化工学报 ›› 2019, Vol. 70 ›› Issue (S2): 76-84.DOI: 10.11949/0438-1157.20190493

收稿日期:2019-05-09

修回日期:2019-07-11

出版日期:2019-09-06

发布日期:2019-09-06

通讯作者:

叶树亮

作者简介:侯德鑫(1983—),男,硕士,实验师,基金资助:

Dexin HOU( ),Yue CHEN,Shuliang YE(

),Yue CHEN,Shuliang YE( )

)

Received:2019-05-09

Revised:2019-07-11

Online:2019-09-06

Published:2019-09-06

Contact:

Shuliang YE

摘要:

导热石墨膜广泛用于电子设备中的发热器件散热,面向热导率是反映其传热性能的关键参数,但目前行业中一般只提供裸材数据,无法对背胶石墨膜进行测试,给石墨膜用户的热设计和产品质量管理带来不便。提出一种基于热成像的背胶石墨膜面向热导率稳态测试方法,样品直接黏附于平整台面测试,通过温度梯度环路积分消除热流不均匀的影响,通过热损失标定减小表面换热和旁路传热带来的测试误差。基于多种规格石墨膜产品和具有参考数据的金属薄片进行实验,结果证明了方法的有效性。背胶石墨膜测试数据和裸材参数的比较表明二者有很大偏差,表明石墨膜产品标称参数和实际参数可能有较大偏差,应用中需直接测试背胶石墨膜参数。

中图分类号:

侯德鑫,陈玥,叶树亮. 基于热成像的背胶石墨膜面向热导率测试方法[J]. 化工学报, 2019, 70(S2): 76-84.

Dexin HOU,Yue CHEN,Shuliang YE. Measurement of in-plane thermal conductivity of glued graphite film based on thermal imaging[J]. CIESC Journal, 2019, 70(S2): 76-84.

