化工学报 ›› 2019, Vol. 70 ›› Issue (4): 1272-1281.DOI: 10.11949/j.issn.0438-1157.20181235

梁倩卿1,2( ),马学虎1(

),马学虎1( ),王凯1,春江1,郝婷婷1,兰忠1,王亚雄2

),王凯1,春江1,郝婷婷1,兰忠1,王亚雄2

收稿日期:2018-10-19

修回日期:2019-01-07

出版日期:2019-04-05

发布日期:2019-04-05

通讯作者:

马学虎

作者简介:<named-content content-type="corresp-name">梁倩卿</named-content>(1985—),女,博士,讲师,<email>liangqianqing119@hotmail.com</email>|马学虎(1965—),男,博士,教授,<email>xuehuma@dlut.edu.cn</email>

基金资助:

Qianqing LIANG1,2( ),Xuehu MA1(

),Xuehu MA1( ),Kai WANG1,Jiang CHUN1,Tingting HAO1,Zhong LAN1,Yaxiong WANG2

),Kai WANG1,Jiang CHUN1,Tingting HAO1,Zhong LAN1,Yaxiong WANG2

Received:2018-10-19

Revised:2019-01-07

Online:2019-04-05

Published:2019-04-05

Contact:

Xuehu MA

摘要:

主要测定了低分压CO2(混合气相组成为5%CO2和95%N2,简写为CO2/N2)在矩形截面多弯头微通道中气-液两相Taylor流的流动压降。通过对比六个气液相体系,发现液相的物理性质对气液两相Taylor流压降的影响显著不同。表面张力变化组(CO2/N2-水、CO2/N2 -2%正丙醇水溶液和CO2/N2 -5%正丙醇水溶液)的气液两相Taylor流压降随液相流速的增大呈现线性增长趋势;黏度变化组(CO2/N2-甲醇、CO2/N2-乙醇和CO2/N2-正丙醇)的气液两相Taylor流压降随着

中图分类号:

梁倩卿, 马学虎, 王凯, 春江, 郝婷婷, 兰忠, 王亚雄. 矩形截面弯曲型微通道气液两相Taylor流压降的研究[J]. 化工学报, 2019, 70(4): 1272-1281.

Qianqing LIANG, Xuehu MA, Kai WANG, Jiang CHUN, Tingting HAO, Zhong LAN, Yaxiong WANG. Gas-liquid Taylor flow pressure drop in rectangular meandering microchannel[J]. CIESC Journal, 2019, 70(4): 1272-1281.

| Liquid phase | Density, ρ/(kg·m-3) | Viscosity, μ/(mPa· s) | Surface tension, σ/(mN·m-1) |

|---|---|---|---|

| deionized water | 997 | 0.890 | 72.2 |

| 2% (mole fraction) propanol aqueous solution (2% NPA) | 987.2 | 1.154 | 41.8 |

| 5% (mole fraction) propanol aqueous solution (5% NPA) | 975.6 | 1.574 | 30.5 |

| methanol(MT) | 786 | 0.546 | 22.2 |

| ethanol(EA) | 785 | 1.099 | 22.7 |

| propanol(NPA) | 800 | 1.942 | 23.4 |

表1 本实验涉及液相体系的物理性质[36]

Table 1 Physicochemical properties of liquid phase[36]

| Liquid phase | Density, ρ/(kg·m-3) | Viscosity, μ/(mPa· s) | Surface tension, σ/(mN·m-1) |

