim M A. Liquid-liquid equilibria for the extraction of aromatics from naphtha reformate by dimethylformamide/ethylene glycol mixed solvent[J]. Fluid Phase Equilibria, 1997, 129(1/2): 175-186. |

| 40 | 薛凤凤, 李冬, 张琳娜, 等. 煤基石脑油萃取脱芳复合萃取剂[J]. 化工进展, 2017, 36(8): 2897-2902. |

| Xue F F, Li D, Zhang L N, et al. Composite extractant of liquid-liquid extraction aromatics for the coal-derived naphtha[J]. Chemical Industry and Engineering Progress, 2017, 36(8): 2897-2902. | |

| 41 | Sherwood J, De bruyn M, Constantinou A, et al. Dihydrolevoglucosenone (Cyrene) as a bio-based alternative for dipolar aprotic solvents[J]. Chemical Communications, 2014, 50(68): 9650-9652. |

| 42 | Brouwer T, Schuur B. Bio-based solvents as entrainers for extractive distillation in aromatic/aliphatic and olefin/paraffin separation[J]. Green Chemistry, 2020, 22(16): 5369-5375. |

| 43 | 李欣宇. 含氮杂环类功能化溶剂萃取分离柴油中芳烃/烷烃的研究[D]. 北京: 北京化工大学, 2023. |

| Li X Y. Study on extraction and separation of aromatic hydrocarbons/alkanes from diesel oil with nitrogen-containing heterocyclic functionalized solvents[D]. Beijing: Beijing University of Chemical Technology, 2023. | |

| 44 | 张锁江, 徐春明, 吕兴梅, 等. 离子液体与绿色化学[M]. 北京: 科学出版社, 2017. |

| Zhang S J, Xu C M, Lyu X M, et al. Ionic Liquids and Green Chemistry[M]. Beijing: Science Press, 2017. | |

| 45 | 史云鹤. 石脑油脱芳烃工艺技术研究[D]. 兰州: 兰州交通大学, 2015. |

| Shi Y H. Study on dearomatization technology of naphtha[D]. Lanzhou: Lanzhou Jiatong University, 2015. | |

| 46 | 王均凤, 张锁江, 陈慧萍, 等. 离子液体的性质及其在催化反应中的应用[J]. 过程工程学报, 2003, 3(2): 177-185. |

| Wang J F, Zhang S J, Chen H P, et al. Properties of ionic liquids and its applications in catalytic reactions[J]. The Chinese Journal of Process Engineering, 2003, 3(2): 177-185. | |

| 47 | García S, García J, Larriba M, et al. Sulfonate-based ionic liquids in the liquid-liquid extraction of aromatic hydrocarbons[J]. Journal of Chemical & Engineering Data, 2011, 56(7): 3188-3193. |

| 48 | Larriba M, Navarro P, García J, et al. Liquid-liquid extraction of toluene from heptane using [emim][DCA], [bmim][DCA], and [emim][TCM] ionic liquids[J]. Industrial & Engineering Chemistry Research, 2013, 52(7): 2714-2720. |

| 49 | Larriba M, Navarro P, García J, et al. Selective extraction of toluene from n-heptane using [emim][SCN] and [bmim][SCN] ionic liquids as solvents[J]. The Journal of Chemical Thermodynamics, 2014, 79: 266-271. |

| 50 | Larriba M, Navarro P, Delgado-Mellado N, et al. Extraction of aromatic hydrocarbons from pyrolysis gasoline using tetrathiocyanatocobaltate-based ionic liquids: experimental study and simulation[J]. Fuel Processing Technology, 2017, 159: 96-110. |

| 51 | Yao C F, Hou Y C, Wu W Z, et al. Imidazolium-based dicationic ionic liquids: highly efficient extractants for separating aromatics from aliphatics[J]. Green Chemistry, 2018, 20(13): 3101-3111. |

| 52 | Sakal S A, Lu Y Z, Jiang X C, et al. A promising ionic liquid [BMIM][FeCl4] for the extractive separation of aromatic and aliphatic hydrocarbons[J]. Journal of Chemical & Engineering Data, 2014, 59(3): 533-539. |

| 53 | Zhou T, Wang Z Y, Chen L F, et al. Evaluation of the ionic liquids 1-alkyl-3-methylimidazolium hexafluorophosphate as a solvent for the extraction of benzene from cyclohexane: (liquid+liquid) equilibria[J]. The Journal of Chemical Thermodynamics, 2012, 48: 145-149. |

| 54 | González E J, Calvar N, González B, et al. (Liquid+liquid) equilibria for ternary mixtures of (alkane+ benzene+[EMpy][ESO4]) at several temperatures and atmospheric pressure[J]. The Journal of Chemical Thermodynamics, 2009, 41(11): 1215-1221. |

