化工学报 ›› 2024, Vol. 75 ›› Issue (9): 3198-3209.DOI: 10.11949/0438-1157.20240115

王冉1( ), 王焕2, 熊晓云3, 关慧敏1, 郑云锋3, 陈彩琳1, 秦玉才1(

), 王焕2, 熊晓云3, 关慧敏1, 郑云锋3, 陈彩琳1, 秦玉才1( ), 宋丽娟1,2

), 宋丽娟1,2

收稿日期:2024-01-25

修回日期:2024-05-19

出版日期:2024-09-25

发布日期:2024-10-10

通讯作者:

秦玉才

作者简介:王冉(1998—),女,硕士研究生,2248409310@qq.com

基金资助:

Ran WANG1( ), Huan WANG2, Xiaoyun XIONG3, Huimin GUAN1, Yunfeng ZHENG3, Cailin CHEN1, Yucai QIN1(

), Huan WANG2, Xiaoyun XIONG3, Huimin GUAN1, Yunfeng ZHENG3, Cailin CHEN1, Yucai QIN1( ), Lijuan SONG1,2

), Lijuan SONG1,2

Received:2024-01-25

Revised:2024-05-19

Online:2024-09-25

Published:2024-10-10

Contact:

Yucai QIN

摘要:

流化催化裂化(FCC)催化剂传质性能抑制活性位利用效率是影响其催化性能的关键因素,选用6种不同基质材料制备的FCC催化剂样品,在系统分析催化孔结构和酸性质的基础上,利用激光共聚焦荧光显微成像技术和吸附穿透曲线法模拟考察了重油大分子的传质扩散行为;并运用单分子荧光成像技术,以B酸中心催化噻吩低聚反应生成低聚物的数量作为判据考察了系列催化剂的活性位利用效率。研究发现,相比于传统的高岭土和拟薄水铝石作为基质材料,本课题组设计开发的大孔富B酸的基质材料(APM-9)明显优化了大分子在FCC催化剂上的传质性能,从而显著提升了活性位的利用效率。发展了一种新颖的FCC催化剂结构参数与其传质性能、酸中心利用效率构效关系建立的方法,可为催化剂基质材料的设计和优化提供数据支撑和理论指导。

中图分类号:

王冉, 王焕, 熊晓云, 关慧敏, 郑云锋, 陈彩琳, 秦玉才, 宋丽娟. FCC催化剂传质强化活性位利用效率的可视化分析[J]. 化工学报, 2024, 75(9): 3198-3209.

Ran WANG, Huan WANG, Xiaoyun XIONG, Huimin GUAN, Yunfeng ZHENG, Cailin CHEN, Yucai QIN, Lijuan SONG. Visual analysis of mass transfer enhanced active site utilization efficiency of FCC catalyst[J]. CIESC Journal, 2024, 75(9): 3198-3209.

| 样品 | 比表 面积/ (m2·g-1) | 微孔 面积/ (m2·g-1) | 介孔 面积/(m2·g-1) | 总孔 体积/(cm3·g-1) | 微孔 体积/(cm3·g-1) | 介孔 体积/(cm3·g-1) |

|---|---|---|---|---|---|---|

| CAT-1 | 156 | 88 | 68 | 0.167 | 0.046 | 0.121 |

| CAT-2 | 186 | 95 | 91 | 0.198 | 0.050 | 0.148 |

| CAT-3 | 188 | 95 | 93 | 0.202 | 0.050 | 0.152 |

| CAT-4 | 185 | 98 | 87 | 0.218 | 0.056 | 0.162 |

| CAT-5 | 190 | 101 | 89 | 0.229 | 0.059 | 0.170 |

| CAT-6 | 193 | 104 | 88 | 0.248 | 0.061 | 0.187 |

表1 6种催化剂样品织构性质参数

Table 1 Texture property parameters of six catalyst samples

| 样品 | 比表 面积/ (m2·g-1) | 微孔 面积/ (m2·g-1) | 介孔 面积/(m2·g-1) | 总孔 体积/(cm3·g-1) | 微孔 体积/(cm3·g-1) | 介孔 体积/(cm3·g-1) |

