化工学报 ›› 2022, Vol. 73 ›› Issue (5): 2052-2059.DOI: 10.11949/0438-1157.20220046

收稿日期:2022-01-09

修回日期:2022-02-10

出版日期:2022-05-05

发布日期:2022-05-24

通讯作者:

冯霄

作者简介:段文婷(1998—),女,硕士研究生,基金资助:

Wenting DUAN1( ),Siyue REN1,Xiao FENG1(

),Siyue REN1,Xiao FENG1( ),Yufei WANG2

),Yufei WANG2

Received:2022-01-09

Revised:2022-02-10

Online:2022-05-05

Published:2022-05-24

Contact:

Xiao FENG

摘要:

调整精馏塔的操作条件是节省塔能耗的有效途径之一,然而在对已有装置进行用能优化时,需同时考虑精馏塔操作条件对塔能耗和换热网络能耗的影响。基于装置所有流股的冷热复合曲线,针对跨夹点的精馏塔,同时考虑了精馏塔的再沸、冷凝以及过程流股,分析了塔压变化对装置公用工程消耗的影响,并对某连续重整装置汽提塔进行了案例分析。结果显示,塔压降低可使冷凝器能耗增加,再沸器能耗减小,而对于塔顶塔底出装置流股,塔压降低可节省冷却公用工程但增加加热公用工程。装置总体的节能效果为塔顶冷凝器、塔底再沸器和塔顶塔底出装置流股节能效果的综合作用。对某连续重整装置汽提塔分析表明,塔压降低200.0 kPa时,其加热公用工程用量将减少577.5 kW。

中图分类号:

段文婷, 任思月, 冯霄, 王彧斐. 与换热网络热集成的精馏塔压优化[J]. 化工学报, 2022, 73(5): 2052-2059.

Wenting DUAN, Siyue REN, Xiao FENG, Yufei WANG. Distillation column pressure optimization integrated with the heat exchanger network[J]. CIESC Journal, 2022, 73(5): 2052-2059.

