化工学报 ›› 2019, Vol. 70 ›› Issue (5): 1923-1931.DOI: 10.11949/j.issn.0438-1157.20181452

武永健1( ),罗春欢1,2,魏琳1,朱探金1,苏庆泉1,2(

),罗春欢1,2,魏琳1,朱探金1,苏庆泉1,2( )

)

收稿日期:2018-12-05

修回日期:2019-02-11

出版日期:2019-05-05

发布日期:2019-05-05

通讯作者:

苏庆泉

作者简介:<named-content content-type="corresp-name">武永健</named-content>(1992—),男,博士研究生,<email>wuyongjian@xs.ustb.edu.cn</email>|苏庆泉(1961—),男,博士,教授,<email>suqingquan@ustb.edu.cn</email>

基金资助:

Yongjian WU1( ),Chunhuan LUO1,2,Lin WEI1,Tanjin ZHU1,Qingquan SU1,2(

),Chunhuan LUO1,2,Lin WEI1,Tanjin ZHU1,Qingquan SU1,2( )

)

Received:2018-12-05

Revised:2019-02-11

Online:2019-05-05

Published:2019-05-05

Contact:

Qingquan SU

摘要:

在固定床反应器和热重分析仪上对浸渍法制备的过渡金属氧化物载氧体MnO2/Al2O3、Fe2O3/Al2O3和CuO/Al2O3与转炉放散煤气中CO的反应特性进行了研究,并结合比表面积分析、脉冲化学吸附和扫描电镜等手段表征了CuO/Al2O3的循环寿命性能。结果表明,在上述三种载氧体中CuO/Al2O3表现出了最佳的反应活性,反应进行2 min时的CO转化率在225℃以上的反应温度下就能达到90%。在350℃、还原反应空速4000 h-1和氧化反应空速159 h-1的条件下,CuO/Al2O3能够保持良好且稳定的CO脱除性能和机械强度,因而具有良好的循环寿命。据此,提出了基于化学链燃烧的转炉放散煤气利用新工艺,本工艺可安全利用间歇排放的转炉放散煤气,并实现对用户的连续供热。

中图分类号:

武永健, 罗春欢, 魏琳, 朱探金, 苏庆泉. 基于化学链燃烧的转炉放散煤气利用研究[J]. 化工学报, 2019, 70(5): 1923-1931.

Yongjian WU, Chunhuan LUO, Lin WEI, Tanjin ZHU, Qingquan SU. Utilization of converter off-gas based on chemical-looping combustion[J]. CIESC Journal, 2019, 70(5): 1923-1931.

