化工学报 ›› 2020, Vol. 71 ›› Issue (11): 5140-5149.DOI: 10.11949/0438-1157.20200221

收稿日期:2020-03-03

修回日期:2020-08-09

出版日期:2020-11-05

发布日期:2020-11-05

通讯作者:

沈向阳

作者简介:沈向阳(1982—),男,博士,副教授,基金资助:

Xiangyang SHEN1( ),Jing DING2,Jianfeng LU2

),Jing DING2,Jianfeng LU2

Received:2020-03-03

Revised:2020-08-09

Online:2020-11-05

Published:2020-11-05

Contact:

Xiangyang SHEN

摘要:

建立熔盐吸热管瞬态传热的实验台和数值计算模型,分析管外壁热通量突变、熔盐流速突减、外壁热通量和熔盐流速同时突减对吸热管瞬态传热特性的影响规律,结果表明:管外壁热通量突变(突增或突减)时,吸热管入口段的管中心熔盐温度变化较小,但其管壁温度变化较快。管内熔盐流速突减时,熔盐出口温度和管外壁温度均随时间的推移逐渐增大,而管外壁与管内壁温差随时间的推移先降低后升高,t≥16.0 s,各温度和温差基本稳定。吸热管外壁热通量和管内熔盐流速同时减半时,管中心及出口熔盐温度均随时间的推移先升高后降低,稳态后两处熔盐温度保持定值且与瞬态开始前对应熔盐温度接近。吸热管瞬态稳定后的管外壁与管内壁温差和管外壁热通量变化呈正比,与熔盐流速变化无关。得到瞬态稳定后吸热管熔盐出口温度表达式,为瞬态传热过程中吸热器熔盐出口温度控制提供理论依据。

中图分类号:

沈向阳,丁静,陆建峰. 熔盐吸热管瞬态传热特性的数值研究[J]. 化工学报, 2020, 71(11): 5140-5149.

Xiangyang SHEN,Jing DING,Jianfeng LU. Numerical study of transient heat transfer performance for molten salt receiver tube[J]. CIESC Journal, 2020, 71(11): 5140-5149.

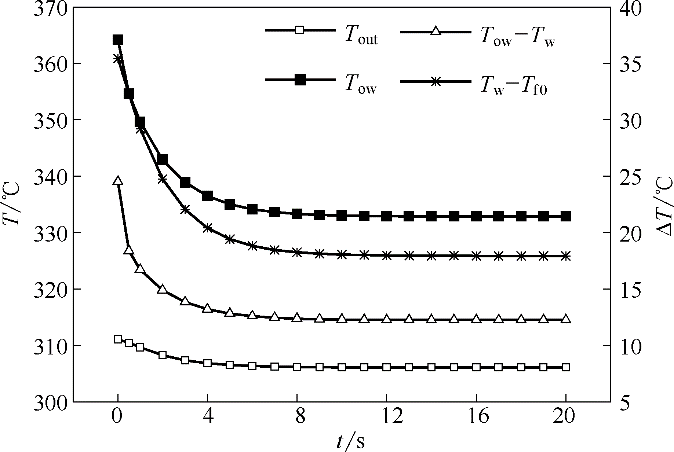

图6 Tout及x=0.65 m处Tow、Tow-Tw和Tw-Tf0的变化(qtran=0→201.8 kW/m2)

Fig.6 Temperature responses of Tout and Tow, Tow-Tw, Tw-Tf0 at x=0.65 m (qtran=0→201.8 kW/m2)

图8 Tout及x=0.65 m处Tow、Tow-Tw和Tw-Tf0的变化(qtran=201.8→100.9 kW/m2)

Fig.8 Temperature responses of Tout and Tow, Tow-Tw, Tw-Tf0 at x=0.65 m (qtran=201.8→100.9 kW/m2)

图10 Tout及x=0.65 m处Tow、Tow-Tw和Tw-Tf0的变化(uin=2.98→1.49 m/s)

Fig.10 Temperature responses of Tout and Tow, Tow-Tw, Tw-Tf0 at x=0.65 m (uin=2.98→1.49 m/s)