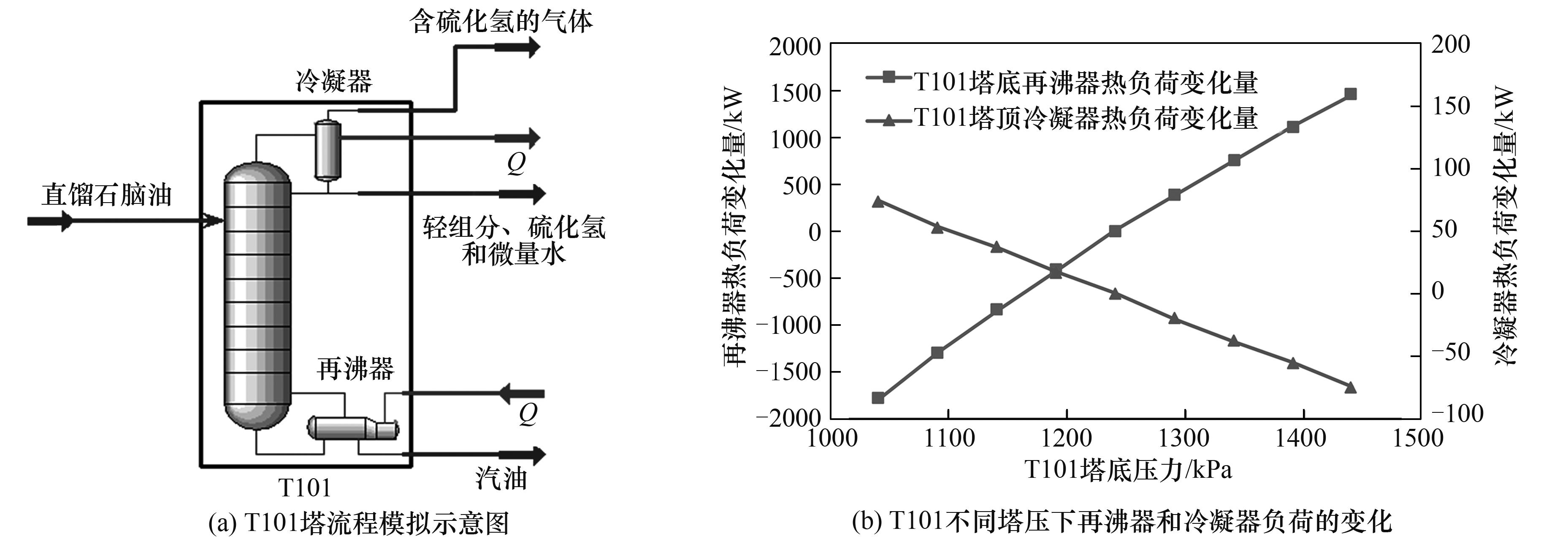

图1 T101塔流程及不同塔压下再沸器和冷凝器的负荷

Fig.1 The process of column T101 and the heat load of reboiler and condenser under different pressure of distillation column

