化工学报 ›› 2024, Vol. 75 ›› Issue (9): 3074-3082.DOI: 10.11949/0438-1157.20240141

唐昊1( ), 胡定华1(

), 胡定华1( ), 李强1, 张轩畅1, 韩俊杰2

), 李强1, 张轩畅1, 韩俊杰2

收稿日期:2024-01-30

修回日期:2024-05-08

出版日期:2024-09-25

发布日期:2024-10-10

通讯作者:

胡定华

作者简介:唐昊(1999—),男,硕士研究生,tanghao@njust.edu.cn

基金资助:

Hao TANG1( ), Dinghua HU1(

), Dinghua HU1( ), Qiang LI1, Xuanchang ZHANG1, Junjie HAN2

), Qiang LI1, Xuanchang ZHANG1, Junjie HAN2

Received:2024-01-30

Revised:2024-05-08

Online:2024-09-25

Published:2024-10-10

Contact:

Dinghua HU

摘要:

机载电子设备的散热系统设计对飞行器的长航时安全运行具有重要意义。设计了抗加速度的双切线弧流道,针对流道内的气泡动力学行为,开展了基于VOF多相流模型的数值分析与基于高速相机的可视化研究。仿真分析表明,相比于直流道,双切线弧流道中的气泡在流经弯管时,由于离心力的作用,会破裂成小气泡并被甩到远离加热面的位置,使得气液分离。30°双切线弧流道分离能力最弱,但残留在壁面的气泡最少;60°双切线弧流道分离能力最强,但壁面处气泡不易流动。对45°双切线弧流道进行了可视化实验研究,可视化结果与仿真分析一致。仿真计算表明,当流速为1 m/s时,45°双切线弧流道可以有效抵抗5g的加速度。

中图分类号:

唐昊, 胡定华, 李强, 张轩畅, 韩俊杰. 抗加速度双切线弧流道内气泡动力学行为数值与可视化研究[J]. 化工学报, 2024, 75(9): 3074-3082.

Hao TANG, Dinghua HU, Qiang LI, Xuanchang ZHANG, Junjie HAN. Numerical and visualization study on dynamic behavior of bubbles in anti-acceleration double tangent arc channel[J]. CIESC Journal, 2024, 75(9): 3074-3082.