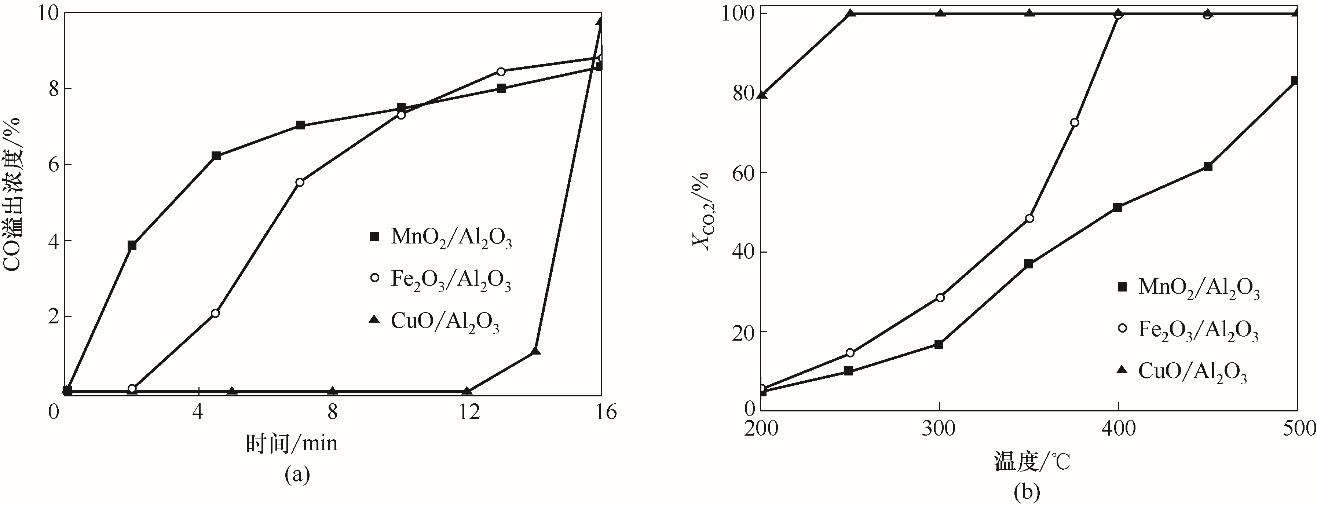

图4 三种载氧体的还原反应中,空速2000 h-1时, 450℃下,出口气体中CO浓度随反应时间的变化及 X C O , 2 随反应温度的变化

Fig.4 In reduction reaction for three OCs at 2000 h-1, outlet CO concentration versus reaction time at 450℃(a), and X C O , 2 versus reaction temperature(b)

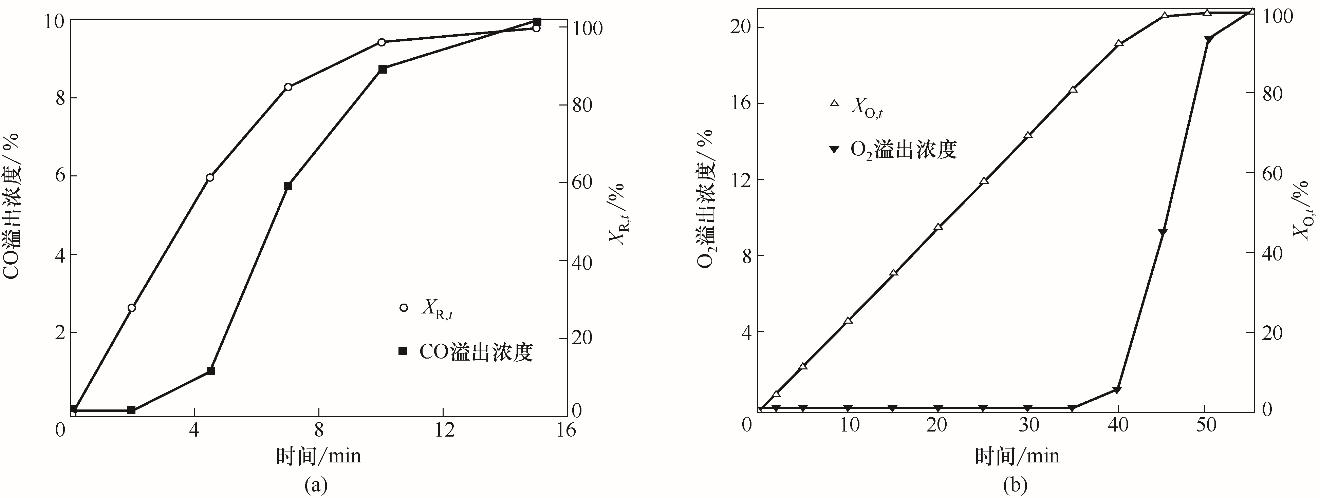

图5 空速4000 h-1、温度350℃,CuO/Al2O3的还原反应出口气体中CO浓度和 X R , t 随时间的变化(a)及空速159 h-1、温度350℃,Cu/Al2O3的氧化反应出口气体中O2浓度和 X O , t 随时间的变化(b)

Fig.5 Outlet CO concentration and X R , t versus time in reduction reaction of CuO/Al2O3 at 350℃ and 4000 h-1(a), and outlet O2 concentration and X O , t versus time in oxidation reaction of Cu/Al2O3 at 350℃ and 159 h-1(b)