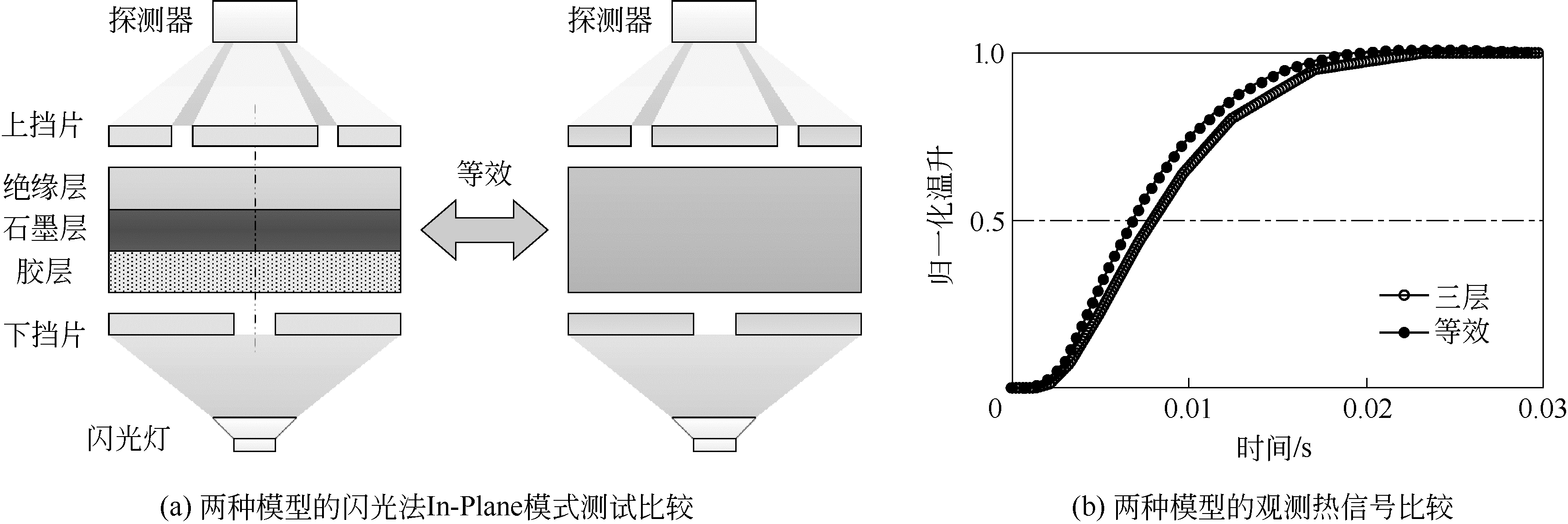

图1 闪光法In-Plane模式测试时多层复合结构与单一均质等效模型对比

Fig.1 Comparison of multilayer composite structure and single homogeneous equivalent model in Flash In-Plane mode testing

| 薄层材料 | 密度/ (kg·m-3) | 比热容/ (J·kg-1·K-1) | 面向热导率/ (W·m-1·K-1) | 纵向热导率/ (W·m-1·K-1) | 厚度/μm |

|---|---|---|---|---|---|

| 绝缘层 | 1200 | 2000 | 0.25 | 0.25 | 15 |

| 石墨层 | 1900 | 850 | 1500 | 10 | 25 |

| 胶层 | 800 | 2000 | 1 | 1 | 20 |

表1 背胶石墨膜结构和材料参数

Table 1 Structure and material parameters of glued graphite film

| 薄层材料 | 密度/ (kg·m-3) | 比热容/ (J·kg-1·K-1) | 面向热导率/ (W·m-1·K-1) | 纵向热导率/ (W·m-1·K-1) | 厚度/μm |

|---|---|---|---|---|---|

| 绝缘层 | 1200 | 2000 | 0.25 | 0.25 | 15 |

| 石墨层 | 1900 | 850 | 1500 | 10 | 25 |

| 胶层 | 800 | 2000 | 1 | 1 | 20 |

| 模型 | 密度/(kg·m-3) | 比热容/(J·kg-1·K-1) | 面向热导率/(W·m-1·K-1) | 纵向热导率/(W·m-1·K-1) | 厚度/μm |

|---|---|---|---|---|---|

| 稳态等效 | 1358 | 1330 | 625 | 0.73 | 60 |

表2 等效的单一均质材料参数

Table 2 Equivalent single homogeneous material parameters

| 模型 | 密度/(kg·m-3) | 比热容/(J·kg-1·K-1) | 面向热导率/(W·m-1·K-1) | 纵向热导率/(W·m-1·K-1) | 厚度/μm |

