化工学报 ›› 2020, Vol. 71 ›› Issue (1): 122-137.DOI: 10.11949/0438-1157.20191232

王清莲1( ),王晓达1,王红星2,黄智贤1,叶长燊1,邱挺1(

),王晓达1,王红星2,黄智贤1,叶长燊1,邱挺1( )

)

收稿日期:2019-10-23

修回日期:2019-10-29

出版日期:2020-01-05

发布日期:2020-01-05

通讯作者:

邱挺

作者简介:王清莲(1989—),女,博士,基金资助:

Qinglian WANG1( ),Xiaoda WANG1,Hongxing WANG2,Zhixian HUANG1,Changshen YE1,Ting QIU1(

),Xiaoda WANG1,Hongxing WANG2,Zhixian HUANG1,Changshen YE1,Ting QIU1( )

)

Received:2019-10-23

Revised:2019-10-29

Online:2020-01-05

Published:2020-01-05

Contact:

Ting QIU

摘要:

酶反应精馏是将酶催化反应与精馏过程进行耦合,可有效打破反应化学平衡的限制,提高酶反应转化率和选择性,是一种新型化工过程强化技术。本文分别从酶催化剂及其催化反应机制、酶催化剂装填方式、酶催化反应与精馏耦合型式、酶反应精馏耦合技术的应用案例等方面综述了酶反应精馏耦合技术的研究进展,分析表明:目前酶反应精馏耦合技术的开发尚不成熟,且与化学催化剂催化的反应精馏过程不同,酶反应精馏工艺过程开发还需考虑酶催化反应温度、底物浓度等因素对酶催化活性影响。在后续研究中,可分别从研究体系、酶的固定化技术、酶催化剂装填方式、酶反应精馏理论研究、酶反应精馏耦合工艺开发等方面开展强化研究。

中图分类号:

王清莲, 王晓达, 王红星, 黄智贤, 叶长燊, 邱挺. 酶反应精馏耦合技术研究进展[J]. 化工学报, 2020, 71(1): 122-137.

Qinglian WANG, Xiaoda WANG, Hongxing WANG, Zhixian HUANG, Changshen YE, Ting QIU. Recent developments in enzymatic reactive distillation coupling technology[J]. CIESC Journal, 2020, 71(1): 122-137.

