化工学报 ›› 2025, Vol. 76 ›› Issue (4): 1391-1403.DOI: 10.11949/0438-1157.20241161

马韶阳( ), 徐涵卓, 张亮亮, 孙宝昌, 邹海魁, 罗勇, 初广文(

), 徐涵卓, 张亮亮, 孙宝昌, 邹海魁, 罗勇, 初广文( )

)

收稿日期:2024-10-21

修回日期:2024-11-14

出版日期:2025-04-25

发布日期:2025-05-12

通讯作者:

初广文

作者简介:马韶阳(2001—),男,博士研究生,2023410004@mail.buct.edu.cn

基金资助:

Shaoyang MA( ), Hanzhuo XU, Liangliang ZHANG, Baochang SUN, Haikui ZOU, Yong LUO, Guangwen CHU(

), Hanzhuo XU, Liangliang ZHANG, Baochang SUN, Haikui ZOU, Yong LUO, Guangwen CHU( )

)

Received:2024-10-21

Revised:2024-11-14

Online:2025-04-25

Published:2025-05-12

Contact:

Guangwen CHU

摘要:

液-液非均相反应广泛存在于石油化工和精细化工的各个领域中。由于液-液两相物理化学性质差异以及相界面的存在,其反应过程通常受本征反应动力学和传递过程的共同影响。因此,增强液-液非均相反应传递过程并使之与反应动力学相匹配,实现原料、能源高效利用一直是研究者们关注的热点之一。围绕液-液非均相反应与传递过程强化机理与应用,以硝化反应、脱氯化氢反应等典型非均相反应为例,结合反应动力学、热力学和传递过程基本特征,综述了传递-反应过程耦合影响反应选择性和时空产率机制,阐述了工业化应用面临的挑战及过程强化解决策略,进而从传递过程匹配反应过程出发,展望了液-液非均相反应过程强化发展方向。

中图分类号:

马韶阳, 徐涵卓, 张亮亮, 孙宝昌, 邹海魁, 罗勇, 初广文. 液-液非均相反应与传递过程强化方法研究进展[J]. 化工学报, 2025, 76(4): 1391-1403.

Shaoyang MA, Hanzhuo XU, Liangliang ZHANG, Baochang SUN, Haikui ZOU, Yong LUO, Guangwen CHU. Research progress of liquid-liquid heterogeneous reactions and intensification methods towards their transfer processes[J]. CIESC Journal, 2025, 76(4): 1391-1403.

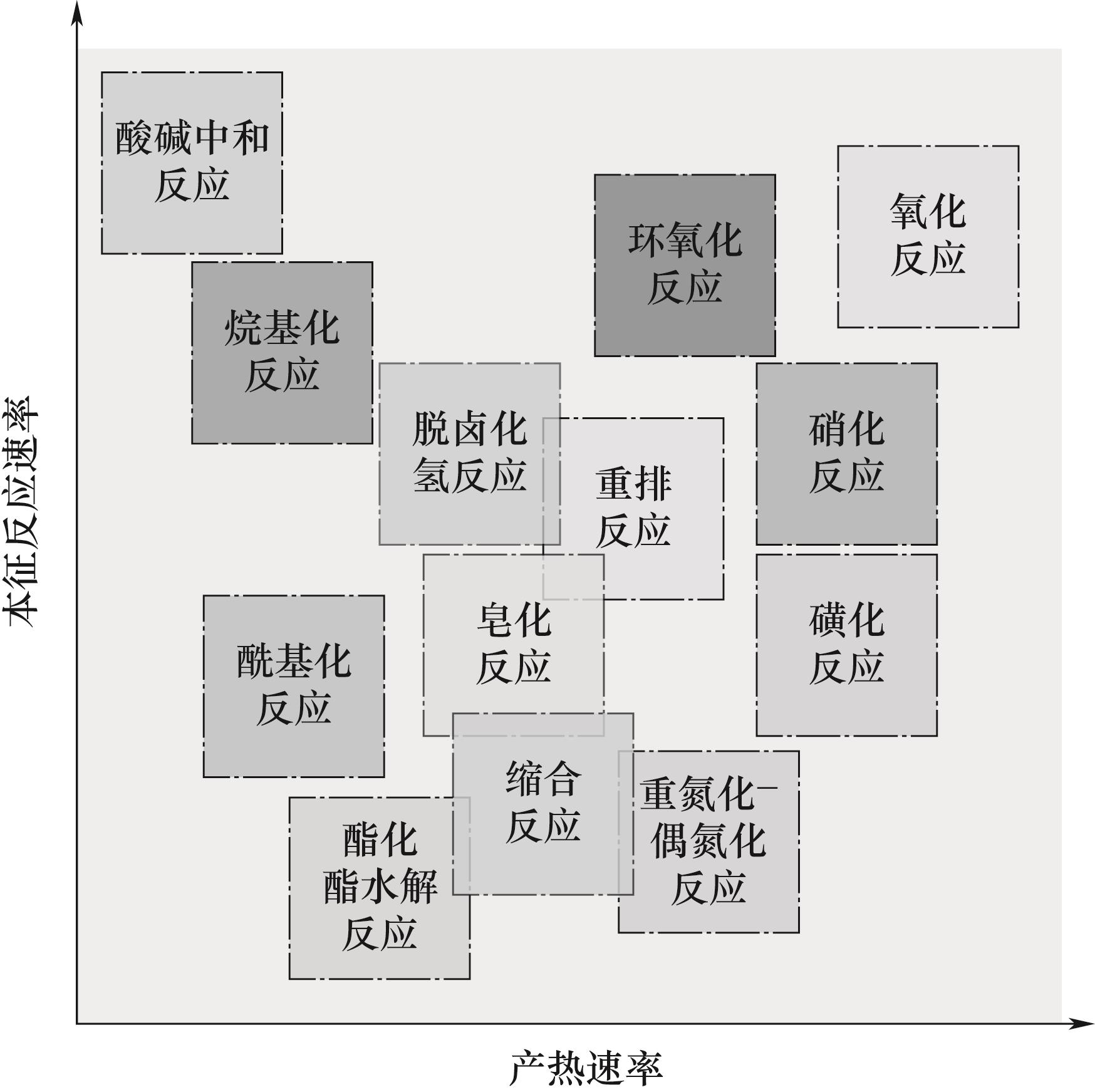

图2 不同液-液非均相反应的本征反应速率与产热速率比较[19,22-26]

Fig.2 Comparison of intrinsic reaction rates and heat production rates of different liquid-liquid heterogeneous reactions[19,22-26]

