化工学报 ›› 2023, Vol. 74 ›› Issue (8): 3203-3215.DOI: 10.11949/0438-1157.20230541

张佳怡1( ), 何佳莉1, 谢江鹏1, 王健1, 赵鹬1,2, 张栋强1,2(

), 何佳莉1, 谢江鹏1, 王健1, 赵鹬1,2, 张栋强1,2( )

)

收稿日期:2023-06-05

修回日期:2023-08-02

出版日期:2023-08-25

发布日期:2023-10-18

通讯作者:

张栋强

作者简介:张佳怡(1998—),女,硕士研究生,212081702005@lut.edu.cn

基金资助:

Jiayi ZHANG1( ), Jiali HE1, Jiangpeng XIE1, Jian WANG1, Yu ZHAO1,2, Dongqiang ZHANG1,2(

), Jiali HE1, Jiangpeng XIE1, Jian WANG1, Yu ZHAO1,2, Dongqiang ZHANG1,2( )

)

Received:2023-06-05

Revised:2023-08-02

Online:2023-08-25

Published:2023-10-18

Contact:

Dongqiang ZHANG

摘要:

N-甲基吡咯烷酮(NMP)作为生产锂电池的必备溶剂,需求量逐年攀升。然而在锂电池生产后期NMP以废气形式排出,将会造成环境污染和资源浪费。用水吸收NMP废气形成相应溶液是一种有效的回收方法,进而将NMP溶液回收利用可以降低锂电池生产成本,促进锂电行业绿色可持续发展。相较于蒸馏等传统工艺,采用渗透汽化技术回收NMP废液具有能耗低、高效、环保等优势。从渗透汽化膜分离技术的优势和机理展开,系统总结了用于回收NMP废液的渗透汽化膜材料和分离工艺,通过比较不同膜材料和工艺的应用范围及分离效果,指出了其相应的优缺点和适用场合,为NMP的有效利用提供合理的参考。对渗透汽化技术用于NMP回收面临的挑战进行讨论并对发展前景做出展望。

中图分类号:

张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215.

Jiayi ZHANG, Jiali HE, Jiangpeng XIE, Jian WANG, Yu ZHAO, Dongqiang ZHANG. Research progress of pervaporation technology for N-methylpyrrolidone recovery in lithium battery production[J]. CIESC Journal, 2023, 74(8): 3203-3215.