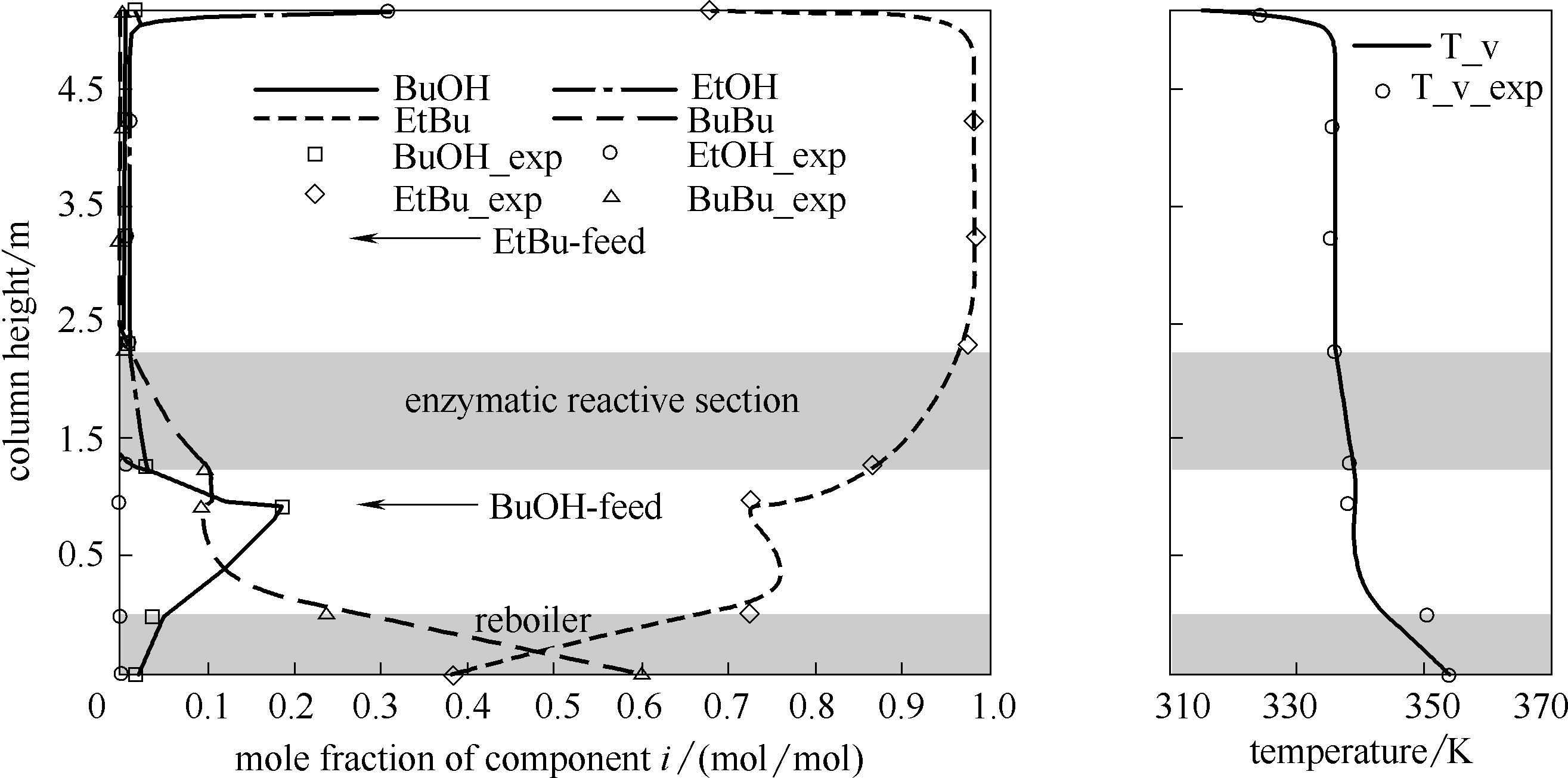

图13 丁酸丁酯合成工艺过程酶反应精馏塔内各物质浓度和温度分布

Fig.13 Concentration and temperature profiles inside enzymatic reactive distillation column for transesterification of ethyl butyrate

图16 酶反应精馏拆分(R/S)-1-苯乙醇工艺过程中酶反应精馏塔内各物质浓度、温度分布

Fig.16 Concentration and temperature profiles inside enzymatic reactive distillation column for kinetic resolution of racemic (R/S)-1-phenylethanol