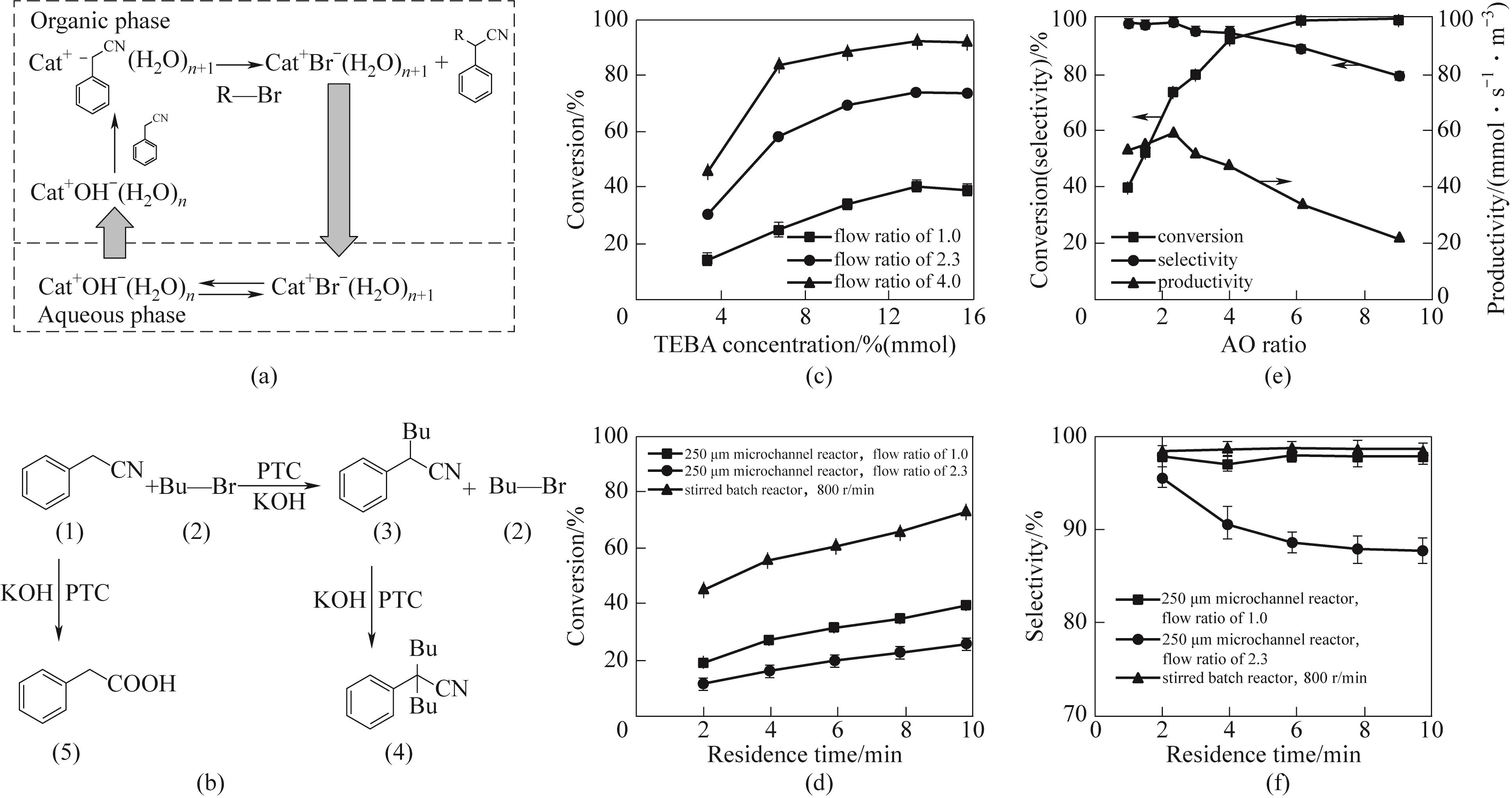

图4 (a)苯乙腈相转移烷基化过程中的传质和反应动力学步骤; (b)苯乙腈与正丁基溴烷基化反应中的主反应和副反应; (c)不同水-有机相体积流量比下催化剂浓度对转化率的影响; (d)停留时间对反应转化率的影响; (e)水相、有机相流速比对转化率、选择性和产率的影响; (f)停留时间对反应选择性的影响

Fig.4 (a) Mass-transfer and kinetic steps in the phase-transfer alkylation of phenylacetonitrile; (b) Main reaction and side reactions in alkylation of phenylacetonitrile with n-butyl bromide; (c) Conversion as a function of catalyst concentration at different aqueous-to-organic phase volumetric flow ratios; (d) The effect of residence time on the conversion rate of reaction; (e) Conversion, selectivity, and productivity as functions of AO flow ratio; (f) Effect of residence time on reaction selectivity