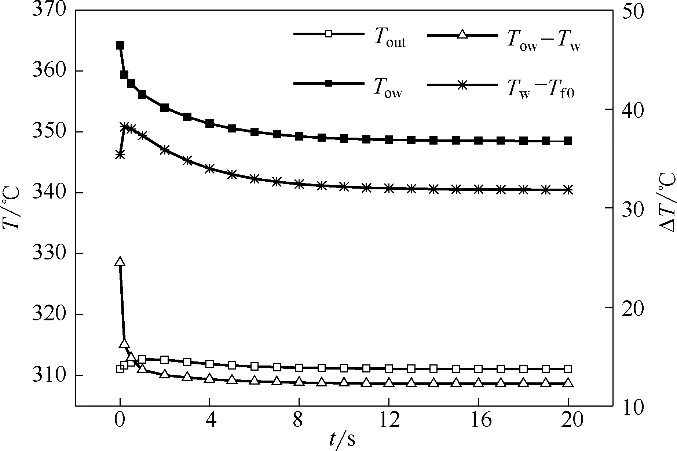

图12 Tout及x=0.65 m处Tow、Tow-Tw和Tw-Tf0的变化(qtran=201.8→100.9 kW/m2,uin=2.98→1.49 m/s)

Fig.12 Temperature responses of Tout and Tow, Tow-Tw, Tw-Tf0 at x=0.65 m (qtran=201.8→100.9 kW/m2,uin=2.98→1.49 m/s)

| 1 | Wang W J, Malmquist A, Aichmayer L, et al. Transient performance of an impinging receiver: an indoor experimental study[J]. Energy Conversion and Management, 2018, 158: 193-200. |

| 2 | 何雅玲, 王坤, 杜保存, 等. 聚光型太阳能热发电系统非均匀辐射能流特性及解决方法的研究进展[J]. 科学通报, 2016, 61: 3208-3237. |

| He Y L, Wang K, Du B C, et al. Non-uniform characteristics of solar flux distribution in the concentrating solar power systems and its corresponding solutions: a review[J]. Chinese Science Bulletin, 2016, 61: 3208-3237. | |

| 3 | Xu L, Stein W, Kim J, et al. Transient numerical model for the thermal performance of the solar receiver[J]. Applied Thermal Engineering, 2018, 141: 1035-1047. |

| 4 | Xu L, Stein W, Kim J, et al. Three-dimensional transient numerical model for the thermal performance of the solar receiver [J]. Renewable Energy, 2018, 120: 550-566. |

| 5 | 陈政伟, 王跃社, 陈开拓, 等. 瞬态阶跃热通量下腔式吸热器动态特性研究[J]. 工程热物理学报, 2012, 33(10): 1719-1722. |

| Chen Z W, Wang Y S, Chen K T, et al. Numerical research on dynamic characteristics in solar cavity receiver based on step-change radiation flux[J]. Journal of Engineering Thermophysics, 2012, 33(10): 1719-1722. | |

| 6 | 盛玲霞, 李佳燕, 赵豫红. 塔式太阳能电站接收器的建模及动态仿真[J]. 化工学报, 2016, 67(3): 736-742. |

| Sheng L X, Li J Y, Zhao Y H. Modeling and dynamic simulation of receiver in a solar tower power station[J]. CIESC Journal, 2016, 67(3): 736-742. | |

| 7 | 许昌, 刘德有, 郑源, 等. 塔式太阳能发电多孔介质吸热器动态模型[J]. 中国电机工程学报, 2010, 30(29): 122-127. |

| Xu C, Liu D Y, Zheng Y, et al. Dynamic models research on a porous media receiver of solar tower power[J]. Proceedings of the CSEE, 2010, 30(29): 122-127. | |

| 8 | Wu Z Y, Wang Z F. Fully coupled transient modeling of ceramic foam volumetric solar air receiver[J]. Solar Energy, 2013, 89: 122-133. |

| 9 | Wang F Q, Guan Z N, Tan J Y, et al. Transient thermal performance response characteristics of porous-medium receiver heated by multi-dish concentrator[J]. International Communications in Heat and Mass Transfer, 2016, 75: 36-41. |

| 10 | Ribeiro R R, de Lemos M J S. Transient behavior and thermal efficiency of volumetric heat receivers [J]. International Journal of Heat and Mass Transfer, 2019, 149: 119-128. |

| 11 | Najafabadi H A, Ozalp N, Ophoff C, et al. An experimental study on temperature control of a solar receiver under transient solar load[J]. Solar Energy, 2019, 186: 52-59. |

| 12 | 屠楠, 方嘉宾, 魏进家. 太阳能腔式吸热器不同启动状态下启动性能研究[J]. 工程热物理学报, 2012, 33(11): 1900-1903. |

| Tu N, Fang J B, Wei J J. Numerical simulation of different start-up performance of a solar cavity receiver[J]. Journal of Engineering Thermophysics, 2012, 33(11): 1900-1903. | |

| 13 | 张强强, 李鑫, 常春, 等. 多云气象条件下熔融盐腔式吸热器的热性能分析[J]. 中国电机工程学报, 2014, 34(8): 1291-1296. |

