化工学报 ›› 2024, Vol. 75 ›› Issue (11): 4205-4216.DOI: 10.11949/0438-1157.20240560

收稿日期:2024-05-26

修回日期:2024-07-22

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

马学虎

作者简介:侯静静(1995—),女,博士研究生,Houjj0420@mail.dlut.edu.cn

基金资助:

Jingjing HOU( ), Da RUAN, Ziyi BO, Xuehu MA(

), Da RUAN, Ziyi BO, Xuehu MA( )

)

Received:2024-05-26

Revised:2024-07-22

Online:2024-11-25

Published:2024-12-26

Contact:

Xuehu MA

摘要:

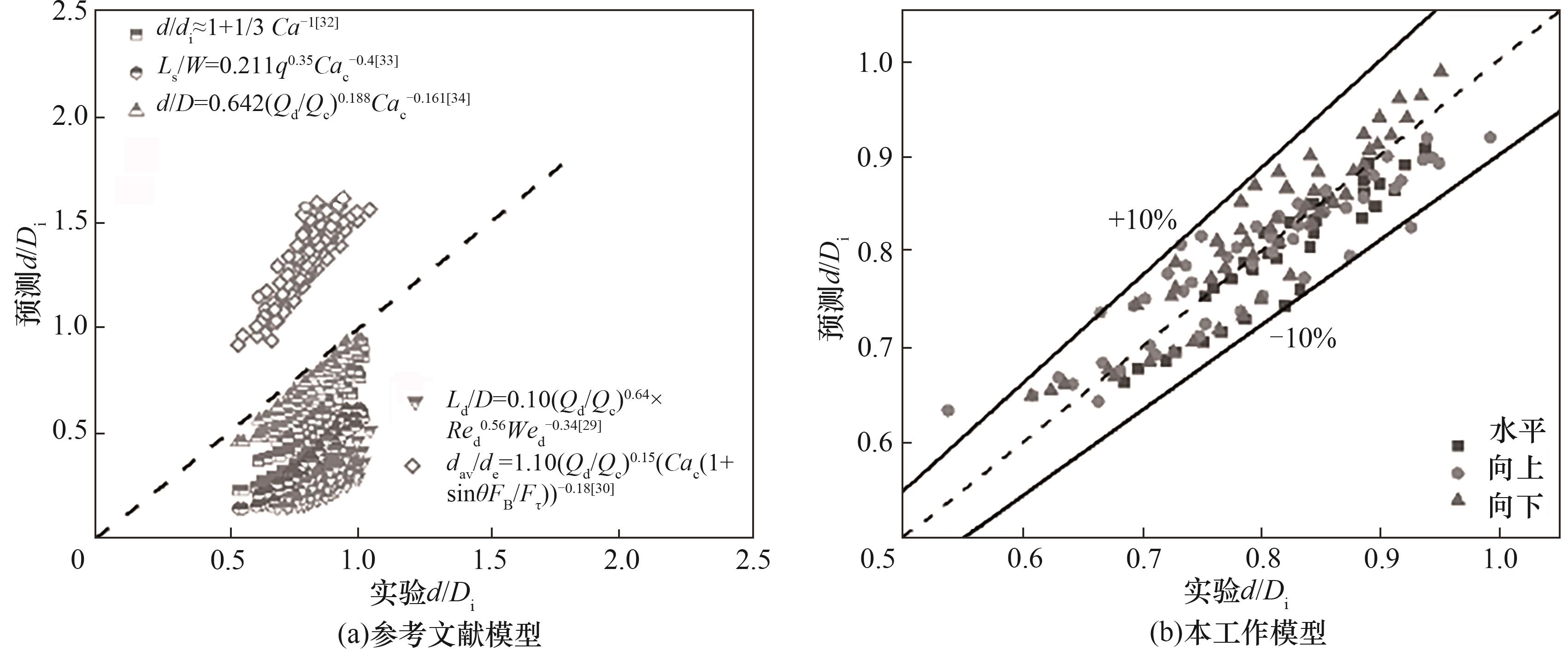

液滴基微反应器制备量子点过程中,作为连续相的全氟聚醚油与分散相由于密度差较大,会改变液滴运动行为并影响反应的热质传递。实验利用同轴微通道研究了浮力与流动的相对方向及两相流量对液滴动态行为的影响。结果表明,浮力影响水平液滴内部流场的轴对称性使其在脱落前期同轴度降至0%。通过调控流动与浮力的相对方向,实现液滴在较低的连续相流量(Qc=1.514 ml/min)下同轴度稳定至100%,但在较高Qc(3.666 ml/min)向下液滴的同轴度(96.8%)仅降低了3.2%。调控两相流量,液滴尺寸可控制在537~980 μm,基于浮力分别对水平/向上和向下液滴的促进和抑制作用机制,建立液滴尺寸预测模型,偏差约为±10%。实验阐明了微通道内浮力对液滴行为的影响,为液滴基微反应器设计提供指导。

中图分类号:

侯静静, 阮达, 薄紫一, 马学虎. 浮力方向对同轴微通道内液滴同轴度的影响规律[J]. 化工学报, 2024, 75(11): 4205-4216.

Jingjing HOU, Da RUAN, Ziyi BO, Xuehu MA. Influence of buoyancy direction on droplet coaxiality in a coaxial microchannel[J]. CIESC Journal, 2024, 75(11): 4205-4216.