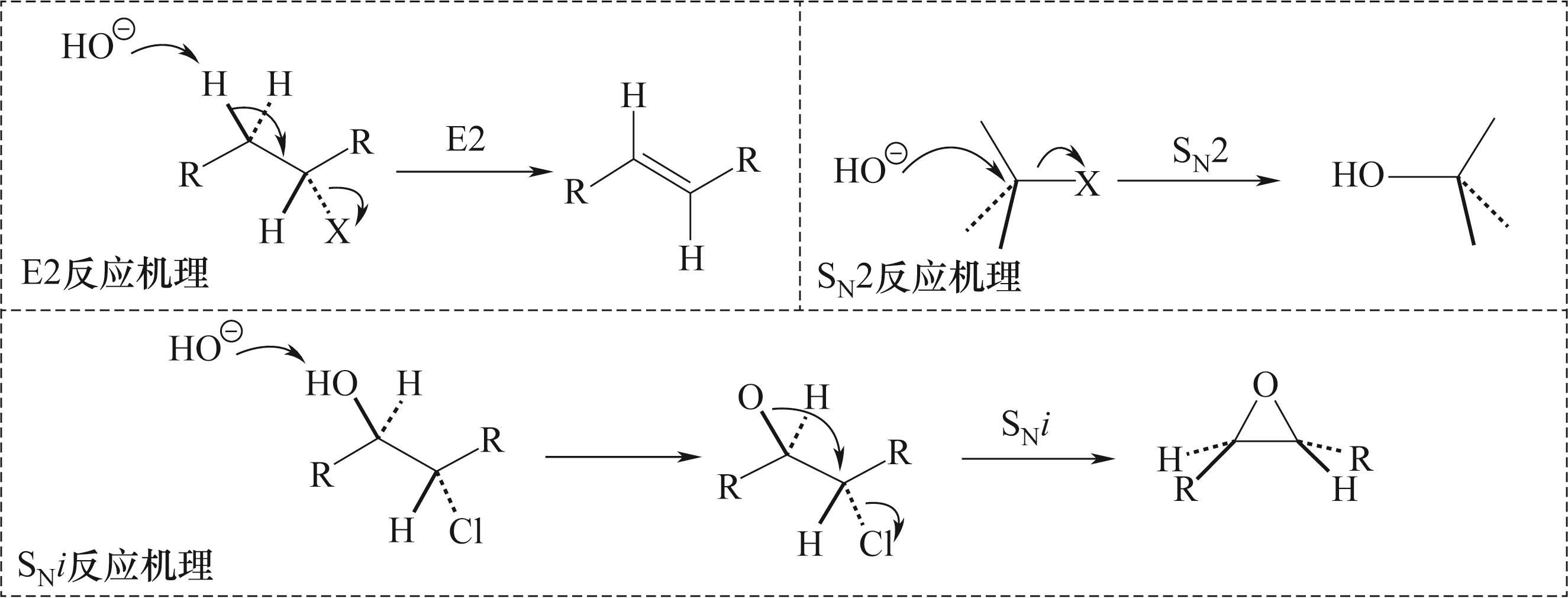

图5 双分子消除反应(E2)机理,双分子亲核取代反应(SN2)机理和分子内亲核取代反应(SNi)机理

Fig.5 Bimolecular elimination reaction (E2) mechanism, bimolecular nucleophilic substitution reaction (SN2) mechanism and intramolecular nucleophilic substitution reaction (SNi) mechanism

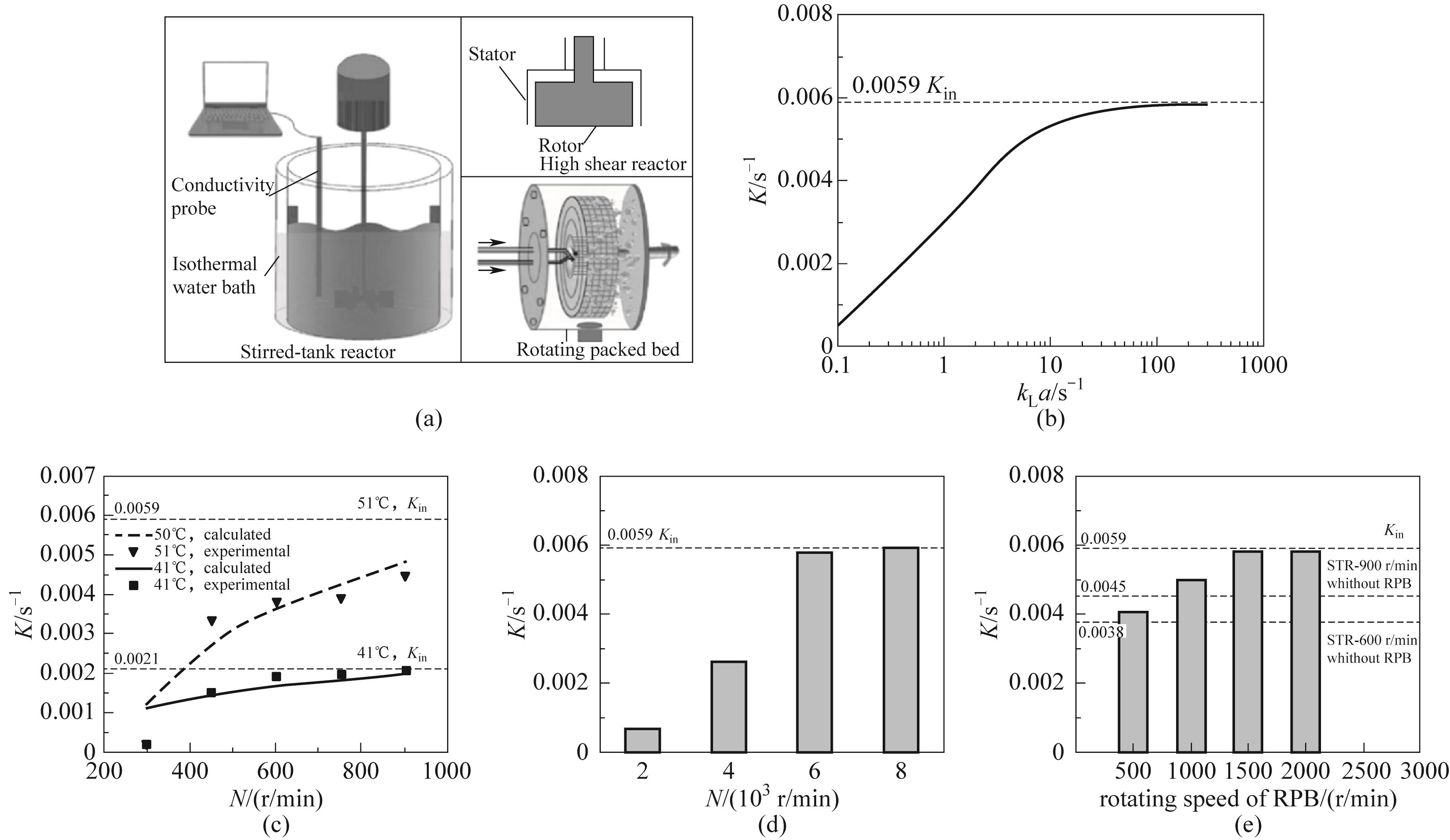

图6 (a)搅拌釜、高剪切和旋转填充床反应器; (b) 1,1,2-三氯乙烷脱氯化氢反应表观反应速率与传质效率的理论关系; (c)转速和温度对搅拌釜中反应速率的影响; (d)高剪切反应器对反应的强化效果; (e)旋转填充床反应器对反应的强化效果

Fig.6 (a) Apparatus used in the experiments: standard stirred tank, high-speed homogenizer and rotating packed bed; (b) Theoretical relation of the apparent reaction rate and mass transfer efficiency; (c) Effects of rotating speeds and temperature on reaction rate in the stirred tank; (d) The results of reaction intensifying by a homogenizer; (e) The results of reaction intensifying by a rotating packed bed