| Zhang Q Q, Li X, Chang C, et al. Thermal performance analysis of molten salt cavity receivers under cloudy conditions[J]. Proceedings of the CSEE, 2014, 34(8): 1291-1296. | |

| 14 | Zhang Q Q, Li X, Wang Z F, et al. Experimental and theoretical analysis of a dynamic test method for molten salt cavity receiver[J]. Renewable Energy, 2013, 50: 214-221. |

| 15 | Samanes J, Garcia-Barberena J. A model for the transient performance simulation of solar cavity receivers[J]. Solar Energy, 2014, 110: 789-806. |

| 16 | Schöttl P, Bern G, Rooyen D W V, et al. Efficient modeling of variable solar flux distribution on solar tower receivers by interpolation of few discrete representations[J]. Solar Energy, 2018, 160: 43-55. |

| 17 | 王楚航. 塔式太阳能热发电系统熔盐回路瞬态模拟分析[D]. 上海: 中国科学院上海应用物理研究所, 2018. |

| Wang C H. Dynamic simulation of molten salt loop in solar tower thermal power plant[D]. Shanghai: Shanghai Institute of Applied Physics, Chinese Academy of Sciences, 2018. | |

| 18 | Li Z, Zhang Q Q, Wang Z F, et al. Numerical and experimental study of solidification dangers in a molten salt receiver for cloudy conditions[J]. Solar Energy, 2019, 193: 118-131. |

| 19 | Crespi F, Toscani A, Zani P, et al. Effect of passing clouds on the dynamic performance of a CSP tower receiver with molten salt heat storage[J]. Applied Energy, 2018, 229: 224-235. |

| 20 | Fritsch A, Uhlig R, Marocco L, et al. A comparison between transient CFD and FEM simulations of solar central receiver tubes using molten salt and liquid metals[J]. Solar Energy, 2017, 155: 259-266. |

| 21 | Augsburger G, Favrat D. Modelling of the receiver transient flux distribution due to cloud passages on a solar tower thermal power plant[J]. Solar Energy, 2013, 87: 42-52. |

| 22 | Too Y C S, García J, Padilla R V, et al. A transient optical-thermal model with dynamic matrix controller for solar central receivers[J]. Applied Thermal Engineering, 2019, 154: 686–698. |

| 23 | García J, Too Y C S, Padilla R V, et al. Dynamic performance of an aiming control methodology for solar central receivers due to cloud disturbances[J]. Renewable Energy, 2018, 121: 355-367. |

| 24 | Terdalkar R, Doupis D, Clark M, et al. Transient simulation of high temperature high pressure solar tower receiver[J]. Energy Procedia, 2015, 69:1451-1460. |

| 25 | 刘闪威, 吴玉庭, 崔武军, 等. 低熔点熔盐圆管内强迫对流换热[J]. 化工学报, 2015, 66(2): 530-536. |

| Liu S W, Wu Y T, Cui W J, et al. Forced convection heat transfer with low-melting point molten salt in circular pipe[J]. CIESC Journal, 2015, 66(2): 530-536. | |

| 26 | 杨世铭, 陶文铨. 传热学 [M]. 4版. 北京: 高等教育出版社, 2018. |

| Yang S M, Tao W Q. Heat Transfer [M].4th ed. Beijing: Higher Education Press, 2108. | |

| 27 | 杨敏林, 杨晓西, 丁静, 等. 半周加热半周绝热的熔盐吸热管传热特性研究[J]. 太阳能学报, 2009, 30(8): 1007-1012. |

| Yang M L, Yang X X, Ding J, et al. Heat transfer research on molten salt receiver with semi-circumference heat[J]. Acta Energiae Solaris Sinica, 2009, 30(8): 1007-1012. | |

| 28 | Lu J F, Shen X Y, Ding J, et al. Convective heat transfer of high temperature molten salt in transversely grooved tube[J]. Applied Thermal Engineering, 2013, 61: 157-162. |

| 29 | Lu J F, Shen X Y, Ding J, et al. Transition and turbulent convective heat transfer of molten salt in spirally grooved tube[J]. Experimental Thermal and Fluid Science, 2013, 47: 180-185. |

| 30 | 沈向阳, 张奇淄, 陆建峰, 等. 熔盐吸热管非稳态对流换热特性[J]. 化工学报, 2012, 63: 36-40. |

| Shen X Y, Zhang Q Z, Lu J F, et al. Unsteady convective heat transfer performances of molten salt in receiver tube[J]. CIESC Journal, 2012, 63: 36-40. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [4] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [5] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [6] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [7] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [8] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [9] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [10] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [11] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [12] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [13] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [14] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [15] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号