|---|---|---|---|---|---|

| 稳态等效 | 1358 | 1330 | 625 | 0.73 | 60 |

| 编号 | 材料 | 厚度/mm | 面向热导率参考值/( W·m-1·K-1) | 面向热导率测试值/(W·m-1·K-1) | 相对偏差/% |

|---|---|---|---|---|---|

| 1 | 1060 | 0.17 | 234 | 255 | 9.0 |

| 2 | 304 | 0.34 | 16 | 17.1 | 6.7 |

| 3 | 304 | 0.44 | 16 | 16.1 | 0.7 |

| 4 | 304 | 0.44 | 16 | 16.5 | 2.9 |

| 5 | 5020 | 0.46 | 138 | 132 | -4.0 |

| 6 | T2 | 0.58 | 407 | 394 | -3.1 |

| 7 | 1060 | 0.46 | 234 | 225 | -3.8 |

| 8 | A3 | 0.49 | 80 | 71.8 | -10.2 |

| 9 | H62 | 0.39 | 108.9 | 115 | 5.7 |

| 10 | H62 | 0.48 | 108.9 | 108 | -0.5 |

| 11 | T2 | 0.39 | 407 | 386 | -5.1 |

| 12 | T2 | 0.39 | 407 | 400 | -1.8 |

| 13 | 1060 | 0.17 | 234 | 255 | 9.0 |

| 14 | A3 | 0.30 | 80 | 83.3 | 4.2 |

表3 金属薄片面向热导率测试结果

Table 3 In-plane thermal conductivity test results of metal sheets

| 编号 | 材料 | 厚度/mm | 面向热导率参考值/( W·m-1·K-1) | 面向热导率测试值/(W·m-1·K-1) | 相对偏差/% |

|---|---|---|---|---|---|

| 1 | 1060 | 0.17 | 234 | 255 | 9.0 |

| 2 | 304 | 0.34 | 16 | 17.1 | 6.7 |

| 3 | 304 | 0.44 | 16 | 16.1 | 0.7 |

| 4 | 304 | 0.44 | 16 | 16.5 | 2.9 |

| 5 | 5020 | 0.46 | 138 | 132 | -4.0 |

| 6 | T2 | 0.58 | 407 | 394 | -3.1 |

| 7 | 1060 | 0.46 | 234 | 225 | -3.8 |

| 8 | A3 | 0.49 | 80 | 71.8 | -10.2 |

| 9 | H62 | 0.39 | 108.9 | 115 | 5.7 |

| 10 | H62 | 0.48 | 108.9 | 108 | -0.5 |

| 11 | T2 | 0.39 | 407 | 386 | -5.1 |

| 12 | T2 | 0.39 | 407 | 400 | -1.8 |

| 13 | 1060 | 0.17 | 234 | 255 | 9.0 |

| 14 | A3 | 0.30 | 80 | 83.3 | 4.2 |

| 石墨膜规格 | 面向热导率/( W·m-1·K-1) | |||||

|---|---|---|---|---|---|---|

| 测试1 | 测试2 | 测试3 | 均值 | 标准差 | 相对标准差/% | |

| 17 μm单层背胶 | 945 | 977 | 984 | 969 | 20.8 | 2.1 |

| 17 μm双层背胶 | 529 | 524 | 539 | 531 | 7.6 | 1.4 |

| 25 μm单层背胶 | 672 | 674 | 667 | 671 | 3.6 | 0.5 |

| 25 μm双层背胶 | 800 | 829 | 805 | 811 | 15.5 | 1.9 |

| 40 μm单层背胶(A款) | 681 | 663 | 657 | 667 | 12.5 | 1.9 |

| 40 μm单层背胶(B款) | 642 | 660 | 651 | 651 | 9.0 | 1.4 |

| 40 μm双层背胶 | 725 | 713 | 755 | 731 | 21.6 | 3.0 |

表4 石墨膜样品面向热导率测试结果

Table 4 In-plane thermal conductivity test results of graphite film samples

| 石墨膜规格 | 面向热导率/( W·m-1·K-1) | |||||

|---|---|---|---|---|---|---|

| 测试1 | 测试2 | 测试3 | 均值 | 标准差 | 相对标准差/% | |

| 17 μm单层背胶 | 945 | 977 | 984 | 969 | 20.8 | 2.1 |

| 17 μm双层背胶 | 529 | 524 | 539 | 531 | 7.6 | 1.4 |

| 25 μm单层背胶 | 672 | 674 | 667 | 671 | 3.6 | 0.5 |

| 25 μm双层背胶 | 800 | 829 | 805 | 811 | 15.5 | 1.9 |

| 40 μm单层背胶(A款) | 681 | 663 | 657 | 667 | 12.5 | 1.9 |

| 40 μm单层背胶(B款) | 642 | 660 | 651 | 651 | 9.0 | 1.4 |

| 40 μm双层背胶 | 725 | 713 | 755 | 731 | 21.6 | 3.0 |