|---|---|---|---|

| deionized water | 997 | 0.890 | 72.2 |

| 2% (mole fraction) propanol aqueous solution (2% NPA) | 987.2 | 1.154 | 41.8 |

| 5% (mole fraction) propanol aqueous solution (5% NPA) | 975.6 | 1.574 | 30.5 |

| methanol(MT) | 786 | 0.546 | 22.2 |

| ethanol(EA) | 785 | 1.099 | 22.7 |

| propanol(NPA) | 800 | 1.942 | 23.4 |

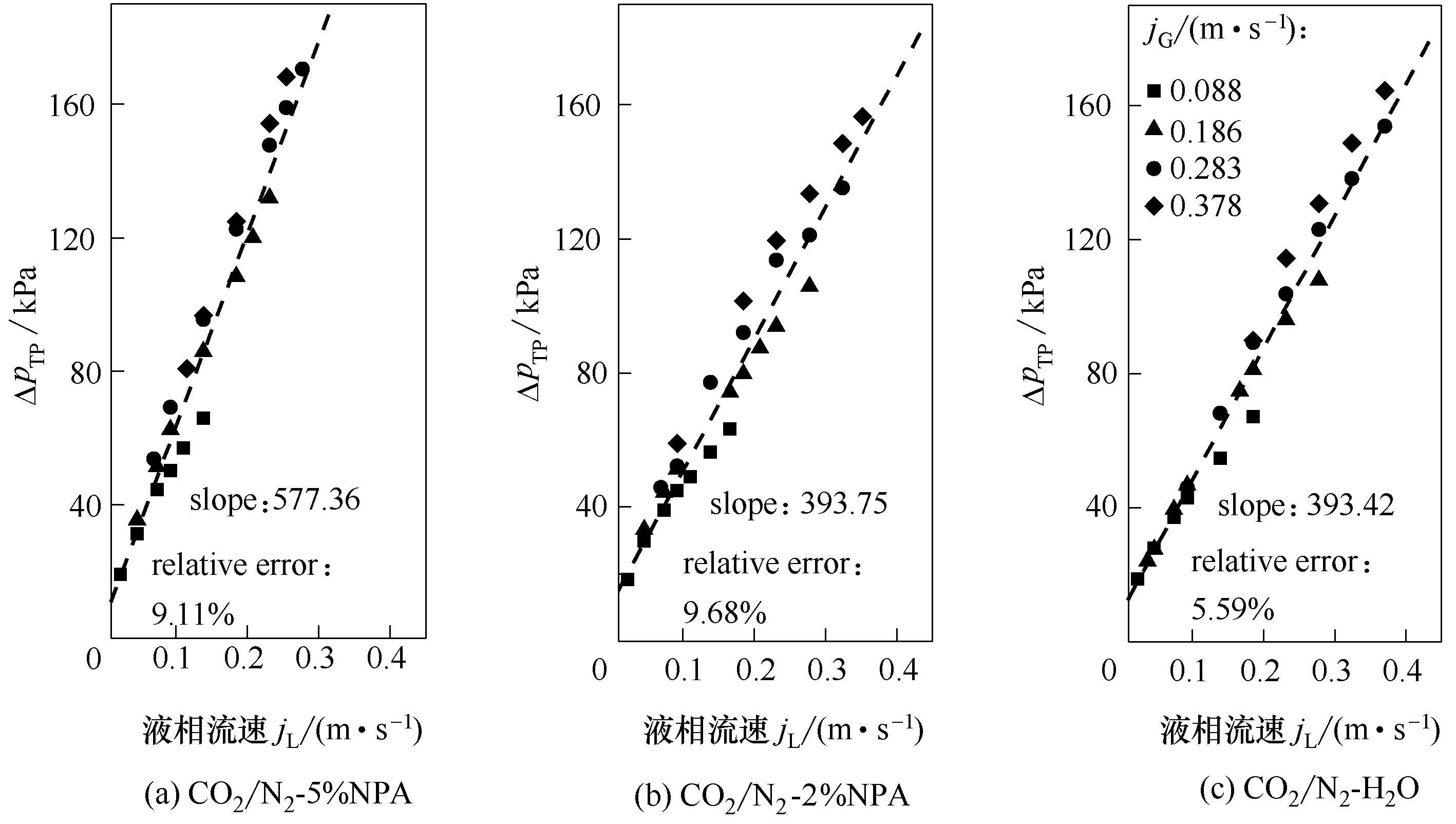

图3 表面张力变化组Taylor流压降随液相流速的变化

Fig.3 Effect of liquid-phase velocity on pressure drop of two-phase flow variation in CO2/N2-5%NPA, CO2/N2-2%NPA,CO2/N2-H2O