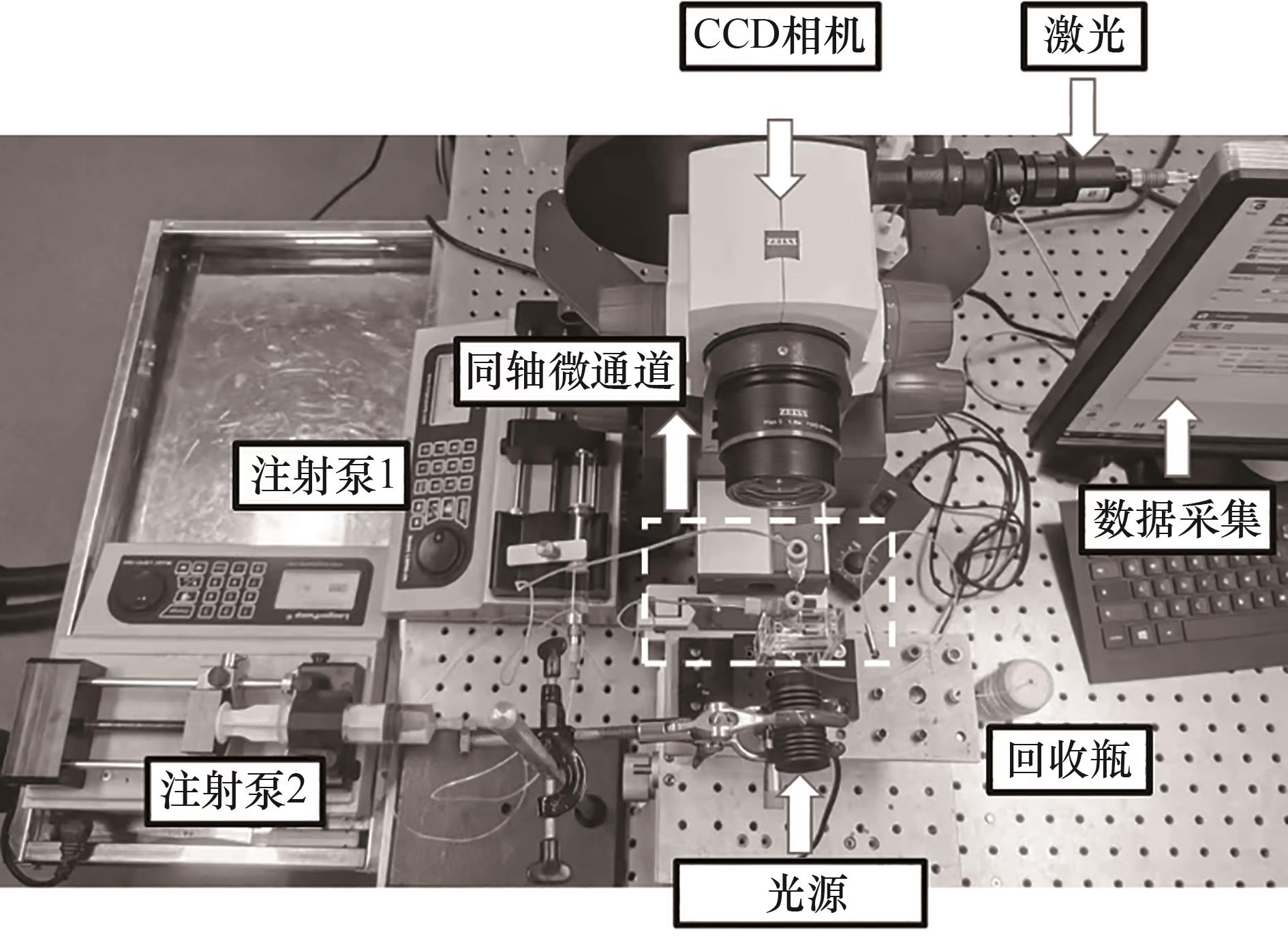

图2 微粒子图像测速技术(micro-PIV)原位观测同轴微通道内液滴的实验装置

Fig.2 Microparticle image velocimetry (micro-PIV) is an experimental device for in-situ observation of droplets in coaxial microchannels

| 试剂 | 密度/(g/cm3) | 黏度/(mPa∙s) | 表面张力/(mN/m) |

|---|---|---|---|

| ODE | 0.789 | 2.840 | 27.9 |

| 乙醇 | 0.789 | 1.170 | 22.3 |

| Galden HT-200 | 1.790 | 4.296 | 16.0 |

表1 试剂物性参数

Table 1 Physical property parameters of reagents

| 试剂 | 密度/(g/cm3) | 黏度/(mPa∙s) | 表面张力/(mN/m) |

|---|---|---|---|

| ODE | 0.789 | 2.840 | 27.9 |

| 乙醇 | 0.789 | 1.170 | 22.3 |

| Galden HT-200 | 1.790 | 4.296 | 16.0 |

图4 水平、向上和向下流动方向下的液-液两相流型图像(图中标记的为各流动方向的重力方向,Qd=0.178 ml/min)

Fig.4 Liquid-liquid two-phase flow pattern images in horizontal, upward and downward flow directions

