化工学报 ›› 2023, Vol. 74 ›› Issue (1): 380-396.DOI: 10.11949/0438-1157.20220954

黄宽1,2( ), 马永德1, 蔡镇平1, 曹彦宁1,2, 江莉龙1,2(

), 马永德1, 蔡镇平1, 曹彦宁1,2, 江莉龙1,2( )

)

收稿日期:2022-07-06

修回日期:2022-08-24

出版日期:2023-01-05

发布日期:2023-03-20

通讯作者:

江莉龙

作者简介:黄宽(1990—),男,博士,教授,huangk@fzu.edu.cn

基金资助:

Kuan HUANG1,2( ), Yongde MA1, Zhenping CAI1, Yanning CAO1,2, Lilong JIANG1,2(

), Yongde MA1, Zhenping CAI1, Yanning CAO1,2, Lilong JIANG1,2( )

)

Received:2022-07-06

Revised:2022-08-24

Online:2023-01-05

Published:2023-03-20

Contact:

Lilong JIANG

摘要:

生物柴油是一种清洁的可再生能源,是应对温室效应、环境污染、能源短缺等问题最有潜力的发展方向之一。第二代生物柴油是油脂与氢气(H2)进行加氢转化反应制得的与传统石化柴油组成类似的烃类混合物,除具有绿色环保、十六烷值高、可再生等优点外,还具有低温流动性好、含氧量低、稳定性高、热值高等特点,可与石化柴油无比例限制地混合使用。系统总结了近年来油脂催化加氢转化制备第二代生物柴油方面的研究进展,包括加氢转化机理、催化剂活性相、催化剂载体和加氢转化工艺四个方面,着重介绍高效加氢转化催化剂的设计和开发。此外,还分析了油脂催化加氢转化制备第二代生物柴油领域所面临的机遇和挑战,并对未来的发展方向进行了展望。

中图分类号:

黄宽, 马永德, 蔡镇平, 曹彦宁, 江莉龙. 油脂催化加氢转化制备第二代生物柴油研究进展[J]. 化工学报, 2023, 74(1): 380-396.

Kuan HUANG, Yongde MA, Zhenping CAI, Yanning CAO, Lilong JIANG. Research progress in catalytic hydroconversion of lipid to second-generation biodiesel[J]. CIESC Journal, 2023, 74(1): 380-396.

