化工学报 ›› 2020, Vol. 71 ›› Issue (8): 3416-3427.DOI: 10.11949/0438-1157.20200191

仉利1,2( ),姚宗路2,赵立欣1,2(

),姚宗路2,赵立欣1,2( ),李志合1,易维明1,付鹏1,袁超3

),李志合1,易维明1,付鹏1,袁超3

收稿日期:2020-02-27

修回日期:2020-03-26

出版日期:2020-08-05

发布日期:2020-08-05

通讯作者:

赵立欣

作者简介:仉利(1988—),女,博士研究生,基金资助:

Li ZHANG1,2( ),Zonglu YAO2,Lixin ZHAO1,2(

),Zonglu YAO2,Lixin ZHAO1,2( ),Zhihe LI1,Weiming YI1,Peng FU1,Chao YUAN3

),Zhihe LI1,Weiming YI1,Peng FU1,Chao YUAN3

Received:2020-02-27

Revised:2020-03-26

Online:2020-08-05

Published:2020-08-05

Contact:

Lixin ZHAO

摘要:

生物质通过热化学转化制备高品质生物油和高附加值精细化工品是未来工业发展的重要方向,是解决能源短缺、实现碳的闭路循环的有效方式,如何提升生物质热化学转化品质和效率是目前学术界和工业界关注的热点。本文介绍了不同技术路径下的生物质热化学转化研究进展,重点阐述了催化热解、水热催化、化学链转化三种方式的反应机理及其催化剂类型,讨论了生物质热化学转化提质策略。最后,针对生物质热化学转化目前尚存在的问题提出建议,期望为生物质高值化利用提供参考和借鉴。

中图分类号:

仉利, 姚宗路, 赵立欣, 李志合, 易维明, 付鹏, 袁超. 生物质热化学转化提质及其催化剂研究进展[J]. 化工学报, 2020, 71(8): 3416-3427.

Li ZHANG, Zonglu YAO, Lixin ZHAO, Zhihe LI, Weiming YI, Peng FU, Chao YUAN. Research progress on thermochemical conversion of biomass to enhance quality and catalyst[J]. CIESC Journal, 2020, 71(8): 3416-3427.

| 转化路径 | 转化条件 | 转化产物 | 产物利用价值 | 转化特点 | 文献 |

|---|---|---|---|---|---|

| 燃烧 | 富氧、着火点 | 能量、CO2、H2O等 | 热力、电力等 | 能源利用率低,环境污染大 | [ |

| 催化热解 | 缺氧或少氧 高温(300~1500℃) | 热解气、生物油、生物炭 | 热力、电力、活性炭、燃气、 液体燃料、化学品等 | 设备要求低,转化效率高,技术成熟 | [ |

| 水热催化 | 缺氧或少氧 高压(5~25 MPa) 高温(200~600℃) | 热解气、生物油、生物炭 | 热力、电力、活性炭、燃气、 液体燃料、化学品等 | (1)水作为溶剂或催化反应介质,绿色环保无污染; (2)水热催化传质传热速率较快,反应迅速,节约能量; (3)生物质原材料无须脱水,经定向反应后产物收率较高 | [ |

| 化学链转化 | 高温(700~1000℃)氧载体 | 能量、CO2、H2O、合成 气等 | 热力、电力、干冰、燃气等 | (1)燃料反应器中产物为CO2和水蒸气,可通过冷凝实现CO2内分离; (2)空气反应器中温度较低避免了NOx的生成,降低了环境污染; (3)分步转化过程实现了能量梯级利用,提高了能量的利用率 | [ |