|---|---|---|---|---|---|---|

| CAT-1 | 156 | 88 | 68 | 0.167 | 0.046 | 0.121 |

| CAT-2 | 186 | 95 | 91 | 0.198 | 0.050 | 0.148 |

| CAT-3 | 188 | 95 | 93 | 0.202 | 0.050 | 0.152 |

| CAT-4 | 185 | 98 | 87 | 0.218 | 0.056 | 0.162 |

| CAT-5 | 190 | 101 | 89 | 0.229 | 0.059 | 0.170 |

| CAT-6 | 193 | 104 | 88 | 0.248 | 0.061 | 0.187 |

| 样品 | 弱酸量/ (mmol·g-1) | 中强酸量/ (mmol·g-1) | 强酸量/ (mmol·g-1) |

|---|---|---|---|

| CAT1 | 4.07 | 11.55 | 15.70 |

| CAT2 | 4.11 | 12.45 | 15.79 |

| CAT3 | 5.10 | 14.09 | 16.70 |

| CAT-4 | 5.98 | 16.75 | 18.87 |

| CAT-5 | 6.58 | 21.37 | 18.99 |

| CAT-6 | 6.50 | 21.77 | 19.41 |

表2 6种FCC催化剂的酸密度分布定量数据

Table 2 Quantitative data on acid density distribution of six FCC catalysts

| 样品 | 弱酸量/ (mmol·g-1) | 中强酸量/ (mmol·g-1) | 强酸量/ (mmol·g-1) |

|---|---|---|---|

| CAT1 | 4.07 | 11.55 | 15.70 |

| CAT2 | 4.11 | 12.45 | 15.79 |

| CAT3 | 5.10 | 14.09 | 16.70 |

| CAT-4 | 5.98 | 16.75 | 18.87 |

| CAT-5 | 6.58 | 21.37 | 18.99 |

| CAT-6 | 6.50 | 21.77 | 19.41 |

| 样品 | 酸量/(mmol·g-1) | |||

|---|---|---|---|---|

| 150℃ | 400℃ | |||

| B酸 | L酸 | B酸 | L酸 | |

| CAT-1 | 0.065 | 0.064 | 0.043 | 0.010 |

| CAT-2 | 0.069 | 0.070 | 0.047 | 0.014 |

| CAT-3 | 0.087 | 0.071 | 0.067 | 0.010 |

| CAT-4 | 0.072 | 0.082 | 0.056 | 0.009 |

| CAT-5 | 0.086 | 0.135 | 0.057 | 0.005 |

| CAT-6 | 0.089 | 0.137 | 0.061 | 0.010 |

表3 催化剂酸性数据

Table 3 Catalyst acidity

| 样品 | 酸量/(mmol·g-1) | |||

|---|---|---|---|---|

| 150℃ | 400℃ | |||

| B酸 | L酸 | B酸 | L酸 | |

| CAT-1 | 0.065 | 0.064 | 0.043 | 0.010 |

| CAT-2 | 0.069 | 0.070 | 0.047 | 0.014 |

| CAT-3 | 0.087 | 0.071 | 0.067 | 0.010 |

| CAT-4 | 0.072 | 0.082 | 0.056 | 0.009 |

| CAT-5 | 0.086 | 0.135 | 0.057 | 0.005 |

| CAT-6 | 0.089 | 0.137 | 0.061 | 0.010 |

| 样品 | 时间/min | 时间/min | ||||

|---|---|---|---|---|---|---|

| 萘穿透 | 菲穿透 | 吖啶穿透 | 萘饱和 | 菲饱和 | 吖啶饱和 | |

| CAT-1 | 1.92 | 3.71 | 10.70 | 6.10 | 9.21 | 43.37 |

| CAT-2 | 2.59 | 4.55 | 13.87 | 7.01 | 11.18 | 50.73 |

| CAT-3 | 2.84 | 4.93 | 18.85 | 7.28 | 12.35 | 54.18 |

| CAT-4 | 3.32 | 5.37 | 20.02 | 8.87 | 14.34 | 59.20 |

| CAT-5 | 3.75 | 6.62 | 21.45 | 9.10 | 16.91 | 66.09 |

| CAT-6 | 3.84 | 6.98 | 23.41 | 9.17 | 18.47 | 73.10 |

表4 6种催化剂样品上萘、菲、吖啶的吸附穿透点与饱和时间

Table 4 Adsorption penetration and saturation time of naphthalene, phenanthrene and acridine on six catalyst samples

| 样品 | 时间/min | 时间/min | ||||

|---|---|---|---|---|---|---|

| 萘穿透 | 菲穿透 | 吖啶穿透 | 萘饱和 | 菲饱和 | 吖啶饱和 | |

| CAT-1 | 1.92 | 3.71 | 10.70 | 6.10 | 9.21 | 43.37 |

| CAT-2 | 2.59 | 4.55 | 13.87 | 7.01 | 11.18 | 50.73 |

| CAT-3 | 2.84 | 4.93 | 18.85 | 7.28 | 12.35 | 54.18 |

| CAT-4 | 3.32 | 5.37 | 20.02 | 8.87 | 14.34 | 59.20 |

| CAT-5 | 3.75 | 6.62 | 21.45 | 9.10 | 16.91 | 66.09 |

| CAT-6 | 3.84 | 6.98 | 23.41 | 9.17 | 18.47 | 73.10 |

| 探针分子 | KCAT-1/min-1 | KCAT-2/min-1 | KCAT-3/min-1 | KCAT-4/min-1 | KCAT-5/min-1 | KCAT-6/min-1 |