| 催化剂 | 反应原料 | 反应器形式 | 反应条件 | 主要产物 | 转化率/% | 选择性/% | 文献 |

|---|---|---|---|---|---|---|---|

| Pd/Al2O3 | 油酸 | 间歇式 | 325℃、2 MPa | C17烷烃 | 100 | 95 | [ |

| Ru/H-ZSM-5 | 硬脂酸甲酯 | 间歇式 | 200℃、3 MPa | C17烷烃 | 91 | 71 | [ |

| Rh/ZrO2 | 棕榈酸甲酯 | 间歇式 | 300℃、8 MPa | C15烷烃 | — | — | [ |

| Pd/HPS | 硬脂酸 | 间歇式 | 260℃、0.18 MPa | C17烷烃 | — | — | [ |

| Ru/TpPON | 油酸、棕榈酸、肉豆蔻酸等 | 间歇式 | 180℃、3 MPa | 奇数碳烷烃 | — | — | [ |

| Pt/C | 棕榈酸 | 间歇式 | 370℃ | C15烷烃 | 68 | 62 | [ |

| PtSn/SAPO-11 | 棕榈酸甲酯 | 连续式 | 375℃、3 MPa | C16烷烃 | 87 | 79 | [ |

| RuRe/TiO2 | 硬脂酸乙酯 | 间歇式 | 220℃、3 MPa | C18烷烃 | 100 | 70 | [ |

| PdFeNi/MCF | 油酸 | 间歇式 | 278℃、4 MPa | C18烷烃 | 100 | — | [ |

| PtNi/Al2O3 | 油酸 | 间歇式 | 275℃、6.21 MPa | C17烷烃 | 91 | — | [ |

| PdCu/MN270 | 油酸、亚油酸 | 间歇式 | 270℃、2 MPa | C17烷烃 | — | 99 | [ |

| Ni/Al2O3 | 油酸 | 间歇式 | 325℃、2 MPa | C17烷烃 | 77 | 58 | [ |

| Ni/Al2O3 | 硬脂酸 | 间歇式 | 300℃、3 MPa | C17烷烃 | 99 | 97 | [ |

| Ni/Al2O3 | 月桂酸甲酯 | 连续式 | 400℃、2 MPa | C11烷烃 | 91 | 69 | [ |

| Ni/HBeta | 微藻油脂 | 间歇式 | 260℃、4 MPa | C18烷烃 | — | — | [ |

| Ni/H-Y-80 | 脂肪酸甲酯、动物油脂 | 间歇式 | 300℃、3 MPa | 偶数碳烷烃 | — | — | [ |

| Ni/TS-1 | 棕榈酸 | 间歇式 | 260℃、3 MPa | C15烷烃 | 100 | 92 | [ |

| Co/H-ZSM-5 | 硬脂酸 | 间歇式 | 270℃、3 MPa | C18烷烃 | 100 | 96 | [ |

| Co/H-ZSM-22 | 棕榈酸 | 间歇式 | 260℃、2 MPa | C16烷烃 | 100 | 73 | [ |

| Fe/SBA-15 | 油酸 | 间歇式 | 290℃、3 MPa | C18烷烃 | 100 | 83 | [ |

| Fe/NC-Al2O3 | 硬脂酸 | 间歇式 | 320℃、4 MPa | C18烷烃 | — | — | [ |

| NiCu/ZrO2 | 硬脂酸 | 间歇式 | 260℃、4 MPa | C17烷烃 | — | — | [ |

| NiFe/SiO2 | 月桂酸 | 间歇式 | 300℃、3.5 MPa | C11烷烃 | 99 | 87 | [ |

| NiMo/SAPO-11 | 月桂酸甲酯 | 连续式 | 375℃、3 MPa | C12烷烃 | 100 | — | [ |

| CoMo/CNT | 棕榈酸 | 间歇式 | 200℃、4 MPa | C16烷烃 | 100 | 91 | [ |

| NiMo/PSi | 棕榈酸甲酯 | 间歇式 | 220℃、1 MPa | C15烷烃 | 100 | 71 | [ |

| CoMo/SG | 油酸 | 间歇式 | 300℃、2 MPa | C17烷烃 | 89 | 48 | [ |

| NiW/meso-Y | 微藻油脂 | 连续式 | 255℃、2 MPa | C15烷烃 | 97 | 46 | [ |

| NiMo/SiO2 | 硬脂酸 | 间歇式 | 260℃、3 MPa | C18烷烃 | 100 | 65 | [ |

| Ni/NbOx | 硬脂酸 | 间歇式 | 240℃、2.5 MPa | C17烷烃 | 99 | 73 | [ |

| NiW/SiO2 | 油酸 | 连续式 | 320℃、4 MPa | C17烷烃 | 100 | — | [ |

| MoO2/CNT | 棕榈酸 | 间歇式 | 220℃、4 MPa | C16烷烃 | 100 | 92 | [ |

表1 用于油脂加氢转化的还原态金属催化剂及其性能

Table 1 Performance of reduced metal catalysts for lipid hydroconversion

| 催化剂 | 反应原料 | 反应器形式 | 反应条件 | 主要产物 | 转化率/% | 选择性/% | 文献 |

|---|---|---|---|---|---|---|---|

| Pd/Al2O3 | 油酸 | 间歇式 | 325℃、2 MPa | C17烷烃 | 100 | 95 | [ |

| Ru/H-ZSM-5 | 硬脂酸甲酯 | 间歇式 | 200℃、3 MPa | C17烷烃 | 91 | 71 | [ |

| Rh/ZrO2 | 棕榈酸甲酯 | 间歇式 | 300℃、8 MPa | C15烷烃 | — | — | [ |

| Pd/HPS | 硬脂酸 | 间歇式 | 260℃、0.18 MPa | C17烷烃 | — | — | [ |

| Ru/TpPON | 油酸、棕榈酸、肉豆蔻酸等 | 间歇式 | 180℃、3 MPa | 奇数碳烷烃 | — | — | [ |

| Pt/C | 棕榈酸 | 间歇式 | 370℃ | C15烷烃 | 68 | 62 | [ |

| PtSn/SAPO-11 | 棕榈酸甲酯 | 连续式 | 375℃、3 MPa | C16烷烃 | 87 | 79 | [ |

| RuRe/TiO2 | 硬脂酸乙酯 | 间歇式 | 220℃、3 MPa | C18烷烃 | 100 | 70 | [ |

| PdFeNi/MCF | 油酸 | 间歇式 | 278℃、4 MPa | C18烷烃 | 100 | — | [ |

| PtNi/Al2O3 | 油酸 | 间歇式 | 275℃、6.21 MPa | C17烷烃 | 91 | — | [ |

| PdCu/MN270 | 油酸、亚油酸 | 间歇式 | 270℃、2 MPa | C17烷烃 | — | 99 | [ |

| Ni/Al2O3 | 油酸 | 间歇式 | 325℃、2 MPa | C17烷烃 | 77 | 58 | [ |

| Ni/Al2O3 | 硬脂酸 | 间歇式 | 300℃、3 MPa | C17烷烃 | 99 | 97 | [ |

| Ni/Al2O3 | 月桂酸甲酯 | 连续式 | 400℃、2 MPa | C11烷烃 | 91 | 69 | [ |

| Ni/HBeta | 微藻油脂 | 间歇式 | 260℃、4 MPa | C18烷烃 | — | — | [ |