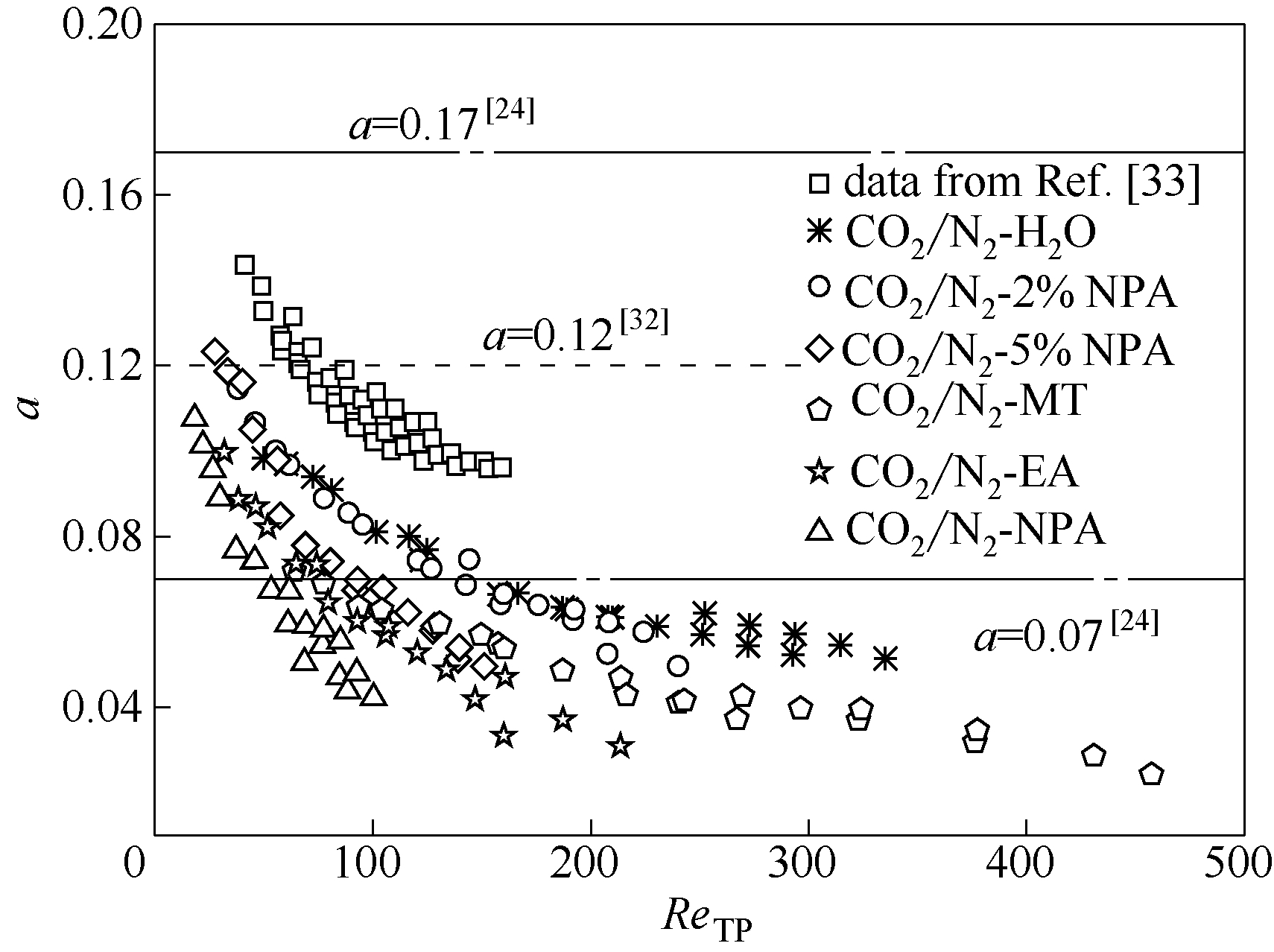

图6 不同气液相体系中Kreutzer等[24]提出的模型中参数a与Re TP 的关系

Fig.6 Parameter a in model of Kreutzer et al. [24] and plotted as a function of Re TP in various gas-liquid systems