| 55 | 史军军, 吴巍, 葸雷. 离子液体1-己基-4-甲基吡啶四氟硼酸盐与烃类的相互作用规律[J]. 石油学报(石油加工), 2021, 37(3): 541-548. |

| Shi J J, Wu W, Xi L. Interaction mechanism between [C6MPy][BF4] ionic liquid and hydrocarbons[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2021, 37(3): 541-548. | |

| 56 | García S, Larriba M, García J, et al. Separation of toluene from n-heptane by liquid-liquid extraction using binary mixtures of [bpy][BF4] and [4bmpy][Tf2N] ionic liquids as solvent[J]. The Journal of Chemical Thermodynamics, 2012, 53: 119-124. |

| 57 | García S, Larriba M, García J, et al. Liquid-liquid extraction of toluene from n-heptane using binary mixtures of N-butylpyridinium tetrafluoroborate and N-butylpyridinium bis(trifluoromethylsulfonyl)imide ionic liquids[J]. Chemical Engineering Journal, 2012, 180: 210-215. |

| 58 | Larriba M, Navarro P, García J, et al. Liquid-liquid extraction of toluene from n-heptane by {[emim][TCM]+[emim][DCA]}binary ionic liquid mixtures[J]. Fluid Phase Equilibria, 2014, 364: 48-54. |

| 59 | García S, García J, Larriba M, et al. Liquid-liquid extraction of toluene from heptane by {[4bmpy][Tf2N]+[emim][CHF2CF2SO3]} ionic liquid mixed solvents[J]. Fluid Phase Equilibria, 2013, 337: 47-52. |

| 60 | García S, Larriba M, Casas A, et al. Separation of toluene and heptane by liquid-liquid extraction using binary mixtures of the ionic liquids 1-butyl-4-methylpyridinium bis(trifluoromethylsulfonyl)imide and 1-ethyl-3-methylimidazolium ethylsulfate[J]. Journal of Chemical & Engineering Data, 2012, 57(9): 2472-2478. |

| 61 | Hou Y C, Li Z Y, Ren S H, et al. Separation of toluene from toluene/alkane mixtures with phosphonium salt based deep eutectic solvents[J]. Fuel Processing Technology, 2015, 135: 99-104. |

| 62 | Pena-Pereira F, Namieśnik J. Ionic liquids and deep eutectic mixtures: sustainable solvents for extraction processes[J]. ChemSusChem, 2014, 7(7): 1784-1800. |

| 63 | Kareem M A, Mjalli F S, Ali Hashim M, et al. Phosphonium-based ionic liquids analogues and their physical properties[J]. Journal of Chemical & Engineering Data, 2010, 55(11): 4632-4637. |

| 64 | Prof A A, Barron J, Dr K R, et al. Eutectic-based ionic liquids with metal-containing anions and cations[J]. Chemistry-A European Journal, 2007, 13(22): 6495-6501. |

| 65 | 赵地顺, 王娜, 李雪刚. 配位离子液体[3(CH3CH2)4N+Cl-·(NH2)2CO]的合成及表征[J]. 化工学报, 2007, 58(6): 1457-1460. |

| Zhao D S, Wang N, Li X G. Synthesis and characteristics of coordinated ionic liquid [3(CH3CH2)4N+Cl-·(NH2)2CO][J]. Journal of Chemical Industry and Engineering (China), 2007, 58(6): 1457-1460. | |

| 66 | Wang Y, Hou Y C, Wu W Z, et al. Roles of a hydrogen bond donor and a hydrogen bond acceptor in the extraction of toluene from n-heptane using deep eutectic solvents[J]. Green Chemistry, 2016, 18(10): 3089-3097. |

| 67 | Rodriguez N R, Gerlach T, Scheepers D, et al. Experimental determination of the LLE data of systems consisting of {hexane+benzene+deep eutectic solvent} and prediction using the conductor-like screening model for real solvents[J]. The Journal of Chemical Thermodynamics, 2017, 104: 128-137. |

| 68 | 冯善花. 低共熔溶剂的制备及在芳烃烷烃体系分离中的基础研究[D]. 北京: 北京化工大学, 2019. |

| Feng S H. Preparation of deep eutectic solvents and its basic research on separation of aromatic hydrocarbons and alkanes[D]. Beijing: Beijing University of Chemical Technology, 2019. | |

| 69 | Salleh Z, Wazeer I, Mulyono S, et al. Efficient removal of benzene from cyclohexane-benzene mixtures using deep eutectic solvents-COSMO-RS screening and experimental validation[J]. The Journal of Chemical Thermodynamics, 2017, 104: 33-44. |