| Ni/H-Y-80 | 脂肪酸甲酯、动物油脂 | 间歇式 | 300℃、3 MPa | 偶数碳烷烃 | — | — | [ |

| Ni/TS-1 | 棕榈酸 | 间歇式 | 260℃、3 MPa | C15烷烃 | 100 | 92 | [ |

| Co/H-ZSM-5 | 硬脂酸 | 间歇式 | 270℃、3 MPa | C18烷烃 | 100 | 96 | [ |

| Co/H-ZSM-22 | 棕榈酸 | 间歇式 | 260℃、2 MPa | C16烷烃 | 100 | 73 | [ |

| Fe/SBA-15 | 油酸 | 间歇式 | 290℃、3 MPa | C18烷烃 | 100 | 83 | [ |

| Fe/NC-Al2O3 | 硬脂酸 | 间歇式 | 320℃、4 MPa | C18烷烃 | — | — | [ |

| NiCu/ZrO2 | 硬脂酸 | 间歇式 | 260℃、4 MPa | C17烷烃 | — | — | [ |

| NiFe/SiO2 | 月桂酸 | 间歇式 | 300℃、3.5 MPa | C11烷烃 | 99 | 87 | [ |

| NiMo/SAPO-11 | 月桂酸甲酯 | 连续式 | 375℃、3 MPa | C12烷烃 | 100 | — | [ |

| CoMo/CNT | 棕榈酸 | 间歇式 | 200℃、4 MPa | C16烷烃 | 100 | 91 | [ |

| NiMo/PSi | 棕榈酸甲酯 | 间歇式 | 220℃、1 MPa | C15烷烃 | 100 | 71 | [ |

| CoMo/SG | 油酸 | 间歇式 | 300℃、2 MPa | C17烷烃 | 89 | 48 | [ |

| NiW/meso-Y | 微藻油脂 | 连续式 | 255℃、2 MPa | C15烷烃 | 97 | 46 | [ |

| NiMo/SiO2 | 硬脂酸 | 间歇式 | 260℃、3 MPa | C18烷烃 | 100 | 65 | [ |

| Ni/NbOx | 硬脂酸 | 间歇式 | 240℃、2.5 MPa | C17烷烃 | 99 | 73 | [ |

| NiW/SiO2 | 油酸 | 连续式 | 320℃、4 MPa | C17烷烃 | 100 | — | [ |

| MoO2/CNT | 棕榈酸 | 间歇式 | 220℃、4 MPa | C16烷烃 | 100 | 92 | [ |

| 催化剂 | 反应原料 | 反应器形式 | 反应条件 | 主要产物 | 转化率/% | 选择性/% | 文献 |

|---|---|---|---|---|---|---|---|

| CoMoS x | 废弃餐饮油脂 | 间歇式 | 375℃、9 MPa | C17烷烃 | 100 | 77 | [ |

| NiMoS x | 油酸 | 间歇式 | 280℃、6 MPa | C18烷烃 | 100 | 79 | [ |

| NiMoS x | 棕榈酸 | 间歇式 | 320℃、7 MPa | C16烷烃 | 95 | 79 | [ |

| NiMoS x /Al2O3 | 菜籽油 | 连续式 | 280℃、5 MPa | C18烷烃 | — | — | [ |

| CoMoS x /Al2O3 | 棕榈酸甲酯 | 间歇式 | 300℃、3.5 MPa | C16烷烃 | 100 | 72 | [ |

| NiMoS x /Al2O3 | 油酸、油酸甲酯、三油酸甘油酯 | 连续式 | 260℃、6 MPa | C17烷烃 | 80 | 60 | [ |

| NiMoS x /Al2O3 | 硬脂酸 | 间歇式 | 300℃、7 MPa | C18烷烃 | — | — | [ |

| NiWS x /Al2O3 | 废弃植物油脂 | 间歇式、连续式 | 350℃、7 MPa | C17烷烃 | 100 | — | [ |

| NiWS x /SiO2-Al2O3 | 废弃餐饮油脂 | 间歇式 | 350℃ | C17烷烃 | — | — | [ |

| NiMoS x /Al2O3 | 油酸甲酯 | 连续式 | 260℃、3 MPa | C18烷烃 | 22 | 60 | [ |

表2 用于油脂加氢转化的金属硫化物催化剂及其性能

Table 2 Performance of metal sulfide catalysts for lipid hydroconversion

| 催化剂 | 反应原料 | 反应器形式 | 反应条件 | 主要产物 | 转化率/% | 选择性/% | 文献 |

|---|---|---|---|---|---|---|---|

| CoMoS x | 废弃餐饮油脂 | 间歇式 | 375℃、9 MPa | C17烷烃 | 100 | 77 | [ |

| NiMoS x | 油酸 | 间歇式 | 280℃、6 MPa | C18烷烃 | 100 | 79 | [ |

| NiMoS x | 棕榈酸 | 间歇式 | 320℃、7 MPa | C16烷烃 | 95 | 79 | [ |

| NiMoS x /Al2O3 | 菜籽油 | 连续式 | 280℃、5 MPa | C18烷烃 | — | — | [ |

| CoMoS x /Al2O3 | 棕榈酸甲酯 | 间歇式 | 300℃、3.5 MPa | C16烷烃 | 100 | 72 | [ |

| NiMoS x /Al2O3 | 油酸、油酸甲酯、三油酸甘油酯 | 连续式 | 260℃、6 MPa | C17烷烃 | 80 | 60 | [ |

| NiMoS x /Al2O3 | 硬脂酸 | 间歇式 | 300℃、7 MPa | C18烷烃 | — | — | [ |

| NiWS x /Al2O3 | 废弃植物油脂 | 间歇式、连续式 | 350℃、7 MPa | C17烷烃 | 100 | — | [ |

| NiWS x /SiO2-Al2O3 | 废弃餐饮油脂 | 间歇式 | 350℃ | C17烷烃 | — | — | [ |

| NiMoS x /Al2O3 | 油酸甲酯 | 连续式 | 260℃、3 MPa | C18烷烃 | 22 | 60 | [ |

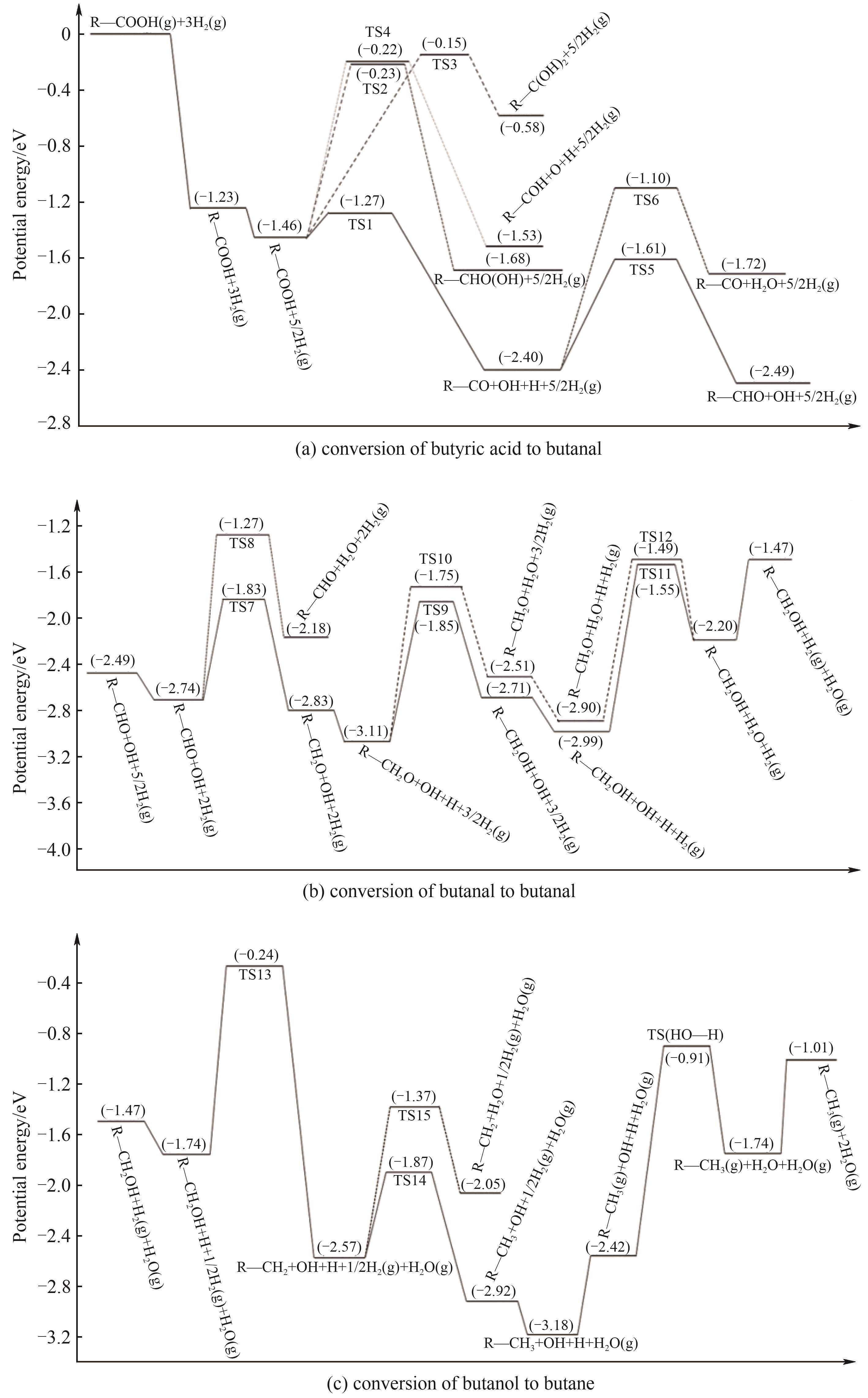

图8 丁酸在六方Mo2C (101)晶面上加氢转化生成丁烷的全势能面[90]

Fig.8 Full potential energy surface for hydroconversion of butyric acid to butane on hexagonal Mo2C (101) surface[90]

图10 棕榈酸甲酯在Pt/SiO2-ZSM-22催化剂上的加氢转化及异构化[104](1 Å=0.1 nm)

Fig.10 Hydroconversion and isomerization of methyl palmitate over Pt/SiO2-ZSM-22 catalysts[104]

| 1 | 刘明亮, 卫浩, 盖玉龙, 等. 中国、美国、欧盟及世界一次能源消费现状与展望[J]. 煤化工, 2022, 50(2): 1-5. |