|---|---|---|---|---|---|---|

| 萘 | 1.3461 | 1.1570 | 1.1327 | 1.1145 | 1.0281 | 0.8897 |

| 菲 | 1.0907 | 0.9867 | 0.9335 | 0.8698 | 0.7798 | 0.7454 |

| 吖啶 | 0.2875 | 0.2562 | 0.2540 | 0.2531 | 0.2260 | 0.1950 |

表5 Yoon-Nelson模型拟合所得6种催化剂样品上萘、菲、吖啶的吸附速率常数

Table 5 The adsorption rate constants of naphthene, phenanthrene and acridine for six catalyst samples obtained by fitting Yoon-Nelson model

| 探针分子 | KCAT-1/min-1 | KCAT-2/min-1 | KCAT-3/min-1 | KCAT-4/min-1 | KCAT-5/min-1 | KCAT-6/min-1 |

|---|---|---|---|---|---|---|

| 萘 | 1.3461 | 1.1570 | 1.1327 | 1.1145 | 1.0281 | 0.8897 |

| 菲 | 1.0907 | 0.9867 | 0.9335 | 0.8698 | 0.7798 | 0.7454 |

| 吖啶 | 0.2875 | 0.2562 | 0.2540 | 0.2531 | 0.2260 | 0.1950 |

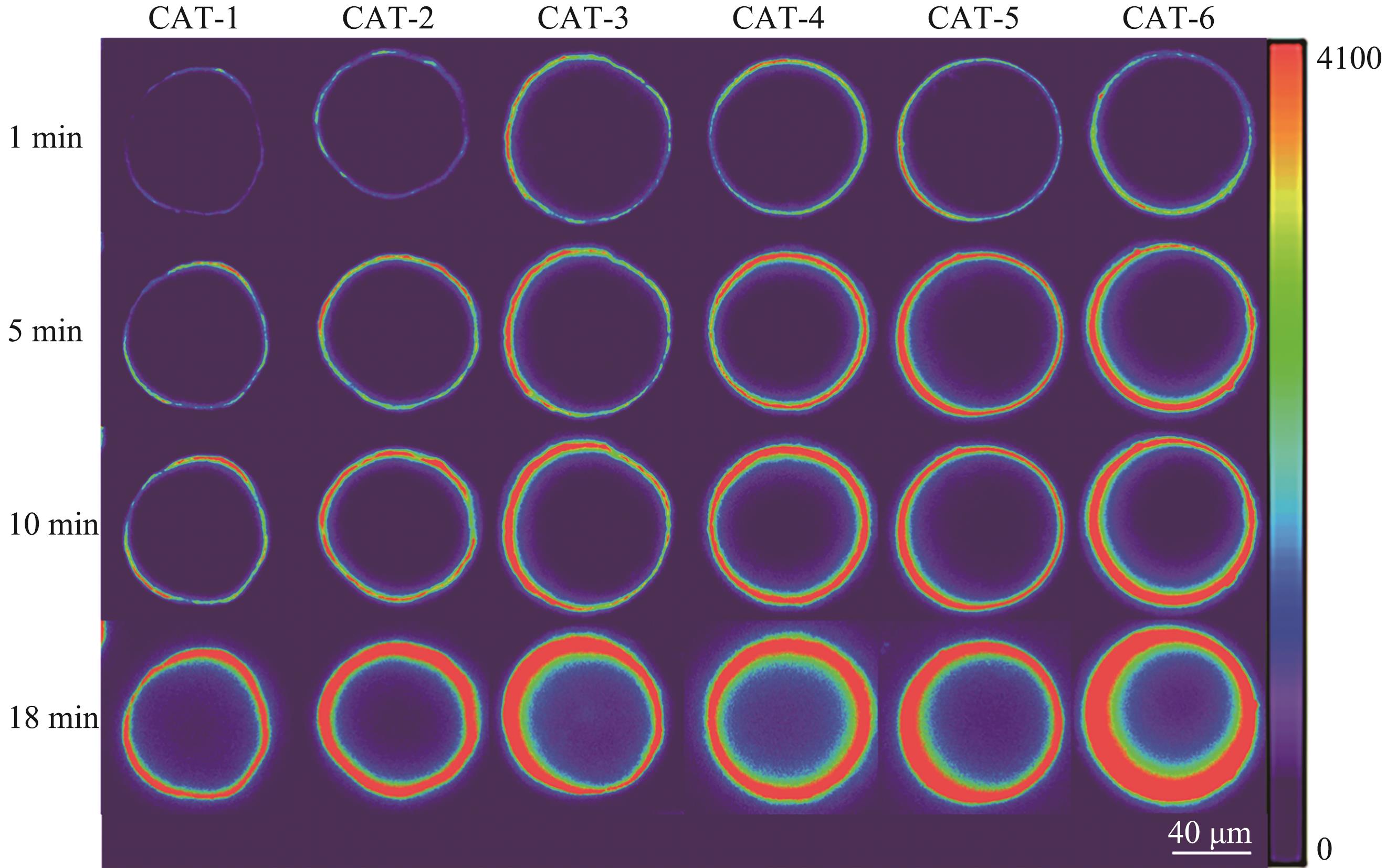

图9 6种催化剂微球球心最大切面上罗丹明B分子的荧光分布(比色条显示不同颜色所代表的荧光强度)

Fig.9 Fluorescence mapping of the maximum section surface of catalyst samples soaked in Rhodamine B probe (color bar displays the fluorescence intensity)

| 催化剂 | L18min/m | Deff/(m2·s-1) |

|---|---|---|

| CAT-1 | 1.76×10-5 | 2.72×10-15 |

| CAT-2 | 2.16×10-5 | 3.63×10-15 |

| CAT-3 | 2.63×10-5 | 6.04×10-15 |

| CAT-4 | 3.01×10-5 | 1.10×10-14 |

| CAT-5 | 3.22×10-5 | 1.65×10-14 |

| CAT-6 | 3.69×10-5 | 6.68×10-14 |

表6 Fick第一定律计算罗丹明B在6种催化剂样品中的扩散系数

Table 6 The diffusion coefficients of Rhodamine B in six catalyst samples calculated by the Fick’s first law