| 70 | Rodriguez N R, Requejo P F, Kroon M C. Aliphatic-aromatic separation using deep eutectic solvents as extracting agents[J]. Industrial & Engineering Chemistry Research, 2015, 54(45): 11404-11412. |

| 71 | Feng S H, Sun J J, Ren Z Q, et al. Effective separation of aromatic hydrocarbons by pyridine-based deep eutectic solvents[J]. The Canadian Journal of Chemical Engineering, 2019, 97(12): 3138-3147. |

| 72 | Kareem M A, Mjalli F S, Ali Hashim M, et al. Phase equilibria of toluene/heptane with deep eutectic solvents based on ethyltriphenylphosphonium iodide for the potential use in the separation of aromatics from naphtha[J]. The Journal of Chemical Thermodynamics, 2013, 65: 138-149. |

| 73 | Kareem M A, Mjalli F S, Ali Hashim M, et al. Phase equilibria of toluene/heptane with tetrabutylphosphonium bromide based deep eutectic solvents for the potential use in the separation of aromatics from naphtha[J]. Fluid Phase Equilibria, 2012, 333: 47-54. |

| 74 | 吴小佳. 离子液体基低共熔溶剂用于萃取分离芳烃烷烃的基础研究[D]. 北京: 北京化工大学, 2022. |

| Wu X J. Basic study on extraction and separation of aromatic alkanes by ionic liquid-based deep eutectic solvents[D]. Beijing: Beijing University of Chemical Technology, 2022. | |

| 75 | 张曾, 阚一群, 刘峰, 等. 从乙烯焦油中提取萘、 1-甲基萘和2-甲基萘的方法: 102134500B[P]. 2013-05-15. |

| Zhang Z, Kan Y Q, Liu F, et al. Method for extracting naphthalene, 1-methylnaphthalene and 2-methylnaphthalene from ethylene tar: 102134500B[P]. 2013-05-15. | |

| 76 | Kiss A A. Distillation technology—still young and full of breakthrough opportunities[J]. Journal of Chemical Technology & Biotechnology, 2014, 89(4): 479-498. |

| 77 | 杨晨阳, 朱怀工, 蔡旺锋, 等. 循环精馏技术研究进展[J]. 化工进展, 2024, 43(3): 1109-1117. |

| Yang C Y, Zhu H G, Cai W F, et al. Research progress of cyclic distillation technology[J]. Chemical Industry and Engineering Progress, 2024, 43(3): 1109-1117. | |

| 78 | 宁亚中. 抽提蒸馏分离芳烃工艺NFM分解原因分析及对策[J]. 石油化工设计, 2012, 29(4): 10-12, 15, 5. |

| Ning Y Z. Cause analysis of NFM solvent decomposition and the improvement measures[J]. Petrochemical Design, 2012, 29(4): 10-12, 15, 5. | |

| 79 | 田胜利. 环丁砜抽提蒸馏工艺分离芳烃与非芳烃影响因素的分析[J]. 辽宁化工, 2014, 43(6): 705-707. |

| Tian S L. Analysis of influencing factors for sulfolane extraction distillation separation of aromatic and nonaromatic hydrocarbons[J]. Liaoning Chemical Industry, 2014, 43(6): 705-707. | |

| 80 | 赵明, 蹇中立, 田龙胜, 等. 芳烃抽提蒸馏工艺(SED-BTX)的开发与应用[J]. 石油炼制与化工, 2024, 55(5): 14-19. |

| Zhao M, Jian Z L, Tian L S, et al. Development and application of aromatics extraction and distillation process (SED-BTX)[J]. Petroleum Processing and Petrochemicals, 2024, 55(5): 14-19. | |

| 81 | Lotkhov V A, Kvashnin S Y, Kulov N N. Effect of separating agent in extractive distillation[J]. Theoretical Foundations of Chemical Engineering, 2020, 54(1): 172-177. |

| 82 | Perkar T, Choksi N, Modi C, et al. Simulation studies of n-heptane/toluene separation by extractive distillation using sulfolane, phenol, and NMP[J]. International Journal of Chemical Reactor Engineering, 2021, 19(8): 829-837. |

| 83 | 雷志刚, 周荣琪, 段占庭. NMP萃取精馏分离芳烃和非芳烃[J]. 高校化学工程学报, 2001, 15(2): 183-186. |

| Lei Z G, Zhou R Q, Duan Z T. Separation of aromatic and non-aromatic hydrocarbons by NMP extractive distillation[J]. Journal of Chemical Engineering of Chinese Universities, 2001, 15(2): 183-186. | |

| 84 | Li L M, Guo L J, Tu Y Q, et al. Comparison of different extractive distillation processes for 2-methoxyethanol/toluene separation: design and control[J]. Comput. Chem. Eng., 2017, 99: 117-134. |