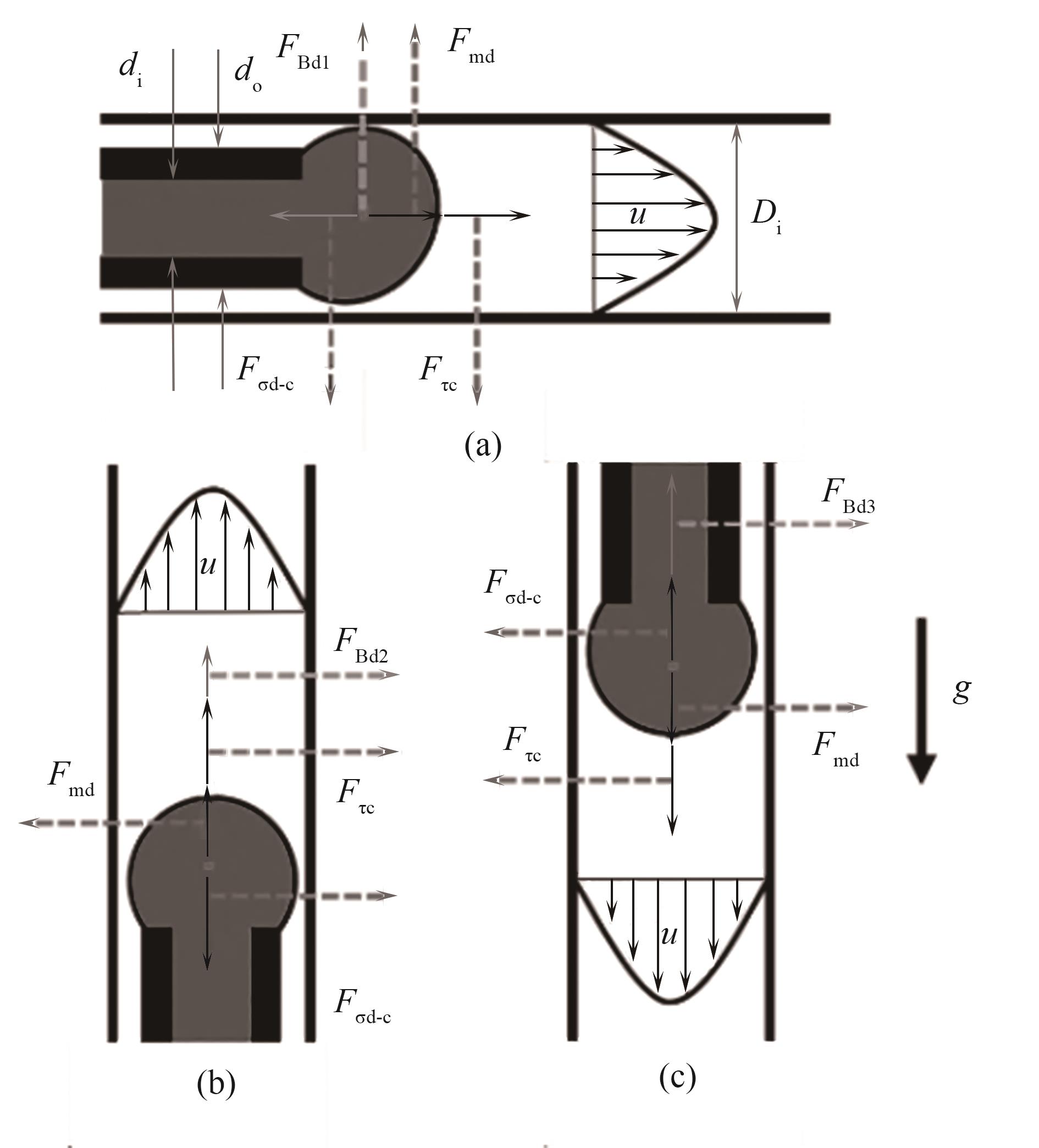

图5 水平、向上和向下的液滴受力分析[图中标记重力方向均是向下;Fmd为动量力;Fτc为黏性剪切力;FBd1(水平),FBd2(向上),FBd3(向下)为浮力;Fσd-c为两相界面张力;内通道内直径di=0.4 mm;外通道内直径Di=1.0 mm]