| 催化剂 | L18min/m | Deff/(m2·s-1) |

|---|---|---|

| CAT-1 | 1.76×10-5 | 2.72×10-15 |

| CAT-2 | 2.16×10-5 | 3.63×10-15 |

| CAT-3 | 2.63×10-5 | 6.04×10-15 |

| CAT-4 | 3.01×10-5 | 1.10×10-14 |

| CAT-5 | 3.22×10-5 | 1.65×10-14 |

| CAT-6 | 3.69×10-5 | 6.68×10-14 |

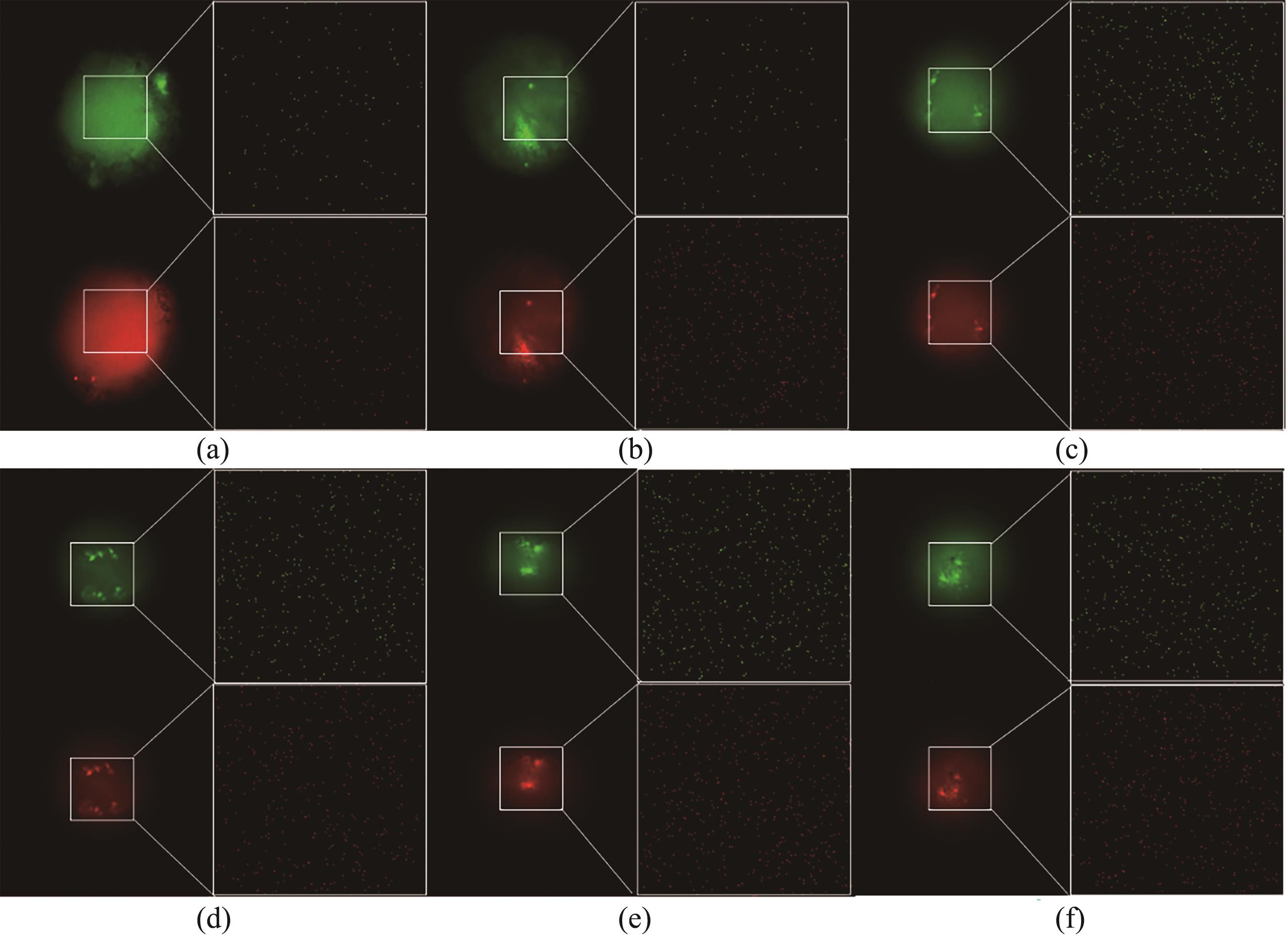

图10 6种FCC催化剂上噻吩二聚产物(绿色)和三聚产物(红色)的单分子成像

Fig.10 Single molecule imaging of dimeric products (green) and trimeric products (red) on the six FCC catalyst samples

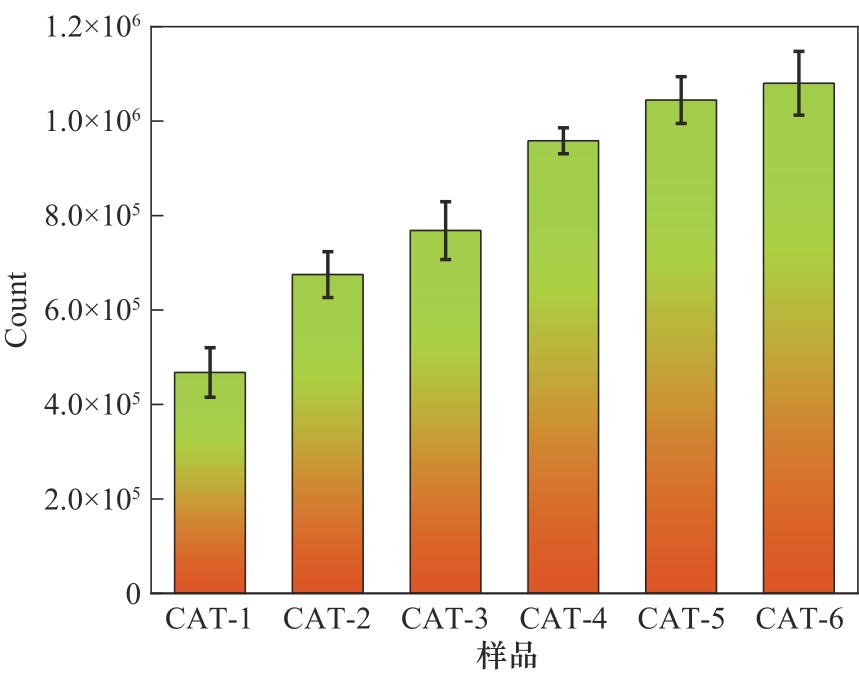

图11 6种FCC催化剂样品上噻吩二聚和三聚产物总荧光亮点数的统计对比

Fig.11 Statistical comparison of total fluorescence brightness points of thiophene dimers and trimers in the six FCC catalyst samples

| 1 | Vogt E T C, Weckhuysen B M. Fluid catalytic cracking: recent developments on the grand old lady of zeolite catalysis[J]. Chemical Society Reviews, 2015, 44(20): 7342-7370. |

| 2 | 王铃. 2030年炼油催化剂市场规模将达到150亿美元[J]. 石油炼制与化工, 2023, 54(11): 33. |

| Wang L. In 2030, the market size of refining catalyst will reach 15 billion US dollars[J]. Petroleum Processing and Petrochemicals, 2023, 54(11): 33. | |

| 3 | 张玉明, 纪德馨, 朱翰文, 等. 微型流化床中萘裂解生成小分子气体的反应动力学研究[J]. 化工学报, 2021, 72(5): 2604-2615. |