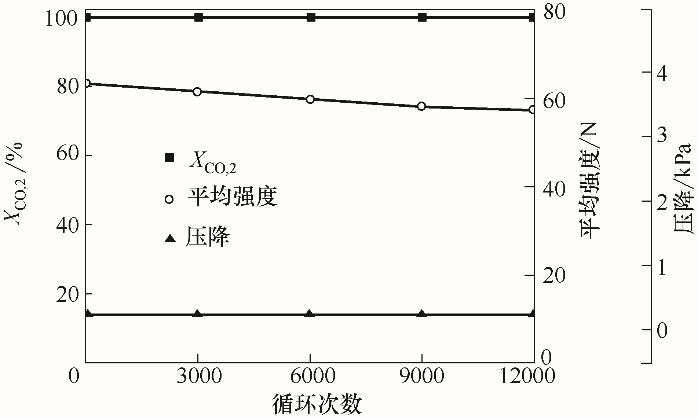

图7 CuO/Al2O3循环寿命实验中, X C O , 2 、还原反应的床层压降、载氧体的平均破碎强度随循环次数的变化

Fig.7 X C O , 2 , pressure drop in reduction reaction and average crushing strength of OCs versus cycle times in cyclic life experiment of CuO/Al2O3

| 循环次数 | 比表面积/(m2?g-1) | 孔容/(ml?g-1) | 平均孔径/nm | CO化学吸附量/(ml?g-1) |

|---|---|---|---|---|

| 0 | 164.78 | 0.376 | 9.12 | 1.60 |

| 3000 | 156.81 | 0.382 | 9.87 | 1.43 |

| 6000 | 145.52 | 0.375 | 10.41 | 1.15 |

| 9000 | 131.44 | 0.381 | 12.15 | 0.54 |

| 12000 | 114.54 | 0.389 | 13.60 | 0.32 |

表1 不同循环次数下的CuO/Al2O3的比表面积、孔容、孔径及CO吸附量

Table 1 Specific surface area, pore volume, average pore size and CO adsorption for CuO/Al2O3 under different cycle times

| 循环次数 | 比表面积/(m2?g-1) | 孔容/(ml?g-1) | 平均孔径/nm | CO化学吸附量/(ml?g-1) |

|---|---|---|---|---|

| 0 | 164.78 | 0.376 | 9.12 | 1.60 |

| 3000 | 156.81 | 0.382 | 9.87 | 1.43 |

| 6000 | 145.52 | 0.375 | 10.41 | 1.15 |

| 9000 | 131.44 | 0.381 | 12.15 | 0.54 |

| 12000 | 114.54 | 0.389 | 13.60 | 0.32 |

| 反应 | (kJ·mol-1) | (kJ·mol-1) | |

|---|---|---|---|

| 还原反应 | 2CuO + CO | -154.56 | -146.22 |

| Cu2O + CO | -105.38 | -113.80 | |

| 氧化反应 | 4Cu + O2 | -246.45 | -339.58 |

| 2Cu2O + O2 | -148.10 | -274.74 | |

表2 还原反应和氧化反应的热力学数据

Table 2 Thermodynamic data for reduction and oxidation reactions

| 反应 | (kJ·mol-1) | (kJ·mol-1) | |

|---|---|---|---|

| 还原反应 | 2CuO + CO | -154.56 | -146.22 |

| Cu2O + CO | -105.38 | -113.80 | |

| 氧化反应 | 4Cu + O2 | -246.45 | -339.58 |

| 2Cu2O + O2 | -148.10 | -274.74 | |

| 1 | 赵贤聪, 白皓, 李宏煦, 等 . 钢铁生产过程富余煤气动态优化分配模型[J]. 工程科学学报, 2015, 37(1): 97-105. |

| Zhao X C , Bai H , Li H X , et al . Dynamic optimal distribution model of surplus byproduct gases in iron and steel making process[J]. Chinese J. Eng., 2015, 37(1): 97-105. | |

| 2 | 刘辉, 王雯, 魏晓明, 等 . 工业副产煤气的资源化利用研究进展[J]. 现代化工, 2016, 36(4): 46-52. |

| Liu H , Wang W , Wei X M , et al . Research progress of utilization of industrial by-product gas[J]. Mod. Chem. Ind., 2016, 36(4): 46-52. | |