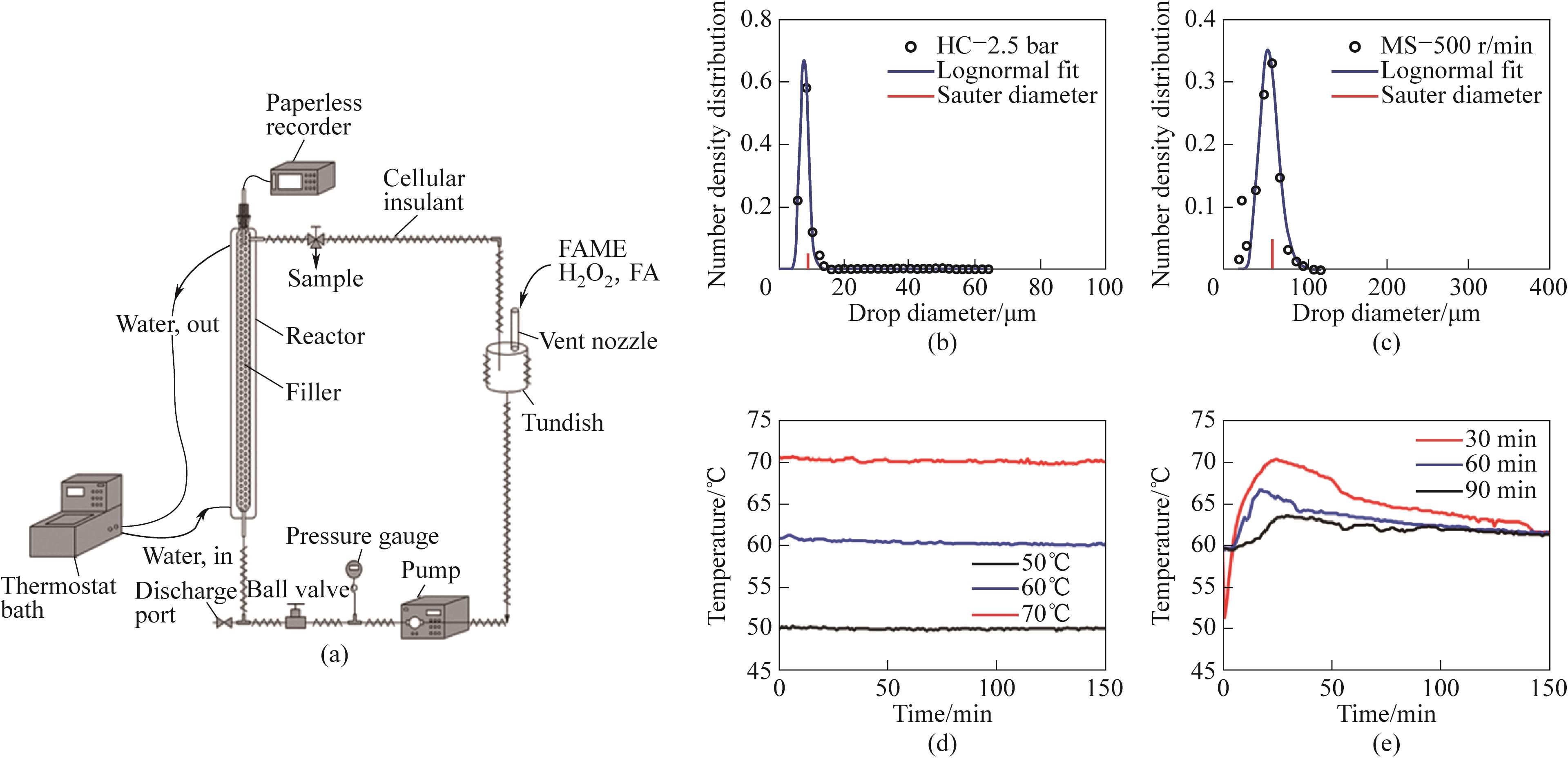

图8 (a)水力空化反应装置; (b)搅拌釜反应器在500 r/min下分散相液滴尺寸分布和Sauter平均直径; (c)水力空化反应器在2.5 bar(1 bar=0.1 MPa)入口压力下分散相液滴尺寸分布和Sauter平均直径; (d)反应过程中水力空化反应器中的温度变化; (e)反应过程中搅拌釜反应器中的温度变化

Fig.8 (a) Schematic diagram of the experimental apparatus; (b) The size distribution and Sauter diameter of dispersed droplets in stirred tank reactor at 500 r/min; (c) The size distribution and Sauter diameter of dispersed phase droplets in the hydraulic cavitation reactor with inlet pressure of 2.5 bar; (d) Temperature changes in a hydrodynamic cavitation reactor; (e) Temperature changes in a stirred-tank reactor

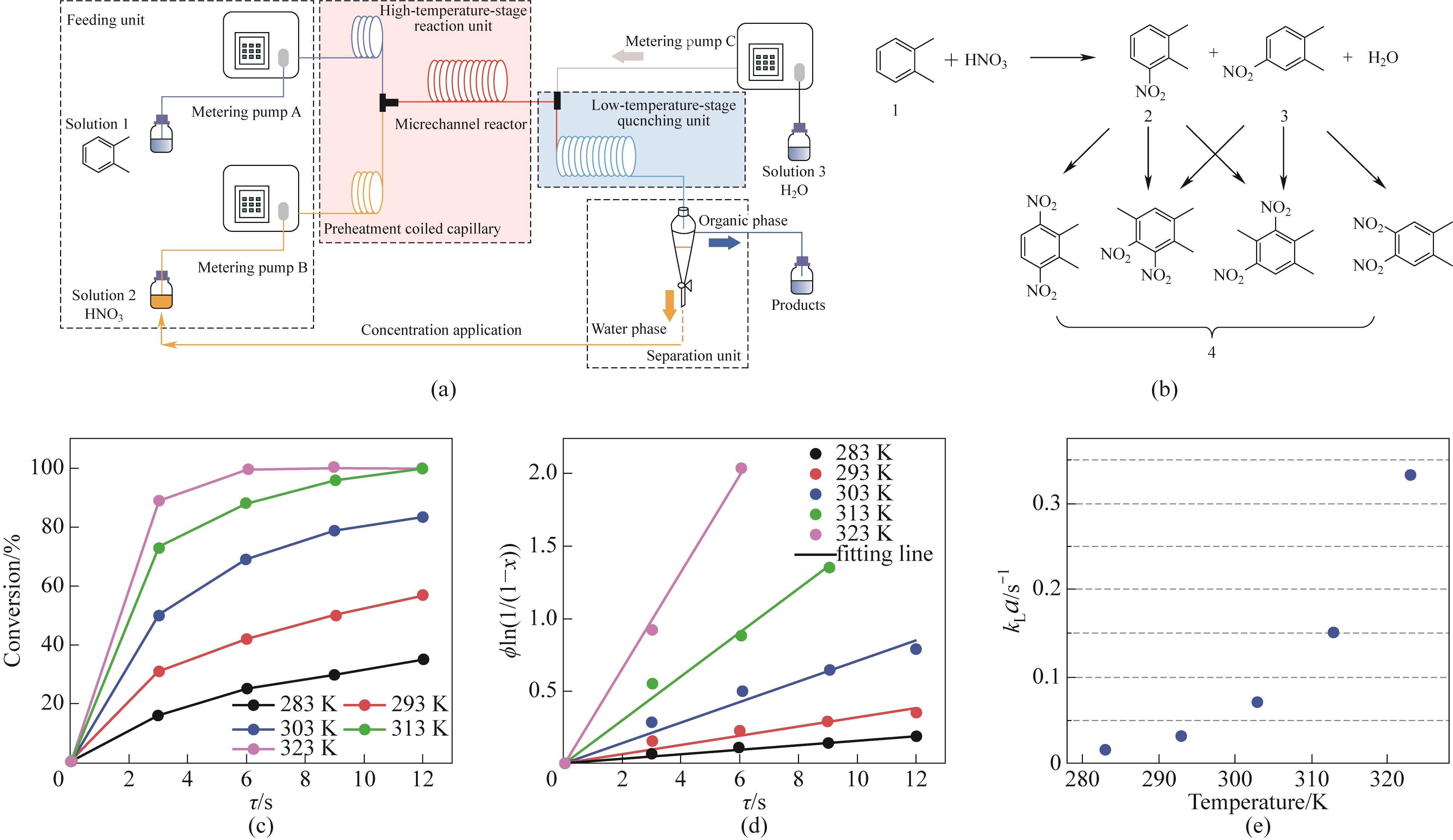

图10 (a)微通道反应器实验装置示意图; (b)邻二甲苯的硝化反应网络; (c) 不同温度下邻二甲苯的转化率随停留时间的变化曲线; (d)停留时间对传质的影响; (e)温度对传质的影响