| Liu M L, Wei H, Gai Y L, et al. Current situation and outlook of primary energy consumption in China, US, EU and the world[J]. Coal Chemical Industry, 2022, 50(2): 1-5. | |

| 2 | Kaarstad O. Fossil fuels and responses to global warming[J]. Energy Conversion and Management, 1995, 36(6/7/8/9): 869-872. |

| 3 | 张臻烨, 胡山鹰, 金涌. 2060中国碳中和: 化石能源转向化石资源时代[J]. 现代化工, 2021, 41(6): 1-5. |

| Zhang Z Y, Hu S Y, Jin Y. China achieving carbon neutral in 2060: fossil energy to fossil resource era[J]. Modern Chemical Industry, 2021, 41(6): 1-5. | |

| 4 | 王东军, 姜伟, 赵仲阳, 等. 油脂制备生物柴油工业化技术进展[J]. 天然气化工(C1化学与化工), 2017, 42(5): 114-119. |

| Wang D J, Jiang W, Zhao Z Y, et al. Progress in industrialization technologies for preparation of biodiesel from oils and fats[J]. Natural Gas Chemical Industry, 2017, 42(5): 114-119. | |

| 5 | 雪晶, 侯丹, 王旻烜, 等. 世界生物质能产业与技术发展现状及趋势研究[J]. 石油科技论坛, 2020, 39(3): 25-35. |

| Xue J, Hou D, Wang M X, et al. Research on current conditions and development trends of global biomass energy industry and technology[J]. Petroleum Science and Technology Forum, 2020, 39(3): 25-35. | |

| 6 | Meher L C, Sagar D V, Naik S N. Technical aspects of biodiesel production by transesterification—a review[J]. Renewable and Sustainable Energy Reviews, 2006, 10(3): 248-268. |

| 7 | Demirbas A. Biodiesel production from vegetable oils via catalytic and non-catalytic supercritical methanol transesterification methods[J]. Progress in Energy and Combustion Science, 2005, 31(5/6): 466-487. |

| 8 | Bhuiya M M K, Rasul M G, Khan M M K, et al. Second generation biodiesel: potential alternative to-edible oil-derived biodiesel[J]. Energy Procedia, 2014, 61: 1969-1972. |

| 9 | Mohammad M, Kandaramath H T, Yaakob Z, et al. Overview on the production of paraffin based-biofuels via catalytic hydrodeoxygenation[J]. Renewable and Sustainable Energy Reviews, 2013, 22: 121-132. |

| 10 | Ameen M, Azizan M T, Yusup S, et al. Catalytic hydrodeoxygenation of triglycerides: an approach to clean diesel fuel production[J]. Renewable and Sustainable Energy Reviews, 2017, 80: 1072-1088. |

| 11 | Li X, Luo X Y, Jin Y B, et al. Heterogeneous sulfur-free hydrodeoxygenation catalysts for selectively upgrading the renewable bio-oils to second generation biofuels[J]. Renewable and Sustainable Energy Reviews, 2018, 82: 3762-3797. |

| 12 | Smith B, Greenwell H C, Whiting A. Catalytic upgrading of tri-glycerides and fatty acids to transport biofuels[J]. Energy Environ. Sci., 2009, 2(3): 262-271. |

| 13 | Şenol O İ, Viljava T R, Krause A O I. Hydrodeoxygenation of methyl esters on sulphided NiMo/γ-Al2O3 and CoMo/γ-Al2O3 catalysts[J]. Catalysis Today, 2005, 100(3/4): 331-335. |

| 14 | Monnier J, Sulimma H, Dalai A, et al. Hydrodeoxygenation of oleic acid and canola oil over alumina-supported metal nitrides[J]. Applied Catalysis A: General, 2010, 382(2): 176-180. |

| 15 | Yoosuk B, Sanggam P, Wiengket S, et al. Hydrodeoxygenation of oleic acid and palmitic acid to hydrocarbon-like biofuel over unsupported Ni-Mo and Co-Mo sulfide catalysts[J]. Renewable Energy, 2019, 139: 1391-1399. |

| 16 | Zhou L, Lawal A. Kinetic study of hydrodeoxygenation of palmitic acid as a model compound for microalgae oil over Pt/γ-Al2O3 [J]. Applied Catalysis A: General, 2017, 532: 40-49. |