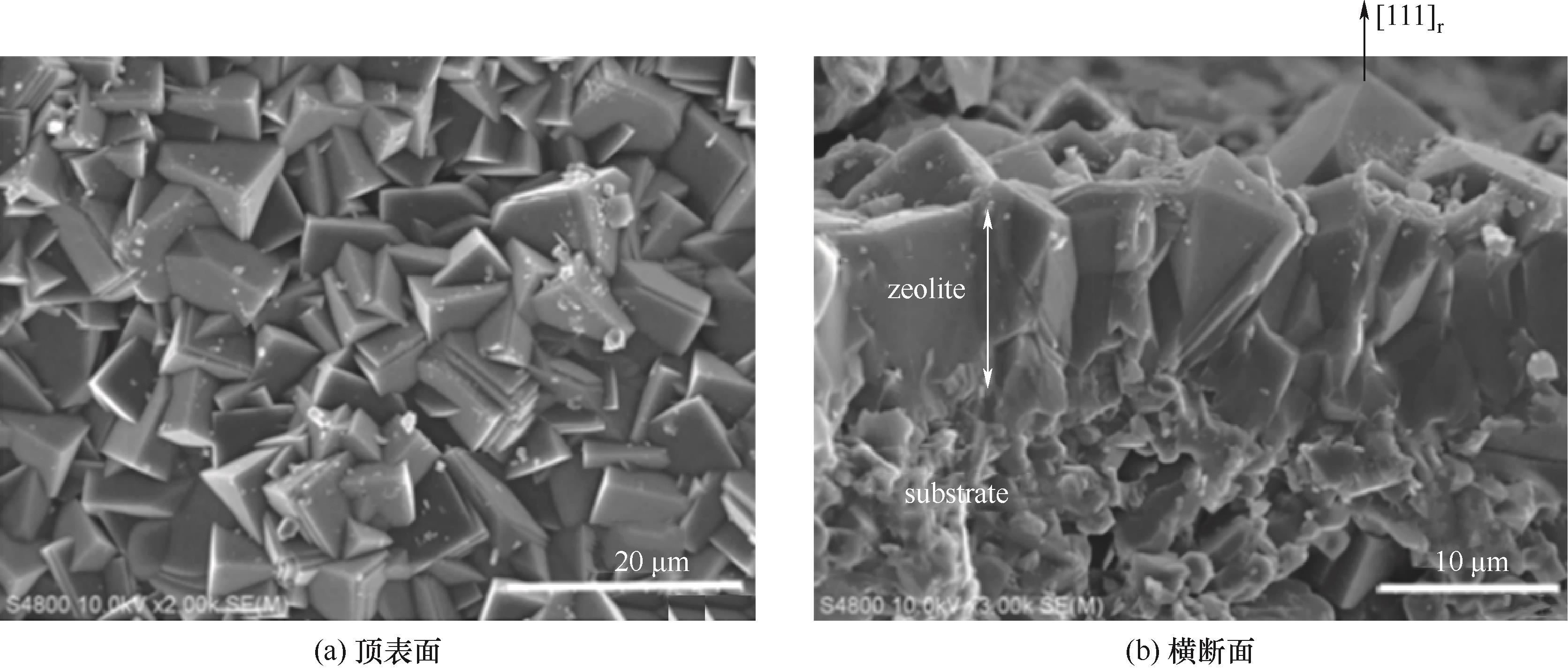

图3 高硅CHA型沸石膜的顶表面和横断面的SEM图像[62]

Fig.3 SEM (scanning electron microscopy) images for top surface and cross-section of a high silica CHA-type zeolite membrane synthesized for 48 h[62]

| 膜类型 | 进料/% | 渗透液/% | 通量/(g/(m2·h)) | 选择性 | ||

|---|---|---|---|---|---|---|

| NMP | H2O | NMP | H2O | |||

| 15% PEBA-2533 | 97.12 | 2.88 | 37.22 | 63 | 41.50 | 56.96 |

| 15% PEBA-2533 + 10% zeolite | 97.12 | 2.88 | 36.47 | 64 | 45.14 | 58.84 |

| 15% PEBA-2533 + 20% zeolite | 97.12 | 2.88 | 33.28 | 67 | 48.64 | 67.71 |

| 15% PEBA-2533 + 30% zeolite | 97.12 | 2.88 | 38.18 | 62 | 50.48 | 54.68 |

| 15% PEBA-2533 + 2% TDI crosslinked for 2 h | 97.12 | 2.88 | 35.14 | 65 | 44.64 | 62.34 |

| 15% PEBA-2533 + 10% zeolite + 2% TDI crosslinked for 2 h | 97.12 | 2.88 | 35.9 | 64 | 49.47 | 60.3 |

| 15% PEBA-2533 + 20% zeolite + 2% TDI crosslinked for 2 h | 97.12 | 2.88 | 30.75 | 69 | 51.74 | 76.06 |

| 15% PEBA-2533 + 30% zeolite + 2% TDI crosslinked for 2 h | 97.12 | 2.88 | 21.69 | 78 | 54.94 | 121.95 |

表1 不同沸石负载量下PEBA-2533膜渗透汽化回收NMP的性能[64]

Table 1 Effect of zeolite loading on membrane performance for NMP dehydration at constant temperature (30℃) and permeate pressure (133.3 Pa)[64]

| 膜类型 | 进料/% | 渗透液/% | 通量/(g/(m2·h)) | 选择性 | ||

|---|---|---|---|---|---|---|

| NMP | H2O | NMP | H2O | |||

| 15% PEBA-2533 | 97.12 | 2.88 | 37.22 | 63 | 41.50 | 56.96 |

| 15% PEBA-2533 + 10% zeolite | 97.12 | 2.88 | 36.47 | 64 | 45.14 | 58.84 |

| 15% PEBA-2533 + 20% zeolite | 97.12 | 2.88 | 33.28 | 67 | 48.64 | 67.71 |

| 15% PEBA-2533 + 30% zeolite | 97.12 | 2.88 | 38.18 | 62 | 50.48 | 54.68 |

| 15% PEBA-2533 + 2% TDI crosslinked for 2 h | 97.12 | 2.88 | 35.14 | 65 | 44.64 | 62.34 |

| 15% PEBA-2533 + 10% zeolite + 2% TDI crosslinked for 2 h | 97.12 | 2.88 | 35.9 | 64 | 49.47 | 60.3 |

| 15% PEBA-2533 + 20% zeolite + 2% TDI crosslinked for 2 h | 97.12 | 2.88 | 30.75 | 69 | 51.74 | 76.06 |

| 15% PEBA-2533 + 30% zeolite + 2% TDI crosslinked for 2 h | 97.12 | 2.88 | 21.69 | 78 | 54.94 | 121.95 |