| 石墨膜裸材规格 | 厚度/μm | 密度/(g·cm-3) | 闪光法测试/ (W·m-1·K-1) |

|---|---|---|---|

| 17 μm裸材 | 18 | 1.979 | 1588 |

| 25 μm裸材 | 26 | 1.882 | 1398 |

| 40 μm裸材 | 40 | 1.978 | 1464 |

表5 裸材样品的闪光法测试数据

Table 5 Flash test data of bare sample

| 石墨膜裸材规格 | 厚度/μm | 密度/(g·cm-3) | 闪光法测试/ (W·m-1·K-1) |

|---|---|---|---|

| 17 μm裸材 | 18 | 1.979 | 1588 |

| 25 μm裸材 | 26 | 1.882 | 1398 |

| 40 μm裸材 | 40 | 1.978 | 1464 |

| 石墨膜规格 | 总厚/μm | 实测密度/ (kg·m-3) | 密度预测/ (kg·m-3) | 热导率预测/ (W·m-1·K-1) | 本文测试/ (W·m-1·K-1) | 相对偏差/% |

|---|---|---|---|---|---|---|

| 17 μm单层背胶 | 35 | 1785 | 1424 | 771 | 969 | 23 |

| 17 μm双层背胶 | 90 | 1002 | 1308 | 600 | 531 | -12 |

| 25 μm单层背胶 | 40 | 1317 | 1514 | 874 | 671 | -26 |

| 25 μm双层背胶 | 80 | 1548 | 1514 | 874 | 811 | -7.5 |

| 40 μm单层背胶A款 | 65 | 1354 | 1563 | 901 | 667 | -30 |

| 40 μm单层背胶B款 | 55 | 1222 | 1684 | 1065 | 651 | -48 |

| 40 μm双层背胶 | 125 | 1467 | 1590 | 937 | 731 | -25 |

表6 石墨膜样品测试数据和基于裸材预测的数据对比

Table 6 Comparison of graphite film sample test data and bare material prediction data

| 石墨膜规格 | 总厚/μm | 实测密度/ (kg·m-3) | 密度预测/ (kg·m-3) | 热导率预测/ (W·m-1·K-1) | 本文测试/ (W·m-1·K-1) | 相对偏差/% |

|---|---|---|---|---|---|---|

| 17 μm单层背胶 | 35 | 1785 | 1424 | 771 | 969 | 23 |

| 17 μm双层背胶 | 90 | 1002 | 1308 | 600 | 531 | -12 |

| 25 μm单层背胶 | 40 | 1317 | 1514 | 874 | 671 | -26 |

| 25 μm双层背胶 | 80 | 1548 | 1514 | 874 | 811 | -7.5 |

| 40 μm单层背胶A款 | 65 | 1354 | 1563 | 901 | 667 | -30 |

| 40 μm单层背胶B款 | 55 | 1222 | 1684 | 1065 | 651 | -48 |

| 40 μm双层背胶 | 125 | 1467 | 1590 | 937 | 731 | -25 |

| 1 | Takasugi H , Teraki S , Kurokawa T , et al . Development of the thin film with high thermal conductivity for power devices[C]// IEEE Components, Packaging and Manufacturing Technology Society. 2014 IEEE 64th Electronic Components and Technology Conference (ECTC). Florida, USA: IEEE, 2014: 1776-1781. |

| 2 | 姜辉 . 基于石墨烯/铜复合材料的散热薄膜导热性能研究[D]. 南京: 南京航空航天大学, 2017. |

| Jiang H . Research on thermal conductance of thin films based on graphene / copper composite[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017. | |

| 3 | Sharma S , Kumar P , Chandra R . Mechanical and thermal properties of grapheme-carbon nanotube-reinforced metal matrix composites: a molecular dynamics study[J]. Journal of Composite Materials, 2017, 51(23): 3299-3313. |

| 4 | 周春玉, 曾亮, 吉莉, 等 . 石墨烯及其复合材料导热性能的研究现状[J]. 材料开发与应用, 2010, 25(6): 94-100. |

| Zhou C Y , Zeng L , Ji L , et al . Research on the thermal conductivities of graphene and graphene based composite materials[J]. Development and Application of Materials, 2010, 25(6): 94-100. | |

