化工学报 ›› 2020, Vol. 71 ›› Issue (S2): 176-186.DOI: 10.11949/0438-1157.20200688

武永和1,2( ),林志敏1,2(

),林志敏1,2( ),刘树山1,2,张永恒1,2,王良璧1,2

),刘树山1,2,张永恒1,2,王良璧1,2

收稿日期:2020-06-02

修回日期:2020-07-08

出版日期:2020-11-06

发布日期:2020-11-06

通讯作者:

林志敏

作者简介:武永和(1993—),男,硕士研究生,基金资助:

Yonghe WU1,2( ),Zhimin LIN1,2(

),Zhimin LIN1,2( ),Shushan LIU1,2,Yongheng ZHANG1,2,Liangbi WANG1,2

),Shushan LIU1,2,Yongheng ZHANG1,2,Liangbi WANG1,2

Received:2020-06-02

Revised:2020-07-08

Online:2020-11-06

Published:2020-11-06

Contact:

Zhimin LIN

摘要:

内插扰流元件是一种可操作性强的管内强化传热方式,其强化传热机理主要是在管内诱导产生了二次流。在均匀壁温热边界条件下,对内插不同形状涡产生器管内层流流动与传热特性进行了数值分析。研究发现:在扭带基础上裁去部分面积相同的条件下,管内插等腰梯形涡产生器的换热能力最强,直角梯形涡产生器次之,矩形涡产生器的换热能力最差,管壁上的局部Nusselt数的峰值所在圆周位置及其大小与涡产生器形状有关,而不同形状的涡产生器对管内流动的阻力系数影响较小。插入涡产生器后,管内二次流强度参数Se和平均Nusselt数Nu均随Reynolds数Re的增大而增大,二者随Reynolds数Re的变化规律具有一致性。平均Nusselt数Nu与二次流强度参数Se呈幂函数相关,内插涡产生器管内的二次流强度决定了其对流换热强度。

中图分类号:

武永和, 林志敏, 刘树山, 张永恒, 王良璧. 内插不同形状涡产生器管内层流流动与传热特性的对比分析[J]. 化工学报, 2020, 71(S2): 176-186.

Yonghe WU, Zhimin LIN, Shushan LIU, Yongheng ZHANG, Liangbi WANG. Comparative analysis of laminar flow and heat transfer characteristics in a circular tube with different shape vortex generators[J]. CIESC Journal, 2020, 71(S2): 176-186.