| 膜类型 | 进料水含量/%(质量) | 温度/ ℃ | 通量/(kg/(m2·h)) | 分离因子 | 文献 |

|---|---|---|---|---|---|

| polyurethane urea | — | 45 | 0.013 | 3396 | [ |

| BTESE | 8 | 130 | 3.2 | 1183 | [ |

| high-silica CHA-type | 50 | 130 | 36 | 1100 | [ |

| PAN hollow fiber | 30 | 70 | 1.5 | — | [ |

| poly(ether-block-amide) 2533 + 4A zeolite + TDI | 3 | 30 | 1.2 | 180 | [ |

chitosan/poly(ether-block-amide) composite (TEOS crosslinked) | 1.3 | 30 | 0.02 | 1007 | [ |

| polyvinyl alcohol (PVA)/CNT composite membranes | — | 80 | 0.06 | 3500 | [ |

| NaA zeolite | 0.1 | 150 | 0.11 | 9997 | [ |

表2 渗透汽化技术用于NMP回收的膜材料汇总

Table 2 Summary of membrane materials used for NMP recovery by pervaporation technology

| 膜类型 | 进料水含量/%(质量) | 温度/ ℃ | 通量/(kg/(m2·h)) | 分离因子 | 文献 |

|---|---|---|---|---|---|

| polyurethane urea | — | 45 | 0.013 | 3396 | [ |

| BTESE | 8 | 130 | 3.2 | 1183 | [ |

| high-silica CHA-type | 50 | 130 | 36 | 1100 | [ |

| PAN hollow fiber | 30 | 70 | 1.5 | — | [ |

| poly(ether-block-amide) 2533 + 4A zeolite + TDI | 3 | 30 | 1.2 | 180 | [ |

chitosan/poly(ether-block-amide) composite (TEOS crosslinked) | 1.3 | 30 | 0.02 | 1007 | [ |

| polyvinyl alcohol (PVA)/CNT composite membranes | — | 80 | 0.06 | 3500 | [ |

| NaA zeolite | 0.1 | 150 | 0.11 | 9997 | [ |

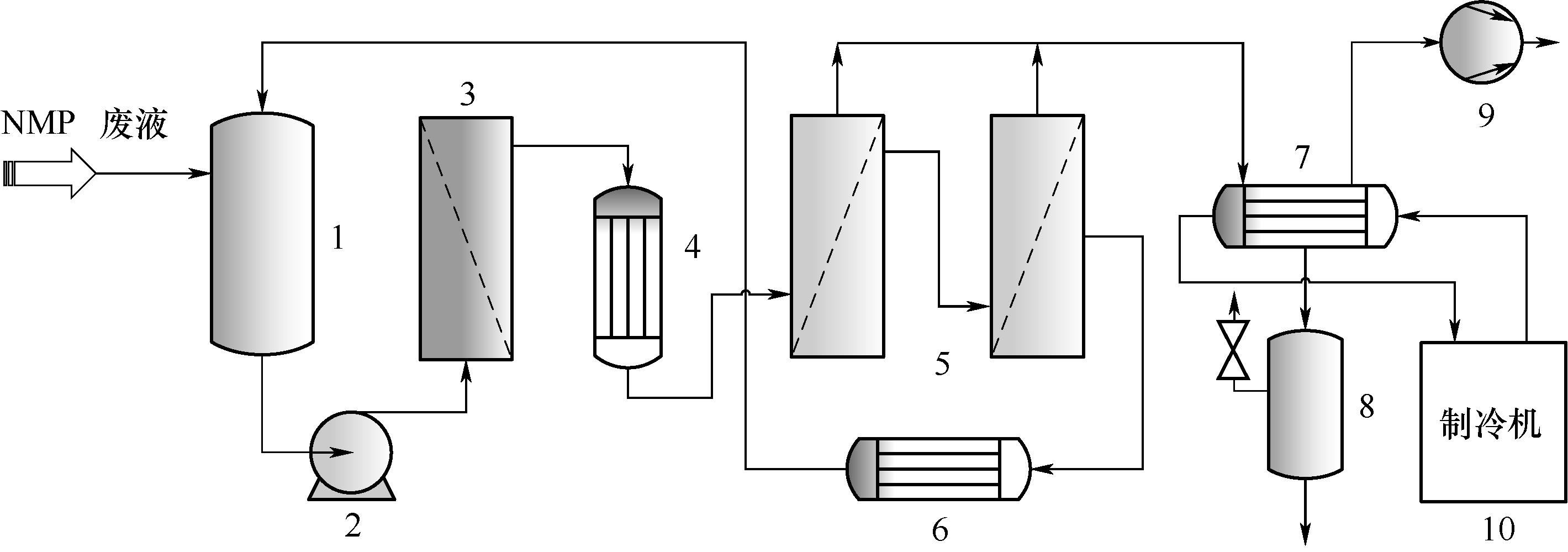

图7 渗透汽化分离耦合膜过滤技术工艺流程图1—原料罐; 2—原料输送泵;3—陶瓷过滤膜;4—原料预热器;5—渗透汽化膜组件;6—渗余液冷凝器;7—渗透液冷凝器;8—渗透液储罐;9—真空泵;10—制冷机