| 物流 编号 | 物流 名称 | 换热器 | 初始 温度/℃ | 目标 温度/℃ | 热负荷/ kW |

|---|---|---|---|---|---|

| H1 | R204底 | E201 | 493.4 | 117.0 | 58300.0 |

| H2 | R204底-2 | E202 | 490.8 | 190.0 | 42.4 |

| H3 | T101底 | E105 | 208.5 | 132.3 | 9914.0 |

| H4 | T102底 | E102 | 156.3 | 102.6 | 6031.0 |

| H5 | 蒸汽冷凝水 | E100 | 150.0 | 70.0 | 4690.0 |

| H6 | A201流股 | A201 | 117.2 | 42.0 | 7860.0 |

| H7 | T102顶 | A103 | 87.4 | 30.5 | 4060.0 |

| H8 | T101顶 | E104 | 69.1 | 59.4 | 2152.0 |

| A102 | 59.4 | 38.7 | 1374.0 | ||

| C1 | F201流股 | E201 | 85.5 | 453.9 | 58300.0 |

| F201 | 453.9 | 525.9 | 11070.0 | ||

| C2 | T101底-2 | F102 | 208.5 | 221.1 | 8538.0 |

| C3 | 吹扫氢 | E202 | 27.0 | 180.6 | 42.4 |

| C4 | T101进料 | E102 | 48.7 | 102.0 | 6031.0 |

| E105 | 102.0 | 179.8 | 9914.0 | ||

| C5 | T102底-2 | F103 | 156.3 | 164.4 | 9440.0 |

| C6 | 预加氢进料 | E104 | 40.0 | 58.0 | 2152.0 |

表1 换热网络的物流数据

Table 1 Stream data of the heat exchanger network

| 物流 编号 | 物流 名称 | 换热器 | 初始 温度/℃ | 目标 温度/℃ | 热负荷/ kW |

|---|---|---|---|---|---|

| H1 | R204底 | E201 | 493.4 | 117.0 | 58300.0 |

| H2 | R204底-2 | E202 | 490.8 | 190.0 | 42.4 |

| H3 | T101底 | E105 | 208.5 | 132.3 | 9914.0 |

| H4 | T102底 | E102 | 156.3 | 102.6 | 6031.0 |

| H5 | 蒸汽冷凝水 | E100 | 150.0 | 70.0 | 4690.0 |

| H6 | A201流股 | A201 | 117.2 | 42.0 | 7860.0 |

| H7 | T102顶 | A103 | 87.4 | 30.5 | 4060.0 |

| H8 | T101顶 | E104 | 69.1 | 59.4 | 2152.0 |

| A102 | 59.4 | 38.7 | 1374.0 | ||

| C1 | F201流股 | E201 | 85.5 | 453.9 | 58300.0 |

| F201 | 453.9 | 525.9 | 11070.0 | ||

| C2 | T101底-2 | F102 | 208.5 | 221.1 | 8538.0 |

| C3 | 吹扫氢 | E202 | 27.0 | 180.6 | 42.4 |

| C4 | T101进料 | E102 | 48.7 | 102.0 | 6031.0 |

| E105 | 102.0 | 179.8 | 9914.0 | ||

| C5 | T102底-2 | F103 | 156.3 | 164.4 | 9440.0 |

| C6 | 预加氢进料 | E104 | 40.0 | 58.0 | 2152.0 |

| 物流 | 改变 | 入口温度/℃ | 出口温度/℃ | 压力/kPa | 热负荷/kW | 热容流率/(kW/℃) |

|---|---|---|---|---|---|---|

| H3 | 前 | 208.5 | 132.3 | 1241.0 | 9914.0 | 130.1 |

| 后 | 201.9 | 132.3 | 1041.0 | 9007.0 | 129.4 | |

| H8 | 前 | 69.1 | 38.7 | 1187.0 | 3526.0 | 116.0 |

| 后 | 61.8 | 32.2 | 987.0 | 3605.0 | 121.8 | |

| C2 | 前 | 208.5 | 221.1 | 1241.0 | 8538.0 | 677.6 |

| 后 | 201.9 | 209.8 | 1041.0 | 6751.0 | 854.5 | |

| C4 | 前 | 48.7 | 179.8 | 1241.0 | 15945.0 | 121.6 |

| 后 | 48.7 | 179.8 | 1041.0 | 16244.0 | 123.9 |

表2 T101压力降低200.0 kPa前后相关流股数据

Table 2 Stream data before and after 200.0 kPa pressure reduction of T101

| 物流 | 改变 | 入口温度/℃ | 出口温度/℃ | 压力/kPa | 热负荷/kW | 热容流率/(kW/℃) |

|---|---|---|---|---|---|---|

| H3 | 前 | 208.5 | 132.3 | 1241.0 | 9914.0 | 130.1 |

| 后 | 201.9 | 132.3 | 1041.0 | 9007.0 | 129.4 | |

| H8 | 前 | 69.1 | 38.7 | 1187.0 | 3526.0 | 116.0 |

| 后 | 61.8 | 32.2 | 987.0 | 3605.0 | 121.8 | |

| C2 | 前 | 208.5 | 221.1 | 1241.0 | 8538.0 | 677.6 |

| 后 | 201.9 | 209.8 | 1041.0 | 6751.0 | 854.5 | |

| C4 | 前 | 48.7 | 179.8 | 1241.0 | 15945.0 | 121.6 |

| 后 | 48.7 | 179.8 | 1041.0 | 16244.0 | 123.9 |

| 换热器 名称 | 热通量/ (kJ/(℃·h)) | 降低200.0 kPa后 热通量/(kJ/(℃·h)) | 增加 倍数 |

|---|---|---|---|

| E102 | 401263.7 | 498896.5 | 1.2 |

| E104 | 520916.9 | 1037990.3 | 2.0 |

| E105 | 1209558.0 | 1533242.4 | 1.3 |

| E1 | — | 51069.6(26.8 m2) | — |

表3 T101操作压力降低200.0 kPa前后换热器热通量

Table 3 Heat flux of the heat exchangers before and after 200.0 kPa pressure reduction of T101

| 换热器 名称 | 热通量/ (kJ/(℃·h)) | 降低200.0 kPa后 热通量/(kJ/(℃·h)) | 增加 倍数 |

|---|---|---|---|

| E102 | 401263.7 | 498896.5 | 1.2 |

| E104 | 520916.9 | 1037990.3 | 2.0 |

| E105 | 1209558.0 | 1533242.4 | 1.3 |

| E1 | — | 51069.6(26.8 m2) | — |

| 13 | Lai Y Q, Wan Alwi S R, Manan Z A. Customised retrofit of heat exchanger network combining area distribution and targeted investment[J]. Energy, 2019, 179: 1054-1066. |

| 14 | Diban P, Foo D C Y. A pinch-based automated targeting technique for heating medium system[J]. Energy, 2019, 166: 193-212. |

| 15 | 刘兴隆, 刘睿, 孙兰义. 基于夹点技术的苯酚丙酮装置能量分析与节能改造[J]. 石油化工设计, 2021, 38(3): 68-74, 7. |

| Liu X L, Liu R, Sun L Y. Energy analysis and energy-saving reconstruction of phenol-acetone plant based on pinch technology[J]. Petrochemical Design, 2021, 38(3): 68-74, 7. | |