| 85 | Gao S L, Tang W C, Zhao M, et al. Extractive distillation of benzene, toluene, and xylenes from pyrolysis gasoline using methylsulfonylethane as a cosolvent[J]. Asia-Pacific Journal of Chemical Engineering, 2021, 16(3): e2609. |

| 86 | Ghiaci M, Abbaspur A, Kia R, et al. Equilibrium isotherm studies for the sorption of benzene, toluene, and phenol onto organo-zeolites and as-synthesized MCM-41[J]. Separation and Purification Technology, 2004, 40(3): 217-229. |

| 87 | Simpson E J, Abukhadra R K, Koros W J, et al. Sorption equilibrium isotherms for volatile organics in aqueous solution. Comparison of head-space gas chromatography and on-line UV stirred cell results[J]. Industrial & Engineering Chemistry Research, 1993, 32(10): 2269-2276. |

| 88 | Herm Z R, Bloch E D, Long J R. Hydrocarbon separations in metal-organic frameworks[J]. Chemistry of Materials, 2014, 26(1): 323-338. |

| 89 | Wang C M, Chang K S, Chung T W, et al. Adsorption equilibria of aromatic compounds on activated carbon, silica gel, and 13X zeolite[J]. Journal of Chemical & Engineering Data, 2004, 49(3): 527-531. |

| 90 | Sapianik A A, Kovalenko K A, Samsonenko D G, et al. Exceptionally effective benzene/cyclohexane separation using a nitro-decorated metal-organic framework[J]. Chemical Communications, 2020, 56(59): 8241-8244. |

| 91 | Macreadie L K, Qazvini O T, Babarao R. Reversing benzene/cyclohexane selectivity through varying supramolecular interactions using aliphatic, isoreticular MOFs[J]. ACS Applied Materials & Interfaces, 2021, 13(26): 30885-30890. |

| 92 | Mukherjee S, Sensharma D, Qazvini O T, et al. Advances in adsorptive separation of benzene and cyclohexane by metal-organic framework adsorbents[J]. Coordination Chemistry Reviews, 2021, 437: 213852. |

| 93 | 赵闯, 陈自浩, 张博宇, 等. 分子筛吸附剂对不同类型柴油吸附分离性能的研究[J]. 无机盐工业, 2024, 56(3): 80-85. |

| Zhao C, Chen Z H, Zhang B Y, et al. Study on adsorption and separation performance of molecular sieve adsorbents for different types of diesel[J]. Inorganic Chemicals Industry, 2024, 56(3): 80-85. | |

| 94 | 赵闯, 张博宇, 李犇, 等. 吸附剂对多环芳烃吸附分离技术的研究[J]. 无机盐工业, 2024, 56(7): 61-68. |

| Zhao C, Zhang B Y, Li B, et al. Study on adsorption and separation technology of polycyclic aromatic hydrocarbons by adsorbent[J]. Inorganic Chemicals Industry, 2024, 56(7): 61-68. | |

| 95 | 党宇. 多环芳烃在γ-Al2O3上吸附和扩散的分子模拟[D]. 东营: 中国石油大学(华东), 2019. |

| Dang Y. Molecular simulation of adsorption and diffusion of polycyclic aromatic hydrocarbons on γ-Al2O3 [D]. Dongying: China University of Petroleum (Huadong), 2019. | |

| 96 | 李战胜, 郭春刚, 张犇, 等. 芳烃优先透过的渗透汽化复合膜的制备及分离性能研究[J]. 化学工业与工程, 2010, 27(2): 177-182. |

| Li Z S, Guo C G, Zhang B, et al. Preparation of aromatic-selective composite membranes and their pervaporation performances[J]. Chemical Industry and Engineering, 2010, 27(2): 177-182. | |

| 97 | 陈艳. 膜分离技术在石油化工领域中的应用探析[J]. 中国战略新兴产业, 2024(2): 119-121. |

| Chen Y. Application of membrane separation technology in petrochemical industry[J]. China Strategic Emerging Industry, 2024(2): 119-121. | |

| 98 | 叶宏, 李继定, 林阳政, 等. 聚氨酯脲和聚氨酯酰亚胺膜的制备与渗透汽化芳烃/烷烃分离性能研究[J]. 膜科学与技术, 2009, 29(2): 40-46. |

| Ye H, Li J D, Lin Y Z, et al. Preparation of polyurethaneurea and polyurethaneimide membranes and their pervaporation performances to aromatic/aliphatic hydrocarbon mixtures[J]. Membrane Science and Technology, 2009, 29(2): 40-46. | |