Fig.7 Process flow chart of pervaporation separation coupled membrane filtration technology

图8 渗透汽化膜分离耦合精馏工艺流程图1—原料罐;2—原料输送泵;3—原料预热器;4—渗透汽化膜组件;5—渗余液冷凝器;6—渗透液冷凝器;7—渗透液储罐;8—真空泵;9—制冷机;10—精馏塔

Fig.8 Process flow chart of pervaporized membrane separation coupled distillation

| 27 | 朱本伟, 姚忠, 仲兆祥, 等. 渗透汽化分离精油中挥发性芳香化合物的研究进展[J]. 化工进展, 2021, 40(11): 5875-5882. |

| Zhu B W, Yao Z, Zhong Z X, et al. Research progress of pervaporation in separation of volatile aromatic compounds within essential oils[J]. Chemical Industry and Engineering Progress, 2021, 40(11): 5875-5882. | |

| 28 | Geens J, van der Bruggen B, Vandecasteele C. Transport model for solvent permeation through nanofiltration membranes[J]. Separation and Purification Technology, 2006, 48(3): 255-263. |

| 29 | 顾学红, 徐南平. 渗透汽化脱水分子筛膜的制备与应用研究[J]. 中国工程科学, 2014, 16(12): 52-58. |

| Gu X H, Xu N P. Study of zeolite membranes for pervaporation dehydration and their applications[J]. Strategic Study of Chinese Academy of Engineering, 2014, 16(12): 52-58. | |

| 30 | 程浩, 张国才. 渗透汽化膜分离技术最新研究进展[J]. 应用化工, 2021, 50(12): 3489-3493. |

| Cheng H, Zhang G C. The research progress of pervaporation membrane separation technology[J]. Applied Chemical Industry, 2021, 50(12): 3489-3493. | |

| 31 | Ng T C A, Lyu Z Y, Wang C S, et al. Effect of surface-patterned topographies of ceramic membranes on the filtration of activated sludge and their interaction with different particle sizes[J]. Journal of Membrane Science, 2022, 645: 120125. |

| 32 | 熊柏闻, 吴红丹, 周志辉. 渗透汽化有机-无机杂化膜研究进展[J]. 精细化工, 2021, 38(3): 433-438, 453. |

| Xiong B W, Wu H D, Zhou Z H. Research progress of organic-inorganic hybrid membranes for pervaporation[J]. Fine Chemicals, 2021, 38(3): 433-438, 453. | |

| 33 | 张静. PDMS渗透汽化膜分离水中有机物的研究进展[J]. 净水技术, 2022, 41(1): 14-22. |

| Zhang J. Research progress of PDMS pervaporation membranes for organics removal in aqueous solution[J]. Water Purification Technology, 2022, 41(1): 14-22. | |

| 34 | Zhang Z X, Gu Q L, Ng T C A, et al. Hierarchically porous interlayer for highly permeable and fouling-resistant ceramic membranes in water treatment[J]. Separation and Purification Technology, 2022, 293: 121092. |

| 35 | 林源. 渗透汽化分离膜的制备与应用研究进展[J]. 南京工业大学学报, 2020, 42(6): 700-709. |

| Lin Y. Advances of preparation and application of pervaporation separation membrane[J]. Journal of Nanjing Tech University (Natural Science Edition), 2020, 42(6): 700-709. | |

| 36 | Nunes S P, Culfaz-Emecen P Z, Ramon G Z, et al. Thinking the future of membranes: perspectives for advanced and new membrane materials and manufacturing processes[J]. Journal of Membrane Science, 2020, 598: 117761. |

| 37 | Gu Q L, Ng T C A, Bao Y P, et al. Developing better ceramic membranes for water and wastewater treatment: where microstructure integrates with chemistry and functionalities[J]. Chemical Engineering Journal, 2022, 428: 130456. |

| 38 | Cheng X X, Pan F S, Wang M R, et al. Hybrid membranes for pervaporation separations[J]. Journal of Membrane Science, 2017, 541: 329-346. |