表1 生物质热化学转化路径及其特点

Table 1 Path and characteristics of biomass thermochemical conversion

| 转化路径 | 转化条件 | 转化产物 | 产物利用价值 | 转化特点 | 文献 |

|---|---|---|---|---|---|

| 燃烧 | 富氧、着火点 | 能量、CO2、H2O等 | 热力、电力等 | 能源利用率低,环境污染大 | [ |

| 催化热解 | 缺氧或少氧 高温(300~1500℃) | 热解气、生物油、生物炭 | 热力、电力、活性炭、燃气、 液体燃料、化学品等 | 设备要求低,转化效率高,技术成熟 | [ |

| 水热催化 | 缺氧或少氧 高压(5~25 MPa) 高温(200~600℃) | 热解气、生物油、生物炭 | 热力、电力、活性炭、燃气、 液体燃料、化学品等 | (1)水作为溶剂或催化反应介质,绿色环保无污染; (2)水热催化传质传热速率较快,反应迅速,节约能量; (3)生物质原材料无须脱水,经定向反应后产物收率较高 | [ |

| 化学链转化 | 高温(700~1000℃)氧载体 | 能量、CO2、H2O、合成 气等 | 热力、电力、干冰、燃气等 | (1)燃料反应器中产物为CO2和水蒸气,可通过冷凝实现CO2内分离; (2)空气反应器中温度较低避免了NOx的生成,降低了环境污染; (3)分步转化过程实现了能量梯级利用,提高了能量的利用率 | [ |

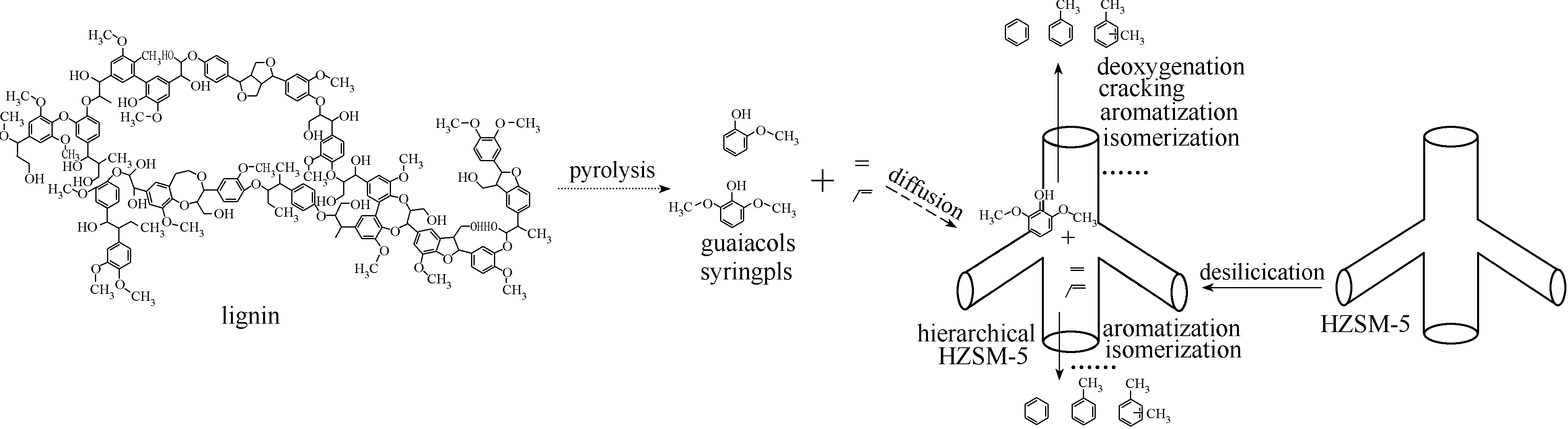

图2 碱改性HZSM-5分子筛与木质素催化热解反应路线[41]

Fig.2 Reaction path of catalytic pyrolysis of lignin over hierarchical HZSM-5 zeolites prepared by post-treatment with alkaline solutions[41]

图3 木质素在赤泥与HZSM-5两级催化系统下的反应路径[52]