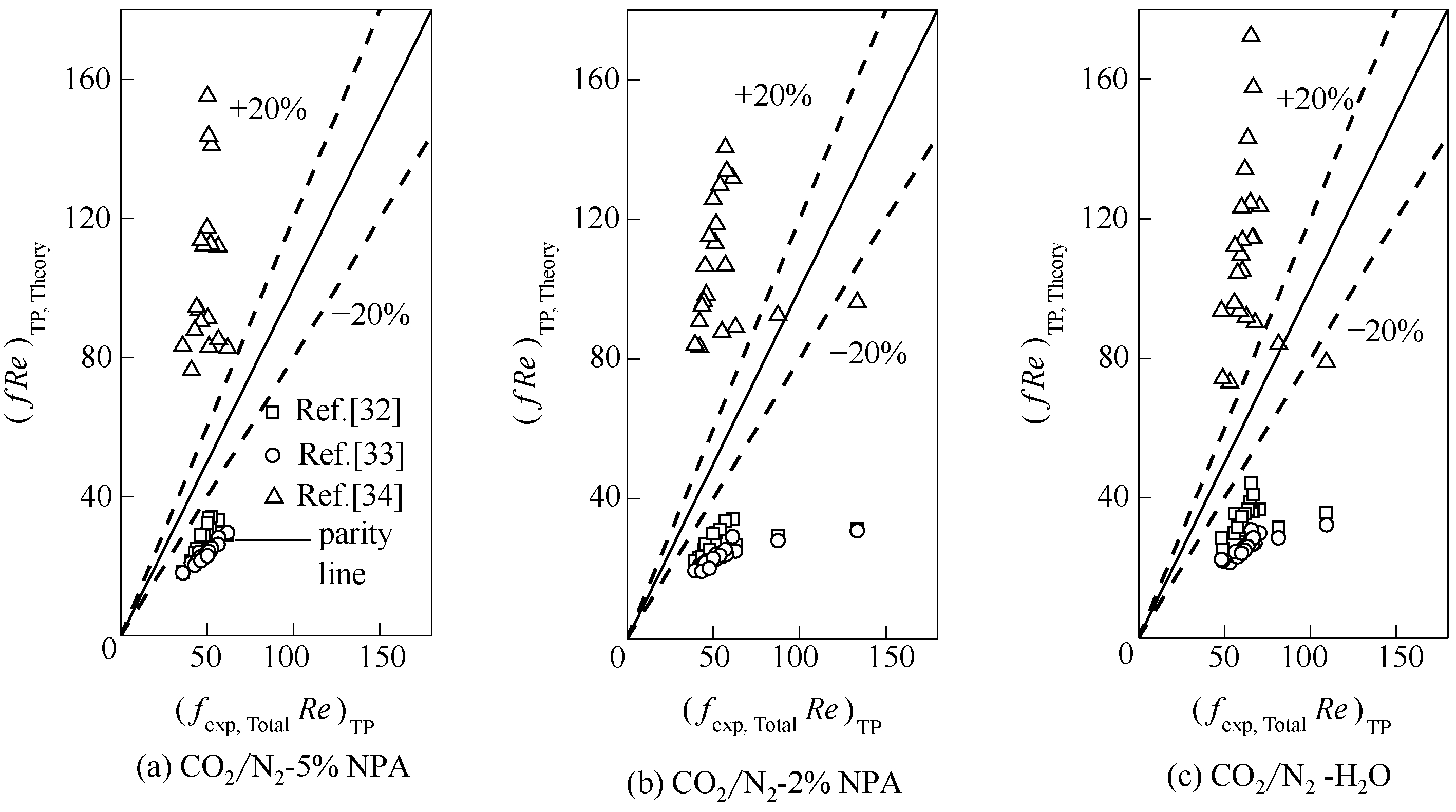

图7 表面张力变化的气液相体系实验得到的表观摩擦系数与文献的比较

Fig.7 Experimental (f exp,Total Re)TP plotted against (fRe)TP, Theory with literature in CO2/N2-5% NPA, CO2/N2-2% NPA and CO2/N2 -H2O