| 99 | Shao P, Huang R Y M. Polymeric membrane pervaporation[J]. Journal of Membrane Science, 2007, 287(2): 162-179. |

| 100 | Inui K, Tsukamoto K, Miyata T, et al. Permeation and separation of a benzene/cyclohexane mixture through benzoylchitosan membranes[J]. Journal of Membrane Science, 1998, 138(1): 67-75. |

| 101 | Sun H, Wang N X, Xu Y H, et al. Aromatic-aliphatic hydrocarbon separation with oriented monolayer polyhedral membrane[J]. Science, 2024, 386(6725): 1037-1042. |

| 102 | Schwarz H, Malsch G. Polyelectrolyte membranes for aromatic-aliphatic hydrocarbon separation by pervaporation[J]. Journal of Membrane Science, 2005, 247(1/2): 143-152. |

| 103 | Li Z S, Zhang B, Qu L X, et al. A novel atmospheric dielectric barrier discharge (DBD) plasma graft-filling technique to fabricate the composite membranes for pervaporation of aromatic/aliphatic hydrocarbons[J]. Journal of Membrane Science, 2011, 371(1/2): 163-170. |

| 104 | Wang N X, Ji S L, Li J, et al. Poly(vinyl alcohol)-graphene oxide nanohybrid "pore-filling" membrane for pervaporation of toluene/n-heptane mixtures[J]. Journal of Membrane Science, 2014, 455: 113-120. |

| 105 | Wang N X, Wang L, Zhang R, et al. Highly stable "pore-filling" tubular composite membrane by self-crosslinkable hyperbranched polymers for toluene/n-heptane separation[J]. Journal of Membrane Science, 2015, 474: 263-272. |

| 106 | Roizard D, Nilly A, Lochon P. Preparation and study of crosslinked polyurethane films to fractionate toluene-n-heptane mixtures by pervaporation[J]. Separation and Purification Technology, 2001, 22: 45-52. |

| 107 | Ribeiro C P, Freeman B D, Kalika D S, et al. Aromatic polyimide and polybenzoxazole membranes for the fractionation of aromatic/aliphatic hydrocarbons by pervaporation[J]. Journal of Membrane Science, 2012, 390: 182-193. |

| 108 | 李战胜, 高波, 张守海, 等. 渗透汽化分离芳烃/烷烃的聚芳醚腈酮复合膜的制备[J]. 膜科学与技术, 2019, 39(5): 18-22. |

| Li Z S, Gao B, Zhang S H, et al. Development of PPENK composite membranes for pervaporation of aromatic/aliphatic hydrocarbons[J]. Membrane Science and Technology, 2019, 39(5): 18-22. | |

| 109 | 曾昭容, 丁立, 彭勇, 等. 用于芳烃/烷烃体系蒸汽渗透分离的离子液体支撑液膜研究[J]. 高校化学工程学报, 2009, 23(5): 762-767. |

| Zeng Z R, Ding L, Peng Y, et al. Separation of aromatic hydrocarbon/alkane mixtures using supported liquid membrane with ionic liquids[J]. Journal of Chemical Engineering of Chinese Universities, 2009, 23(5): 762-767. | |

| 110 | Kuila S B, Ray S K. Separation of benzene-cyclohexane mixtures by filled blend membranes of carboxymethyl cellulose and sodium alginate[J]. Separation and Purification Technology, 2014, 123: 45-52. |

| 111 | 王静康, 张远谋. 熔融结晶过程的新进展[J]. 化工进展, 1991, 10(1): 35-40. |

| Wang J K, Zhang Y M. New progress in melt crystallization process[J]. Chemical Industry and Engineering Progress, 1991, 10(1): 35-40. | |

| 112 | Wynn N. Separate organics by melt crystallization[J]. Chemical Engineering Progress, 2022, 88: 52-60. |

| 113 | 何选明, 李维, 方嘉淇, 等. 萘油深加工及分离技术研究进展[J]. 燃料与化工, 2013, 44(4): 49-51. |

| He X M, Li W, Fang J Q, et al. Further processing and separation technology for naphthalene oil[J]. Fuel & Chemical Processes, 2013, 44(4): 49-51. | |

| 114 | 张东明, 许松林, 张德立, 等. 气泡塔分步结晶法从乙烯副产焦油中提取精萘[J]. 石油炼制与化工, 1997, 28(8): 18-21. |

| Zhang D M, Xu S L, Zhang D L, et al. Preparation of refined naphthalene from ethylene by-product tar by fractional crystallization in a bubble column[J]. Petroleum Processing and Petrochemicals, 1997, 28(8): 18-21. | |