| 参数 | 数值 |

|---|---|

| 液相密度/(kg/m3) | 1520 |

| 气相密度/(kg/m3) | 9.7 |

| 比热容/(kJ/(kg·K)) | 1.1 |

| 热导率/(W/(m·K)) | 0.058 |

| 沸点/℃ | 61 |

| 潜热/(kJ/kg) | 50 |

表1 HFE-7100物性参数

Table 1 HFE-7100 physical parameters

| 参数 | 数值 |

|---|---|

| 液相密度/(kg/m3) | 1520 |

| 气相密度/(kg/m3) | 9.7 |

| 比热容/(kJ/(kg·K)) | 1.1 |

| 热导率/(W/(m·K)) | 0.058 |

| 沸点/℃ | 61 |

| 潜热/(kJ/kg) | 50 |

| 流道 | 网格数/个 | 气泡平均 速度/(m/s) | 误差/% |

|---|---|---|---|

| 直流道 | 41720 | 1.078 | |

| 20656 | 1.041 | 3.41 | |

| 13676 | 0.976 | 9.46 | |

| 10944 | 0.989 | 8.25 | |

| 30°双切线弧流道 | 44770 | 1.314 | |

| 23532 | 1.291 | 1.75 | |

| 16950 | 1.408 | 7.15 | |

| 11719 | 1.419 | 7.99 | |

| 45°双切线弧流道 | 46718 | 1.415 | |

| 27351 | 1.461 | 3.25 | |

| 21796 | 1.497 | 5.79 | |

| 17641 | 1.512 | 6.86 | |

| 60°双切线弧流道 | 61094 | 1.742 | |

| 33746 | 1.709 | 1.89 | |

| 25209 | 1.685 | 3.27 | |

| 18014 | 1.576 | 9.53 |

表2 网格无关性验证

Table 2 Grid independence verification

| 流道 | 网格数/个 | 气泡平均 速度/(m/s) | 误差/% |

|---|---|---|---|

| 直流道 | 41720 | 1.078 | |

| 20656 | 1.041 | 3.41 | |

| 13676 | 0.976 | 9.46 | |

| 10944 | 0.989 | 8.25 | |

| 30°双切线弧流道 | 44770 | 1.314 | |

| 23532 | 1.291 | 1.75 | |

| 16950 | 1.408 | 7.15 | |

| 11719 | 1.419 | 7.99 | |

| 45°双切线弧流道 | 46718 | 1.415 | |

| 27351 | 1.461 | 3.25 | |

| 21796 | 1.497 | 5.79 | |

| 17641 | 1.512 | 6.86 | |

| 60°双切线弧流道 | 61094 | 1.742 | |

| 33746 | 1.709 | 1.89 | |

| 25209 | 1.685 | 3.27 | |

| 18014 | 1.576 | 9.53 |

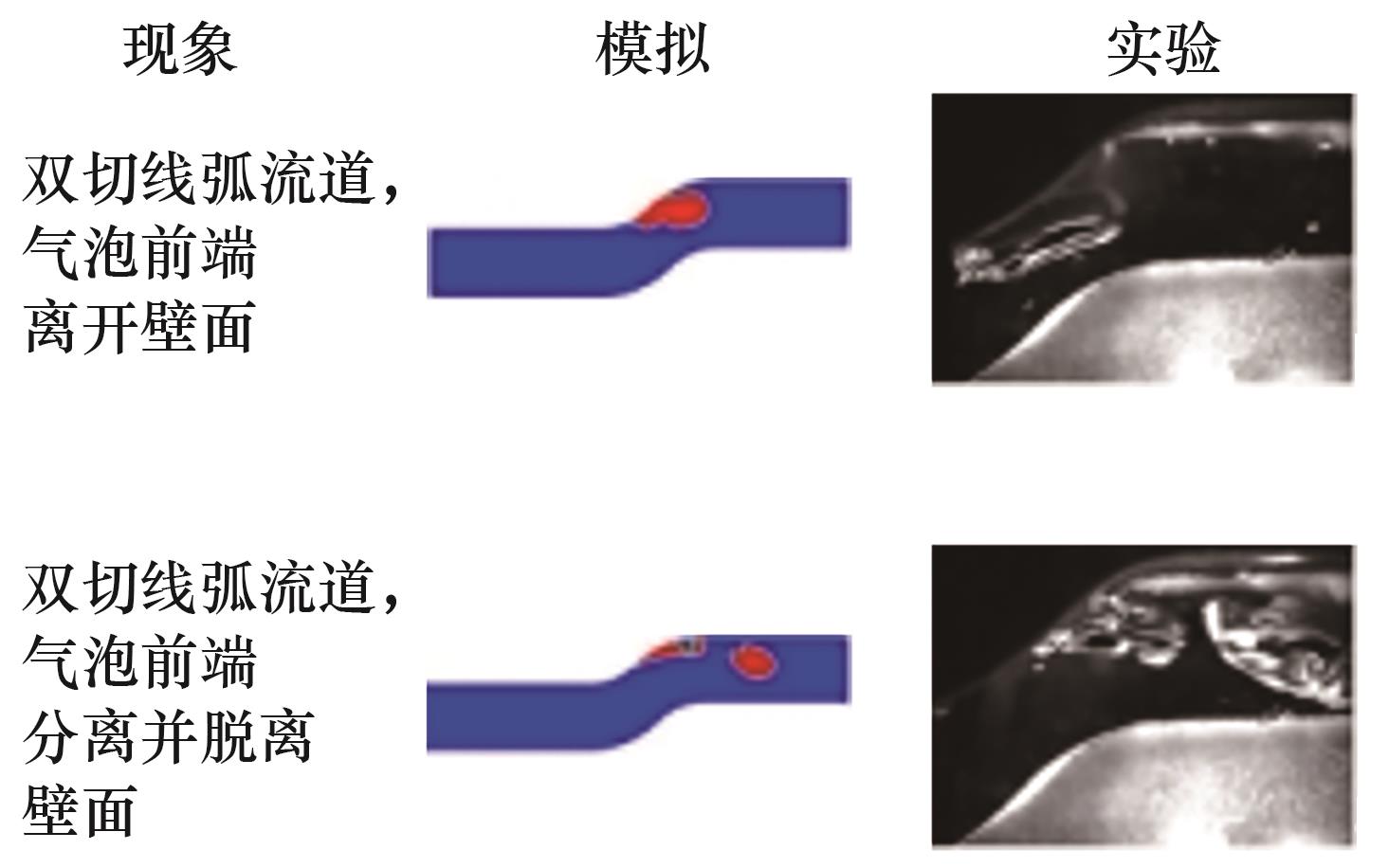

图11 45 °双切线弧流道内气泡运动的数值计算与可视化实验对比

Fig.11 Comparison between numerical calculation and visualization experiment of bubble movement in 45° double tangent arc channel