Fig.3 Reaction path of catalytic pyrolysis of lignin in a cascade dual-catalyst system of modified red mud and HZSM-5[52]

| 1 | Pang S. Advances in thermochemical conversion of woody biomass to energy, fuels and chemicals[J]. Biotechnology Advances, 2019, 37(4): 589-597. |

| 2 | Mitsos A, Asprion N, Floudas C A, et al. Challenges in process optimization for new feedstocks and energy sources[J]. Computers & Chemical Engineering, 2018, 113: 209-221. |

| 3 | Mohapatra S, Mishra C, Behera S S, et al. Application of pretreatment, fermentation and molecular techniques for enhancing bioethanol production from grass biomass—a review[J]. Renewable and Sustainable Energy Reviews, 2017, 78: 1007-1032. |

| 4 | Balat M. Biomass energy and biochemical conversion processing for fuels and chemicals[J]. Energy Sources, Part A, 2006, 28(6): 517-525. |

| 5 | Azizi K, Moraveji M K, Najafabadi H A. A review on bio-fuel production from microalgal biomass by using pyrolysis method[J]. Renewable and Sustainable Energy Reviews, 2018, 82: 3046-3059. |

| 6 | Chen W H, Lin B J, Huang M Y, et al. Thermochemical conversion of microalgal biomass into biofuels: a review[J]. Bioresource Technology, 2015, 184: 314-327. |

| 7 | Kan T, Strezov V, Evans T J. Lignocellulosic biomass pyrolysis: a review of product properties and effects of pyrolysis parameters[J]. Renewable and Sustainable Energy Reviews, 2016, 57: 1126-1140. |

| 8 | Sansaniwal S K, Pal K, Rosen M A, et al. Recent advances in the development of biomass gasification technology: a comprehensive review[J]. Renewable and Sustainable Energy Reviews, 2017, 72: 363-384. |

| 9 | Du L, Shao Y, Sun J, et al. Electrocatalytic valorisation of biomass derived chemicals[J]. Catalysis Science & Technology, 2018, 8(13): 3216-3232. |

| 10 | Nilges P, dos Santos T R, Harnisch F, et al. Electrochemistry for biofuel generation: electrochemical conversion of levulinic acid to octane[J]. Energy & Environmental Science, 2012, 5(1): 5231-5235. |

| 11 | Isahak W N R W, Hisham M W M, Yarmo M A, et al. A review on bio-oil production from biomass by using pyrolysis method[J]. Renewable and Sustainable Energy Reviews, 2012, 16(8): 5910-5923. |

| 12 | Kan T, Strezov V, Evans T J. Lignocellulosic biomass pyrolysis: a review of product properties and effects of pyrolysis parameters[J]. Renewable and Sustainable Energy Reviews, 2016, 57: 1126-1140. |

| 13 | Ong H C, Chen W H, Farooq A, et al. Catalytic thermochemical conversion of biomass for biofuel production: a comprehensive review[J]. Renewable and Sustainable Energy Reviews, 2019, 113: 109266. |

| 14 | Adanez J, Abad A, Garcia-Labiano F, et al. Progress in chemical-looping combustion and reforming technologies[J]. Progress in Energy and Combustion Science, 2012, 38(2): 215-282. |

| 15 | Saidur R, Abdelaziz E A, Demirbas A, et al. A review on biomass as a fuel for boilers[J]. Renewable and Sustainable Energy Reviews, 2011, 15(5): 2262-2289. |

| 16 | Abuelnuor A A A, Wahid M A, Hosseini S E, et al. Characteristics of biomass in flameless combustion: a review[J]. Renewable and Sustainable Energy Reviews, 2014, 33: 363-370. |

| 17 | Goyal H B, Seal D, Saxena R C. Bio-fuels from thermochemical conversion of renewable resources: a review[J]. Renewable and Sustainable Energy Reviews, 2008, 12(2): 504-517. |

| 18 | Hu X, Gholizadeh M. Biomass pyrolysis: a review of the process development and challenges from initial researches up to the commercialisation stage[J]. Journal of Energy Chemistry, 2019, 39: 109-143. |

| 19 | Pavlovic I, Knez Z, Skerget M. Hydrothermal reactions of agricultural and food processing wastes in sub- and supercritical water: a review of fundamentals, mechanisms, and state of research[J]. Journal of Agricultural and Food Chemistry, 2013, 61(34): 8003-8025. |

| 20 | Tekin K, Karagöz S, Bektaş S. A review of hydrothermal biomass processing[J]. Renewable and Sustainable Energy Reviews, 2014, 40: 673-687. |

| 21 | Kobayashi N, Fan L S. Biomass direct chemical looping process: a perspective[J]. Biomass and Bioenergy, 2011, 35(3): 1252-1262. |