| 16 | 雷杨, 熊高源, 何昌春, 等. 考虑塔压变量优化的精馏塔间热集成[J]. 高校化学工程学报, 2017, 31(2): 329-336. |

| Lei Y, Xiong G Y, He C C, et al. Heat integration of different distillation columns considering pressure variable optimization[J]. Journal of Chemical Engineering of Chinese Universities, 2017, 31(2): 329-336. | |

| 17 | Cui C T, Zhang X D, Sun J S. Design and optimization of energy-efficient liquid-only side-stream distillation configurations using a stochastic algorithm[J]. Chemical Engineering Research and Design, 2019, 145: 48-52. |

| 18 | Shi T, Chun W, Yang A, et al. Optimization and control of energy saving side-stream extractive distillation with heat integration for separating ethyl acetate-ethanol azeotrope[J]. Chemical Engineering Science, 2020, 215: 115373. |

| 19 | 李广忠. 多效精馏节能在化工分离中的应用[J]. 广东化工, 2021, 48(22): 186-187. |

| Li G Z. Application of energy-saving multi-effect distillation in chemical separation[J]. Guangdong Chemical Industry, 2021, 48(22): 186-187. | |

| 20 | Chen X, Wang R Z, Du S. Heat integration of ammonia-water absorption refrigeration system through heat-exchanger network analysis[J]. Energy, 2017, 141: 1585-1599. |

| 21 | Hojjati M R, Namdari Ghareghani H. Conceptual design of distillation columns sequence for separation of pentane and hexane from C5+ stream of LPG unit[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020, 42(3): 267-280. |

| 1 | 黄长军. 工业污水处理过程中节能优化控制方法研究[J]. 中国高新科技, 2020(14): 110-111. |

| Huang C J. Study on the optimal control method of energy saving in industrial sewage treatment process[J]. China High and New Technology, 2020(14): 110-111. | |

| 22 | Fang J, Cheng X M, Li Z Y, et al. A review of internally heat integrated distillation column[J]. Chinese Journal of Chemical Engineering, 2019, 27(6): 1272-1281. |

| 23 | Zhang S, Luo Y Q, Ma Y J, et al. Simultaneous optimization of nonsharp distillation sequences and heat integration networks by simulated annealing algorithm[J]. Energy, 2018, 162: 1139-1157. |

| 24 | Khalili N, Kasiri N, Ivakpour J, et al. Optimal configuration of ternary distillation columns using heat integration with external heat exchangers[J]. Energy, 2020, 191: 116479. |

| 25 | Smith R, Linnhoff B. The design of separators in the context of overall processes[J]. Chemical Engineering Research and Design, 1988, 66(3): 195-228. |

| 26 | 冯霄, 王彧斐. 化工节能原理与技术[M]. 4版. 北京: 化学工业出版社, 2015. |

| Feng X, Wang Y F. Principle and Technology of Energy-saving in Chemical Industry[M]. 4th ed. Beijing: Chemical Industry Press, 2015. | |

| 27 | Smith R. Chemical Process Design and Integration[M]. 2nd ed. United Kingdom: John Wiley & Sons Inc., 2016: 923. |

| 28 | 湛世辉, 王彧斐, 冯霄. 苯乙烯装置塔系热集成[J]. 化工进展, 2015, 34(6): 1564-1568. |

| Zhan S H, Wang Y F, Feng X. Heat integration of columns in styrene plant[J]. Chemical Industry and Engineering Progress, 2015, 34(6): 1564-1568. | |

| 29 | 李婷, 李贻青, 王冬萍, 等. 己烷溶剂回收流程精馏塔系热集成[J]. 大连理工大学学报, 2019, 59(3): 232-238. |

| Li T, Li Y Q, Wang D P, et al. Heat integration of distillation column system in hexane solvent recovery process[J]. Journal of Dalian University of Technology, 2019, 59(3): 232-238. | |