| 17 | Zhang H P, Lin H F, Wang W Z, et al. Hydroprocessing of waste cooking oil over a dispersed nano catalyst: kinetics study and temperature effect[J]. Applied Catalysis B: Environmental, 2014, 150/151: 238-248. |

| 18 | Zhang L L, Zhou M X, Wang A Q, et al. Selective hydrogenation over supported metal catalysts: from nanoparticles to single atoms[J]. Chemical Reviews, 2020, 120(2): 683-733. |

| 19 | Filonenko G A, van Putten R, Hensen E J M, et al. Catalytic (de) hydrogenation promoted by non-precious metals-Co, Fe and Mn: recent advances in an emerging field[J]. Chemical Society Reviews, 2018, 47(4): 1459-1483. |

| 20 | Madsen A T, Ahmed E H, Christensen C H, et al. Hydrodeoxygenation of waste fat for diesel production: study on model feed with Pt/alumina catalyst[J]. Fuel, 2011, 90(11): 3433-3438. |

| 21 | Chen J Z, Xu Q Y. Hydrodeoxygenation of biodiesel-related fatty acid methyl esters to diesel-range alkanes over zeolite-supported ruthenium catalysts[J]. Catalysis Science & Technology, 2016, 6(19): 7239-7251. |

| 22 | Bie Y W, Lehtonen J, Kanervo J. Hydrodeoxygenation (HDO) of methyl palmitate over bifunctional Rh/ZrO2 catalyst: insights into reaction mechanism via kinetic modeling[J]. Applied Catalysis A: General, 2016, 526: 183-190. |

| 23 | Sapunov V N, Stepacheva А А, Sulman E M, et al. Stearic acid hydrodeoxygenation over Pd nanoparticles embedded in mesoporous hypercrosslinked polystyrene[J]. Journal of Industrial and Engineering Chemistry, 2017, 46: 426-435. |

| 24 | Mondal S, Singuru R, Chandra S S, et al. Ruthenium nanoparticle-decorated porous organic network for direct hydrodeoxygenation of long-chain fatty acids to alkanes[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(2): 1610-1619. |

| 25 | Liu X, Yang M, Deng Z H, et al. Hydrothermal hydrodeoxygenation of palmitic acid over Pt/C catalyst: mechanism and kinetic modeling[J]. Chemical Engineering Journal, 2021, 407: 126332. |

| 26 | Chen N, Ren Y X, Qian E W. Elucidation of the active phase in PtSn/SAPO-11 for hydrodeoxygenation of methyl palmitate[J]. Journal of Catalysis, 2016, 334: 79-88. |

| 27 | Zhou L L, Lin W W, Liu K, et al. Hydrodeoxygenation of ethyl stearate over re-promoted Ru/TiO2 catalysts: rate enhancement and selectivity control by the addition of Re[J]. Catalysis Science & Technology, 2020, 10(1): 222-230. |

| 28 | Bhattacharjee S, Lu W Y, Tan C S. A cleaner route for hydrodeoxygenation of oleic acid in hexane containing pressurized CO2 over a MCF supported Fe-Pd-Ni trimetallic catalyst[J]. Fuel, 2019, 243: 210-220. |

| 29 | Domínguez-Barroso V, Herrera C, Larrubia M Á, et al. Coupling of glycerol-APR and in situ hydrodeoxygenation of fatty acid to produce hydrocarbons[J]. Fuel Processing Technology, 2019, 190: 21-28. |

| 30 | Schipanskaya E O, Stepacheva A A, Markova M E, et al. Alkane production from unsaturated fatty acids over transition metal-doped Pd catalysts[J]. Chemical Engineering & Technology, 2021, 44(11): 2109-2115. |

| 31 | Jeništová K, Hachemi I, Mäki-Arvela P, et al. Hydrodeoxygenation of stearic acid and tall oil fatty acids over Ni-alumina catalysts: influence of reaction parameters and kinetic modelling[J]. Chemical Engineering Journal, 2017, 316: 401-409. |

| 32 | Chen S, Zhou G L, Xie H M, et al. Hydrodeoxygenation of methyl laurate over the sulfur-free Ni/γ-Al2O3 catalysts[J]. Applied Catalysis A: General, 2019, 569: 35-44. |

| 33 | Peng B X, Yao Y, Zhao C, et al. Towards quantitative conversion of microalgae oil to diesel-range alkanes with bifunctional catalysts[J]. Angewandte Chemie International Edition, 2012, 51(9): 2072-2075. |

| 34 | Hachemi I, Murzin D Y. Kinetic modeling of fatty acid methyl esters and triglycerides hydrodeoxygenation over nickel and palladium catalysts[J]. Chemical Engineering Journal, 2018, 334: 2201-2207. |

| 35 | Chen J L, Zhu Y F, Li W B, et al. Production of diesel-like hydrocarbons via hydrodeoxygenation of palmitic acid over Ni/TS-1 catalyst[J]. Biomass and Bioenergy, 2021, 149: 106081. |

| 36 | Wu G J, Zhang N, Dai W L, et al. Construction of bifunctional Co/H-ZSM-5 catalysts for the hydrodeoxygenation of stearic acid to diesel-range alkanes[J]. ChemSusChem, 2018, 11(13): 2179-2188. |

| 37 | Cao Y Y, Shi Y C, Bi Y F, et al. Hydrodeoxygenation and hydroisomerization of palmitic acid over bi-functional Co/H-ZSM-22 catalysts[J]. Fuel Processing Technology, 2018, 172: 29-35. |

| 38 | Bhattacharjee S, Tan C S. Hydrodeoxygenation of oleic acid in hexane containing pressurized CO2 using Fe/SBA-15 as catalyst[J]. Journal of Cleaner Production, 2017, 156: 203-213. |

| 39 | Li J, Zhang J J, Wang S, et al. Chemoselective hydrodeoxygenation of carboxylic acids to hydrocarbons over nitrogen-doped carbon-alumina hybrid supported iron catalysts[J]. ACS Catalysis, 2019, 9(2): 1564-1577. |