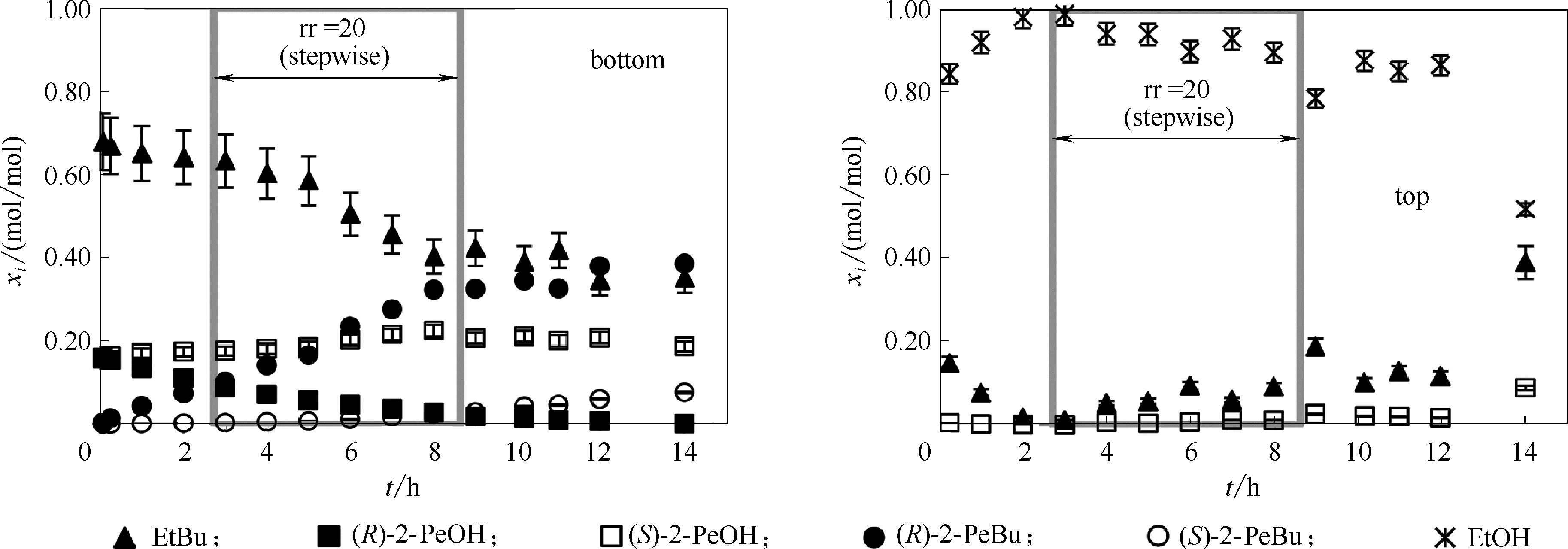

图19 (R/S)-2-戊醇动力学拆分过程中间歇酶反应精馏塔塔顶和塔釜各物质浓度分布 (丁酸丙酯和(R/S)-2-戊醇进料摩尔比为2∶1,操作压力为(60~115)×102 Pa,总进料量800 g,塔釜反应温度为63℃)

Fig.19 Time dependent concentration progress curves of all reaction components in the bottom and top of column for kinetic resolution of (R/S)-2-pentanol

图20 (R/S)-2-戊醇与丁酸丙酯反应的间歇酶反应精馏塔塔顶组成分布 (操作压力为80×102 Pa,塔釜反应温度为70~74℃,总进料量800 g,丁酸丙酯和(R/S)-2-戊醇进料摩尔比为9∶1)

Fig.20 Molar fractions in the top of RD column for kinetic resolution of (R/S)-2-pentanol with propyl butyrate

| 1 | Liese A , Seelbach K , Wandrey C . Industrial Biotransformations[M]. 2nd ed. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2006. |

| 2 | Jones J B . Biotransformations in Organic Chemistry[M]. Spring, 2000. |

| 3 | Tan T , Lu J , Nie K , et al . Biodiesel production with immobilized lipase: a review[J]. Biotechnology Advances, 2010, 28(5): 628-634. |

| 4 | Berger M , Laumen K , Schneider M P . Enzymatic esterification of glycerol (Ⅰ): Lipase-catalyzed synthesis of regioisomerically pure 1,3-sn-diacylglycerols[J]. Journal of the American Oil Chemists Society, 1992, 69(10): 955-960. |

| 5 | Stinson S C . Chiral drug market shows signs of maturity[J]. Chemical & Engineering News, 1997, 75(42): 38-70. |

| 6 | Wu J C , Ho P , Poh T Y , et al . Enhanced enantioselectivity of immobilized Candida Antarctica lipase for hydrolysis of ketoprofen ethyl ester at pH 1[J]. Korean Journal of Chemical Engineering, 2007, 24(4): 648-650. |

| 7 | Balcão V M , Paiva A L , Malcata F X . Bioreactors with immobilized lipases: state of the art[J]. Enzyme and Microbial Technology, 1996, 18(6): 392-416. |

| 8 | Paiva A L , Malcata F X . Integration of reaction and separation with lipases: an overview[J]. Journal of Molecular Catalysis B: Enzymatic, 1997, 3(1): 99-109. |