| 参数 | 数值 |

|---|---|

| Tr | 4 |

| β/(°) | 60,90 |

| γ/(°) | 60,90,120 |

| B/W | 0.376,0.477,0.578 |

| St /W | 0.989 |

| Wb/W | 0.3 |

表1 涡产生器结构参数

Table 1 Geometrical parameters of vortex generator

| 参数 | 数值 |

|---|---|

| Tr | 4 |

| β/(°) | 60,90 |

| γ/(°) | 60,90,120 |

| B/W | 0.376,0.477,0.578 |

| St /W | 0.989 |

| Wb/W | 0.3 |

| 序号 | 网格数量 | Num | f |

|---|---|---|---|

| 网格1 | 913996 | 16.75 | 0.666 |

| 网格2 | 1066100 | 16.74 | 0.666 |

| 网格3 | 1310744 | 16.74 | 0.664 |

表2 网格独立性考核

Table 2 Grid independence test

| 序号 | 网格数量 | Num | f |

|---|---|---|---|

| 网格1 | 913996 | 16.75 | 0.666 |

| 网格2 | 1066100 | 16.74 | 0.666 |

| 网格3 | 1310744 | 16.74 | 0.664 |

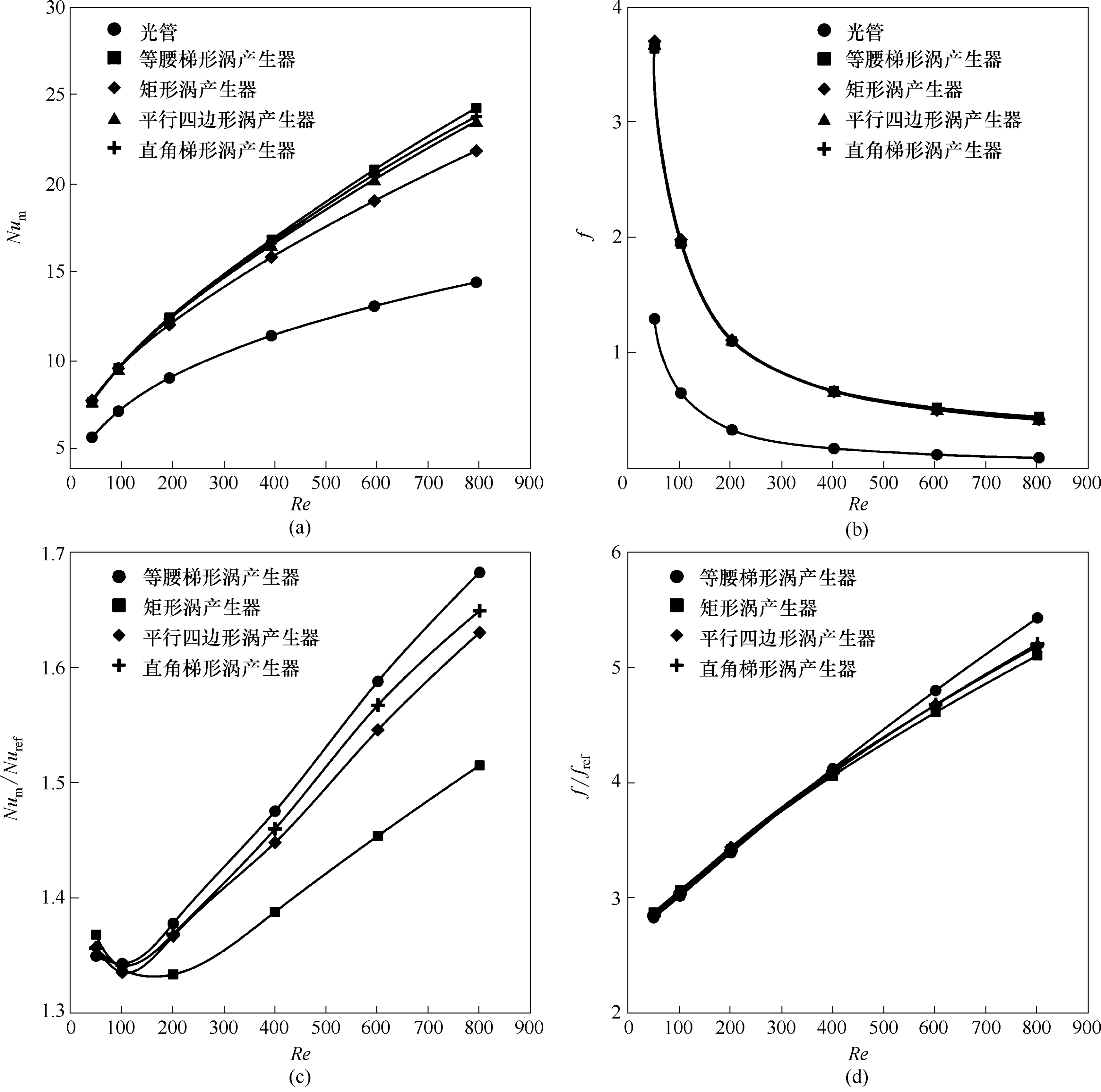

图5 管内插不同形状的涡产生器时Num, f, Num/Nuref和f/fref随Re的变化

Fig.5 Change of Num, f, Num/Nuref and f/fref with Re of different shapes vortex generators inserting in tubes

图6 Re = 400时管内插不同形状涡产生器在x = 0.268 m截面上的主流速度分布

Fig.6 Distribution of mainstream velocity of different shapes vortex generators inserting in tubes at x = 0.268 m when Re=400

图7 Re = 400时管内插不同形状涡产生器在x = 0.268 m截面上的二次流速度分布

Fig.7 Distribution of secondary flow velocity of different shapes vortex generators inserting in tubes at x = 0.268 m when Re = 400