| 40 | Denk C, Foraita S, Kovarik L, et al. Rate enhancement by Cu in Ni x Cu1– x /ZrO2 bimetallic catalysts for hydrodeoxygenation of stearic acid[J]. Catalysis Science & Technology, 2019, 9(10): 2620-2629. |

| 41 | Han D P, Yin W, Luo D, et al. Hydrodeoxygenation of aliphatic acid over NiFe intermetallic compounds: insights into the mechanism via model compound study[J]. Fuel, 2021, 305: 121545. |

| 42 | Chen N, Gong S F, Qian E W. Effect of reduction temperature of NiMoO3- x /SAPO-11 on its catalytic activity in hydrodeoxygenation of methyl laurate[J]. Applied Catalysis B: Environmental, 2015, 174/175: 253-263. |

| 43 | Ding R R, Wu Y L, Chen Y, et al. Catalytic hydrodeoxygenation of palmitic acid over a bifunctional Co-doped MoO2/CNTs catalyst: an insight into the promoting effect of cobalt[J]. Catalysis Science & Technology, 2016, 6(7): 2065-2076. |

| 44 | Yan L, Liu X X, Deng J, et al. Molybdenum modified nickel phyllosilicates as a high performance bifunctional catalyst for deoxygenation of methyl palmitate to alkanes under mild conditions[J]. Green Chemistry, 2017, 19(19): 4600-4609. |

| 45 | Shim J O, Jeon K W, Jang W J, et al. Facile production of biofuel via solvent-free deoxygenation of oleic acid using a CoMo catalyst[J]. Applied Catalysis B: Environmental, 2018, 239: 644-653. |

| 46 | Cheng J, Zhang Z, Zhang X, et al. Hydrodeoxygenation and hydrocracking of microalgae biodiesel to produce jet biofuel over H3PW12O40-Ni/hierarchical mesoporous zeolite Y catalyst[J]. Fuel, 2019, 245: 384-391. |

| 47 | Cao X C, Long F, Zhai Q L, et al. Enhancement of fatty acids hydrodeoxygenation selectivity to diesel-range alkanes over the supported Ni-MoO x catalyst and elucidation of the active phase[J]. Renewable Energy, 2020, 162: 2113-2125. |

| 48 | Chen L, Li G C, Zhang M J, et al. Preparation of reduced Ni-Nb-O composite hydrogenation catalysts for highly selective conversion of free fatty acids to n-alkanes[J]. Fuel, 2020, 282: 118842. |

| 49 | Xing S Y, Liu Y, Liu X C, et al. Solvent-free hydrodeoxygenation of bio-lipids into renewable alkanes over NiW bimetallic catalyst under mild conditions[J]. Applied Catalysis B: Environmental, 2020, 269: 118718. |

| 50 | Lee C W, Lin P Y, Chen B H, et al. Hydrodeoxygenation of palmitic acid over zeolite-supported nickel catalysts[J]. Catalysis Today, 2021, 379: 124-131. |

| 51 | Ding R R, Wu Y L, Chen Y, et al. Effective hydrodeoxygenation of palmitic acid to diesel-like hydrocarbons over MoO2/CNTs catalyst[J]. Chemical Engineering Science, 2015, 135: 517-525. |

| 52 | Pecoraro T. Hydrodesulfurization catalysis by transition metal sulfides[J]. Journal of Catalysis, 1981, 67(2): 430-445. |

| 53 | Chianelli R R. Fundamental studies of transition metal sulfide hydrodesulfurization catalysts[J]. Catalysis Reviews, 1984, 26(3/4): 361-393. |

| 54 | Liu D, Li Z H, Wu C C, et al. Exploration of in situ formed MoSx catalyst for co-hydrodeoxygenation of sawdust and vacuum gas oil in pilot-scale plant[J]. Applied Catalysis B: Environmental, 2021, 297: 120499. |

| 55 | Rana M S, Ramírez J, Gutiérrez-Alejandre A, et al. Support effects in CoMo hydrodesulfurization catalysts prepared with EDTA as a chelating agent[J]. Journal of Catalysis, 2007, 246(1): 100-108. |

| 56 | Lai W K, Xu Y R, Ren Y H, et al. Insight into the effect of non-stoichiometric sulfur on a NiMoS hydrodesulfurization catalyst[J]. Catalysis Science & Technology, 2016, 6(2): 497-506. |

| 57 | Shan S F, Liu H Y, Yue Y Y, et al. Trimetallic WMoNi diesel ultra-deep hydrodesulfurization catalysts with enhanced synergism prepared from inorganic-organic hybrid nanocrystals[J]. Journal of Catalysis, 2016, 344: 325-333. |

| 58 | Kubička D, Kaluža L. Deoxygenation of vegetable oils over sulfided Ni, Mo and NiMo catalysts[J]. Applied Catalysis A: General, 2010, 372(2): 199-208. |

| 59 | Liu G L, Robertson A W, Li M M J, et al. MoS2 monolayer catalyst doped with isolated Co atoms for the hydrodeoxygenation reaction[J]. Nature Chemistry, 2017, 9(8): 810-816. |

| 60 | Nguyen M T, Nguyen N T, Cho J, et al. A review on the oil-soluble dispersed catalyst for slurry-phase hydrocracking of heavy oil[J]. Journal of Industrial and Engineering Chemistry, 2016, 43: 1-12. |

| 61 | Zhang S Y, Liu D, Deng W A, et al. A review of slurry-phase hydrocracking heavy oil technology[J]. Energy & Fuels, 2007, 21(6): 3057-3062. |

| 62 | Ma Y D, Zhang J Y, Wu W Q, et al. Trialkylmethylammonium molybdate ionic liquids as novel oil-soluble precursors of dispersed metal catalysts for slurry-phase hydrocracking of heavy oils[J]. Chemical Engineering Science, 2022, 253: 117516. |

| 63 | Cai Z P, Ma Y D, Zhang J Y, et al. Tunable ionic liquids as oil-soluble precursors of dispersed catalysts for suspended-bed hydrocracking of heavy residues[J]. Fuel, 2022, 313: 122664. |