Fig.5 Horizontal, upward and downward droplet force analysis

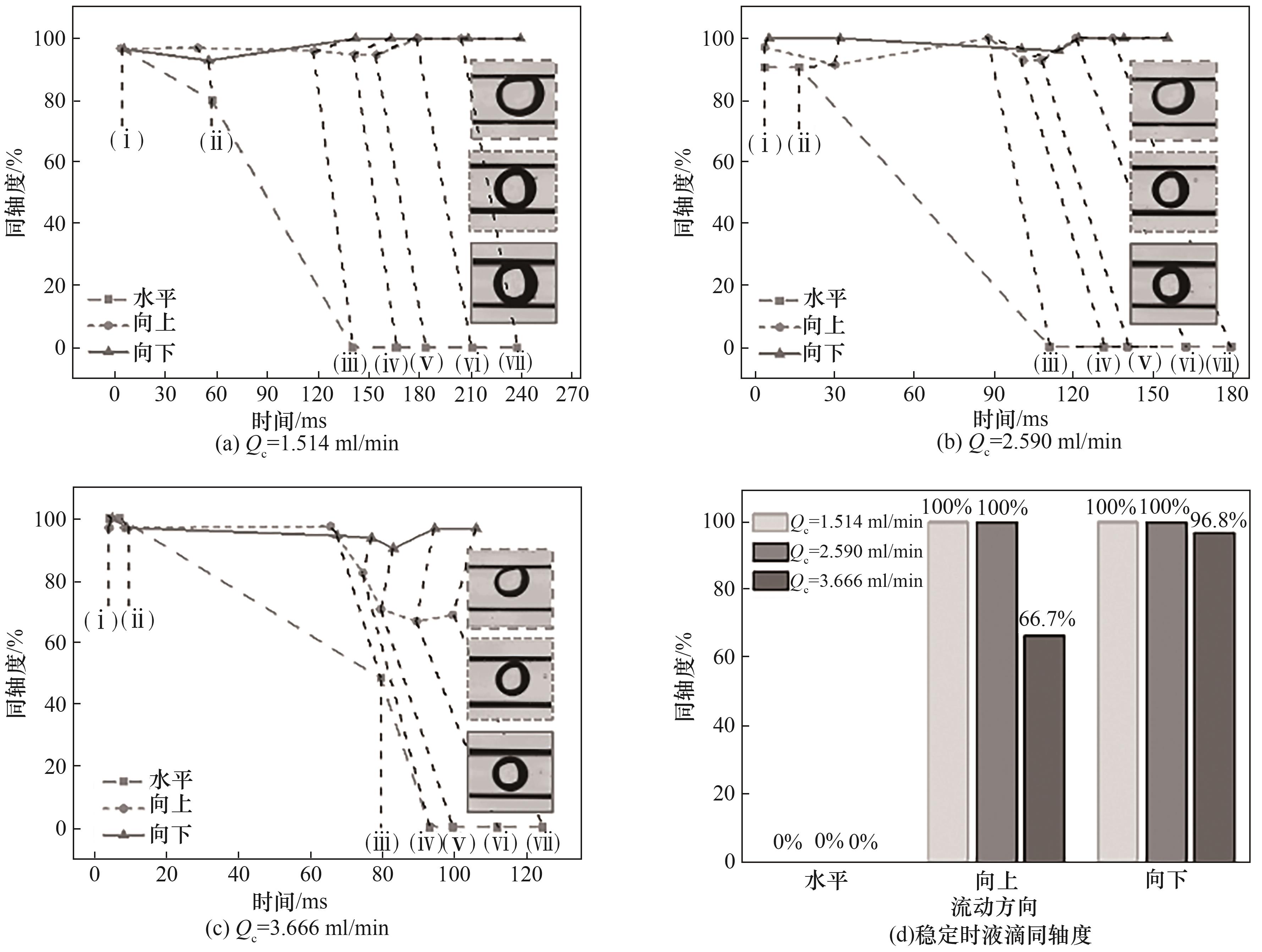

图7 不同流动方向液滴的同轴度随形成时间的演化规律(Qd=0.178 ml/min)[(ⅰ)为分散相回弹后;(ⅱ)为分散相拉伸生长后;(ⅲ)为液滴脱落时;(ⅳ)~(ⅶ)分别为液滴移动距离入口2.5、3.1、4.2和5.3 mm后;图中液滴图像在距离内通道出口5.3 mm处获得]

Fig.7 Evolution of coaxiality of droplets in different flow directions with formation time (Qd=0.178 ml/min)