Fig.10 (a) Schematic diagram of the microchannel reactor experimental device; (b) Network of the o-xylene nitration reaction; (c) The plot of conversion of o-xylene versus residence time at different temperatures; (d) The effect of residence time on mass transfer; (e) The effect of temperature on mass transfer

| 1 | Pu X, Li G X, Song Y, et al. Droplet coalescence phenomena during liquid-liquid heterogeneous reactions in microreactors[J]. Industrial & Engineering Chemistry Research, 2017, 56(43): 12316-12325. |

| 2 | Cao J Z, Tao S Y. Liquid-liquid reactions performed by cellular reactors[J]. Nature Communications, 2024, 15(1): 5579. |

| 3 | Wang K, Li L T, Xie P, et al. Liquid-liquid microflow reaction engineering[J]. Reaction Chemistry & Engineering, 2017, 2(5): 611-627. |

| 4 | 马韶阳, 徐涵卓, 张亮亮, 等. 液-液非均相反应器研究进展[J]. 化工学报, 2024, 75(3): 727-742. |

| Ma S Y, Xu H Z, Zhang L L, et al. Research progress of reactors for liquid-liquid heterogeneous system[J]. CIESC Journal, 2024, 75(3): 727-742. | |

| 5 | Ghotli R A, Abdul Aziz A R, Ibrahim S. Liquid-liquid mass transfer studies in various stirred vessel designs[J]. Reviews in Chemical Engineering, 2015, 31(4): 329-343. |

| 6 | Moioli E. Process intensification and energy transition: a necessary coupling?[J]. Chemical Engineering and Processing- Process Intensification, 2022, 179: 109097. |

| 7 | Keil F J. Process intensification[J]. Reviews in Chemical Engineering, 2018, 34(2): 135-200. |

| 8 | Sitter S, Chen Q, Grossmann I E. An overview of process intensification methods[J]. Current Opinion in Chemical Engineering, 2019, 25: 87-94. |

| 9 | Song J, Cui Y J, Sheng L, et al. Determination of nitration kinetics of p-nitrotoluene with a homogeneously continuous microflow[J]. Chemical Engineering Science, 2022, 247: 117041. |

| 10 | Wu Z Y, Fang J J, Xie Q L, et al. Macroscopic kinetics modelling of liquid-liquid reaction system: epoxidation of fatty acid methyl esters[J]. Industrial Crops and Products, 2018, 122: 266-276. |

| 11 | Sun B C, Zhang L L, Weng Z, et al. Sulfonation of alkylbenzene using liquid sulfonating agent in rotating packed bed: experimental and numerical study[J]. Chemical Engineering and Processing: Process Intensification, 2017, 119: 93-100. |

| 12 | Tian Y T, Li Z X, Mei S J, et al. Alkylation of isobutane and 2-butene by concentrated sulfuric acid in a rotating packed bed reactor[J]. Industrial & Engineering Chemistry Research, 2018, 57(40): 13362-13371. |

| 13 | Zhang Y D, Zhang L L, Xiong X Y, et al. Matching relation between intrinsic kinetics and liquid-liquid mass transfer of medium-rate reaction: take 1,1,2-trichloroethane dehydrochlorination as an example[J]. Chemical Engineering Science, 2023, 280(5): 119102. |

| 14 | 张一栋. 超重力强化液液非均相分子混合与反应过程研究[D]. 北京: 北京化工大学, 2024. |

| Zhang Y D. Resarch of process intensification of liquid-liquid hetergeneous micromixing and reaction by high gravity technology[D]. Beijing: Beijing University of Chemical Technology, 2024. | |

| 15 | Rudelstorfer G, Neubauer M, Siebenhofer M, et al. Esterification of acetic acid with methanol and simultaneous product isolation by liquid-liquid extraction in a Taylor-Couette disc contactor[J]. Chemie Ingenieur Technik, 2022, 94(5): 671-680. |

| 16 | Liu S E, Pasha M, Shang M J, et al. Kinetic study on the reaction routes in the oxidation of K/A oil by nitric acid with microreactors[J]. Chemical Engineering Science, 2023, 266: 118273. |

| 17 | 鲍俊. 超重力反应器强化缩合反应新工艺的研究[D]. 北京: 北京化工大学, 2015. |

| Bao J. Study on the intensification of the new process of condensation reaction with a higee reactor[D]. Beijing: Beijing University of Chemical Technology, 2015. | |

| 18 | Chu G W, Xu H Z, Luo Y, et al. Higee-intensified process reengineering in fine chemistry industry: principle and case studies[J]. Scientia Sinica Chimica, 2024, 54(11): 1959-1966 |

| 19 | Xie Y, Feng M J, Zhang M, et al. Kinetics model of piperacillin synthesis in a microreactor[J]. Chemical Engineering Science, 2022, 259: 117821. |

| 20 | Zhang L L, Wang F Y, Zhang Y D, et al. Enhanced chemical deacidification of crude soybean oil by rotating packed bed reactor[J]. Chemical Engineering Science, 2023, 282(2): 119242. |

| 21 | Kashid M N, Yuranov I, Raspail P, et al. Cyclization of pseudoionone to β-ionone: reaction mechanism and kinetics[J]. Industrial & Engineering Chemistry Research, 2011, 50(13): 7920-7926. |

| 22 | Yan Z F, Du C C, Wang Y B, et al. Dehydrochlorination of β-chlorohydrin in continuous microflow system: reaction kinetics and process intensification[J]. Chemical Engineering Journal, 2022, 444: 136498. |

| 23 | Santacesaria E, Turco R, Russo V, et al. Kinetics of soybean oil epoxidation in a semibatch reactor[J]. Industrial & Engineering Chemistry Research, 2020, 59(50): 21700-21711. |

| 24 | Guo S, Zhan L W, Li B D. Nitration of o-xylene in the microreactor: reaction kinetics and process intensification[J]. Chemical Engineering Journal, 2023, 468(15): 143468. |