| 22 | Chiu P C, Ku Y. Chemical looping process—a novel technology for inherent CO2 capture[J]. Aerosol Air Qual. Res., 2012, 12: 1421-1432. |

| 23 | Wang S, Dai G, Yang H, et al. Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review[J]. Progress in Energy and Combustion Science, 2017, 62: 33-86. |

| 24 | Dahl I M, Kolboe S. On the reaction mechanism for hydrocarbon formation from methanol over SAPO-34 (Ⅰ): Isotopic labeling studies of the co-reaction of ethene and methanol[J]. Journal of Catalysis, 1994, 149(2): 458-464. |

| 25 | Dahl I M, Kolboe S. On the reaction mechanism for hydrocarbon formation from methanol over SAPO-34 (Ⅱ): Isotopic labeling studies of the co-reaction of propene and methanol[J]. Journal of Catalysis, 1996, 161(1): 304-309. |

| 26 | Wang K, Kim K H, Brown R C. Catalytic pyrolysis of individual components of lignocellulosic biomass[J]. Green Chemistry, 2014, 16(2): 727-735. |

| 27 | Shen D K, Gu S. The mechanism for thermal decomposition of cellulose and its main products[J]. Bioresource Technology, 2009, 100(24): 6496-6504. |

| 28 | Werner K, Pommer L, Broström M. Thermal decomposition of hemicelluloses[J]. Journal of Analytical and Applied Pyrolysis, 2014, 110: 130-137. |

| 29 | Wang W L, Ren X Y, Li L F, et al. Catalytic effect of metal chlorides on analytical pyrolysis of alkali lignin[J]. Fuel Processing Technology, 2015, 134: 345-351. |

| 30 | Wang W L, Ren X Y, Chang J M, et al. Characterization of bio-oils and bio-chars obtained from the catalytic pyrolysis of alkali lignin with metal chlorides[J]. Fuel Processing Technology, 2015, 138: 605-611. |

| 31 | Wang S, Li Z, Bai X, et al. Influence of inherent hierarchical porous char with alkali and alkaline earth metallic species on lignin pyrolysis[J]. Bioresource Technology, 2018, 268: 323-331. |

| 32 | Peng C, Zhang G, Yue J, et al. Pyrolysis of lignin for phenols with alkaline additive[J]. Fuel Processing Technology, 2014, 124: 212-221. |

| 33 | Mochizuki T, Atong D, Chen S Y, et al. Effect of SiO2 pore size on catalytic fast pyrolysis of Jatropha residues by using pyrolyzer-GC/MS[J]. Catalysis Communications, 2013, 36: 1-4. |

| 34 | 李文斌, 郑云武, 李水荣, 等. 玉米芯热解催化转化制备呋喃类化合物工艺优化[J]. 农业工程学报, 2019, 35(17): 256-262. |

| Li W B, Zheng Y W, Li S R, et al. Optimization of process for preparation of furan compounds by pyrolysis catalytic conversion of corncob[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(17): 256-262. | |

| 35 | Li R, Zhong Z P, Jin B S, et al. Application of mineral bed materials during fast pyrolysis of rice husk to improve water-soluble organics production[J]. Bioresource Technology, 2012, 119: 324-330. |

| 36 | Lin Y, Zhang C, Zhang M, et al. Deoxygenation of bio-oil during pyrolysis of biomass in the presence of CaO in a fluidized-bed reactor[J]. Energy & Fuels, 2010, 24(10): 5686-5695. |

| 37 | Lu Q, Xiong W M, Li W Z, et al. Catalytic pyrolysis of cellulose with sulfated metal oxides: a promising method for obtaining high yield of light furan compounds[J]. Bioresource Technology, 2009, 100(20): 4871-4876. |

| 38 | Ammendola P, Lisi L, Piriou B, et al. Rh-perovskite catalysts for conversion of tar from biomass pyrolysis[J]. Chemical Engineering Journal, 2009, 154(1/2/3): 361-368. |