| 39 | 周宗尧, 张朔, 王宁, 等. 有机溶剂分离膜技术研究进展[J]. 膜科学与技术, 2018, 38(1): 104-113. |

| Zhou Z Y, Zhang S, Wang N, et al. Progress in the technology of organic solvent separation membrane[J]. Membrane Science and Technology, 2018, 38(1): 104-113. | |

| 40 | 李敬, 周佳欣, 尤颖, 等. 用于乙醇脱水的亲水性渗透汽化膜材料研究进展[J]. 化工新型材料, 2020, 48(9): 7-11, 15. |

| Li J, Zhou J X, You Y, et al. Research progress of hydrophilic pervaporation membrane material for ethanol dehydration[J]. New Chemical Materials, 2020, 48(9): 7-11, 15. | |

| 41 | Hasegawa Y, Matsuura W, Abe C, et al. Influence of organic solvent species on dehydration behaviors of NaA-type zeolite membrane[J]. Membranes, 2021, 11(5): 347. |

| 42 | 王学瑞, 张春, 张玉亭, 等. 中空纤维分子筛膜制备与应用研究进展[J]. 膜科学与技术, 2020, 40(1): 313-321. |

| Wang X R, Zhang C, Zhang Y T, et al. Fabrication and application of hollow fiber zeolite membranes[J]. Membrane Science and Technology, 2020, 40(1): 313-321. | |

| 43 | Yang W H, Yang X, Wang Y X, et al. Pervaporation separation of C6 alkane isomers by Al-bttotb membrane[J]. Journal of Membrane Science, 2022, 661: 120916. |

| 44 | Rostovtseva V, Faykov I, Pulyalina A. A review of recent developments of pervaporation membranes for ethylene glycol purification[J]. Membranes, 2022, 12(3): 312. |

| 45 | Luo R W, Bai P, Lyu J F, et al. Fabrication of melamine-based hybrid organic membrane for ethanol/water pervaporation[J]. Microporous and Mesoporous Materials, 2022, 335: 111810. |

| 46 | Wang J L, Cao B, Zhang R, et al. Spray-coated tough thin film composite membrane for pervaporation desalination[J]. Chemical Engineering Research and Design, 2022, 179: 493-501. |

| 47 | Wang M, Xu Q S, Tang H J, et al. Machine learning-enabled prediction and high-throughput screening of polymer membranes for pervaporation separation[J]. ACS Applied Materials & Interfaces, 2022, 14(6): 8427-8436. |

| 1 | Su Y J, Zhou K, Yuan Y C, et al. Study on prediction of binder distribution in the drying process of the coated web of positive electrode for lithium ion battery[J]. IOP Conference Series: Materials Science and Engineering, 2020, 793: 012025. |

| 2 | 朱伟伟, 张建, 刘一凡, 等. 先进锂离子电池用黏结剂介绍[J]. 浙江化工, 2020, 51(10): 26-32. |

| Zhu W W, Zhang J, Liu Y F, et al. Introduction of binders for advanced lithium ion batteries[J]. Zhejiang Chemical Industry, 2020, 51(10): 26-32. | |

| 3 | Wang H M, Wu B Z, Jiang F, et al. Experimental study on distillation and purification of reclaimed NMP[J]. Journal of Physics: Conference Series, 2022, 2393: 012022. |

| 4 | 肖忠良, 尹碧露, 宋刘斌, 等. 废旧锂离子电池回收工艺研究进展及其安全风险分析[J]. 化工学报, 2023, 74(4): 1446-1456. |

| Xiao Z L, Yin B L, Song L B, et al. Research progress of waste lithium-ion battery recycling process and its safety risk analysis[J]. CIESC Journal, 2023, 74(4): 1446-1456. | |

| 5 | Ahmed S, Nelson P A, Gallagher K G, et al. Energy impact of cathode drying and solvent recovery during lithium-ion battery manufacturing[J]. Journal of Power Sources, 2016, 322: 169-178. |

| 6 | 迪建东, 李国盛, 郑晓舟, 等. 锂电正极涂敷NMP回收技术综述[J]. 广东化工, 2020, 47(3): 112-114. |

| Di J D, Li G S, Zheng X Z, et al. Review of recycling technology of NMP coating for lithium battery positive electrode[J]. Guangdong Chemical Industry, 2020, 47(3): 112-114. | |

| 7 | Wang H, Xie K, Wang L Y, et al. N-methyl-2-pyrrolidone as a solvent for the non-aqueous electrolyte of rechargeable Li-air batteries[J]. Journal of Power Sources, 2012, 219: 263-271. |