| 64 | Deliy I V, Vlasova E N, Nuzhdin A L, et al. Hydrodeoxygenation of methyl palmitate over sulfided Mo/Al2O3, CoMo/Al2O3 and NiMo/Al2O3 catalysts[J]. RSC Advances, 2014, 4(5): 2242-2250. |

| 65 | Coumans A E, Hensen E J M. A model compound (methyl oleate, oleic acid, triolein) study of triglycerides hydrodeoxygenation over alumina-supported NiMo sulfide[J]. Applied Catalysis B: Environmental, 2017, 201: 290-301. |

| 66 | Arora P, Grennfelt E L, Olsson L, et al. Kinetic study of hydrodeoxygenation of stearic acid as model compound for renewable oils[J]. Chemical Engineering Journal, 2019, 364: 376-389. |

| 67 | Toba M, Abe Y, Kuramochi H, et al. Hydrodeoxygenation of waste vegetable oil over sulfide catalysts[J]. Catalysis Today, 2011, 164(1): 533-537. |

| 68 | Hidalgo-Herrador J M, Frątczak J, Velvarská R, et al. Oxalic acid-mediated catalytic transfer hydrodeoxygenation of waste cooking oil[J]. Molecular Catalysis, 2020, 491: 110973. |

| 69 | Ojagh H, Creaser D, Tamm S, et al. Effect of dimethyl disulfide on activity of NiMo based catalysts used in hydrodeoxygenation of oleic acid[J]. Industrial & Engineering Chemistry Research, 2017, 56(19): 5547-5557. |

| 70 | Wang W Y, Wu K, Tan S, et al. Hydrothermal synthesis of carbon-coated CoS2-MoS2 catalysts with enhanced hydrophobicity and hydrodeoxygenation activity[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(10): 8602-8609. |

| 71 | Wu K, Liu Y, Wang W Y, et al. Preparation of hydrophobic MoS2, NiS2-MoS2 and CoS2-MoS2 for catalytic hydrodeoxygenation of lignin-derived phenols[J]. Molecular Catalysis, 2019, 477: 110537. |

| 72 | Wang R, Smith K J. Hydrodesulfurization of 4, 6-dimethyldibenzothiophene over high surface area metal phosphides[J]. Applied Catalysis A: General, 2009, 361(1/2): 18-25. |

| 73 | Guan Q X, Cheng X, Li R G, et al. A feasible approach to the synthesis of nickel phosphide for hydrodesulfurization[J]. Journal of Catalysis, 2013, 299: 1-9. |

| 74 | Peroni M, Mancino G, Baráth E, et al. Bulk and γ-Al2O3-supported Ni2P and MoP for hydrodeoxygenation of palmitic acid[J]. Applied Catalysis B: Environmental, 2016, 180: 301-311. |

| 75 | Guan Q X, Wan F F, Han F, et al. Hydrodeoxygenation of methyl palmitate over MCM-41 supported nickel phosphide catalysts[J]. Catalysis Today, 2016, 259: 467-473. |

| 76 | Shamanaev I V, Deliy I V, Aleksandrov P V, et al. Methyl palmitate hydrodeoxygenation over silica-supported nickel phosphide catalysts in flow reactor: experimental and kinetic study[J]. Journal of Chemical Technology & Biotechnology, 2019, 94(9): 3007-3019. |

| 77 | Ruangudomsakul M, Osakoo N, Keawkumay C, et al. Influential properties of activated carbon on dispersion of nickel phosphides and catalytic performance in hydrodeoxygenation of palm oil[J]. Catalysis Today, 2021, 367: 153-164. |

| 78 | Pan Z Y, Wang R J, Nie Z Y, et al. Effect of a second metal (Co, Fe, Mo and W) on performance of Ni2P/SiO2 for hydrodeoxygenation of methyl laurate[J]. Journal of Energy Chemistry, 2016, 25(3): 418-426. |

| 79 | Zhang Z G, Bi G C, Zhang H D, et al. Highly active and selective hydrodeoxygenation of oleic acid to second generation bio-diesel over SiO2-supported Co x Ni1- x P catalysts[J]. Fuel, 2019, 247: 26-35. |

| 80 | García-Pérez D, Alvarez-Galvan M C, Capel-Sanchez M C, et al. Influence of bimetallic characteristics on the performance of MoCoP and MoFeP catalysts for methyl laurate hydrodeoxygenation[J]. Catalysis Today, 2021, 367: 43-50. |

| 81 | Rodriguez J A, Liu P, Stacchiola D J, et al. Hydrogenation of CO2 to methanol: importance of metal-oxide and metal-carbide interfaces in the activation of CO2 [J]. ACS Catalysis, 2015, 5(11): 6696-6706. |

| 82 | Prats H, Piñero J J, Viñes F, et al. Assessing the usefulness of transition metal carbides for hydrogenation reactions[J]. Chemical Communications, 2019, 55(85): 12797-12800. |

| 83 | Han J X, Duan J Z, Chen P, et al. Nanostructured molybdenum carbides supported on carbon nanotubes as efficient catalysts for one-step hydrodeoxygenation and isomerization of vegetable oils[J]. Green Chemistry, 2011, 13(9): 2561. |

| 84 | Hollak S A W, Gosselink R W, van Es D S, et al. Comparison of tungsten and molybdenum carbide catalysts for the hydrodeoxygenation of oleic acid[J]. ACS Catalysis, 2013, 3(12): 2837-2844. |

| 85 | Qin Y, Chen P, Duan J Z, et al. Carbon nanofibers supported molybdenum carbide catalysts for hydrodeoxygenation of vegetable oils[J]. RSC Advances, 2013, 3(38): 17485. |

| 86 | Souza M L, Oliveira R R, van Haasterecht T, et al. Influence of synthesis method on molybdenum carbide crystal structure and catalytic performance in stearic acid hydrodeoxygenation[J]. Applied Catalysis B: Environmental, 2019, 241: 81-88. |

| 87 | Smirnov A A, Geng Z, Khromova S A, et al. Nickel molybdenum carbides: synthesis, characterization, and catalytic activity in hydrodeoxygenation of anisole and ethyl caprate[J]. Journal of Catalysis, 2017, 354: 61-77. |