| 25 | Zhan W, Wang J N, He C X, et al. Kinetics of glyoxal oxidation by nitric acid in a capillary microreactor[J]. Chemical Engineering Science, 2023, 276(15): 118813. |

| 26 | Zhang Y D, Zhang L L, Wang Z X, et al. Liquid-liquid heterogeneous mixing efficiency in a rotating packed bed reactor[J]. AIChE Journal, 2023, 69(6): e18000. |

| 27 | Bourne J R. Mixing and the selectivity of chemical reactions[J]. Organic Process Research & Development, 2003, 7(4): 471-508. |

| 28 | Cogliano T, Russo V, Eränen K, et al. Epoxidation of vegetable oils in continuous device: kinetics, mass transfer and reactor modelling[J]. Chemical Engineering Science, 2024, 294(15): 120079. |

| 29 | Zhang H R, Bai M Q, Wang X Y, et al. Thermal runaway incidents—a serious cause of concern: an analysis of runaway incidents in China[J]. Process Safety and Environmental Protection, 2021, 155: 277-286. |

| 30 | Wang Z, Cao D L, Xu Z S, et al. Thermal safety study on the synthesis of HMX by nitrourea method[J]. Process Safety and Environmental Protection, 2020, 137: 282-288. |

| 31 | Li S F, Zhang X L, Ji D S, et al. Continuous flow nitration of 3-[2-chloro-4-(trifluoromethyl) phenoxy]benzoic acid and its chemical kinetics within droplet-based microreactors[J]. Chemical Engineering Science, 2022, 255(29):117657. |

| 32 | Adhvaryu A, Erhan S Z. Epoxidized soybean oil as a potential source of high-temperature lubricants[J]. Industrial Crops and Products, 2002, 15(3): 247-254. |

| 33 | de Quadros J V, Giudici R. Epoxidation of soybean oil at maximum heat removal and single addition of all reactants[J]. Chemical Engineering and Processing: Process Intensification, 2016, 100: 87-93. |

| 34 | Vianello C, Piccolo D, Lorenzetti A, et al. Study of soybean oil epoxidation: effects of sulfuric acid and the mixing program[J]. Industrial & Engineering Chemistry Research, 2018, 57(34): 11517-11525. |

| 35 | Sagandira M B, Sagandira C R, Watts P. Continuous flow synthesis of xylidines via biphasic nitration of xylenes and nitro-reduction[J]. Journal of Flow Chemistry, 2021, 11(2): 193-208. |

| 36 | Santacesaria E, Turco R, Russo V, et al. Soybean oil epoxidation: kinetics of the epoxide ring opening reactions[J]. Processes, 2020, 8(9): 1134. |

| 37 | Yao H, Ni L, Liu Y S, et al. Process hazard and thermal risk evaluation of m-xylene nitration with mixed acid[J]. Process Safety and Environmental Protection, 2023, 175: 238-250. |

| 38 | Patel B A, Pereira C S. Process intensification at scale: an industrial perspective[J]. Chemical Engineering and Processing- Process Intensification, 2022, 181: 109098. |

| 39 | Hosseini Kakavandi F, Rahimi M, Jafari O, et al. Liquid-liquid two-phase mass transfer in T-type micromixers with different junctions and cylindrical pits[J]. Chemical Engineering and Processing- Process Intensification, 2016, 107: 58-67. |

| 40 | Li G X, Pu X, Shang M J, et al. Intensification of liquid-liquid two-phase mass transfer in a capillary microreactor system[J]. AIChE Journal, 2019, 65(1): 334-346. |

| 41 | Bello Yaya N, Habert A C, de Araujo Kronemberger F. Evaluation of a hollow fiber membrane contactor reactor for reactive extraction in biodiesel production[J]. Chemical Engineering and Processing - Process Intensification, 2023, 194: 109574. |

| 42 | Gonawan F N, Abu Bakar M Z, Abd Karim K, et al. The effect of mass transfer on reaction rates during immobilized β-galactosidase-catalyzed conversion of lactose in hollow fiber membrane[J]. Chemical Engineering Communications, 2019, 206(5): 630-646. |

| 43 | Wang Z H, Yang T, Liu Z X, et al. Mass transfer in a rotating packed bed: a critical review[J]. Chemical Engineering and Processing - Process Intensification, 2019, 139: 78-94. |

| 44 | Vashisth V, Nigam K D P, Kumar V. Design and development of high shear mixers: fundamentals, applications and recent progress[J]. Chemical Engineering Science, 2021, 232(15): 116296. |

| 45 | Zhang J L, Xu S Q, Li W. High shear mixers: A review of typical applications and studies on power draw, flow pattern, energy dissipation and transfer properties[J]. Chemical Engineering and Processing: Process Intensification, 2012, 57: 25-41. |

| 46 | Magosso M, Hazen L J W, van den Berg M, et al. Intensified sulfite reduction of alkyl hydroperoxides in a rotor-stator spinning-disc reactor[J]. Industrial & Engineering Chemistry Research, 2021, 60(43): 15540-15548. |

| 47 | Sharma M, Mohapatra T, Ghosh P. Hydrodynamics, mass and heat transfer study for emerging heterogeneous Fenton process in multiphase fluidized-bed reactor system for wastewater treatment-a review[J]. Chemical Engineering Research and Design, 2021, 171: 48-62. |

| 48 | Wang D X, Gu C J, Sun C, et al. Flow pattern transition and wave characteristics of impinging jet flow on a spinning disk reactor[J]. Chemical Engineering Journal, 2023, 451: 138790. |

| 49 | Zhao S N, Dong Z Y, Yao C Q, et al. Liquid-liquid two-phase flow in ultrasonic microreactors: cavitation, emulsification, and mass transfer enhancement[J]. AIChE Journal, 2018, 64(4): 1412-1423. |

| 50 | Yang M, Gao Y, Liu Y, et al. Integration of microfluidic systems with external fields for multiphase process intensification[J]. Chemical Engineering Science, 2021, 234(28): 116450. |

| 51 | Azimi N, Rahimi M. Magnetic nanoparticles stimulation to enhance liquid-liquid two-phase mass transfer under static and rotating magnetic fields[J]. Journal of Magnetism and Magnetic Materials, 2017, 422: 188-196. |

| 52 | Zhao S N, Yao C Q, Dong Z Y, et al. Intensification of liquid-liquid two-phase mass transfer by oscillating bubbles in ultrasonic microreactor[J]. Chemical Engineering Science, 2018, 186: 122-134. |

| 53 | Liang C, Zhu Y G, Sun B C, et al. Rotating packed bed reactor integrated with plasma: mass transfer intensification and wastewater treatment[J]. Industrial & Engineering Chemistry Research, 2023, 62(21): 8444-8453. |