| 30 | 张迪, 刘桂莲. 基于换热网络集成的二甲苯分离精馏塔参数优化[J]. 化工进展, 2016, 35(4): 1062-1067. |

| Zhang D, Liu G L. Distillation parameters optimization based on heat exchanger network integration of xylene separation process[J]. Chemical Industry and Engineering Progress, 2016, 35(4): 1062-1067. | |

| 31 | Zhang D, Liu G L. Integration of heat exchanger network considering the pressure variation of distillation column[J]. Applied Thermal Engineering, 2017, 116: 777-783. |

| 2 | 郭江申, 张嘉欣. 浅析近年来化工系统工程的发展与应用[J]. 现代盐化工, 2020, 47(1): 38-39. |

| Guo J S, Zhang J X. Brief analysis on the development and application of chemical system engineering in recent years[J]. Modern Salt and Chemical Industry, 2020, 47(1): 38-39. | |

| 3 | 王子健, 车景华, 宋昭峥, 等. AEA在常减压装置换热网络优化中的应用分析[J]. 石油石化绿色低碳, 2021, 6(4): 17-21, 51. |

| Wang Z J, Che J H, Song Z Z, et al. Application analysis of AEA optimization in heat exchange network of AVU[J]. Green Petroleum & Petrochemicals, 2021, 6(4): 17-21, 51. | |

| 4 | Linnhoff B, Hindmarsh E. The pinch design method for heat exchanger networks[J]. Chemical Engineering Science, 1983, 38(5): 745-763. |

| 5 | Cerda J, Westerberg A W, Mason D, et al. Minimum utility usage in heat exchanger network synthesis A transportation problem[J]. Chemical Engineering Science, 1983, 38(3): 373-387. |

| 6 | 王彧斐, 冯霄. 换热网络集成与优化研究进展[J]. 化学反应工程与工艺, 2014, 30(3): 271-280. |

| Wang Y F, Feng X. Progress on heat exchanger network synthesis and optimization[J]. Chemical Reaction Engineering and Technology, 2014, 30(3): 271-280. | |

| 7 | 朱文琦, 王彧斐, 冯霄. 不同操作周期下考虑结垢问题的换热网络优化[J]. 大连理工大学学报, 2019, 59(3): 264-270. |

| Zhu W Q, Wang Y F, Feng X. Heat exchanger network optimization considering fouling under different operation periods[J]. Journal of Dalian University of Technology, 2019, 59(3): 264-270. | |

| 8 | Jilak A, Assareh E, Nedaei M. Application of a novel multi-objective optimisation method integrated with the artificial neural networks for optimum design of a plate heat exchanger[J]. Australian Journal of Mechanical Engineering, 2020, 18(1): 1-15. |

| 9 | Hemmat Esfe M. Designing a neural network for predicting the heat transfer and pressure drop characteristics of Ag/water nanofluids in a heat exchanger[J]. Applied Thermal Engineering, 2017, 126: 559-565. |

| 10 | Othman A, Almomani F, Al-musleh E I, et al. Heat recovery in an actual LNG supply chain: retrofitting of designed heat exchange networks (HENs) for potential fuel saving[J]. Chemical Engineering and Processing-Process Intensification, 2021, 166: 108477. |

| 11 | Lai Y Q, Alwi S R W, Manan Z A. Heat exchanger network synthesis considering different minimum approach temperatures[J]. Chemical Engineering Transaction, 2019, 72: 283-288. |

| 12 | Li B H, Chota Castillo Y E, Chang C T. An improved design method for retrofitting industrial heat exchanger networks based on Pinch Analysis[J]. Chemical Engineering Research and Design, 2019, 148: 260-270. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [3] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [4] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [5] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [6] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [7] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [8] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [9] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [10] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [11] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [12] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [13] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [14] | 李贵贤, 曹阿波, 孟文亮, 王东亮, 杨勇, 周怀荣. 耦合固体氧化物电解槽的CO2制甲醇过程设计与评价研究[J]. 化工学报, 2023, 74(7): 2999-3009. |

| [15] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号