| Zhang Y M, Ji D X, Zhu H W, et al. Reaction kinetics of naphthalene cracking into small molecule gas in a micro fluidized bed[J]. CIESC Journal, 2021, 72(5): 2604-2615. | |

| 4 | Fleury M, Pirngruber G, Jolimaitre E. Probing diffusional exchange in mesoporous zeolite by NMR diffusion and relaxation methods[J]. Microporous and Mesoporous Materials, 2023, 355: 112575. |

| 5 | Liu X L, Wang C M, Zhou J, et al. Molecular transport in zeolite catalysts: depicting an integrated picture from macroscopic to microscopic scales[J]. Chemical Society Reviews, 2022, 51(19): 8174-8200. |

| 6 | 周鹏. 基质Lewis酸性调控及其催化轻烃裂化反应性能研究[D]. 徐州: 中国矿业大学, 2023. |

| Zhou P. Lewis acidity regulation of matrix and its effects on the catalytic cracking of light hydrocarbons[D]. Xuzhou: China University of Mining and Technology, 2023. | |

| 7 | 洪梅, 高金强, 李彤, 等. 原位刻蚀调控多级孔分子筛策略及其应用进展[J]. 化学学报, 2023, 81(8): 937-948. |

| Hong M, Gao J Q, Li T, et al. In-situ etching strategy for manipulation of hierarchical zeolite and its application[J]. Acta Chimica Sinica, 2023, 81(8): 937-948. | |

| 8 | 万艳春, 王玉军, 骆广生. 并流滴加法制备大孔容纤维状γ-氧化铝[J]. 化工学报, 2018, 69(11): 4840-4847. |

| Wan Y C, Wang Y J, Luo G S. Preparation of fibrous γ-alumina with large pore volume via co-current dropwise addition method[J]. CIESC Journal, 2018, 69(11): 4840-4847. | |

| 9 | 熊晓云, 曹庚振, 杜学敏, 等. 炭黑模板法制备大孔原位晶化型催化裂化催化剂[J]. 无机盐工业, 2023, 55(9): 134-139. |

| Xiong X Y, Cao G Z, Du X M, et al. Preparation of macroporous in situ crystallized FCC catalyst by carbon black template method[J]. Inorganic Chemicals Industry, 2023, 55(9): 134-139. | |

| 10 | 魏娟, 王玉军, 骆广生. 铝源孔容和焙烧升温过程对碳热还原法制备氮化铝粉体的影响[J]. 化工学报, 2021, 72(2): 1156-1168. |

| Wei J, Wang Y J, Luo G S. Influence of pore volume and heating process on preparation of aluminum nitride powder by carbothermal reduction method[J]. CIESC Journal, 2021, 72(2): 1156-1168. | |

| 11 | 熊晓云, 潘志爽, 胡清勋, 等. 高岭土酸碱复合改性制备多孔材料及其应用[J]. 石油炼制与化工, 2023, 54(7): 46-51. |

| Xiong X Y, Pan Z S, Hu Q X, et al. Preparation and application of porous materials by combining base and acid modification of kaolin[J]. Petroleum Processing and Petrochemicals, 2023, 54(7): 46-51. | |

| 12 | Bondarenko A V, Bondarenko V V, Petukhova, G A, et al. Adsorption properties of kaolinite and montmorillonite activated by thermochemical treatment[J]. Protection of Metals and Physical Chemistry of Surfaces, 2023, 59(5): 828-836. |

| 13 | 张莉, 刘超伟, 胡清勋, 等. 高岭土族矿物原位晶化合成Y型分子筛催化剂的研究进展[J]. 工业催化, 2020, 28(11): 1-8. |

| Zhang L, Liu C W, Hu Q X, et al. Research progress on in situ crystallization of zeolite catalyst from kaolin group minerals for RFCC[J]. Industrial Catalysis, 2020, 28(11): 1-8. | |

| 14 | 黄校亮, 姚文君, 郑云锋, 等. 改性高岭土在催化裂化催化剂中的应用研究[J]. 炼油与化工, 2011, 22(6): 25-27, 63. |

| Huang X L, Yao W J, Zheng Y F, et al. Modification of kaolin and its application in FCC catalyst[J]. Refining and Chemical Industry, 2011, 22(6): 25-27, 63. | |

| 15 | Baker B R, Pearson R M. Water content of pseudoboehmite: a new model for its structure[J]. Journal of Catalysis, 1974, 33(2): 265-278. |

| 16 | 闫涛, 袁程远, 柴军军, 等. 硅改性拟薄水铝石的合成及其在FCC催化剂中的应用[J]. 石油化工, 2021, 50(11): 1115-1120. |