| 54 | Yao C Q, Zhao Y C, Ma H Y, et al. Two-phase flow and mass transfer in microchannels: a review from local mechanism to global models[J]. Chemical Engineering Science, 2021, 229: 116017. |

| 55 | Plouffe P, Roberge D M, Macchi A. Liquid-liquid flow regimes and mass transfer in various micro-reactors[J]. Chemical Engineering Journal, 2016, 300: 9-19. |

| 56 | Manzano Martínez A N, Assirelli M, van der Schaaf J. Droplet size and liquid-liquid mass transfer with reaction in a rotor-stator Spinning Disk Reactor[J]. Chemical Engineering Science, 2021, 242: 116706. |

| 57 | Yang H, Chu G, Xiang Y, et al. Characterization of micromixing efficiency in rotating packed beds by chemical methods[J]. Chemical Engineering Journal, 2006, 121(2/3): 147-152. |

| 58 | Noorpoor Z, Rahmani M. A review of computational fluid dynamics modeling for isobutane alkylation: process optimization, reactor design, and future perspectives[J]. Energy & Fuels, 2024, 38(13): 11403-11436. |

| 59 | Pedersen M J, Holm T L, Rahbek J P, et al. Full-scale continuous mini-reactor setup for heterogeneous Grignard alkylation of a pharmaceutical intermediate[J]. Organic Process Research & Development, 2013, 17(9): 1142-1148. |

| 60 | Keglevich G, Grün A, Bálint E. Microwave irradiation and phase transfer catalysis in C-, O- and N-alkylation reactions[J]. Current Organic Synthesis, 2013, 10(5): 751-763. |

| 61 | Simon P, Lőrinczi B, Szatmári I. Alkoxyalkylation of electron-rich aromatic compounds[J]. International Journal of Molecular Sciences, 2024, 25(13): 6966. |

| 62 | 李明伟, 李涛, 任保增. 烷基化工艺及硫酸烷基化反应器研究进展[J]. 化工进展, 2017, 36(5): 1573-1580. |

| Li M W, Li T, Ren B Z. Advance of alkylation process and concentrated sulfuric acid alkylation reactor[J]. Chemical Industry and Engineering Progress, 2017, 36(5): 1573-1580. | |

| 63 | Jovanović J, Rebrov E V, Nijhuis T A X, et al. Phase-transfer catalysis in segmented flow in a microchannel: fluidic control of selectivity and productivity[J]. Industrial & Engineering Chemistry Research, 2010, 49(6): 2681-2687. |

| 64 | Tian Y, Mei S, Zhang L L, et al. Improved H2SO4-catalyzed alkylation reaction in a rotating packed bed reactor by adding additives[J]. The Canadian Journal of Chemical Engineering, 2022, 100(11): 3395-3407. |

| 65 | Ueno M, Hisamoto H, Kitamorib T, et al. Phase-transfer alkylation reactions using microreactors[J]. Chemical Communications, 2003(8): 936-937. |

| 66 | Nieves-Remacha M J, Torres M, Ruiz-Abad M, et al. Scale-up of N-alkylation reaction using phase-transfer catalysis with integrated separation in flow[J]. Reaction Chemistry & Engineering, 2019, 4(2): 334-345. |

| 67 | Yang G W, Zhang Y Y, Xie R, et al. High-activity organocatalysts for polyether synthesis via intramolecular ammonium cation assisted SN2 ring-opening polymerization[J]. Angewandte Chemie International Edition, 2020, 59(39): 16910-16917. |

| 68 | Tang T T, Fan X S, Jin Y, et al. Synthesis and characterization of graft copolymers with poly(epichlorohydrin-co-ethylene oxide) as backbone by combination of ring-opening polymerization with living anionic polymerization[J]. Polymer, 2014, 55(16): 3680-3687. |

| 69 | Kester J E. Vinylidene Chloride (VDC)[M]//Encyclopedia of Toxicology. Amsterdam: Elsevier, 2014: 942-947. |

| 70 | Cowdrey W A, Hughes E D, Ingold C K, et al. Reaction kinetics and the Walden inversion. Part Ⅵ. Relation of steric orientation to mechanism in substitutions involving halogen atoms and simple or substituted hydroxyl groups[J]. Journal of the Chemical Society, 1937: 1252-1271. |

| 71 | Aleskerov M A, Yufit S S, Kucherov V F. The mechanism of the β-elimination reaction[J]. Russian Chemical Reviews, 1978, 47(2): 134-147. |

| 72 | Zhang J S, Lu Y C, Jin Q R, et al. Determination of kinetic parameters of dehydrochlorination of dichloropropanol in a microreactor[J]. Chemical Engineering Journal, 2012, 203: 142-147. |

| 73 | de Araujo Filho C A, Heredia S, Eränen K, et al. Advanced millireactor technology for the kinetic investigation of very rapid reactions: dehydrochlorination of 1, 3-dichloro-2-propanol to epichlorohydrin[J]. Chemical Engineering Science, 2016, 149: 35-41. |

| 74 | Zhang L L, Li T J, Zhang Y D, et al. Simulation and experimental study on mechanism and kinetics of 1,1,2-trichloroethane dehydrochlorination reaction[J]. Chemical Engineering Science, 2022, 262(23): 117990. |

| 75 | Prileschajew N. Oxydation ungesättigter Verbindungen mittels organischer Superoxyde[J]. Berichte Der Deutschen Chemischen Gesellschaft, 1909, 42(4): 4811-4815. |

| 76 | Olivieri G V, de Quadros J V, Giudici R. Epoxidation reaction of soybean oil: experimental study and comprehensive kinetic modeling[J]. Industrial & Engineering Chemistry Research, 2020, 59(42): 18808-18823. |

| 77 | Kleiner J, Hinrichsen O. Epoxidation of methyl oleate in a rotor-stator spinning disc reactor[J]. Chemical Engineering and Processing- Process Intensification, 2019, 136: 152-162. |

| 78 | Chavan V P, Patwardhan A V, Gogate P R. Intensification of epoxidation of soybean oil using sonochemical reactors[J]. Chemical Engineering and Processing: Process Intensification, 2012, 54: 22-28. |

| 79 | Piccolo D, Vianello C, Lorenzetti A, et al. Epoxidation of soybean oil enhanced by microwave radiation[J]. Chemical Engineering Journal, 2019, 377(1): 120113. |

| 80 | He W, Fang Z, Ji D, et al. Epoxidation of soybean oil by continuous micro-flow system with continuous separation[J]. Organic Process Research & Development, 2013, 17(9): 1137-1141. |

| 81 | Olivieri G V, Meira P A, de Mattos T T, et al. Microreactor x millireactor: experimental performance in the epoxidation of soybean oil[J]. Chemical Engineering and Processing - Process Intensification, 2023, 193: 109562. |