| 88 | Masoumi S, Dalai A K. NiMo carbide supported on algal derived activated carbon for hydrodeoxygenation of algal biocrude oil[J]. Energy Conversion and Management, 2021, 231: 113834. |

| 89 | Yu C, Yu S T, Li L. Upgraded methyl oleate to diesel-like hydrocarbons through selective hydrodeoxygenation over Mo-based catalyst[J]. Fuel, 2022, 308: 122038. |

| 90 | Shi Y, Yang Y, Li Y W, et al. Theoretical study about Mo2C(101)-catalyzed hydrodeoxygenation of butyric acid to butane for biomass conversion[J]. Catalysis Science & Technology, 2016, 6(13): 4923-4936. |

| 91 | Wang S M, Ge H, Sun S L, et al. A new molybdenum nitride catalyst with rhombohedral MoS2 structure for hydrogenation applications[J]. Journal of the American Chemical Society, 2015, 137(14): 4815-4822. |

| 92 | Wu Z L, Hao Z X, Ying P L, et al. An IR study on selective hydrogenation of 1, 3-butadiene on transition metal nitrides: 1, 3-butadiene and 1-butene adsorption on Mo2N/γ-Al2O3 catalyst[J]. The Journal of Physical Chemistry B, 2000, 104(51): 12275-12281. |

| 93 | Arun N, Maley J, Chen N, et al. NiMo nitride supported on γ-Al2O3 for hydrodeoxygenation of oleic acid: novel characterization and activity study[J]. Catalysis Today, 2017, 291: 153-159. |

| 94 | Schreiber M W, Rodriguez-Niño D, Gutiérrez O Y, et al. Hydrodeoxygenation of fatty acid esters catalyzed by Ni on nano-sized MFI type zeolites[J]. Catalysis Science & Technology, 2016, 6(22): 7976-7984. |

| 95 | Hachemi I, Jeništová K, Mäki-Arvela P, et al. Comparative study of sulfur-free nickel and palladium catalysts in hydrodeoxygenation of different fatty acid feedstocks for production of biofuels[J]. Catalysis Science & Technology, 2016, 6(5): 1476-1487. |

| 96 | Hachemi I, Kumar N, Mäki-Arvela P, et al. Sulfur-free Ni catalyst for production of green diesel by hydrodeoxygenation[J]. Journal of Catalysis, 2017, 347: 205-221. |

| 97 | Coumans A E, Hensen E J M. A real support effect on the hydrodeoxygenation of methyl oleate by sulfided NiMo catalysts[J]. Catalysis Today, 2017, 298: 181-189. |

| 98 | Phan D P, le V N, Nguyen T H, et al. Effect of amino-defective-MOF materials on the selective hydrodeoxygenation of fatty acid over Pt-based catalysts[J]. Journal of Catalysis, 2021, 400: 283-293. |

| 99 | Liu H F, Han J Y, Huang Q T, et al. Catalytic hydrodeoxygenation of methyl stearate and microbial lipids to diesel-range alkanes over Pd/HPA-SiO2 catalysts[J]. Industrial & Engineering Chemistry Research, 2020, 59(39): 17440-17450. |

| 100 | Ma B, Yi X F, Chen L, et al. Interconnected hierarchical HUSY zeolite-loaded Ni nano-particles probed for hydrodeoxygenation of fatty acids, fatty esters, and palm oil[J]. Journal of Materials Chemistry A, 2016, 4(29): 11330-11341. |

| 101 | Nikulshin P A, Salnikov V A, Varakin A N, et al. The use of CoMoS catalysts supported on carbon-coated alumina for hydrodeoxygenation of guaiacol and oleic acid[J]. Catalysis Today, 2016, 271: 45-55. |

| 102 | Baharudin K B, Arumugam M, Hunns J, et al. Octanoic acid hydrodeoxygenation over bifunctional Ni/Al-SBA-15 catalysts[J]. Catalysis Science & Technology, 2019, 9(23): 6673-6680. |

| 103 | Yang Y H, Wang Q F, Zhang X W, et al. Hydrotreating of C18 fatty acids to hydrocarbons on sulphided NiW/SiO2-Al2O3 [J]. Fuel Processing Technology, 2013, 116: 165-174. |

| 104 | Chen N, Wang N N, Ren Y X, et al. Effect of surface modification with silica on the structure and activity of Pt/ZSM-22@SiO2 catalysts in hydrodeoxygenation of methyl palmitate[J]. Journal of Catalysis, 2017, 345: 124-134. |

| 105 | 吴孟德, 李广慈, 李明时, 等. 重质油悬浮床加氢技术和相关催化剂的研究进展[J]. 工业催化, 2020, 28(12): 1-11. |

| Wu M D, Li G C, Li M S, et al. Research progress on residue slurry-bed hydrogenation technology and related catalysts[J]. Industrial Catalysis, 2020, 28(12): 1-11. | |

| 106 | Garedew M, Young-Farhat D, Jackson J E, et al. Electrocatalytic upgrading of phenolic compounds observed after lignin pyrolysis[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(9): 8375-8386. |

| 107 | Liu W, You W Q, Gong Y T, et al. High-efficiency electrochemical hydrodeoxygenation of bio-phenols to hydrocarbon fuels by a superacid-noble metal particle dual-catalyst system[J]. Energy & Environmental Science, 2020, 13(3): 917-927. |

| 108 | Zhai Q L, Han S M, Wang K, et al. Electrocatalytic cleavage of aryl ether C—O linkages in lignin model dimers[J]. Fuel Processing Technology, 2022, 235: 107350. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [3] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [4] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [5] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [6] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [7] | 倪文翔, 赵京, 李博, 魏小林, 吴东垠, 刘迪, 王强. 转炉煤气全干法显热回收工艺中余热锅炉积灰特性研究[J]. 化工学报, 2023, 74(8): 3485-3493. |

| [8] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [9] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [10] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [11] | 林典, 江国梅, 徐秀彬, 赵波, 刘冬梅, 吴旭. 硅基类液防原油黏附涂层的研制及其减阻性能研究[J]. 化工学报, 2023, 74(8): 3438-3445. |

| [12] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [13] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [14] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [15] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号