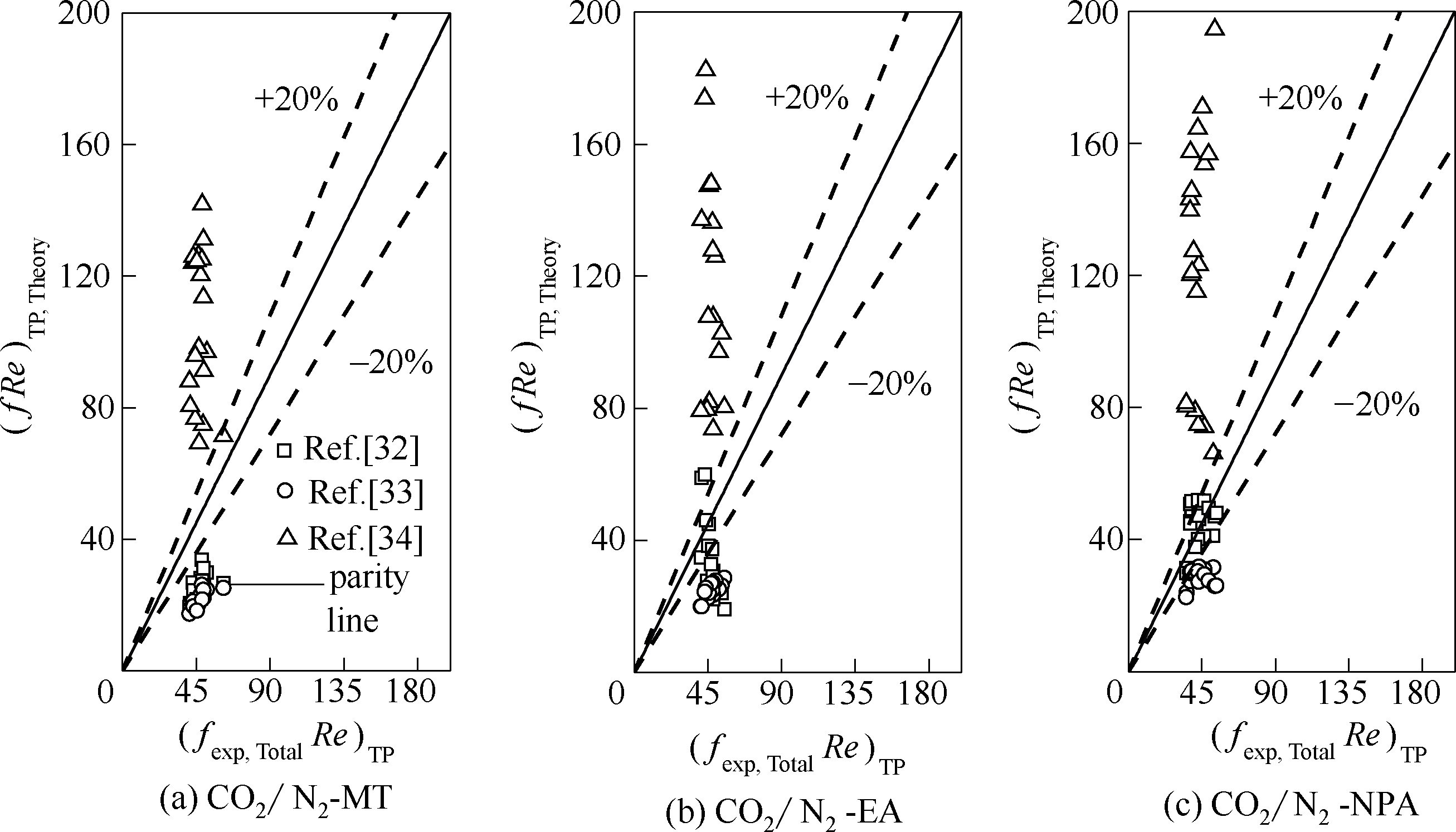

图8 黏度变化的气液相体系实验得到的表观摩擦系数与文献的比较

Fig.8 Experimental (f exp,Total Re)TP plotted against (fRe)TP, Theory with literature in CO2/N2-MT, CO2/N2 -EA and CO2/N2 -NPA