| 5 | Yan Z , Nika D L , Balandin A A . Thermal properties of graphene and few-layer graphene: applications in electronics[J]. IET Circuits, Devices & Systems, 2015, 9(1): 4-12. |

| 6 | 张建生, 杨君友, 朱文, 等 . 薄膜热导率测试方法研究进展[J]. 材料导报, 2010, 24(7): 103-107. |

| Zhang J S , Yang J Y , Zhu W , et al . Research advances in the measurement for the thermal conductivity of thin solid films[J]. Materials Review, 2010, 24(7): 103-107. | |

| 7 | 刘珊, 徐梁, 曾智强 . 微米级超薄石墨膜的导热性能测试[J]. 炭素, 2017, (4): 42-45. |

| Liu S , Xu L , Zeng Z Q . Thermal conductivity testing of thin graphite films[J]. Carbon, 2017, (4): 42-45. | |

| 8 | 厉阳, 侯德鑫, 叶树亮 . 基于热成像的材料热扩散率测量方法研究[J].计量学报, 2017, 38(1): 28-33. |

| Li Y , Hou D X , Ye S L . Research on measurement method of thermal diffusivity of materials based on thermography[J]. Acta Metrologica Sinica, 2017, 38(1): 28-33. | |

| 9 | 朱玉祥 . 改进型瞬态平面热源法的实验研究[D]. 青岛: 青岛理工大学, 2015. |

| Zhu Y X . Experimental study of improved transient plane source[D]. Qingdao: Qingdao University of Technology, 2015. | |

| 10 | Ruffio E , Saury D , Petit D . Improvement and comparison of some estimators dedicated to thermal diffusivity estimation of orthotropic materials with the 3D-flash method[J]. International Journal of Heat & Mass Transfer, 2013, 64(64): 1064-1081. |

| 11 | Krapez J C , Spagnolo L , Frieß M , et al . Measurement of in-plane diffusivity in non-homogeneous slabs by applying flash thermography[J]. International Journal of Thermal Sciences, 2004, 43(10): 967-977. |

| 12 | Forte G , Ronca S . Laser-flash in-plane thermal analysis: the case of oriented UHMWPE[C]// Ⅷ International Conference on “Times of Polymers and Composites”, AIP Conference Proceedings. Naples, Italy: AIP Publishing, 2016, 1736(1): 020171. |

| 13 | Zacharia S G , Siddiqui A O , Lahiri J . In situ thermal diffusivity determination of anisotropic composite structures: transverse diffusivity measurement[J]. NDT & E International, 2012, 48: 1-9. |

| 14 | Ruoho M , Valset K , Finstad T , et al . Measurement of thin film thermal conductivity using the laser flash method[J]. Nanotechnology, 2015, 26(19): 195706. |

| 15 | Ma L , Srivastava R , Barpanda D , et al . An inverse approach to characterize anisotropic thermal conductivities of a dry fibrous preform composite[J]. Journal of Reinforced Plastics & Composites, 2013, 32(24): 1916-1927. |

| 16 | Lei Z , Zhu S K , Pan N . Transient methods of thermal properties measurement on fibrous materials[J]. Journal of Heat Transfer, 2010, 132(3): 39-51. |

| 17 | 江楠竹, 潘江, 王玉刚, 等 . TPS法导热系数测量的仿真分析[J]. 中国测试, 2016, 42(6): 122-126. |

| Jiang N Z , Pan J , Wang Y G , et al . Simulation and analysis of thermal conductivity measurement with TPS method[J]. China Measurement & Testing Technology, 2016, 42(6): 122-126. | |

| 18 | 周倩楠 . 石墨烯/碳纳米管/环氧树脂复合材料的导热性能的实验研究[D]. 青岛: 青岛理工大学, 2018. |

| Zhou Q N . Experimental study on thermal conductivity of GP / MWCNTs /EP composites[D]. Qingdao: Qingdao University of Technology, 2018. | |