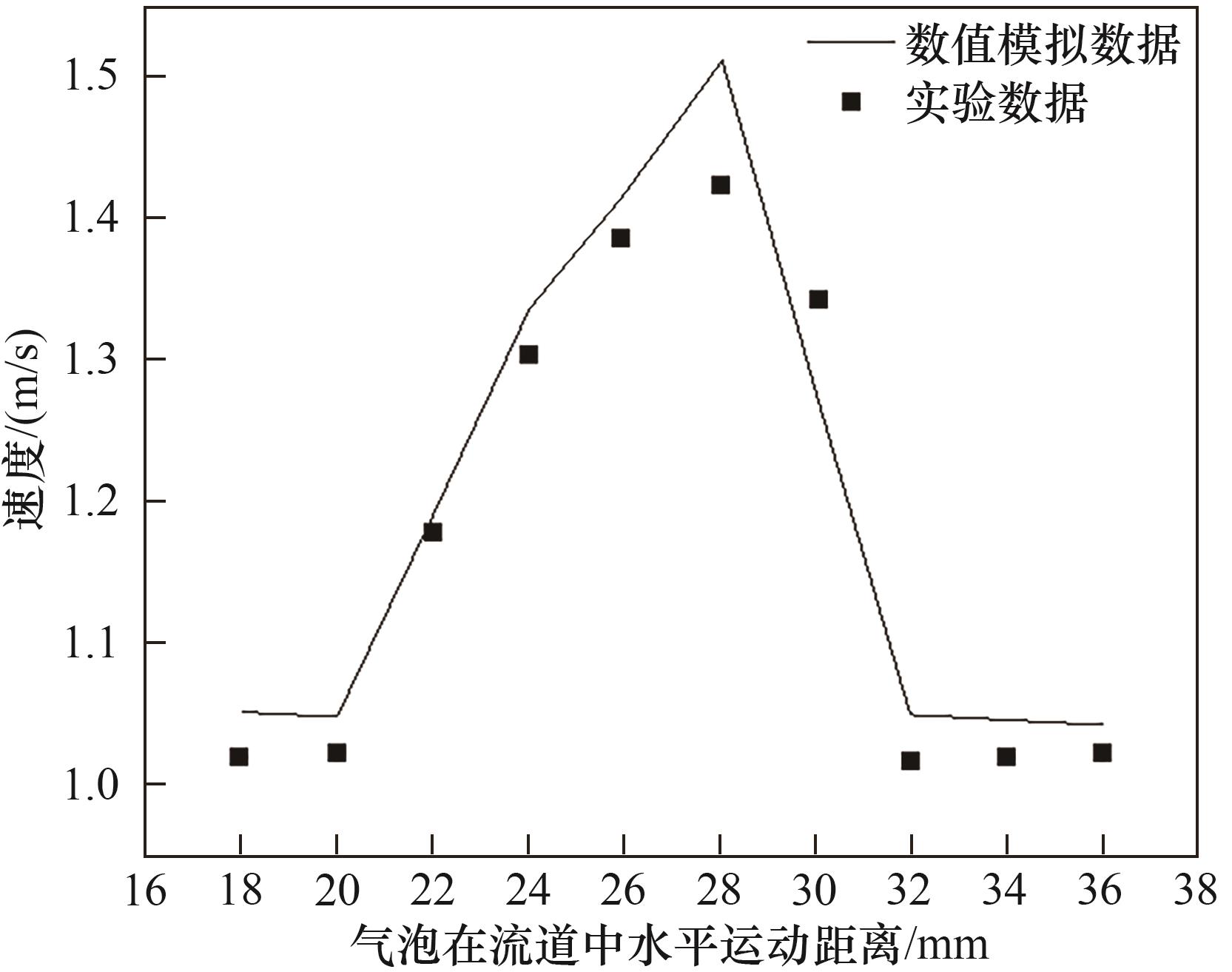

图12 双切线弧流道内气泡平均运动速度的数值计算与实验结果对比

Fig.12 Comparison between numerical calculation and experimental results of average bubble velocity in double tangent arc channel

| 1 | 刘柳, 闫红杰, 谭智凯, 等. 静止液态金属中气泡上升过程实验研究[J]. 中南大学学报(自然科学版), 2021, 52(1): 294-302. |

| Liu L, Yan H J, Tan Z K, et al. Experimental study on bubble rising process in stagnant liquid metals[J]. Journal of Central South University (Science and Technology), 2021, 52(1): 294-302. | |

| 2 | 闫红杰, 赵国建, 刘柳, 等. 静止水中单气泡形状及上升规律的实验研究[J]. 中南大学学报(自然科学版), 2016, 47(7): 2513-2520. |

| Yan H J, Zhao G J, Liu L, et al. Experimental study on shape and rising behavior of single bubble in stagnant water[J]. Journal of Central South University (Science and Technology), 2016, 47(7): 2513-2520. | |

| 3 | Chauhan S P, Eswaran M, Naveen K, et al. Experimental investigation on partially filled liquid pools under combined thermal and vibrational loads[J]. Experimental Thermal and Fluid Science, 2019, 101: 160-174. |

| 4 | 王明阳. 有源相控阵天线微通道冷板拓扑结构研究[D]. 成都: 电子科技大学, 2018. |

| Wang M Y. Research on topological structure of microchannel cold plate for active phased array antenna[D]. Chengdu: University of Electronic Science and Technology of China, 2018. | |