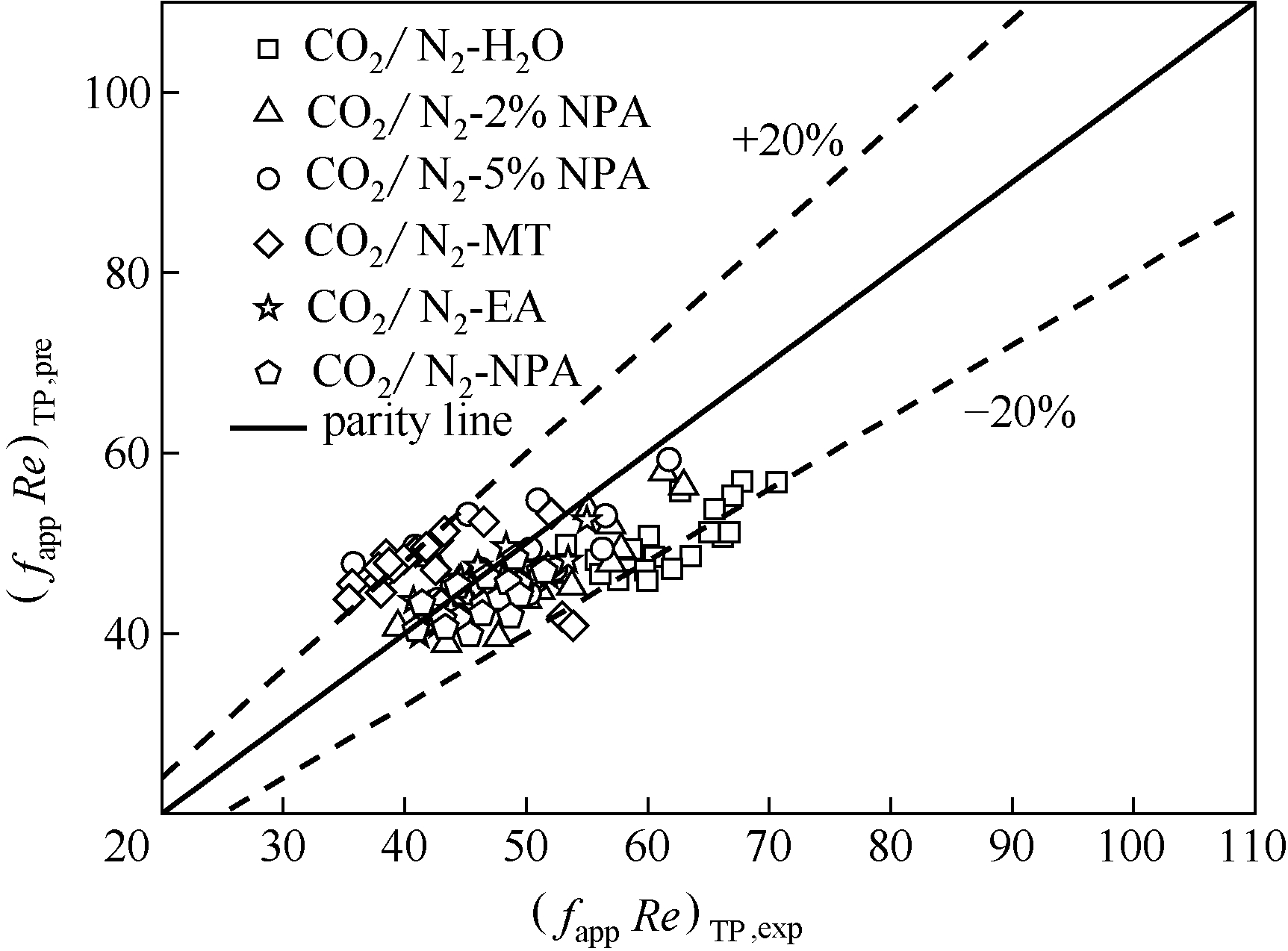

图9 弯曲型矩形微通道中不同气液相体系中f app Re TP的实验值与预测值的比较

Fig.9 Experimental vs predicted f app Re TP in various gas-liquid systems for rectangular meandering microchannels

| 1 | Ganapathy H , Al-hajri E , Ohadi M . Mass transfer characteristics of gas-liquid absorption during Taylor flow in mini/microchannel reactors[J]. Chem. Eng. Sci., 2013, 101: 69-80. |

| 2 | Dutcher B , Fan M , Russell A G . Amine - based CO2 capture technology development from the beginning of 2013—a review [J]. ACS Appl. Mater. Interfaces, 2015, 7(4): 2137-2148. |

| 3 | 马学虎, 兰忠, 王凯, 等 . 舞动的液滴:界面现象与过程调控[J]. 化工学报, 2018, 69(1): 9-43. |

| Ma X H , Lan Z , Wang K , et al . Dancing droplet: interface phenomena and progress regulation[J]. CIESC Journal, 2018, 69(1): 9-43. | |

| 4 | 陈光文, 袁权 . 微化工技术[J]. 化工学报, 2003, 54(4): 427-439. |

| Chen G W , Yuan Q . Micro-chemical technology[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(4): 427-439. | |

| 5 | 袁权, 陈光文, 赵玉潮 . 微化工过程中的传递现象[J]. 化工学报, 2013, 64(1): 63-75. |

| Yuan Q , Chen G W , Zhao Y C . Transport phenomena in micro-chemical engineering[J]. CIESC Journal, 2013, 64(1): 63-75. | |