| 115 | 托马斯·W·比特纳, 乌尔里希·克尼珀斯, 康拉德·施托尔岑贝格. 通过熔融结晶制备蒽和咔唑: 1229314C[P]. 2005-11-30. |

| Thomas W B, Ulrich K, Konrad S. Obtaining anthracene and carbazole by melt-crystallization: 1229314C[P]. 2005-11-30. | |

| 116 | 郭永刚, 王景芹. 超声波在石油化工中应用的研究进展[J]. 当代化工, 2008, 37(1): 5-7, 10. |

| Guo Y G, Wang J Q. The advance of ultrasonic in petrochemical industry[J]. Contemporary Chemical Industry, 2008, 37(1): 5-7, 10. | |

| 117 | 马锐, 赵德智, 宋小梅, 等. 在超声功率辅助作用下催化裂化油浆糠醛抽提研究[J]. 化学与粘合, 2010, 32(2): 41-44. |

| Ma R, Zhao D Z, Song X M, et al. Study on the extraction of FCC slurry by furfural with ultrasound assistance[J]. Chemistry and Adhesion, 2010, 32(2): 41-44. | |

| 118 | 孙东旭, 戴咏川, 宋官龙, 等. 超声波辅助作用下芳烃萃取分离研究[J]. 现代化工, 2016, 36 (5): 94-97. |

| Sun D X, Dai Y C, Song G L, et al. Ultrasonic extraction of aromatics[J]. Modern Chemical Industry, 2016, 36(5): 94-97. | |

| 119 | 刘健, 李冬燕, 王晓梅. 一种分离提纯连三甲苯的方法: 111302883A[P]. 2020-06-19. |

| Liu J, Li D Y, Wang X M. Method for separating and purifying trimethylbenzene: 111302883A[P]. 2020-06-19. | |

| 120 | Gaile A A, Zalishchevskii G D, Gafur N N, et al. Removal of aromatic hydrocarbons from reforming naphtha. combined extraction: extractive-azeotropic distillation process[J]. Chemistry and Technology of Fuels and Oils, 2004, 40(4): 215-221. |

| 121 | 王德华, 王建伟, 郁灼, 等. 碳八芳烃异构体分离技术评述[J]. 化工进展, 2007, 26(3): 315-319. |

| Wang D H, Wang J W, Yu Z, et al. Review of C8 aromatics separation technologies[J]. Chemical Industry and Engineering Progress, 2007, 26(3): 315-319. | |

| 122 | 陆承东, 胡玛丽. C8芳烃的分离技术[J]. 钢铁研究, 1997, 25(3): 57-62. |

| Lu C D, Hu M L. Technology of separatino C8 arene[J]. Research on Iron and Steel Research, 1997, 25(3): 57-62. | |

| 123 | 刘瑞兴. 结晶法分离混合二甲苯[J]. 现代化工, 1987, 7(4): 54-57. |

| Liu R X. Crystalization-separation of redimethylbenzene from mzxed-dimethylbenzene[J]. Modern Chemical Industry, 1987, 7(4): 54-57. | |

| 124 | 沈澍. 熔融结晶法纯化对二甲苯研究[D]. 天津: 天津大学, 2017. |

| Shen S. Study on purification of para-xylene by melt crystallization[D]. Tianjin: Tianjin University, 2017. | |

| 125 | Kim D, Ghosh S, Akter N, et al. Twin-free, directly synthesized MFI nanosheets with improved thickness uniformity and their use in membrane fabrication[J]. Science Advances, 2022, 8(14): eabm8162. |

| 126 | Wu X C, Wei W, Jiang P J, et al. High-flux high-selectivity metal-organic framework MIL-160 membrane for xylene isomer separation by pervaporation[J]. Angewandte Chemie International Edition, 2018, 57(47): 15354-15358. |

| 127 | Liu S Y, Li W P, Chen C C, et al. Ultrathin cyclodextrin nanofilm composite membranes for efficient separation of xylene isomers[J]. Journal of Membrane Science, 2022, 644: 120165. |

| 128 | Zheng H Y, Yoshikawa M. Molecularly imprinted cellulose membranes for pervaporation separation of xylene isomers[J]. Journal of Membrane Science, 2015, 478: 148-154. |

| 129 | Kasik A, Lin Y S. Organic solvent pervaporation properties of MOF-5 membranes[J]. Separation and Purification Technology, 2014, 121: 38-45. |

| 130 | 卢暄. 从催化重整副产C9芳烃分离制取偏三甲苯、均三甲苯技术[J]. 化学工业, 2010, 28(12): 30-33. |

| Lu X. Technological advance on comprehensive utilization of C9 heavy aromatics[J]. Chemical Industry, 2010, 28(12): 30-33. | |