| 9 | Tian Y , Demirel S E , Hasan M M F , et al . An overview of process systems engineering approaches for process intensification: state of the art[J]. Chemical Engineering and Processing: Process Intensification, 2018, 133(1): 160-210. |

| 10 | Li C , Duan C , Fang J , et al . Process intensification and energy saving of reactive distillation for production of ester compounds[J]. Chinese Journal of Chemical Engineering, 2019, 27(6): 1307-1323. |

| 11 | Tian H , Zheng H , Huang Z , et al . Novel procedure for coproduction of ethyl acetate and n-butyl acetate by reactive distillation[J]. Industrial & Engineering Chemistry Research, 2012, 51(15): 5535-5541. |

| 12 | Qiu T , Kuang C H , Li C G , et al . Study on feasibility of reactive distillation process for the direct hydration of cyclohexene to cyclohexanol using a cosolvent[J]. Industrial & Engineering Chemistry Research, 2013, 52(24): 8139-8148. |

| 13 | Huang Z X , Li J L , Wang L Y , et al . Novel procedure for the synthesis of dimethyl carbonate by reactive distillation[J]. Industrial & Engineering Chemistry Research, 2014, 53(8): 3321-3328. |

| 14 | Qiu T , Zhang P , Yang J B , et al . Novel procedure for production of isopropanol by transesterification of isopropyl acetate with reactive distillation[J]. Industrial & Engineering Chemistry Research, 2014, 53(36): 13881-13891. |

| 15 | Wang H X , Bu X W , Huang Z X , et al . Synthesis of methacrylic anhydride by batch reactive distillation: reaction kinetics and process[J]. Industrial & Engineering Chemistry Research, 2014, 53(44): 17317-17324. |

| 16 | Zhou L , Niu Y , Yang J , et al . Reaction kinetics for synthesis of isopropyl myristate catalyzed by sulfated titania[J]. Korean Journal of Chemical Engineering, 2016, 33(8): 2478-2485. |

| 17 | Huang Z X , Lin Y X , Wang X D , et al . Optimization and control of a reactive distillation process for the synthesis of dimethyl carbonate[J]. Chinese Journal of Chemical Engineering, 2017, 25(8): 1079-1090. |

| 18 | Yang J B , Cai D R , Zeng T , et al . Application of Brönsted acid ionic liquids as green catalyst in the synthesis of 2-propanol with reactive distillation[J]. Chinese Journal of Chemical Engineering, 2016, 24(11): 1561-1569. |

| 19 | Wang X D , Wang Q L , Ye C S , et al . Feasibility study of reactive distillation for the production of propylene glycol monomethyl ether acetate through transesterification[J]. Industrial & Engineering Chemistry Research, 2017, 56(25): 7149-7159. |

| 20 | Lei Z , Zou Z , Dai C , et al . Synthesis of dimethyl ether (DME) by catalytic distillation[J]. Chemical Engineering Science, 2011, 66(14):3195-3203. |

| 21 | Kiss A A . Advanced Distillation Technologies: Design Control and Applications[M]. New York: John Wiley & Sons Inc., 2013. |

| 22 | Berendsen W R , Gendrot G , Resnick S , et al . Kinetic modeling of lipase catalyzed hydrolysis of (R/S)-1-methoxy-2-propyl-acetate as a model reaction for production of chiral secondary alcohols[J]. Journal of Biotechnology, 2006, 121(2): 213-226. |

| 23 | Okasinski M J , Doherty M F . Simultaneous kinetic resolution of chiral propylene oxide and propylene glycol in a continuous reactive distillation column[J]. Chemical Engineering Science, 2003, 58(7): 1289-1300. |

| 24 | Clayden J , Moran W J , Edwards P J , et al . The challenge of atropisomerism in drug discovery[J]. Angewandte Chemie International Edition, 2010, 48(35): 6398-6401. |

| 25 | Margolin A L . Enzymes in the synthesis of chiral drugs[J]. Enzyme and Microbial Technology, 1993, 15(4): 266-280. |