| 6 | 尧超群, 乐军, 赵玉潮,等 . 微通道内气-液状流动及传质特性研究进展[J]. 化工学报, 2015, 66 (8): 2759-2766. |

| Yao C Q , Yue J , Zhao Y C , et al . Review on flow and mass transfer characteristics of gas-liquid slug flow in microchannels[J].CIESC Journal, 2015,66(8): 2759-2766 | |

| 7 | Guzowski J , Garstecki P . Droplet clusters: exploring the phase space of soft mesoscale atoms[J]. Phys. Rev. Lett.,2015, 114(18): 188302. |

| 8 | Costantini M , Colosi C , Jaroszewicz J , et al . Microfluidic foaming: a powerful tool for tailoring the morphological and permeability properties of sponge-like biopolymeric scaffolds[J]. ACS Appl. Mat. Interfaces, 2015, 7(42): 23660-23671. |

| 9 | Li W , Liu K , Simms R , et al . Microfluidic study of fast gas-liquid reactions[J]. J. Am. Chem. Soc., 2012, 134(6): 3127-3132. |

| 10 | Hao T T , Ma X H , Lan Z , et al . Effects of hydrophilic surface on heat transfer performance and oscillating motion for an oscillating heat pipe[J]. Int. J. Heat Mass Transfer, 2014, 72: 50-65. |

| 11 | Hao T T , Ma X H , Lan Z , et al . Effects of superhydrophobic and superhydrophilic surfaces on heat transfer and oscillating motion of an oscillating heat pipe[J]. J. Heat Transfer, 2014, 136(8):082001. |

| 12 | Liang Q Q , Hao T T , Wang K , et al . Startup and transport characteristics of oscillating heat pipe using ionic liquids[J]. Int. Commun. Heat Mass, 2018, 94: 1-13. |

| 13 | Tumarkin E , Nie Z , Park J I , et al . Temperature- controlled “breathing” of carbon dioxide bubbles[J]. Lab Chip, 2011, 11(20): 3545-3450. |

| 14 | Lefortier S G , Hamersma P J , Bardow A , et al . Rapid microfluidic screening of CO2 solubility and diffusion in pure and mixed solvents[J]. Lab Chip, 2012, 12(18): 3387-3391. |

| 15 | 梁倩卿, 春江, 王凯, 等 . 弯曲型微通道吸收CO2/N2 混合气的传质性能[J]. 高校化学工程学报, 2017, 31(4): 784-793. |

| Liang Q Q , Chun J , Wang K , et al . Mass transfer characteristics during CO2 /N2 mixture absorption in a meandering-microchannel[J]. J. Chem. Eng. Chin. Univ., 2017, 31(4): 784-793. | |

| 16 | 马学虎, 梁倩卿, 王凯, 等 . 基于微吸收器的CO2吸收过程研究进展[J]. 化工进展, 2018, 37(4): 1229-1246. |

| Ma X H , Liang Q Q , Wang K , et al . Progress of CO2 absorption process in micro-absorbers[J].Chem. Ind. Eng. Prog., 2018, 37(4): 1229-1246. | |

| 17 | Yao C Q , Zhao Y C , Dang M H , et al . Characteristics of slug flow with inertial effects in a rectangular microchannel[J]. Chem. Eng. Sci., 2013, 95: 246-256. |

| 18 | van Steijn V , Kreutzer M T , Kleijn C R . μ-PIV study of the formation of segmented flow in microfluidic T-junctions[J]. Chem. Eng. Sci., 2007, 62(24): 7505-7514. |

| 19 | Kuhn S , Jensen K F . A pH-sensitive laser-induced fluorescence technique to monitor mass transfer in multiphase flows in microfluidic devices[J]. Ind. Eng. Chem. Res., 2012, 51(26): 8999-9006. |

| 20 | Tan J , Lu Y C , Xu J H , et al . Mass transfer performance of gas-liquid segmented flow in microchannels[J]. Chem. Eng. J., 2012, 181/182: 229-235. |

| 21 | Zaloha P , Kristal J , Jiricny V , et al . Characteristics of liquid slugs in gas- liquid Taylor flow in microchannels[J]. Chem. Eng. Sci., 2012, 68(1): 640-649. |

| 22 | Fries D M , von Rohr P R . Liquid mixing in gas-liquid two-phase flow by meandering microchannels[J].Chem. Eng. Sci., 2009, 64(6): 1326-1335. |

| 23 | Fries D , Waelchli S , Rudolfvonrohr P . Gas-liquid two-phase flow in meandering microchannels[J]. Chem. Eng. J., 2008, 135: S37-S45 |