| Yan T, Yuan C Y, Chai J J, et al. Synthesis of silica-modified pseudo boehmite and its application in FCC catalyst[J]. Petrochemical Technology, 2021, 50(11): 1115-1120. | |

| 17 | 郑金玉, 欧阳颖, 罗一斌, 等. 无序介孔硅铝材料的合成、表征及性能研究[J]. 石油炼制与化工, 2015, 46(9): 47-51. |

| Zheng J Y, Ouyang Y, Luo Y B, et al. Synthesis, characterization and catalytic cracking performance of disordered mesoporous silica-alumina material[J]. Petroleum Processing and Petrochemicals, 2015, 46(9): 47-51. | |

| 18 | 熊晓云, 高雄厚, 胡清勋, 等. 富B酸多级孔材料在催化裂化催化剂中的应用[J]. 精细石油化工, 2019, 36(3): 24-27. |

| Xiong X Y, Gao X H, Hu Q X, et al. Application of hierarchical porous material rich in bronsted acid in FCC catalyst[J]. Speciality Petrochemicals, 2019, 36(3): 24-27. | |

| 19 | Kärger J, Freude D, Haase J. Diffusion in nanoporous materials: novel insights by combining MAS and PFG NMR[J]. Processes, 2018, 6(9): 147. |

| 20 | Hernandez-Tamargo C, Silverwood I P, O'Malley A J, et al. Quasielastic neutron scattering and molecular dynamics simulation study on the molecular behaviour of catechol in zeolite beta[J]. Topics in Catalysis, 2021, 64(9): 707-721. |

| 21 | Talmon Y, Shtirberg L, Harneit W, et al. Molecular diffusion in porous media by PGSE ESR[J]. Physical Chemistry Chemical Physics, 2010, 12(23): 5998-6007. |

| 22 | Wessig M, Spitzbarth M, Drescher M, et al. Multiple scale investigation of molecular diffusion inside functionalized porous hosts using a combination of magnetic resonance methods[J]. Physical Chemistry Chemical Physics, 2015, 17(24): 15976-15988. |

| 23 | Ajith V J, Patil S. Translational diffusion of a fluorescent tracer molecule in nanoconfined water[J]. Langmuir, 2022, 38(3): 1034-1044. |

| 24 | Beschieru V, Rathke B, Will S. Particle diffusion in porous media investigated by dynamic light scattering[J]. Microporous and Mesoporous Materials, 2009, 125(1/2): 63-69. |

| 25 | 秦玉才, 高雄厚, 石利飞, 等. 原位晶化FCC催化剂传质性能的频率响应法辨析[J]. 物理化学学报, 2016, 32(2): 527-535. |

| Qin Y C, Gao X H, Shi L F, et al. Discrimination of the mass transfer performance of in situ crystallization FCC catalysts by the frequency response method[J]. Acta Physico-Chimica Sinica, 2016, 32(2): 527-535. | |

| 26 | Yasuda Y. Determination of vapor diffusion coefficients in zeolite by the frequency response method[J]. The Journal of Physical Chemistry, 1982, 86(10): 1913-1917. |

| 27 | Mehlhorn D, Inayat A, Schwieger W, et al. Probing mass transfer in mesoporous faujasite-type zeolite nanosheet assemblies[J]. Chemphyschem: a European Journal of Chemical Physics and Physical Chemistry, 2014, 15(8): 1681-1686. |

| 28 | Vattipalli V, Qi X D, Dauenhauer P J, et al. Long walks in hierarchical porous materials due to combined surface and configurational diffusion[J]. Chemistry of Materials, 2016, 28(21): 7852-7863. |

| 29 | Xiao Y, Xu W L. Single-molecule fluorescence imaging for probing nanocatalytic process[J]. Chem, 2023, 9(1): 16-28. |

| 30 | González R M, Maris J J E, Wagner M, et al. Fluorescent-probe characterization for pore-space mapping with single-particle tracking[J]. Angewandte Chemie International Edition, 2024, 63(4): e202314528. |

| 31 | Lezcano-González I, Oord R, Rovezzi M, et al. Molybdenum speciation and its impact on catalytic activity during methane dehydroaromatization in zeolite ZSM-5 as revealed by operando X-ray methods[J]. Angewandte Chemie International Edition, 2016, 55(17): 5215-5219. |

| 32 | Werny M J, Siebers K B, Friederichs N H, et al. Advancing the compositional analysis of olefin polymerization catalysts with high-throughput fluorescence microscopy[J]. Journal of the American Chemical Society, 2022, 144(46): 21287-21294. |