| 131 | 匡华. C9芳烃中均三甲苯与邻甲乙苯的分离研究[J]. 化学反应工程与工艺, 2004, 20(2): 184-187. |

| Kuang H. Separation of mesitylene and o-methylethylbenzene from C9 aromatic[J]. Chemical Reaction Engineering and Technology, 2004, 20(2): 184-187. | |

| 132 | 冯海强, 傅吉全. 采用分离集成技术从碳九芳烃中提取均三甲苯[J]. 化工进展, 2011, 30(3): 478-482. |

| Feng H Q, Fu J Q. Extraction of mesitylene from C9 arene by integrated separation technology[J]. Chemical Industry and Engineering Progress, 2011, 30(3): 478-482. | |

| 133 | 赵永祥, 李杰. 新型填料塔技术在C9芳烃分离中的应用[J]. 辽宁化工, 2001, 30(6): 260-262. |

| Zhao Y X, Li J. The use of the new-packing column technology in separation of C9 aromatic hydrocarbon[J]. Liaoning Chemical Industry, 2001, 30(6): 260-262. | |

| 134 | 徐振凯, 马海洪. 偏三甲苯多效热集成分离工艺的模拟研究[J]. 石油炼制与化工, 2011, 42(6): 73-76. |

| Xu Z K, Ma H H. Simulation study of 1,2,4-trimethylbenzen separation process with multi-effect heat integration distillation[J]. Petroleum Processing and Petrochemicals, 2011, 42(6): 73-76. | |

| 135 | 王哲. 重整碳九分离系统的节能流程研究[J]. 资源节约与环保, 2016, 31(6): 17. |

| Wang Z. Study on energy-saving process of reforming C9 separation system[J]. Resources Economization & Environmental Protection, 2016, 31(6): 17. | |

| 136 | 田文彦. C9芳烃中连三甲苯与茚满的精密精馏和深冷分离[J]. 精细石油化工进展, 2007, 8(9): 41-42, 45. |

| Tian W Y. Precise distillation and cryogenic separation of hemellitene and indene from C9 aromatic mixtures[J]. Advances in Fine Petrochemicals, 2007, 8(9): 41-42, 45. | |

| 137 | 张瑞琪, 姜斌, 任海伦, 等. 环丁砜萃取精馏提纯连三甲苯的实验和模拟[J]. 化工进展, 2016, 35(11): 3465-3469. |

| Zhang R Q, Jiang B, Ren H L, et al. Experiment and simulation on the purification of 1,2,3-trimethylbenzene by extractive distillation with sulfolane[J]. Chemical Industry and Engineering Progress, 2016, 35(11): 3465-3469. | |

| 138 | 林军, 顾正桂. 重整C9芳烃中甲乙苯的分离及利用[J]. 化工时刊, 2001, 15(2): 25-26. |

| Lin J, Gu Z G. Application & separation of ethyltoluene in C9 arene[J]. Chemical Industry Times, 2001, 15(2): 25-26. | |

| 139 | 杜建卫, 刘键, 黄奋生. C10重芳烃二乙苯的分离研究[J]. 天津化工, 2010, 24(4): 36-37. |

| Du J W, Liu J, Huang F S. Study on the separation of diethenyl-benzene from C10 heavy aromatics by extractive distillation[J]. Tianjin Chemical Industry, 2010, 24(4): 36-37. | |

| 140 | Cong S, Liu Y, Li H, et al. Purification and separation of durene by static melt crystallization[J]. Chinese Journal of Chemical Engineering, 2015, 23(3): 505-509. |

| 141 | 刘莹. 均四甲苯熔融结晶过程的研究[D]. 天津: 天津大学, 2013. |

| Liu Y. Study on melting crystallization process of durene[D]. Tianjin: Tianjin University, 2013. | |

| 142 | 张洪涛, 黄明凯. 重整C10重芳烃的综合利用[J]. 当代化工, 2001, 30(3): 145-148. |

| Zhang H T, Huang M K. Coprehensive utilization of heavy aromatics C10 in reformer unit[J]. Contemporary Chemical Industry, 2001, 30(3): 145-148. | |

| 143 | 袁国民, 从海峰, 李鑫钢. 重芳烃轻质化与分离研究进展[J]. 化学工业与工程, 2022, 39(3): 60-72. |

| Yuan G M, Cong H F, Li X G. Research progress in conversion to light aromatics and separation of heavy aromatics[J]. Chemical Industry and Engineering, 2022, 39(3): 60-72. | |

| 144 | 刘逸群, 王超, 卢春喜. 2,6-二甲基萘的分离技术进展[J]. 现代化工, 2024, 44(11): 60-65. |

| Liu Y Q, Wang C, Lu C X. Research progress on separation technologies for 2,6-dimethylnaphthalene[J]. Modern Chemical Industry, 2024, 44(11): 60-65. | |