| 26 | Saric M , Wielen L A M V D , Straathof A J J . Theoretical performance of countercurrent reactors for production of enantiopure compounds[J]. Chemical Engineering Science, 2011, 66(3): 510-518. |

| 27 | Shimizu S , Nakano M . Structural characterization of triacylglycerol in several oils containing gamma-linolenic acid[J]. Bioscience, Biotechnology, and Biochemistry, 2003, 67(1): 60-67. |

| 28 | Bisswanger H . Enzyme Kinetics: Principles and Methods[M]. Wiley-VCH, 2008. |

| 29 | Anthonsen H W , Hoff B H , Anthonsen T . Calculation of enantiomer ratio and equilibrium constants in biocatalytic Ping-Pong Bi-Bi resolutions[J]. Tetrahedron: Asymmetry, 1996, 7(9): 2633-2638. |

| 30 | 田雪梅 . 脂肪酶催化有机合成反应的合理调控[D]. 长春: 吉林大学, 2016. |

| Tian X M . Rational regulation of lipase-catalyzed organic synthesis reactions[D]. Changchun: Jilin University, 2016. | |

| 31 | Yesiloğlu Y . Utilization of bentonite as a support material for immobilization of Candida rugosa lipase[J]. Process Biochemistry, 2005, 40(6): 2155-2159. |

| 32 | Gomes F M , Pereira E B , De Castro H F . Immobilization of lipase on chitin and its use in nonconventional biocatalysis[J]. Biomacromolecules, 2004, 5(1): 17-23. |

| 33 | Ivanov A E , Schneider M P . Methods for the immobilization of lipases and their use for ester synthesis[J]. Journal of Molecular Catalysis B: Enzymatic, 1997, 3(6): 303-309. |

| 34 | Wong S S , Wong L J C . Chemical crosslinking and the stabilization of proteins and enzymes[J]. Enzyme and Microbial Technology, 1992, 14(11): 866-874. |

| 35 | Kai S , Kienle A . Reactive Distillation: Status and Future Directions[M]. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2003. |

| 36 | Lawrence A , Smith J . Catalytic distillation structure: US4443559[P].1984-04-17. |

| 37 | Lawrence A , Smith J . Process for separating isobutene from C4 streams: US4242530.1[P].1980-12-30. |

| 38 | Akbarnejad M M , Safekordi A A , Zarrinpashne S . A study on the capacity of reactive distillation bale packings: experimental measurements, evaluation of the existing models, and preparation of a new model[J]. Industrial & Engineering Chemistry Research, 2000, 39(8): 3051-3058. |

| 39 | Götze L , Bailer O , Moritz P , et al . Reactive distillation with Katapak® [J]. Catalysis Today, 2001, 69(1): 201-208. |

| 40 | Han M H , Lin H F , Wang L W , et al . Characteristics of the reactive distillation column with a novel internal[J]. Chemical Engineering Science, 2002, 57(9): 1551-1555. |

| 41 | Li J M , Ding H D , Xiang W Y , et al . Hydraulic performance of Winpak-C modular catalytic structured packing[J]. The Canadian Journal of Chemical Engineering, 2016, 94(3): 556-564. |

| 42 | Wang Q L , Yang C , Wang H X , et al . Optimization of process-specific catalytic packing in catalytic distillation process: a multi-scale strategy[J]. Chemical Engineering Science, 2017, 174(1): 472-486. |

| 43 | Heils R , Niesbach A , Wierschem M , et al . Integration of enzymatic catalysts in a continuous reactive distillation column: reaction kinetics and process simulation[J]. Industrial & Engineering Chemistry Research, 2014, 53(50): 19612-19619. |

| 44 | Oudshoorn O L , Janissen M , Van Kooten W E J , et al . A novel structured catalyst packing for catalytic distillation of ETBE[J]. Chemical Engineering Science, 1999, 54(10): 1413-1418. |

| 45 | Dechaine G P , Ng F T T . A new coated catalyst for the production of diacetone alcohol via catalytic distillation[J]. Industrial & Engineering Chemistry Research, 2008, 47(23): 9304-9313. |