| 8 | Sliz R, Valikangas J, Santos H S, et al. Suitable cathode NMP replacement for efficient sustainable printed Li-ion batteries[J]. ACS Applied Energy Materials, 2022, 5(4): 4047-4058. |

| 9 | Li B F, Qi B, Guo Z Y, et al. Recent developments in the application of membrane separation technology and its challenges in oil-water separation: a review[J]. Chemosphere, 2023, 327: 138528. |

| 10 | Zhuang Y, Si Z H, Pang S Y, et al. Recent progress in pervaporation membranes for furfural recovery: a mini review[J]. Journal of Cleaner Production, 2023, 396: 136481. |

| 48 | Ünügül T, Nigiz F U. Evaluation of halloysite nanotube-loaded chitosan-based nanocomposite membranes for water desalination by pervaporation[J]. Water, Air & Soil Pollution, 2022, 233(2): 1-12. |

| 49 | Wang J C, Dommati H, Hsieh S J. Review of additive manufacturing methods for high-performance ceramic materials[J]. The International Journal of Advanced Manufacturing Technology, 2019, 103: 2627-2647. |

| 50 | 范益群, 漆虹, 徐南平. 多孔陶瓷膜制备技术研究进展[J]. 化工学报, 2013, 64(1): 107-115. |

| Fan Y Q, Qi H, Xu N P. Advance in preparation techniques of porous ceramic membranes[J]. CIESC Journal, 2013, 64(1): 107-115. | |

| 51 | 邢卫红, 范益群, 仲兆祥, 等. 面向过程工业的陶瓷膜制备与应用进展[J]. 化工学报, 2009, 60(11): 2679-2688. |

| Xing W H, Fan Y Q, Zhong Z X, et al. Recent advances in process-engineering oriented preparation and application of ceramic membranes[J]. CIESC Journal, 2009, 60(11): 2679-2688. | |

| 52 | 史冬梅, 张雷, 李丹. 高性能膜材料国内外发展现状与趋势[J]. 科技中国, 2019(4): 4-7. |

| Shi D M, Zhang L, Li D. Development status and trend of high performance membrane materials at home and abroad[J]. Scitech in China, 2019(4): 4-7. | |

| 53 | 吕阳光, 左培培, 杨正金, 等. 三嗪框架聚合物膜用于有机纳滤甲醇/正己烷分离[J]. 化工学报, 2023, 74(4): 1598-1606. |

| Lyu Y G, Zuo P P, Yang Z J, et al. Triazine framework polymer membranes for methanol/n-hexane separation via organic solvent nanofiltration[J]. CIESC Journal, 2023, 74(4): 1598-1606. | |

| 54 | 李继定, 杨正, 金夏阳, 等. 渗透汽化膜技术及其应用[J]. 中国工程科学, 2014, 16(12): 46-51. |

| Li J D, Yang Z, Jin X Y, et al. Pervaporation membrane separation technology and its application[J]. Strategic Study of Chinese Academy of Engineering, 2014, 16(12): 46-51. | |

| 55 | 张春, 王学瑞, 刘华, 等. 面向工业过程碳减排的分子筛膜技术研究进展[J]. 化工进展, 2022, 41(3): 2021-2353. |

| 11 | Elsheniti M B, Ibrahim A, Elsamni O, et al. Experimental and economic investigation of sweeping gas membrane distillation/pervaporation modules using novel pilot scale device[J]. Separation and Purification Technology, 2023, 310: 123165. |

| 12 | 陈献富, 王冬雨, 范益群, 等. 基于3D打印的多孔陶瓷膜研究进展[J]. 化工学报, 2023, 74(1): 105-115. |

| Chen X F, Wang D Y, Fan Y Q, et al. Research progress of porous ceramic membranes based on 3D printing technologies[J]. CIESC Journal, 2023, 74(1): 105-115. | |

| 13 | Chen X F, Qi T, Zhang Y, et al. Facile pore size tuning and characterization of nanoporous ceramic membranes for the purification of polysaccharide[J]. Journal of Membrane Science, 2020, 597: 117631. |

| 14 | Niu B H, Yang L, Meng S J, et al. Time-dependent analysis of polysaccharide fouling by Hermia models: reveal the structure of fouling layer[J]. Separation and Purification Technology, 2022, 302: 122093. |

| 15 | Wang S N, Huang Z, Wang J T, et al. PVA/UiO-66 mixed matrix membranes for n-butanol dehydration via pervaporation and effect of ethanol[J]. Separation and Purification Technology, 2023, 313: 123487. |

| 16 | Lu X T, Huang J C, Pinelo M, et al. Modelling and optimization of pervaporation membrane modules: a critical review[J]. Journal of Membrane Science, 2022, 664: 121084. |