| 39 | Paysepar H, Rao K T V, Yuan Z, et al. Zeolite catalysts screening for production of phenolic bio-oils with high contents of monomeric aromatics/phenolics from hydrolysis lignin via catalytic fast pyrolysis[J]. Fuel Processing Technology, 2018, 178: 362-370. |

| 40 | Zhao Y, Deng L, Liao B, et al. Aromatics production via catalytic pyrolysis of pyrolytic lignins from bio-oil[J]. Energy & Fuels, 2010, 24(10): 5735-5740. |

| 41 | Tang S, Zhang C, Xue X, et al. Catalytic pyrolysis of lignin over hierarchical HZSM-5 zeolites prepared by post-treatment with alkaline solutions[J]. Journal of Analytical and Applied Pyrolysis, 2019, 137: 86-95. |

| 42 | 方书起, 石崇, 李攀, 等. Fe-Zn共改性ZSM-5催化作用下生物质快速热解特性研究[J].化工学报, 2020, 71(4): 1637-1645. |

| Fang S Q, Shi C, Li P, et al. Study on rapid pyrolysis characteristics of biomass catalyzed by Fe-Zn co-modified ZSM-5[J]. CIESC Journal, 2020, 71(4): 1637-1645. | |

| 43 | Chen H, Cheng H, Zhou F, et al. Catalytic fast pyrolysis of rice straw to aromatic compounds over hierarchical HZSM-5 produced by alkali treatment and metal-modification[J]. Journal of Analytical and Applied Pyrolysis, 2018, 131: 76-84. |

| 44 | Garg R, Anand N, Kumar D. Pyrolysis of babool seeds (Acacia nilotica) in a fixed bed reactor and bio-oil characterization[J]. Renewable Energy, 2016, 96: 167-171. |

| 45 | 李攀, 杨海平, 王贤华, 等. 不同酸处理条件下生物质热解产物特性分析[J].太阳能学报, 2015, 36(9): 2065-2070. |

| Li P, Yang H P, Wang X H, et al. The product characteristic of biomass pyrolysis based on different acid pretreatments THE[J]. Acta Energiae Solaris Sinica, 2015, 36(9): 2065-2070. | |

| 46 | Zhang B, Tan G, Zhong Z, et al. Microwave-assisted catalytic fast pyrolysis of spent edible mushroom substrate for bio-oil production using surface modified zeolite catalyst[J]. Journal of Analytical and Applied Pyrolysis, 2017, 123: 92-98. |

| 47 | Liu S, Zhang Y, Fan L, et al. Bio-oil production from sequential two-step catalytic fast microwave-assisted biomass pyrolysis[J]. Fuel, 2017, 196: 261-268. |

| 48 | Zhang B, Zhong Z, Zhang J, et al. Catalytic fast co-pyrolysis of biomass and fusel alcohol to enhance aromatic hydrocarbon production over ZSM-5 catalyst in a fluidized bed reactor[J]. Journal of Analytical and Applied Pyrolysis, 2018, 133: 147-153. |

| 49 | Lee H W, Kim Y M, Lee B, et al. Catalytic copyrolysis of torrefied cork oak and high density polyethylene over a mesoporous HY catalyst[J]. Catalysis Today, 2018, 307: 301-307. |

| 50 | 张会岩, 肖睿, Huber George W. 生物质和废弃油脂流化床共催化热解实验研究[J].工程热物理学报, 2013, 34(4): 771-774. |

| Zhang H Y, Xiao R, George W H. Experimental research on co-catalytic pyrolysis of biomass and waste oil in a fluidized bed[J]. Journal of Engineering Thermophysics, 2013, 34(4): 771-774. | |

| 51 | Ratnasari D K, Yang W, Jönsson P G. Two-stage ex-situ catalytic pyrolysis of lignocellulose for the production of gasoline-range chemicals[J]. Journal of Analytical and Applied Pyrolysis, 2018, 134: 454-464. |

| 52 | Wang S, Li Z, Bai X, et al. Catalytic pyrolysis of lignin in a cascade dual-catalyst system of modified red mud and HZSM-5 for aromatic hydrocarbon production[J]. Bioresource Technology, 2019, 278: 66-72. |