| 33 | Omori N, Candeo A, Mosca S, et al. Multimodal imaging of autofluorescent sites reveals varied chemical speciation in SSZ-13 crystals[J]. Angewandte Chemie International Edition, 2021, 60(10): 5125-5131. |

| 34 | Lee H, Kim K, Kang C M, et al. In situ confocal fluorescence lifetime imaging of nanopore electrode arrays with redox active fluorogenic amplex red[J]. Analytical Chemistry, 2023, 95(2): 1038-1046. |

| 35 | Buurmans I L C, Ruiz-Martínez J, Knowles W V, et al. Catalytic activity in individual cracking catalyst particles imaged throughout different life stages by selective staining[J]. Nature Chemistry, 2011, 3(11): 862-867. |

| 36 | Kox M H, Mijovilovich A, Sättler J J, et al. The catalytic conversion of thiophenes over large H-ZSM-5 crystals: an X-ray, UV/vis, and fluorescence microspectroscopic study[J]. ChemCatChem, 2010, 2(5): 564-571. |

| 37 | Hendriks F C, Meirer F, Kubarev A V, et al. Single-molecule fluorescence microscopy reveals local diffusion coefficients in the pore network of an individual catalyst particle[J]. Journal of the American Chemical Society, 2017, 139(39): 13632-13635. |

| 38 | 刘现玉, 袁程远, 高雄厚, 等. 拟薄水铝石@高岭土复合材料的合成及其在FCC催化剂中的应用[J]. 石油化工, 2020, 49(3): 219-223. |

| Liu X Y, Yuan C Y, Gao X H, et al. Synthesis of pseudo-boehmite@kaolinite composite and its application in FCC catalyst[J]. Petrochemical Technology, 2020, 49(3): 219-223. | |

| 39 | Thommes M, Kaneko K, Neimark A V, et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report)[J]. Pure and Applied Chemistry, 2015, 87(9/10): 1051-1069. |

| [1] | 罗欣怡, 徐强, 佘永璐, 聂腾飞, 郭烈锦. 光电分解水制氢气泡动力学特性及其传质机理研究[J]. 化工学报, 2024, 75(9): 3083-3093. |

| [2] | 杨子驰, 谢冰琪, 石瑞莘, 雷虹, 陈晨, 周才金, 张吉松. 套管膜式微反应器内高效安全的气液传质-反应过程研究进展[J]. 化工学报, 2024, 75(9): 3011-3027. |

| [3] | 杨锦蕊, 郑宏飞, 马兴龙, 金日辉, 梁深. 两级叠置式加湿除湿海水淡化装置性能研究[J]. 化工学报, 2024, 75(7): 2446-2454. |

| [4] | 王金山, 王世学, 朱禹. 冷却表面温差对高温质子交换膜燃料电池性能的影响[J]. 化工学报, 2024, 75(5): 2026-2035. |

| [5] | 冯彬彬, 卢明佳, 黄志宏, 常译文, 崔志明. 碳载体在质子交换膜燃料电池中的应用及优化[J]. 化工学报, 2024, 75(4): 1469-1484. |

| [6] | 蒋方涛, 钱刚, 周兴贵, 段学志, 张晶. 基于[bmim][BF4]相转移催化的氟代碳酸乙烯酯高效合成[J]. 化工学报, 2024, 75(4): 1543-1551. |

| [7] | 程婷, 焦纬洲, 刘有智. 功能性填料在超重力旋转填料床中的应用和研究进展[J]. 化工学报, 2024, 75(4): 1414-1428. |

| [8] | 董霄, 白志山, 杨晓勇, 殷伟, 刘宁普, 于启凡. CHPPO工艺氧化液耦合除杂技术的研究与工业应用[J]. 化工学报, 2024, 75(4): 1630-1641. |

| [9] | 王娟, 李秀明, 邵炜涛, 丁续, 霍莹, 付连超, 白云宇, 李迪. 多孔板鼓泡塔流动与传质特性数值模拟[J]. 化工学报, 2024, 75(3): 801-814. |

| [10] | 王佳琪, 魏皓琦, 苟阿静, 刘佳兴, 周昕霖, 葛坤. 纳米粒子作用下CO2水合物生成机理研究[J]. 化工学报, 2024, 75(3): 956-966. |

| [11] | 李文俊, 赵中阳, 倪震, 周灿, 郑成航, 高翔. 基于气-液传质强化的湿法烟气脱硫CFD模拟研究[J]. 化工学报, 2024, 75(2): 505-519. |

| [12] | 赵若晗, 黄蒙蒙, 朱春英, 付涛涛, 高习群, 马友光. 缩口T型微通道内纳米流体吸收CO2的流动与传质研究[J]. 化工学报, 2024, 75(1): 221-230. |

| [13] | 崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| [14] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [15] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号