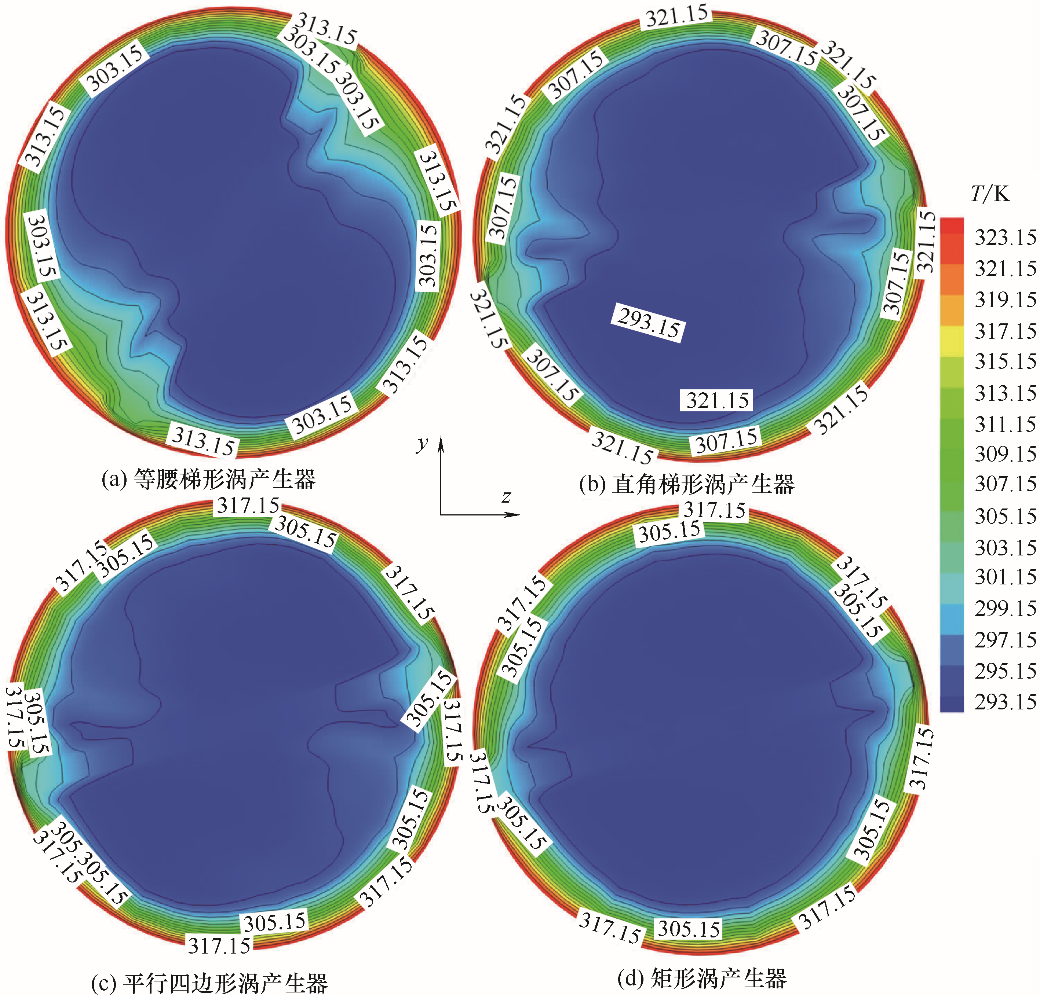

图8 Re = 400时管内插不同形状涡产生器在x = 0.268 m截面上的温度场分布

Fig.8 Distribution of temperature field of different shapes vortex generators inserting in tubes at x = 0.268 m when Re = 400

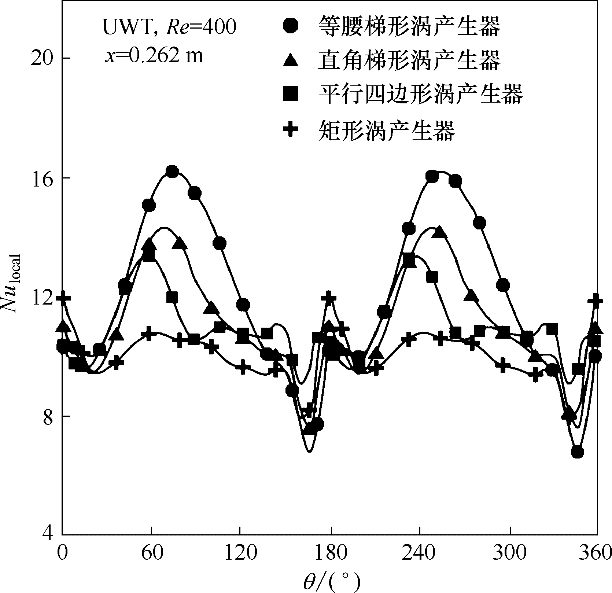

图10 Re = 400时内插不同形状的涡产生器的管壁表面局部Nu沿圆周的分布

Fig.10 Distribution of Nulocal of different shapes vortex generators inserting in tubes at x = 0.262 m when Re = 400