| 53 | Barbier J, Charon N, Dupassieux N, et al. Hydrothermal conversion of lignin compounds. A detailed study of fragmentation and condensation reaction pathways[J]. Biomass and Bioenergy, 2012, 46: 479-491. |

| 54 | Singh R, Balagurumurthy B, Prakash A, et al. Catalytic hydrothermal liquefaction of water hyacinth[J]. Bioresource Technology, 2015, 178: 157-165. |

| 55 | Besse X, Schuurman Y, Guilhaume N. Hydrothermal conversion of lignin model compound eugenol[J]. Catalysis Today, 2015, 258: 270-275. |

| 56 | Miao G, Zan Y, Sun Y, et al. Mn-promoted hydrogenation of microalgae (Chlorococcum sp.) to 1, 2-propanediol and ethylene glycol over Ni-ZnO catalysts[J]. Applied Catalysis A: General, 2018, 565: 34-45. |

| 57 | Yang W, Li X, Liu S, et al. Direct hydrothermal liquefaction of undried macroalgae Enteromorpha prolifera using acid catalysts[J]. Energy Conversion and Management, 2014, 87: 938-945. |

| 58 | Peng C, Zhang G, Han J, et al. Hydrothermal conversion of lignin and black liquor for phenolics with the aids of alkali and hydrogen donor[J]. Carbon Resources Conversion, 2019, 2(2): 141-150. |

| 59 | Kong L, Li G, Wang H, et al. Hydrothermal catalytic conversion of biomass for lactic acid production[J]. Journal of Chemical Technology & Biotechnology: International Research in Process, Environmental & Clean Technology, 2008, 83(3): 383-388. |

| 60 | Shu R, Lin B, Wang C, et al. Hydrogenolysis of dealkaline lignin catalyzed by noble metal cooperated with metal chloride[J]. Energy Procedia, 2019, 158: 406-411. |

| 61 | Tekin K, Karagöz S, Bektaş S. Hydrothermal liquefaction of beech wood using a natural calcium borate mineral[J]. The Journal of Supercritical Fluids, 2012, 72: 134-139. |

| 62 | Wang J J, Tan Z C, Zhu C C, et al. One-pot catalytic conversion of microalgae (Chlorococcum sp.) into 5-hydroxymethylfurfural over the commercial H-ZSM-5 zeolite[J]. Green Chemistry, 2016, 18(2): 452-460. |

| 63 | Valdez P J, Nelson M C, Faeth J L, et al. Hydrothermal liquefaction of bacteria and yeast monocultures[J]. Energy & Fuels, 2014, 28(1): 67-75. |

| 64 | Cantero D A, Bermejo M D, Cocero M J. Kinetic analysis of cellulose depolymerization reactions in near critical water[J]. The Journal of Supercritical Fluids, 2013, 75: 48-57. |

| 65 | Dong W, Shen Z, Peng B, et al. Selective chemical conversion of sugars in aqueous solutions without alkali to lactic acid over a Zn-Sn-Beta Lewis acid-base catalyst[J]. Scientific Reports, 2016, 6: 26713-26720. |

| 66 | Chen Y, Wang F, Yang Z. Preparation and upgrading of hydrocarbon oil from deoxy-liquefaction of oil crop[J]. Bioresource Technology, 2013, 146: 472-477. |

| 67 | Xiong H, Schwartz T J, Andersen N I, et al. Graphitic‐carbon layers on oxides: toward stable heterogeneous catalysts for biomass conversion reactions[J]. Angewandte Chemie International Edition, 2015, 54(27): 7939-7943. |

| 68 | Liu X, Lan G, Su P, et al. Highly stable Ru nanoparticles incorporated in mesoporous carbon catalysts for production of γ-valerolactone[J]. Catalysis Today, 2020, 351: 75-82. |

| 69 | 郝建刚, 吴家桦, 王雷, 等. 基于Fe基载氧体的生物质化学链燃烧试验研究[J].锅炉技术, 2010, 41(2): 65-70. |

| Hao J G, Wu J H, Wang L, et al. Experiments on chemical looping combustion of biomass with a Fe2O3 based oxygen carrier[J].Boiler Technology, 2010, 41(2): 65-70. | |