| 5 | Fang X D, Li G H, Li D K, et al. An experimental study of R134a flow boiling heat transfer in a 4.07 mm tube under earth’s gravity and hypergravity[J]. International Journal of Heat and Mass Transfer, 2015, 87: 399-408. |

| 6 | 张文峰, 庞明军. 单气泡上升对近壁面传热影响的数值研究[J]. 东北电力大学学报, 2021, 41(3): 28-38. |

| Zhang W F, Pang M J. Numerical investigate on the effect of single bubble rising near the wall on heat transfer[J]. Journal of Northeast Electric Power University, 2021, 41(3): 28-38. | |

| 7 | Qian J Y, Wang R, Wei T, et al. Numerical analysis of flow boiling characteristics of a single channel heat sink subjected to multiple heat sources[J]. Energies, 2023, 16(7): 3060. |

| 8 | Takemura F, Takagi S, Magnaudet J, et al. Drag and lift forces on a bubble rising near a vertical wall in a viscous liquid[J]. Journal of Fluid Mechanics, 2002, 461: 277-300. |

| 9 | Sugiyama K, Takemura F. On the lateral migration of a slightly deformed bubble rising near a vertical plane wall[J]. Journal of Fluid Mechanics, 2010, 662: 209-231. |

| 10 | Takemura F, Magnaudet J. The transverse force on clean and contaminated bubbles rising near a vertical wall at moderate Reynolds number[J]. Journal of Fluid Mechanics, 2003, 495: 235-253. |