| 1 | 林宗虎, 汪军, 李瑞阳, 等. 强化传热技术[M]. 北京: 化学工业出版社, 2007: 1 - 150. |

| Lin Z H, Wang J, Li R Y, et al. Enhanced Heat Transfer Technology [M]. Beijing: Chemical Industry Press, 2007: 1 – 150. | |

| 2 | 过增元, 黄素逸. 场协同原理与强化传热新技术[M]. 北京: 中国电力出版社, 2004: 213 - 290. |

| Guo Z Y, Huang S Y. Field Synergy Theory and New Technology for Heat Transfer Enhancement [M]. Beijing: China Electric Power Press, 2004: 213 - 290. | |

| 3 | 吴金星, 韩东方, 曹海亮, 等. 高效换热器及其节能应用[M]. 北京: 化学工业出版社, 2009. |

| Wu J X, Han D F, Cao H L, et al. High Efficiency Heat Exchanger and Energy-saving Application [M]. Beijing: Chemical Industry Press, 2009. | |

| 4 | Fiebig M, Sanchez M A. Enhancement of heat transfer and pressure loss by winglet vortex generators in a fin-tube element [C]//Compact Heat Exchangers for Power and Process Industries. New York: ASME, 1992: 7-14. |

| 5 | Rindt C C M, Sillekens J J M, van Steenhoven A A. The influence of the wall temperature on the development of heat transfer and secondary flow in a coiled heat exchanger [J]. Int. Comm. Heat Mass Transfer, 1999, 26(2): 187-198. |

| 6 | Robert K, Adrian M, Sadanari M, et al. Rib-induced secondary flow effects on local circumferential heat transfer distribution inside a circular rib-roughened tube [J]. Int. J. Heat Mass Transfer, 2004, 47(6): 1403-1412. |

| 7 | Pankaj S, Gautam B, Subrata S. Comparison of winglet-type vortex generators periodically deployed in a plate-fin heat exchanger - a synergy based analysis [J]. Int. J. Heat Mass Transfer, 2014, 74: 292-305. |

| 8 | Sinha A, Chattopadhyay H, Iyengar A K, et al. Enhancement of heat transfer in a fin-tube heat exchanger using rectangular winglet type vortex generators [J]. Int. J. Heat Mass Transfer, 2016, 101: 667-681. |

| 9 | Khanjian A, Habchi C, Russeil S, et al. Effect of the angle of attack of a rectangular wing on the heat transfer enhancement in channel flow at low Reynolds number [J]. Heat Mass Transfer, 2018, 54: 1441-1452. |

| 10 | Habibi Z, Karami M, Jarrahi M, et al. Some observations on the spatiotemporal orbits structure and heat transfer enhancement in pulsating flow [J]. Int. J. Thermal Sciences, 2018, 125: 428-439. |

| 11 | Dean W R, Hurst J M. Note on the motion of fluid motion in a curved pipe [J]. Philosophical Magazine, 1959, 6(1): 77-85. |

| 12 | Hærvig J, Sørensen K, Condra T J. On the fully-developed heat transfer enhancing flow field in sinusoidally, spirally corrugated tubes using computational fluid dynamics [J]. Int. J. Heat Mass Transfer, 2017, 106: 1051-1062. |

| 13 | Lin Z M, Sun D L, Wang L B. The relationship between absolute vorticity flux along the main flow and convention heat transfer in a tube inserting a twisted tape [J]. Heat Mass Transfer, 2009, 45: 1351-1363. |