| 3 | 潘秀兰, 常桂华, 冯士超, 等 . 转炉煤气回收和利用技术的最新进展[J]. 冶金能源, 2010, 29(5): 37-42. |

| Pan X L , Chang G H , Feng S C , et al . Recent progress of recovery and utilization technology of converter gas[J]. Energ. Metall. Ind., 2010, 29(5): 37-42. | |

| 4 | 王永忠, 施锦德 . 转炉煤气节能减排的几种技术措施[J]. 世界钢铁, 2009, 9(4): 39-44. |

| Wang Y Z , Shi J D . Several technical measures about energy-saving and emission-reduction of BOF gas[J]. World Iron Steel, 2009, 9(4): 39-44. | |

| 5 | 于鹏飞, 曾加庆, 林腾昌, 等 . 国内转炉煤气回收概况与研究展望[J]. 铸造技术, 2018, 39(1): 240-245. |

| Yu P F , Zeng J Q , Lin T C , et al . General situation and research prospect of converter gas recovery in China[J]. Foundry Technol., 2018, 39(1): 240-245. | |

| 6 | 尹茂建, 黄伟 . 提高转炉煤气吨钢回收量措施探讨[J]. 冶金动力, 2011, (s 1): 18-19. |

| Yin M J , Huang W . Increasing the amount of converter gas recovery per ton of steel[J]. Metall. Power, 2011, (s 1): 18-19. | |

| 7 | 秦勇 . 提高转炉煤气回收量的研究与应用[J]. 冶金动力, 2013, (3): 27-29. |

| Qin Y . Research and application of enhancing converter gas recovery amount[J]. Metall. Power, 2013, (3): 27-29. | |

| 8 | 王爱华, 蔡九菊, 王鼎, 等 . 转炉煤气回收规律及其影响因素研究[J]. 冶金能源, 2004, 23(4): 52-55. |

| Wang A H , Cai J J , Wang D , et al . Research on LDG recovery law and its affecting factors[J]. Energ. Metall. Ind., 2004, 23(4): 52-55. | |

| 9 | Wang A H , Cai J J , Li X P , et al . Affecting factors and improving measures for converter gas recovery[J]. J. Iron Steel Res. Int., 2007, 14(6): 22-26. |

| 10 | Li S , Wei X L . Numerical simulation of CO and NO emissions during converter off-gas combustion in the cooling stack[J]. Combust. Sci. Technol., 2013, 185(2): 212-225. |

| 11 | Li S , Wei X L , Yu L X . Numerical study on NO x /CO emissions in the diffusion flames of high-temperature off-gas of steelmaking converter[J]. Appl. Energ., 2011, 88(4): 1113-1119. |

| 12 | Sandlobes S , Senk D , Sancho L , et al . In-situ measurement of CO- and CO2-concentrations in BOF off-gas[J]. Steel Res. Int., 2011, 82(6): 632-637. |

| 13 | Maruoka N , Akiyama T . Exergy recovery from steelmaking off-gas by latent heat storage for methanol production[J]. Energy, 2006, 31(10/11): 1632-1642. |

| 14 | 高强, 贾琼 . 转炉煤气热值波动大影响用户使用的分析[J]. 冶金能源, 2011, 30(5): 38-40. |

| Gao Q , Jia Q . Analysis on the fluctuation of the heat value for converter gas[J]. Energ. Metall. Ind., 2011, 30(5): 38-40. | |

| 15 | Nandy A , Loha C , Gu S , et al . Present status and overview of chemical looping combustion technology[J]. Renew. Sust. Energ. Rev., 2016, 59: 597-619. |

| 16 | 覃吴, 李渠, 董长青, 等 . Co-Fe2O3 纳米载氧体作用下CO 化学链燃烧富集CO2 [J]. 化工学报, 2014, 65(8): 3136-3143. |

| Qin W , Li Q , Dong C Q , et al . CO chemical looping combustion using Co-Fe2O3 nano oxygen carrier for enrichment of CO2 [J]. CIESC Journal, 2014, 65(8): 3136-3143. | |

| 17 | Zhang H , Hong H , Jiang Q Q , et al . Development of a chemical-looping combustion reactor having porous honeycomb chamber and experimental validation by using NiO/NiAl2O4 [J]. Applied Energy, 2018, 211: 259-268. |