| 11 | Lee P C, Tseng F G, Pan C. Bubble dynamics in microchannels (Part Ⅰ): Single microchannel[J]. International Journal of Heat and Mass Transfer, 2004, 47(25): 5575-5589. |

| 12 | Zhang H, Mudawar I, Hasan M M. Application of flow boiling for thermal management of electronics in microgravity and reduced gravity space systems[C]//2008 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems. Orlando, FL, USA: IEEE, 2008: 949-959. |

| 13 | Westheimer D T, Peterson G P. Visualization of flow boiling in an annular heat exchanger under microgravity conditions[J]. Journal of Thermophysics and Heat Transfer, 2001, 15(3): 333-339. |

| 14 | Howard A H, Mudawar I. Orientation effects on pool boiling CHF and modeling of CHF for near-vertical surfaces[J]. International Journal of Heat and Mass Transfer, 1999, 42: 1665-1688. |

| 15 | Luo X B, Mao Z M. Thermal modeling and design for microchannel cold plate with high temperature uniformity subjected to multiple heat sources[J]. International Communications in Heat and Mass Transfer, 2012, 39(6): 781-785. |

| 16 | Drummond K P, Back D, Sinanis M D, et al. A hierarchical manifold microchannel heat sink array for high-heat-flux two-phase cooling of electronics[J]. International Journal of Heat and Mass Transfer, 2018, 117: 319-330. |

| 17 | Tan H, Du P G, Zong K, et al. Investigation on the temperature distribution in the two-phase spider netted microchannel network heat sink with non-uniform heat flux[J]. International Journal of Thermal Sciences, 2021, 169: 107079. |

| 18 | Mt Aznam S, Mori S, Ogoshi A, et al. CHF enhancement of a large heated surface by a honeycomb porous plate and a gridded metal structure in a saturated pool boiling of nanofluid[J]. International Journal of Heat and Mass Transfer, 2017, 115: 969-980. |

| 19 | Ebrahimi-Dehshali M, Najm-Barzanji S Z, Hakkaki-Fard A. Pool boiling heat transfer enhancement by twisted-tape fins[J]. Applied Thermal Engineering, 2018, 135: 170-177. |

| 20 | 李根, 方贤德, 罗组分, 等. 过载环境下水平管内水的流动沸腾特性[J]. 航空动力学报, 2022, 37(1): 46-54. |

| Li G, Fang X D, Luo Z F, et al. Flow boiling characteristics of water in a horizontal tube under hypergravity environment[J]. Journal of Aerospace Power, 2022, 37(1): 46-54. | |

| 21 | 吴明婷, 高南京, 苗润晗, 等. 中心正交旋转管道内流动沸腾汽液分布特性的数值分析[J]. 中国电机工程学报, 2020, 40(6): 1947-1954. |

| Wu M T, Gao N J, Miao R H, et al. Numerical analysis of boiling vapor-liquid distribution in a central orthogonal rotating pipe[J]. Proceedings of the CSEE, 2020, 40(6): 1947-1954. | |

| 22 | Tanjung E F, Albdour S A, Jeong Y U. Critical heat flux (CHF) in pool boiling under static and rolling conditions[J]. Nuclear Engineering and Technology, 2020, 52(3): 520-529. |

| 23 | Tanjung E F, Alunda B O, Lee Y J, et al. Experimental study of bubble behaviors and CHF on printed circuit board (PCB) in saturated pool water at various inclination angles[J]. Nuclear Engineering and Technology, 2018, 50(7): 1068-1078. |

| 24 | Tanjung E F, Jo D. Surface orientation effects on bubble behaviors and critical heat flux mechanism in saturated water pool[J]. International Journal of Heat and Mass Transfer, 2019, 133: 179-191. |

| 25 | Manetti L L, Moita A S O H, de Souza R R, et al. Effect of copper foam thickness on pool boiling heat transfer of HFE-7100[J]. International Journal of Heat and Mass Transfer, 2020, 152: 119547. |