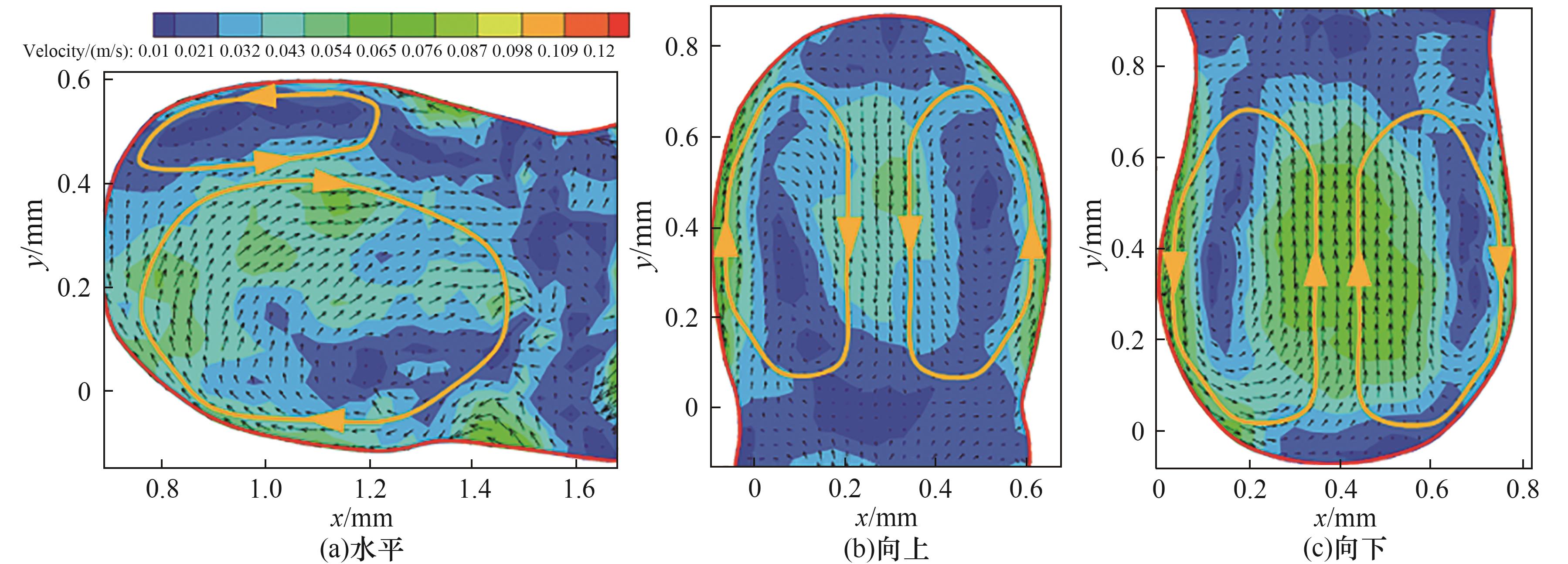

图8 液滴内部速度云图及速度图(红色曲线为液滴边界,Qd=0.178 ml/min,Qc=1.514 ml/min)

Fig.8 Cloud image and velocity diagram of the internal velocity of the droplet (the red curve is the droplet boundary,Qd=0.178 ml/min,Qc=1.514 ml/min)

图11 浮力作用液滴尺寸预测模型的预测值与实验值偏差对比

Fig.11 Comparison of the deviation between the predicted value and the experimental value of the droplet size prediction model under the action of buoyancy force

| 1 | Ye X, Cheng Y Q, Chen Y S, et al. Microcavity-enabled local oscillation of Taylor bubbles in a microchannel[J]. Industrial & Engineering Chemistry Research, 2021, 60(2): 1055-1066. |

| 2 | Liang Q Q, Bu Y F, Men Z W, et al. Taylor flow bubble transport characteristics of low partial pressure CO2 absorption in a serpentine micro contactor[J]. Chemical Engineering and Processing-Process Intensification, 2022, 181: 109168. |

| 3 | Liu Y Y, Yao C Q, Chen G W. Gas-liquid-liquid slug flow and mass transfer in hydrophilic and hydrophobic microreactors[J]. Chinese Journal of Chemical Engineering, 2022, 50: 85-94. |

| 4 | 陈昊, 杨星宇, 扆豪哲, 等. 微液滴强化传质与化学反应的研究进展[J]. 中国科学: 化学, 2024, 54(1): 133-146. |

| Chen H, Yang X Y, Yi H Z, et al. Research progress of enhanced mass transfer and chemical reaction of microdroplet[J]. Scientia Sinica: Chimica, 2024, 54(1): 133-146. | |