| 18 | Bhavsar S , Isenberg N , More A , et al . Lanthana-doped ceria as active support for oxygen carriers in chemical looping combustion[J]. Appl. Energ., 2016, 168: 236-247. |

| 19 | Adánez J , Abad A , Garcia-Labiano F , et al . Progress in chemical-looping combustion and reforming technologies[J]. Prog. Energ. Combust. Sci., 2012, 38(2): 215-282. |

| 20 | Li J , Zhang H D , Gao Z P , et al . CO2 capture with chemical looping combustion of gaseous fuels: an overview[J]. Energ. Fuel, 2017, 31(4): 3475-3524. |

| 21 | Song Q , Liu W , Bohn C D , et al . A high performance oxygen storage material for chemical looping processes with CO2 capture[J]. Energ. Environ. Sci., 2013, 6: 288-298. |

| 22 | Tian Q , Che L X , Ding B , et al . Performance of Cu-Fe-based oxygen carrier in a CLC process based on fixed bed reactors[J]. Greenh. Gases, 2017, 7(4): 731-744. |

| 23 | Gallucci F , Hamers H P , van Zanten M , et al . Experimental demonstration of chemical looping combustion of syngas in packed bed reactors with ilmenite[J]. Chem. Eng. J., 2015, 274: 156-168. |

| 24 | Hwang J H , Baek J I , Ryu H J , et al . Development of MgMnO3- δ as an oxygen carrier material for chemical looping combustion[J]. Fuel, 2018, 231: 290-296. |

| 25 | 彭松, 曾德望, 陈超, 等 . 具有自载体功能的CoFeAlO4载氧体化学链燃烧反应特性[J]. 化工学报, 2018, 69(1): 515-522. |

| Peng S , Zeng D W , Chen C , et al . Chemical looping combustion performance of CoFeAlO4 oxygen carrier with self-supported function[J]. CIESC Journal, 2018, 69(1): 515-522. | |

| 26 | Zheng X M , Su Q Q , Mi W L . Effect of steam reforming on methane-fueled chemical looping combustion with Cu-based oxygen carrier[J]. Int. J. Hydrogen Energ., 2014, 39(17): 9158-9168. |

| 27 | Arjmand M , Leion H , Mattisson T , et al . Investigation of different manganese ores as oxygen carriers in chemical-looping combustion (CLC) for solid fuels[J]. Appl. Energ., 2014, 113: 1883-1894. |

| 28 | Perez-Vega R , Abad A , Garcia-Labiano F , et al . Chemical looping combustion of gaseous and solid fuels with manganese iron mixed oxide as oxygen carrier[J]. Energ. Convers. Manage., 2018, 159: 221-231. |

| 29 | Kwak B S , Park N K , Ryu H J , et al . Reduction and oxidation performance evaluation of manganese-based iron, cobalt, nickel, and copper bimetallic oxide oxygen carriers for chemical-looping combustion[J]. Appl. Therm. Eng., 2018, 128: 1273-1281. |

| 30 | Jiang S X , Shen L H , Wu J , et al . The investigations of hematite-CuO oxygen carrier in chemical looping combustion[J]. Chem. Eng. J., 2017, 317: 132-142. |

| [1] | 胡超, 董玉明, 张伟, 张红玲, 周鹏, 徐红彬. 浓硫酸活化五氧化二钒制备高浓度全钒液流电池正极电解液[J]. 化工学报, 2023, 74(S1): 338-345. |

| [2] | 代宝民, 王启龙, 刘圣春, 张佳宁, 李鑫海, 宗凡迪. 非共沸工质辅助过冷CO2冷热联供系统的热力学性能分析[J]. 化工学报, 2023, 74(S1): 64-73. |

| [3] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [4] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [5] | 杨天阳, 邹慧明, 周晖, 王春磊, 田长青. -30℃电动汽车补气式CO2热泵制热性能实验研究[J]. 化工学报, 2023, 74(S1): 272-279. |

| [6] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [7] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| [8] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [9] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [10] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [11] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [12] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [13] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [14] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [15] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号