| 17 | Saw E T, Ang K L, He W, et al. Molecular sieve ceramic pervaporation membranes in solvent recovery: a comprehensive review[J]. Journal of Environmental Chemical Engineering, 2019, 7(5): 103367. |

| 18 | Xu X, Nikolaeva D, Hartanto Y, et al. MOF-based membranes for pervaporation[J]. Separation and Purification Technology, 2021, 278: 119233. |

| 19 | Cao X T, Wang K A, Feng X S. Removal of phenolic contaminants from water by pervaporation[J]. Journal of Membrane Science, 2021, 623: 119043. |

| 20 | Khan R, Ul Haq I, Mao H, et al. Enhancing the pervaporation performance of PEBA/PVDF membrane by incorporating MAF-6 for the separation of phenol from its aqueous solution[J]. Separation and Purification Technology, 2021, 256: 117804. |

| 21 | Mao H, Li S H, Zhang A S, et al. Furfural separation from aqueous solution by pervaporation membrane mixed with metal organic framework MIL-53(Al) synthesized via high efficiency solvent-controlled microwave[J]. Separation and Purification Technology, 2021, 272: 118813. |

| 22 | Ji Y F, Chen G N, Liu G Z, et al. Ultrathin membranes with a polymer/nanofiber interpenetrated structure for high-efficiency liquid separations[J]. ACS Applied Materials & Interfaces, 2019, 11(40): 36717-36726. |

| 23 | Liu G P, Jin W Q. Pervaporation membrane materials: recent trends and perspectives[J]. Journal of Membrane Science, 2021, 636: 119557. |

| 24 | Mukherjee M, Roy S, Bhowmick K, et al. Development of high performance pervaporation desalination membranes: a brief review[J]. Process Safety and Environmental Protection, 2022, 159: 1092-1104. |

| 25 | Wood D L, Li J L, Daniel C. Prospects for reducing the processing cost of lithium ion batteries[J]. Journal of Power Sources, 2015, 275: 234-242. |

| 26 | Song S, Rong L W, Dong K J, et al. Pore-scale numerical study of intrinsic permeability for fluid flow through asymmetric ceramic microfiltration membranes[J]. Journal of Membrane Science, 2022, 642: 119920. |

| 55 | Zhang C, Wang X R, Liu H, et al. Progress of zeolite membranes for reduction of carbon emission in industrial processes[J]. Chemical Industry and Engineering Progress, 2022, 41(3): 1376-1390. |

| 56 | 吕静, 毛恒, 徐李昊, 等. PD@ZIF-8@PPy/PVA混合基质膜渗透汽化乙醇脱水研究[J]. 膜科学与技术, 2023, 43(1): 45-55. |

| Lyu J, Mao H, Xu L H, et al. Study on ethanol dehydration by pervaporation of PD@ZIF-8@PPy/PVA mixed matrix membrane[J]. Membrane Science and Technology, 2023, 43(1): 45-55. | |

| 57 | Liu S, Zhou G Y, Cheng G B, et al. Emerging membranes for separation of organic solvent mixtures by pervaporation or vapor permeation[J]. Separation and Purification Technology, 2022, 299: 121729. |

| 58 | 洪周, 王圣贤, 张春, 等. T型分子筛膜的制备及其在有机物废水中的应用[J]. 现代化工, 2021, 41(3): 83-87. |

| Hong Z, Wang S X, Zhang C, et al. Preparation of T-type molecular sieve membrane and its application in treatment of organic wastewater[J]. Modern Chemical Industry, 2021, 41(3): 83-87. | |

| 59 | Ghosh U K, Pradhan N C, Adhikari B. Pervaporative recovery of N-methyl-2-pyrrolidone from dilute aqueous solution by using polyurethaneurea membranes[J]. Journal of Membrane Science, 2006, 285(1/2): 249-257. |

| 60 | Shao F F, Hao C Q, Ni L, et al. Experimental and theoretical research on N-methyl-2-pyrrolidone concentration by vacuum membrane distillation using polypropylene hollow fiber membrane[J]. Journal of Membrane Science, 2014, 452: 157-164. |

| 61 | van Veen H M, Rietkerk M D A, Shanahan D P, et al. Pushing membrane stability boundaries with HybSi® pervaporation membranes[J]. Journal of Membrane Science, 2011, 380(1/2): 124-131. |

| 62 | Sato K, Sugimoto K, Shimotsuma N, et al. Development of practically available up-scaled high-silica CHA-type zeolite membranes for industrial purpose in dehydration of N-methyl pyrrolidone solution[J]. Journal of Membrane Science, 2012, 409/410: 82-95. |