| 5 | Geng Y H, Guo J Z, Ling S D, et al. A nano-liter droplet-based microfluidic reactor serves as continuous large-scale production of inorganic perovskite nanocrystals[J]. Science China Materials, 2022, 65(10): 2746-2754. |

| 6 | Zhang K W, Gao Y H, Pinho B, et al. The importance of transport phenomena on the flow synthesis of monodispersed sharp blue-emitting perovskite CsPbBr3 nanoplatelets[J]. Chemical Engineering Journal, 2023, 451: 138752. |

| 7 | Geng Y H, Guo J Z, Wang H Q, et al. Large-scale production of ligand-engineered robust lead halide perovskite nanocrystals by a droplet-based microreactor system[J]. Small, 2022, 18(19): 2200740. |

| 8 | Maceiczyk R M, Dümbgen K, Lignos I, et al. Microfluidic reactors provide preparative and mechanistic insights into the synthesis of formamidinium lead halide perovskite nanocrystals[J]. Chemistry of Materials, 2017, 29(19): 8433-8439. |

| 9 | Lignos I, Protesescu L, Emiroglu D B, et al. Unveiling the shape evolution and halide-ion-segregation in blue-emitting formamidinium lead halide perovskite nanocrystals using an automated microfluidic platform[J]. Nano Letters, 2018, 18(2): 1246-1252. |