| 145 | Ban H, Cheng Y W, Wang L J, et al. Preparation of high-purity 2,6-naphthalenedicarboxylic acid from coal tar distillate[J]. Chemical Engineering & Technology, 2019, 42(6): 1188-1198. |

| 146 | Kim S J. Separation and purification of 2,6-dimethylnaphthalene present in the fraction of light cycle oil by crystallization operation[J]. Applied Chemistry for Engineering, 2018, 29(6): 799-804. |

| 147 | Kang H C, Kim S J. Separation of 2,6-dimethylnaphthalene in dimethylnaphthalene isomers mixture by crystallization operation[J]. Applied Chemistry for Engineering, 2014, 25(1): 116-120. |

| 148 | Bei P Z, Rajendran A, Feng J, et al. Anthracene separation from analogous polycyclic aromatic hydrocarbons using the naphthalene-based solvents[J]. Fuel, 2023, 335: 127029. |

| [1] | 周印洁, 吉思蓓, 何松阳, 吉旭, 贺革. 机器学习辅助高通量筛选金属有机骨架用于富碳天然气中分离CO2[J]. 化工学报, 2025, 76(3): 1093-1101. |

| [2] | 崔家馨, 殷梦凡, 郑涛, 刘晗, 张睿, 刘植昌, 刘海燕, 徐春明, 孟祥海. 铝铜双金属离子液体在1-己烯/正己烷分离中的应用[J]. 化工学报, 2025, 76(2): 686-694. |

| [3] | 贾晶宇, 孔德齐, 沈圆辉, 张东辉, 李文彬, 唐忠利. 合成氨反应器尾气变压吸附氨分离工艺的模拟与分析[J]. 化工学报, 2025, 76(2): 718-730. |

| [4] | 孟祥军, 杨林睿, 彭立培, 杨献奎, 花莹曦, 张人仁, 郑凯天, 许春建. 三氟化氮精馏分离流程的设计与控制[J]. 化工学报, 2025, 76(2): 707-717. |

| [5] | 杨林睿, 刘鉴漪, 李玲, 何永超, 郑凯天, 任建坡, 许春建. 苯/环己烷/环己烯萃取精馏过程的流程设计与节能[J]. 化工学报, 2025, 76(2): 731-743. |

| [6] | 尤潇楠, 范小强, 杨遥, 王靖岱, 阳永荣. 超临界乙烯和高压聚乙烯混合物的减压分离过程建模方法[J]. 化工学报, 2025, 76(2): 695-706. |

| [7] | 李匡奚, 于佩潜, 王江云, 魏浩然, 郑志刚, 冯留海. 微气泡旋流气浮装置内流动分析与结构优化[J]. 化工学报, 2024, 75(S1): 223-234. |

| [8] | 谢慧慧, 姜佳鑫, 王鑫, 李正, 郭鑫, 吕欣然, 王凌云, 刘杨. 深共晶溶剂聚合物包覆膜传输分离铂、钯的研究[J]. 化工学报, 2024, 75(S1): 235-243. |

| [9] | 邱知, 谭明. 聚离子液体膜的制备及其在低钠高钾健康酱油中的应用[J]. 化工学报, 2024, 75(S1): 244-250. |

| [10] | 蒋晓煜, 雒焕婷, 洪瑞, 杜文静. 调制差示扫描量热法测定二元醇型冷却液的比热容[J]. 化工学报, 2024, 75(S1): 40-46. |

| [11] | 刘律, 刘洁茹, 范亮亮, 赵亮. 基于层流效应的被动式颗粒分离微流控方法研究[J]. 化工学报, 2024, 75(S1): 67-75. |

| [12] | 刘亚超, 谭晓杰, 李旭东, 王瑞, 王慧, 韩璇, 赵青山. DES合成高活性CoCO3纳米片及析氧反应性能研究[J]. 化工学报, 2024, 75(9): 3320-3328. |

| [13] | 唐昊, 胡定华, 李强, 张轩畅, 韩俊杰. 抗加速度双切线弧流道内气泡动力学行为数值与可视化研究[J]. 化工学报, 2024, 75(9): 3074-3082. |

| [14] | 李彦熹, 王晔春, 谢向东, 王进芝, 王江, 周煜, 潘盈秀, 丁文涛, 郭烈锦. 蜗壳式多通道气液旋流分离器结构优化及分离特性研究[J]. 化工学报, 2024, 75(8): 2875-2885. |

| [15] | 秦晓巧, 谭宏博, 温娜. 储能式低温空分系统热力学与经济性分析[J]. 化工学报, 2024, 75(7): 2409-2421. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号