| 24 | Günther A , Khan S A , Thalmann M , et al . Transport and reaction in microscale segmented gas-liquid flow[J]. Lab Chip, 2004, 4(4): 278-286. |

| 25 | Günther A , Jhunjhunwala M , Thalmann M . Micromixing of miscible liquids in segmented gas-liquid flow[J]. Langmuir, 2005, 21: 1547-1555. |

| 26 | Mac Giolla Eain M , Egan V , Howard J , et al . Review and extension of pressure drop models applied to Taylor flow regimes[J]. Int. J. Multiphase Flow, 2015, 68: 1-9. |

| 27 | Triplett K A , Ghiaasiaan S M , Abdel-Khalik S I , et al . Gas-liquid two-phase flow in microchannels (Ⅱ): Void fraction and pressure drop [J]. Int. J. Multiphase Flow, 1999, 25(3): 395-410. |

| 28 | Lockhart R W , Martinelli R C . Proposed correlation of data for isothermal two- phase, two- component flow in pipes [J]. Chem. Eng. Prog., 1949, 45(1): 39-48. |

| 29 | Ratulowski J , Chang H C . Transport of gas bubbles in capillaries[J]. Phys. Fluid A: Fluid Dynamics, 1989, 1(10): 1642-1655. |

| 30 | Bretherton F P . The motion of long bubbles in tubes[J]. J. Fluid Mech., 1961, 10: 166-188. |

| 31 | Kreutzer M T , Kapteijn F , Moulijn J A . Inertial and interfacial effects on pressure drop of Taylor flow in capillaries[J]. AIChE J., 2005, 51(9): 2428-2440. |

| 32 | Walsh E , Muzychka Y , Walsh P , et al . Pressure drop in two phase slug/bubble flows in mini scale capillaries[J]. Int. J. Multiphase Flow, 2009, 35(10): 879-884. |

| 33 | Warnier M J F , de Croon M H J M , Rebrov E V , et al . Pressure drop of gas-liquid Taylor flow in round micro-capillaries for low to intermediate Reynolds numbers[J]. Microfluid Nanofluid, 2009, 8(1): 33-45. |

| 34 | Yue J , Luo L G , Gonthier Y , et al . An experimental study of air-water Taylor flow and mass transfer inside square microchannels[J]. Chem. Eng. Sci., 2009, 64(16): 3697-3708. |

| 35 | Garstecki P , Fuerstman M J , Whitesides G M . Oscillations with uniquely long periods in a microfluidic bubble generator[J]. Nature. Phys., 2005,1:168-171. |

| 36 | Won Y S , Chung D K , Mills A F . Density, viscosity, surface tension, and carbon dioxide solubility and diffusivity of methanol, ethanol, aqueous propanol, and aqueous ethylene glycol at 25℃ [J]. J. Chem. Eng. Data, 1981, 26: 140-141. |

| 37 | Chalfi T Y , Ghiaasiaan S M . Pressure drop caused by flow area changes in capillaries under low flow conditions [J]. Int. J. Multiphase Flow, 2008, 34(1):2-12. |

| 38 | Carey V P . Liquid-vapor Phase-change Phenomena [M]. New York : Hemisphere, 1992:521-550. |

| 39 | Kreutzer M T , Kapteijn F , Moulijn J A , et al . Multiphase monolith reactors: chemical reaction engineering of segmented flow in microchannels[J]. Chem. Eng. Sci., 2005, 60(22): 5895-5916. |

| 40 | Berthier J , Silberzan P . Microfluidics for Biotechnology [M]. Boston, London: Artech House, 2010:42-44. |

| 41 | Abiev R S . Bubbles velocity, Taylor circulation rate and mass transfer model for slug flow in milli- and microchannels[J]. Chem. Eng. J., 2013, 227: 66-79. |

| 42 | Kuo J S , Chiu D T . Controlling mass transport in microfluidic devices[J]. Annu. Rev. Anal. Chem., 2011, 4: 275-296. |

| 43 | Waelchli S , von Rohr P R . Two-phase flow characteristics in gas-liquid microreactors[J]. Int. J. Multiphase Flow, 2006, 32(7): 791-806. |

| [1] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [2] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [3] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [4] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [5] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [6] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [7] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [8] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [9] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [10] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [11] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [12] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [13] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [14] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [15] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号