| 46 | Li Y , Huang S , Wu S , et al . Preparation and catalytic distillation testing of an acidic zeolite film catalytic packing for synthesis of ETBE[J]. Catalysis Letters, 2003, 87(1/2):31-35. |

| 47 | Deng T , Ding J , Zhao G , et al . Catalytic distillation for esterification of acetic acid with ethanol: promising SS-fiber@HZSM-5 catalytic packings and experimental optimization via response surface methodology[J]. Journal of Chemical Technology & Biotechnology, 2018, 93(3): 827-841. |

| 48 | Shan Z , Kooten W E J V , Oudshoorn O L , et al . Optimization of the preparation of binderless ZSM-5 coatings on stainless steel monoliths by in situ hydrothermal synthesis[J]. Microporous & Mesoporous Materials, 2000, 34(1):81-91. |

| 49 | Heils R , Sont A , Bubenheim P , et al . Integration of enzymatic catalysts in a reactive distillation column with structured packings[J]. Industrial & Engineering Chemistry Research, 2012, 51(35): 11482-11489. |

| 50 | Heils R , Hu X , Liese A , et al . In situ production and renewal of biocatalytic coatings for use in enzymatic reactive distillation[J]. Chemical Engineering Journal, 2016, 306(1): 992-1000. |

| 51 | Heils R , Jensen J H , Wichert S , et al . Enzymatic reactive distillation: kinetic resolution of rac-2-pentanol with biocatalytic coatings on structured packings[J]. Industrial & Engineering Chemistry Research, 2015, 54(38): 9458-9467. |

| 52 | Kiss A A . Novel catalytic reactive distillation processes for a sustainable chemical industry[J]. Topics in Catalysis, 2018, 1(1): 1-17. |

| 53 | Kiss A A , Jobson M , Gao X . Reactive distillation: stepping up to the next level of process intensification[J]. Industrial & Engineering Chemistry Research, 2018, 58(15): 5909-5918. |

| 54 | Taylor R , Krishna R . Modelling reactive distillation[J]. Chemical Engineering Science, 2000, 55(22): 5183-5229. |

| 55 | Tuchlenski A , Beckmann A , Reusch D , et al . Reactive distillation-industrial applications, process design & scale-up[J]. Chemical Engineering Science, 2001, 56(2): 387-394. |

| 56 | Schoenmakers H G , Bessling B . Reactive and catalytic distillation from an industrial perspective[J]. Chemical Engineering and Processing: Process Intensification, 2003, 42(3): 145-155. |

| 57 | Harmsen G J . Reactive distillation: the front-runner of industrial process intensification: a full review of commercial applications, research, scale-up, design and operation [J]. Chemical Engineering and Processing: Process Intensification, 2007, 46(9): 774-780. |

| 58 | Moulijn J A , Stankiewicz A , Grievink J , et al . Process intensification and process systems engineering: a friendly symbiosis[J]. Computers & Chemical Engineering, 2008, 32(1): 3-11. |

| 59 | 高鑫, 赵悦, 李洪, 等 . 反应精馏过程耦合强化技术基础与应用研究述评[J]. 化工学报, 2018, 69(1): 218-238. |

| Gao X , Zhao Y , Li H , et al . Review of basic and application investigation of reactive distillation technology for process intensification[J]. CIESC Journal, 2018, 69(1): 218-238. | |

| 60 | Paiva A L , Rossum D V , Malcata F X . Lipase-catalyzed synthesis of butyl butyrate by alcoholysis in an integrated liquid-vapor system[J]. Biotechnology Progress, 2003, 19(3): 750-754. |

| 61 | Wierschem M , Schlimper S , Heils R , et al . Pilot-scale validation of enzymatic reactive distillation for butyl butyrate production[J]. Chemical Engineering Journal, 2017, 312(1): 106-117. |

| 62 | Wang X , Wang H , Chen J , et al . High conversion of methyl acetate hydrolysis in a reactive dividing wall column by weakening the self-catalyzed esterification reaction[J]. Industrial & Engineering Chemistry Research, 2017, 56(32): 9177-9187. |