| 19 | 翟德怀 . 基于Hot Disk的薄板材料导热系数测量方法的研究[D]. 广州: 华南理工大学, 2015. |

| Zhai D H . Study on the thermal conductivity measurement of thin samples by Hot Disk thermal constants analyser[D]. Guangzhou: South China University of Technology, 2015. | |

| 20 | Wang Y W , Li Y N . Influence of heat loss through probe electrical leads on thermal conductivity measurement with TPS method[J]. Journal of Measurement Science & Instrumentation, 2018, 9(1): 9-15. |

| 21 | Beyerle R , Smalc M , Wayne R , et al . A comparison of methods to measure the thermal diffusivity of anisotropic graphite heat spreaders[C]// Electronic and Photonic Packaging Division, ASME 2013 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems. California, USA: American Society of Mechanical Engineers, 2013: V002T08A022. |

| 22 | 邓玉杰 . 基于3ω法体块和薄膜材料热物性的研究[D]. 南京: 南京大学, 2016. |

| Deng Y J . Study on buification and thin-film thermal properties based on the 3ω method[D]. Nanjing: Nanjing University, 2016. | |

| 23 | 何龙 . 3ω法在薄膜界面热阻测量中的应用[D]. 成都: 电子科技大学, 2016. |

| He L . Application of the 3-omega method on measuring the interfacial thermal resistance in thin films[D]. Chengdu: University of Electronic Science and Technology of China, 2016. | |

| 24 | 苏国萍, 唐大伟, 郑兴华, 等 . 3ω方法测量各向异性SiC晶体的导热系数[J]. 工程热物理学报, 2011, 32(11): 1885-1888. |

| Su G P , Tang D W , Zheng X H , et al . Determination of thermal conductivity of anisotropic SiC crystal using 3ω method[J]. Journal of Engineering Thermophysics, 2011, 32(11): 1885-1888. | |

| 25 | Zhu Y . Heat-loss modified Angstrom method for simultaneous measurements of thermal diffusivity and conductivity of graphite sheets: the origins of heat loss in Angstrom method[J]. International Journal of Heat and Mass Transfer, 2016, 92: 784-791. |

| 26 | Ras M A , May D , Wunderle B . Novel test stand for thermal diffusivity measurement of bulk and thin films[C]// 2016 22nd International Workshop on Thermal Investigations of ICs and Systems (THERMINIC). Budapest, Hungary: IEEE, 2016: 243-249. |

| 27 | Aaron K , Tang X , Tritt T M . Measurement of the in-plane thermal conductivity of single crystals by the parallel thermal conductance technique[C]// ICT 2005 International Conference on Thermoelectrics. SC, USA: IEEE, 2005: 87-90. |

| 28 | Teertstra P , Karimi G , Li X . Measurement of in-plane effective thermal conductivity in PEM fuel cell diffusion media[J]. Electrochimica Acta, 2011, 56(3): 1670-1675. |

| 29 | Sadeghi E , Djilali N , Bahrami M . A novel approach to determine the in-plane thermal conductivity of gas diffusion layers in proton exchange membrane fuel cells[J]. Journal of Power Sources, 2011, 196(7): 3565-3571. |

| 30 | Gholami A , Ahmadi M , Bahrami M . A modified steady state method for measurement of in-plane thermal conductivity[C]// 32nd Thermal Measurement, Modeling & Management Symposium (SEMI-THERM). Alabama, USA: IEEE, 2016: 22-26. |

| 31 | 蔡北虎, 董德平, 屈金祥 . 国产石墨薄膜低温导热系数测量[J]. 低温工程, 2008, (1): 29-32. |

| Cai B H , Dong D P , Qu J X . Measurement of thermal conductivity for home-made graphite sheet at low temperature[J]. Cryogenics, 2008, (1): 29-32. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [4] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [5] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [6] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [7] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [8] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [9] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [10] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [11] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [12] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [13] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [14] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [15] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号