| 10 | Bezinge L, Maceiczyk R M, Lignos I, et al. Pick a color MARIA: adaptive sampling enables the rapid identification of complex perovskite nanocrystal compositions with defined emission characteristics[J]. ACS Applied Materials & Interfaces, 2018, 10(22): 18869-18878. |

| 11 | Lignos I, Morad V, Shynkarenko Y, et al. Exploration of near-infrared-emissive colloidal multinary lead halide perovskite nanocrystals using an automated microfluidic platform[J]. ACS Nano, 2018, 12(6): 5504-5517. |

| 12 | Wang C Y, Meng W, Li Y C, et al. Ultra-small α-CsPbI3 perovskite quantum dots with stable, bright and pure red emission for Rec. 2020 display backlights[J]. Nanoscale, 2023, 15(4): 1661-1668. |

| 13 | Lien S Y, Chen Y H, Chen W R, et al. Effect of growth temperature on the characteristics of CsPbI3-quantum dots doped perovskite film[J]. Molecules, 2021, 26(15): 4439. |

| 14 | Wang S, Zhao Q, Hazarika A, et al. Thermal tolerance of perovskite quantum dots dependent on A-site cation and surface ligand[J]. Nature Communications, 2023, 14(1): 2216. |

| 15 | Guo W X, Zhu C Y, Fu T T, et al. Coalescence dynamics of two droplets of different viscosities in T-junction microchannel with a funnel-typed expansion chamber[J]. Chinese Journal of Chemical Engineering, 2021, 38: 43-52. |

| 16 | Filatov N A, Evstrapov A A, Bukatin A S. Negative pressure provides simple and stable droplet generation in a flow-focusing microfluidic device[J]. Micromachines, 2021, 12(6): 662. |

| 17 | Venkateshwarlu A, Bharti R P. Effects of capillary number and flow rates on the hydrodynamics of droplet generation in two-phase cross-flow microfluidic systems[J]. Journal of the Taiwan Institute of Chemical Engineers, 2021, 129: 64-79. |

| 18 | Sattari A, Hanafizadeh P. Controllable preparation of double emulsion droplets in a dual-coaxial microfluidic device[J]. Journal of Flow Chemistry, 2021, 11(4): 807-821. |

| 19 | 宋仕容, 刘宏臣, 米晓天, 等. 同轴微通道内管结构对液滴生成的影响规律研究[J]. 化工学报, 2024, 75(2): 566-574. |

| Song S R, Liu H C, Mi X T, et al. Experimental investigation of droplet formation in coaxial microchannels with different geometries of inner channel[J]. CIESC Journal, 2024, 75(2): 566-574. | |

| 20 | Takagi M, Maki T, Miyahara M, et al. Production of titania nanoparticles by using a new microreactor assembled with same axle dual pipe[J]. Chemical Engineering Journal, 2004, 101(1/2/3): 269-276. |

| 21 | Moon S K, Cheong I W, Choi S W. Effect of flow rates of the continuous phase on droplet size in dripping and jetting regimes in a simple fluidic device for coaxial flow[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2014, 454: 84-88. |

| 22 | Muijlwijk K, Berton-Carabin C, Schroën K. Cross-flow microfluidic emulsification from a food perspective[J]. Trends in Food Science & Technology, 2016, 49: 51-63. |

| 23 | Dinh T, Cubaud T. Role of interfacial tension on viscous multiphase flows in coaxial microfluidic channels[J]. Langmuir, 2021, 37(24): 7420-7429. |

| 24 | Ferraro D, Serra M, Filippi D, et al. Controlling the distance of highly confined droplets in a capillary by interfacial tension for merging on-demand[J]. Lab on a Chip, 2018, 19(1): 136-146. |

| 25 | Zhu P G, Wang L Q. Passive and active droplet generation with microfluidics: a review[J]. Lab on a Chip, 2016, 17(1): 34-75. |

| 26 | Khorrami A S, Rezai P. Oscillating dispersed-phase co-flow microfluidic droplet generation: jet length reduction effect[J]. Soft Matter, 2018, 14(48): 9870-9876. |

| 27 | Chen Y P, Wu L Y, Zhang C B. Emulsion droplet formation in coflowing liquid streams[J]. Physical Review E Statistical Nonlinear and Soft Matter Physics, 2013, 87(1): 013002. |