| 70 | Mendiara T, Abad A, De Diego L F, et al. Biomass combustion in a CLC system using an iron ore as an oxygen carrier[J]. International Journal of Greenhouse Gas Control, 2013, 19: 322-330. |

| 71 | Adánez-Rubio I, Pérez-Astray A, Mendiara T, et al. Chemical looping combustion of biomass: CLOU experiments with a Cu-Mn mixed oxide[J]. Fuel Processing Technology, 2018, 172: 179-186. |

| 72 | Udomsirichakorn J, Salam P A. Review of hydrogen-enriched gas production from steam gasification of biomass: the prospect of CaO-based chemical looping gasification[J]. Renewable and Sustainable Energy Reviews, 2014, 30: 565-579. |

| 73 | 陈智豪, 廖艳芬, 莫菲, 等. MnFeO3和 MnFe2O4氧载体在稻草化学链气化中的应用[J]. 化工学报, 2019, 70(12): 4835-4846. |

| Chen Z H, Liao Y F, Mo F, et al. Application of MnFeO3 and MnFe2O4 as oxygen carriers for straw chemical looping gasification[J]. CIESC Journal, 2019, 70(12): 4835-4846. | |

| 74 | Hu Q, Shen Y, Chew J W, et al. Chemical looping gasification of biomass with Fe2O3/CaO as the oxygen carrier for hydrogen-enriched syngas production[J]. Chemical Engineering Journal, 2020, 379: 122346. |

| 75 | Wu Y, Liao Y, Liu G, et al. Reactivity investigation on biomass chemical looping conversion for syngas production[J]. Journal of the Energy Institute, 2019, 92(4): 1137-1148. |

| 76 | Wei G, Huang J, Fan Y, et al. Chemical looping reforming of biomass based pyrolysis gas coupling with chemical looping hydrogen by using Fe/Ni/Al oxygen carriers derived from LDH precursors[J]. Energy Conversion and Management, 2019, 179: 304-313. |

| 77 | Chen J, Zhao K, Zhao Z, et al. Identifying the roles of MFe2O4 (M= Cu, Ba, Ni, and Co) in the chemical looping reforming of char, pyrolysis gas and tar resulting from biomass pyrolysis[J]. International Journal of Hydrogen Energy, 2019, 44(10): 4674-4687. |

| 78 | Zhao H, Guo L, Zou X. Chemical-looping auto-thermal reforming of biomass using Cu-based oxygen carrier[J]. Applied Energy, 2015, 157: 408-415. |

| 79 | Guo L, Zhao H, Zheng C. Synthesis gas generation by chemical-looping reforming of biomass with natural copper ore as oxygen carrier[J]. Waste and Biomass Valorization, 2015, 6(1): 81-89. |

| 80 | Huang Z, Deng Z, He F, et al. Reactivity investigation on chemical looping gasification of biomass char using nickel ferrite oxygen carrier[J]. International Journal of Hydrogen Energy, 2017, 42(21): 14458-14470. |

| 81 | 范峻铭, 洪慧, 金红光. 基于化学链燃烧生物质煤互补的天然气动力联产系统研究[J]. 工程热物理学报, 2017, 38(7): 1466-1471. |

| Fan J M, Hong H, Jin H G. System performance of SNG and power polygeneration system with chemical looping combustion driven by hybrid coal and biomass[J]. Journal of Engineering Thermophysics, 2017, 38(7): 1466-1471. | |

| 82 | Fan J, Hong H, Zhu L, et al. Thermodynamic and environmental evaluation of biomass and coal co-fueled gasification chemical looping combustion with CO2 capture for combined cooling, heating and power production[J]. Applied Energy, 2017, 195: 861-876. |

| 83 | Mehrpooya M, Sharifzadeh M M M, Rajabi M, et al. Design of an integrated process for simultaneous chemical looping hydrogen production and electricity generation with CO2 capture[J]. International Journal of Hydrogen Energy, 2017, 42(12): 8486-8496. |

| [1] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [2] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [3] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [4] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [5] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [6] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [7] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [8] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [9] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [10] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [11] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [12] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [13] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [14] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [15] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号