| 63 | 凌笑媚, 郑伟跃, 王晓达, 等 . 隔壁反应精馏技术进展[J]. 化工进展, 2017, 36(1): 2776-2786. |

| Ling X M , Zheng W Y , Wang X D , et al . Advances in technology of reactive dividing wall column[J]. Chemical Industry and Engineering Progress, 2017, 36(1): 2776-2786. | |

| 64 | Mueller I , Kenig E Y . Reactive distillation in a dividing wall column: rate-based modeling and simulation[J]. Industrial & Engineering Chemistry Research, 2007, 46(11): 3709-3719. |

| 65 | Weinfeld J A , Owens S A , Eldridge R B . Reactive dividing wall columns: a comprehensive review[J]. Chemical Engineering and Processing: Process Intensification, 2018, 123(1): 20-33. |

| 66 | Egger T , Fieg G . Enzymatic catalyzed reactive dividing wall column: experiments and model validation[J]. AIChE Journal, 2017, 63(1): 2198-2211. |

| 67 | Egger T , Fieg G . Dynamic process behavior and model validation of reactive dividing wall columns[J]. Chemical Engineering Science, 2018, 179(1): 284-295. |

| 68 | Kiss A A , Geertman R , Wierschem M , et al . Ultrasound-assisted emerging technologies for chemical processes[J]. Journal of Chemical Technology & Biotechnology, 2018, 93(1): 1219-1227. |

| 69 | Wierschem M , Walz O , Mitsos A , et al . Enzyme kinetics for the transesterification of ethyl butyrate with enzyme beads, coated packing and ultrasound assistance[J]. Chemical Engineering and Processing: Process Intensification, 2017, 111(1): 25-34. |

| 70 | Wierschem M , Skiborowski M , Górak A , et al . Techno-economic evaluation of an ultrasound-assisted enzymatic reactive distillation process[J]. Computers and Chemical Engineering, 2017, 105(1): 123-131. |

| 71 | Baur R , Krishna R . Distillation column with reactive pump arounds: an alternative to reactive distillation[J]. Chemical Engineering and Processing: Process Intensification, 2004, 43(3): 435-445. |

| 72 | Hussain A , Lee M . Optimal design of an intensified column with side-reactor configuration for the methoxy-methylheptane process[J]. Chemical Engineering Research and Design, 2018, 136(1): 11-24. |

| 73 | Wierschem M , Boll S , Lutze P , et al . Evaluation of the enzymatic reactive distillation for the production of chiral compounds[J]. Chemie Ingenieur Technik, 2016, 88(1): 147-157. |

| 74 | Wierschem M , Langen A A , Lins J , et al . Model validation for enzymatic reactive distillation to produce chiral compounds[J]. Journal of Chemical Technology & Biotechnology, 2018, 93(1): 498-507. |

| 75 | Kühn S , Sluyter G , Christlieb M A , et al . In situ separation of the chiral target compound (S)-2-pentanol in biocatalytic reactive distillation[J]. Industrial & Engineering Chemistry Research, 2017, 56(22): 6451-6461. |

| 76 | Au-Yeung P H , Resnick S M , Witt P M , et al . Horizontal reactive distillation for multicomponent chiral resolution[J]. AIChE Journal, 2013, 59(1): 2603-2620. |

| 77 | Egger T , Egger L S , Fieg G . Scale and causes of catalyst activity loss in enzymatic catalyzed reactive distillation[J]. Chemical Engineering Science, 2018, 178(1): 324-334. |

| [1] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [2] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [3] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [4] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [5] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [6] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [7] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [8] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [9] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [10] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [11] | 陈雅鑫, 袁航, 刘冠章, 毛磊, 杨纯, 张瑞芳, 张光亚. 蛋白质纳米笼介导的酶自固定化研究进展[J]. 化工学报, 2023, 74(7): 2773-2782. |

| [12] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [13] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [14] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [15] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号