| 14 | Chang L M, Wang L B, Song K W, et al. Numerical study of the relationship between heat transfer enhancement and absolute vorticity flux along main flow direction in a channel formed by a flat tube bank fin with vortex generators [J]. Int. J. Heat Mass Transfer, 2009, 52: 1794-1801. |

| 15 | Song K W, Hu W L, Liu S, et al. Quantitative relationship between secondary flow intensity and heat transfer intensity in flat-tube-and-fin air heat exchanger with vortex generators [J]. Applied Thermal Engineering, 2016, 103: 1064-1070. |

| 16 | Lin Z M, Wang L B, Fan J F, et al. Characteristics of the absolute vorticity flux along the main flow direction on the cross section of the channel formed by oval tube bank fins [J]. Numerical Heat Transfer, Part A, 2010, 57(9): 666-690. |

| 17 | Fiebig M. Vortices generators and heat transfer [J]. Transactions of the IChemE, 1998, 76(2): 108-123. |

| 18 | Liu S L, Sakr M. A comprehensive review on passive heat transfer enhancements in pipe exchangers [J]. Renewable and Sustainable Energy Reviews, 2013, 19: 64-81. |

| 19 | Hasanpour A, Farhadi M, Sedighi K. A review study on twisted tape inserts on turbulent flow heat exchangers: the overall enhancement ratio criteria [J]. Int. Comm. Heat Mass Transfer, 2014, 55: 53-62. |

| 20 | Varun, Garg M O, Nautiyal H, et al. Heat transfer augmentation using twisted tape inserts: a review [J]. Renewable and Sustainable Energy Reviews, 2016, 63(7): 193-225. |

| 21 | Guo J, Fan A W, Zhang X Y, et al. A numerical study on heat transfer and friction factor characteristics of laminar flow in a circular tube fitted with center-cleared twisted tape [J]. Int. J. Thermal Sciences, 2011, 50(7): 1263-1270. |

| 22 | Suri A R S, Kumar A, Maithani R. Effect of square wings in multiple square perforated twisted tapes on fluid flow and heat transfer of heat exchanger tube [J]. Case Studies in Thermal Engineering, 2017, 10: 28-43. |

| 23 | Thianpong C, Eiamsa-ard P, Promvonge P, et al. Effect of perforated twisted-tapes with parallel wings on heat transfer enhancement in a heat exchanger tube [J]. Energy Procedia, 2012, 14: 1117-1123. |

| 24 | Skullong S, Promvonge P, Thianpong C, et al. Heat transfer and turbulent flow friction in a round tube with staggered-winglet perforated-tapes [J]. Int. J. Heat Mass Transfer, 2016, 95: 230-242. |

| 25 | Eiamsa-ard S, Pimsarn M, Thianpong C. Performance assessment in a heat exchanger tube with opposite/parallel wing twisted tapes [J]. Advances in Mechanical Engineering, 2015, 7(2): 520-536. |

| 26 | Saysroy A, Eiamsa-ard S. Periodically fully-developed heat and fluid flow behaviors in a turbulent tube flow with square-cut twisted tape inserts [J]. Applied Thermal Engineering, 2017, 112: 895-910. |

| 27 | Chang S W, Huang B J. Thermal performances of tubular flows enhanced by ribbed spiky twist tapes with and without edge notches [J]. Int. J. Heat Mass Transfer, 2014, 73: 645-663. |

| 28 | Lin Z M, Wang L B, Lin M, et al. Numerical study of the laminar flow and heat transfer characteristics in a tube inserting a twisted tape having parallelogram winglet vortex generators [J]. Applied Thermal Engineering, 2017, 115: 644-658. |

| 29 | 林志敏. 扭带及涡产生器在管内诱导的二次流强度及其强化传热特性研究[D]. 兰州: 兰州交通大学, 2011. |

| Lin Z M. The characteristics of secondary flow and heat transfer enhancement in circular tube with twisted tape or vortex generators [D]. Lanzhou: Lanzhou Jiaotong University, 2011. | |

| 30 | Abolarin S M, Everts M, Meyer J P. Heat transfer and pressure drop characteristics of alternating clockwise and counter clockwise twisted tape inserts in the transitional flow regime [J]. Int. J. Heat Mass Transfer, 2019, 133: 203-217. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [4] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [5] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [6] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [7] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [8] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [9] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [10] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [11] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [12] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [13] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [14] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [15] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号