| 26 | Chang W, Luo K, Li W M, et al. Enhanced flow boiling of HFE-7100 in silicon microchannels with nanowires coated micro-pinfins[J]. Applied Thermal Engineering, 2022, 216: 119064. |

| 27 | Davani S, Zhang B, Doran B, et al. Subcooled pool boiling on hierarchical micro- and nanostructure-modified copper surfaces in HFE-7100 dielectric liquid[J]. Nanoscale and Microscale Thermophysical Engineering, 2024, 28(1): 59-68. |

| 28 | Samkhaniani N, Ansari M R. Numerical simulation of bubble condensation using CF-VOF[J]. Progress in Nuclear Energy, 2016, 89: 120-131. |

| 29 | Lu Q, Chen D Q, Huang Y P, et al. Visual investigation on the coalescence process and the thermal-hydraulic characteristics of the two-phase interface morphology in narrow vertical channel[J]. International Journal of Heat and Mass Transfer, 2017, 115: 537-550. |

| 30 | Liu H D, Liu W, Yan P G, et al. The role mechanism of vapor-liquid behavior on boiling crisis triggering[J]. International Journal of Heat and Mass Transfer, 2022, 196: 123248. |

| [1] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [2] | 罗欣怡, 徐强, 佘永璐, 聂腾飞, 郭烈锦. 光电分解水制氢气泡动力学特性及其传质机理研究[J]. 化工学报, 2024, 75(9): 3083-3093. |

| [3] | 王皓宇, 杨杨, 荆文婕, 杨斌, 唐雨, 刘毅. 不同旋流器作用下气液螺旋环状流动特性研究[J]. 化工学报, 2024, 75(8): 2744-2755. |

| [4] | 赵亮, 李雨桥, 张德, 沈胜强. 螺旋喷嘴内外流场特性的实验研究[J]. 化工学报, 2024, 75(8): 2777-2786. |

| [5] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [6] | 曾港, 陈林, 杨董, 袁海专, 黄彦平. 矩形通道内超临界CO2局部热流场可视化实验[J]. 化工学报, 2024, 75(8): 2831-2839. |

| [7] | 曲玖哲, 杨鹏, 杨绪飞, 张伟, 宇波, 孙东亮, 王晓东. 硅基微柱簇阵列微通道流动沸腾实验研究[J]. 化工学报, 2024, 75(8): 2840-2851. |

| [8] | 李彦熹, 王晔春, 谢向东, 王进芝, 王江, 周煜, 潘盈秀, 丁文涛, 郭烈锦. 蜗壳式多通道气液旋流分离器结构优化及分离特性研究[J]. 化工学报, 2024, 75(8): 2875-2885. |

| [9] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [10] | 吴邦汉, 林定标, 陆海峰, 郭晓镭, 刘海峰. 竖直管气动物流传输系统管道压降和传送瓶输送特性[J]. 化工学报, 2024, 75(7): 2465-2473. |

| [11] | 罗小平, 侯云天, 范一杰. 逆流相分离结构微细通道流动沸腾传热与均温性[J]. 化工学报, 2024, 75(7): 2474-2485. |

| [12] | 余清杰, 杨洪海, 刘玉浩, 方海洲, 何伟琪, 王军, 卢心诚. 脉动热管温度信号的小波分析及流型识别[J]. 化工学报, 2024, 75(7): 2497-2504. |

| [13] | 周文轩, 刘珍, 张福建, 张忠强. 高通量-高截留率时间维度膜法水处理机理研究[J]. 化工学报, 2024, 75(7): 2583-2593. |

| [14] | 赵赫, 费滢洁, 朱春英, 付涛涛, 马友光. 高黏体系中纳米颗粒稳定气泡的形变及破裂行为[J]. 化工学报, 2024, 75(6): 2180-2189. |

| [15] | 李新泽, 张双星, 杨洪海, 杜文静. 基于电池冷却用新型脉动热管性能的实验研究[J]. 化工学报, 2024, 75(6): 2222-2232. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号