| 28 | Pan D W, Chen Q, Zhang Y J, et al. Investigation on millimeter-scale W1/O/W2 compound droplets generation in a co-flowing device with one-step structure[J]. Journal of Industrial and Engineering Chemistry, 2020, 84: 366-374. |

| 29 | Fu G, Chen F F, Ni L, et al. Liquid-liquid two-phase flow and size distribution of droplets in milli-channels: effect of gravity[J]. International Journal of Multiphase Flow, 2022, 150: 104005. |

| 30 | Li L T, Zhang J S, Wang K, et al. Droplet formation of H2SO4/alkane system in a T-junction microchannel: gravity effect[J]. AIChE Journal, 2016, 62(12): 4564-4573. |

| 31 | Ge H, Chen J W, Wang Y H, et al. Influence of coaxiality on internal mixing of coflow generated droplets[J]. Applied Physics Letters, 2024, 124(7): 074102. |

| 32 | Christopher G F, Anna S L. Microfluidic methods for generating continuous droplet streams[J]. Journal of Physics D: Applied Physics, 2007, 40(19): R319-R336. |

| 33 | Wu Z, Cao Z, Sunden B. Flow patterns and slug scaling of liquid-liquid flow in square microchannels[J]. International Journal of Multiphase Flow, 2019, 112: 27-39. |

| 34 | Chagot L, Quilodrán-Casas C, Kalli M, et al. Surfactant-laden droplet size prediction in a flow-focusing microchannel: a data-driven approach[J]. Lab on a Chip, 2022, 22(20): 3848-3859. |

| [1] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [2] | 陈森洋, 靳蒲航, 谭志明, 谢公南. 质子交换膜燃料电池中蛇形流道液滴运动数值仿真研究[J]. 化工学报, 2024, 75(S1): 183-194. |

| [3] | 赵振刚, 周梦瑶, 金典, 张大骋. 基于泡沫碳扩散层的直接甲醇燃料电池改性研究[J]. 化工学报, 2024, 75(S1): 259-266. |

| [4] | 徐英宇, 杨国强, 彭璟, 孙海宁, 张志炳. 微界面高级氧化处理煤化工废水的研究[J]. 化工学报, 2024, 75(S1): 283-291. |

| [5] | 李雨霜, 王兴成, 温伯尧, 骆政园, 白博峰. 多孔介质中乳状液驱油的两相流动过程及其影响因素[J]. 化工学报, 2024, 75(S1): 56-66. |

| [6] | 刘律, 刘洁茹, 范亮亮, 赵亮. 基于层流效应的被动式颗粒分离微流控方法研究[J]. 化工学报, 2024, 75(S1): 67-75. |

| [7] | 周文博, 殷姜维, 张丹, 杨越, 于佳豪, 赵冰超. 热辐射加热下NaCl水溶液液滴蒸发过程的实验研究[J]. 化工学报, 2024, 75(S1): 85-94. |

| [8] | 杜得辉, 冯威, 张江辉, 项燕龙, 乔高攀, 李蔚. 微型翅片疏水复合强化管管内流动沸腾换热预测模型[J]. 化工学报, 2024, 75(S1): 95-107. |

| [9] | 陈超伟, 柳洋, 杜文静, 李金波, 史大阔, 辛公明. 局部热点下微肋通道流动传热特性[J]. 化工学报, 2024, 75(9): 3113-3121. |

| [10] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [11] | 唐昊, 胡定华, 李强, 张轩畅, 韩俊杰. 抗加速度双切线弧流道内气泡动力学行为数值与可视化研究[J]. 化工学报, 2024, 75(9): 3074-3082. |

| [12] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [13] | 左磊, 王军锋, 高健, 王道睿. 电场调控生物柴油液滴燃烧行为[J]. 化工学报, 2024, 75(8): 2983-2990. |

| [14] | 王皓宇, 杨杨, 荆文婕, 杨斌, 唐雨, 刘毅. 不同旋流器作用下气液螺旋环状流动特性研究[J]. 化工学报, 2024, 75(8): 2744-2755. |

| [15] | 赵亮, 李雨桥, 张德, 沈胜强. 螺旋喷嘴内外流场特性的实验研究[J]. 化工学报, 2024, 75(8): 2777-2786. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号