| 63 | Tsai H A, Chen Y L, Lee K R, et al. Preparation of heat-treated PAN hollow fiber membranes for pervaporation of NMP/H2O mixtures[J]. Separation and Purification Technology, 2012, 100: 97-105. |

| 64 | Sunitha K, Yamuna Rani K, Moulik S, et al. Separation of NMP/water mixtures by nanocomposite PEBA membrane(part I): Membrane synthesis, characterization and pervaporation performance[J]. Desalination, 2013, 330: 1-8. |

| 65 | 王思琪, 顾天宇, 陈献富, 等. 陶瓷膜用于杜仲叶提取液澄清的分离特性与膜污染机制研究[J]. 化工学报, 2023, 74(3): 1113-1125. |

| Wang S Q, Gu T Y, Chen X F, et al. Study on separation characteristics and membrane fouling mechanism of ceramic membrane for clarification of eucommia ulmoides leaves extract[J]. CIESC Journal, 2023, 74(3): 1113-1125. | |

| 66 | Prasad N S, Moulik S, Bohra S, et al. Solvent resistant chitosan/poly(ether-block-amide) composite membranes for pervaporation of n-methyl-2-pyrrolidone/water mixtures[J]. Carbohydrate Polymers, 2016, 136: 1170-1181. |

| 67 | Kang S K, Park J W, Tsegay Tikue E, et al. Self-cross-linking nanocomposite membranes for green recycling of the solvent during lithium-ion battery manufacturing[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(2): 899-910. |

| 68 | 王艳芳, 毛恒, 蔡玮玮, 等. ZIF-L/PDMS混合基质膜蒸气渗透耦合发酵强化乙醇生产效率的研究[J]. 化工学报, 2021, 72(10): 5226-5236. |

| Wang Y F, Mao H, Cai W W, et al. Enhancing ethanol production efficiency by ZIF-L/PDMS mixed matrix membrane via vapor permeation-fermentation coupling process[J]. CIESC Journal, 2021, 72(10): 5226-5236. | |

| 69 | 宋振, 茅慧萍, 蒋旭亮, 等. N-甲基吡咯烷酮中去除甲胺和水分的方法: 101973921A[P]. 2011-02-16. |

| Song Z, Mao H P, Jiang X L, et al. Method for removing methylamine and moisture in N-methyl pyrrolidone: 101973921A[P]. 2011-02-16. | |

| 70 | 曾文豪. NaA分子筛膜的渗透汽化应用及其污染与再生研究[D]. 宁波: 宁波大学, 2020. |

| Zeng W H. The research on pervaporative applications, fouling and regeneration of NaA zeolite membrane[D]. Ningbo: Ningbo University, 2020. | |

| 71 | 顾学红, 仲超, 洪周, 等. 一种膜分离法回收锂电池生产中N-甲基吡咯烷酮废气的方法和装置: 107626186A[P]. 2019-11-01. |

| Gu X H, Zhong C, Hong Z, et al. Method and device for recovering NMP (N-methyl pyrrolidone) waste gas in lithium battery production with membrane separation method: 107626186A[P]. 2019-11-01. | |

| 72 | 李伟, 李辉, 张伟, 等. 一种渗透汽化膜分离精制NMP装置: 214004476U[P]. 2021-08-20. |

| Li W, Li H, Zhang W, et al. Device for separating and refining NMP through pervaporation membrane: 214004476U[P]. 2021-08-20. | |

| 73 | Zeng W H, Li B B, Li H, et al. Mass produced NaA zeolite membranes for pervaporative recycling of spent N-methyl-2-pyrrolidone in the manufacturing process for lithium-ion battery[J]. Separation and Purification Technology, 2019, 228: 115741. |

| 74 | 李安武, 熊纯刚. 一种N-甲基吡咯烷酮的回收方法: 110759844A[P]. 2020-02-07. |

| Li A W, Xiong C G. A recovery method for 1-methyl-2-Pyrrolidone: 110759844A[P]. 2020-02-07. | |

| 75 | 郑晓舟, 刘建楠, 迪建东, 等. 由一条工艺路线浅谈NMP的回收[J]. 广东化工, 2020, 47(2): 89-90. |

| Zheng X Z, Liu J N, Di J D, et al. A brief discussion of NMP recovery based on one method of processes[J]. Guangdong Chemical Industry, 2020, 47(2): 89-90. |

| [1] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [2] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [3] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [4] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [5] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [6] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [7] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [8] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [9] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [10] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [11] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [12] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [13] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [14] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [15] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号