| 82 | Santacesaria E, Renken A, Russo V, et al. Biphasic model describing soybean oil epoxidation with H2O2 in continuous reactors[J]. Industrial & Engineering Chemistry Research, 2012, 51(26): 8760-8767. |

| 83 | Wu Z Y, Zheng T, Wu L H, et al. Novel reactor for exothermic heterogeneous reaction systems: intensification of mass and heat transfer and application to vegetable oil epoxidation[J]. Industrial & Engineering Chemistry Research, 2017, 56(18): 5231-5238. |

| 84 | Cai J J, Wu Z Y, Gao N F, et al. Novel packed bed reactor designed for prileschajew epoxidation of fatty acid methyl ester: intensification of mass/heat transfer[J]. Chemical Engineering and Processing - Process Intensification, 2022, 176: 108960. |

| 85 | Patra S, Mosiagin I, Katayev D, et al. Organic nitrating reagents[J]. Synthesis, 2022, 54(15): 3432-3472. |

| 86 | Badgujar D M, Talawar M B, Mahulikar P P. Review on greener and safer synthesis of nitro compounds[J]. Propellants, Explosives, Pyrotechnics, 2016, 41(1): 24-34. |

| 87 | Patel S S, Patel D B, Patel H D. Synthetic protocols for aromatic nitration: a review[J]. ChemistrySelect, 2021, 6(6): 1337-1356. |

| 88 | Gillespie R J, Hughes E D. Kinetics and mechanism of aromatic nitration[J]. Nature, 1949, 163(4146): 599. |

| 89 | Lan Z, Lu Y C. Continuous nitration of o-dichlorobenzene in micropacked-bed reactor: process design and modelling[J]. Journal of Flow Chemistry, 2021, 11(2): 171-179. |

| 90 | Hussain A, Sharma M, Patil S, et al. Design and scale-up of continuous di-nitration reaction using pinched tube flow reactor[J]. Journal of Flow Chemistry, 2021, 11(3): 611-624. |

| 91 | 秦能, 姚军燕, 刘有智. 喷射硝化法生产硝化甘油的模拟计算[J]. 含能材料, 2002, 10(4): 4. |

| Qin N, Yao J Y, Liu Y Z, et al. Simulating computation of injection nitrator producing nitroglycerine[J]. Energetic Materials, 2002, 10(4): 4. | |

| 92 | 刘晶, 景青, 陈松, 等. 硝化甘油喷射硝化器喷雾效果优化及试验验证[J].爆破器材, 2016, 45(5): 6. |

| Liu J, Jing Q, Chen S, et al. Optimization and experiment verification of nitration spray characteristic used in nitroglycerin[J]. Explosive Materials, 2016, 45(5): 6. | |

| 93 | 王凯, 吕阳成, 邵华伟, 等. 微反应系统内非均相传递和反应过程强化[C]//第六届全国化学工程与生物化工年会. 长沙, 2010. |

| Wang K, Lyu Y C, Shao H W, et al. Enhancement of multiphase transport and reactions with micro-structured chemical systems[C]//Proceedings of the 6th National Chemical Engineering and Biochemistry Annual Meeting. Changsha, 2010. | |

| 94 | 黄正梁, 聂元清, 杨遥, 等. 液-液喷射混合装置微观混合特性的研究进展[J]. 化工进展, 2018, 37(S1): 1-11. |

| Huang Z L, Nie Y Q, Yang Y, et al.Research progress in micro-mixing characteristic of liquid-liquid jet mixers[J]. Chemical Industry and Engineering Progress, 2018, 37(S1): 1-11. | |

| 95 | 廖启江, 秦宏云, 周鸣亮, 等. 高剪切混合器研究与应用进展[J]. 化工进展, 2019, 38(3): 1160-1175. |

| Liao Q J, Qin H Y, Zhou M L, et al. Progress of researches and applications for high shear mixers[J]. Chemical Industry and Engineering Progress, 2019, 38(3): 1160-1175. |

| [1] | 郭恭涵, 丁晖殿, 李强, 贾胜坤, 钱行, 苑杨, 陈海胜, 罗祎青. 间歇精馏操作过程的动态贝叶斯优化方法[J]. 化工学报, 2025, 76(2): 755-768. |

| [2] | 董举, 余留洋, 贾晟哲, 史连军, 王诗瀚, 胡国涛, 汤伟伟, 王静康, 龚俊波. 电子级磷酸的结晶精制技术发展现状与研究进展[J]. 化工学报, 2025, 76(2): 438-453. |

| [3] | 薛潇, 商敏静, 苏远海. 微反应器内药物连续流合成的研究进展[J]. 化工学报, 2024, 75(4): 1439-1454. |

| [4] | 成文凯, 颜金钰, 王嘉骏, 冯连芳. 卧式捏合反应器及其在聚合工业中的研究进展[J]. 化工学报, 2024, 75(3): 768-781. |

| [5] | 马韶阳, 徐涵卓, 张亮亮, 孙宝昌, 邹海魁, 罗勇, 初广文. 液-液非均相反应器研究进展[J]. 化工学报, 2024, 75(3): 727-742. |

| [6] | 陈饶, 赵鑫, 陈戴欣, 姜圣坤, 廉应江, 王金波, 杨梅, 陈光文. 微反应器内甲苯连续二硝化制备二硝基甲苯[J]. 化工学报, 2024, 75(3): 867-876. |

| [7] | 张德旺, 赵乾坤, 郭笑妮, 尧超群, 陈光文. 微反应器内牛顿/非牛顿流体液-液两相流流动和传质研究[J]. 化工学报, 2024, 75(11): 4162-4169. |

| [8] | 王俊男, 何呈祥, 王忠东, 朱春英, 马友光, 付涛涛. T型微混合器内均相混合的数值模拟[J]. 化工学报, 2024, 75(1): 242-254. |

| [9] | 崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| [10] | 赵若晗, 黄蒙蒙, 朱春英, 付涛涛, 高习群, 马友光. 缩口T型微通道内纳米流体吸收CO2的流动与传质研究[J]. 化工学报, 2024, 75(1): 221-230. |

| [11] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [12] | 刘倩, 曹禹, 周琦, 穆景山, 历伟. 孔道结构修饰的Ziegler-Natta催化剂设计与高抗冲低缠结UHMWPE的制备[J]. 化工学报, 2023, 74(3): 1092-1101. |

| [13] | 陈号, 田仪娟, 全学军, 蒋子文, 李纲. 铬铁矿在HCl-HF体系中的分解行为[J]. 化工学报, 2023, 74(3): 1161-1174. |

| [14] | 侯跃辉, 刘璇, 廉应江, 韩梅, 尧超群, 陈光文. 超声微反应器内三硝基间苯三酚合成工艺研究[J]. 化工学报, 2022, 73(8): 3597-3607. |

| [15] | 刘梦溪, 范怡平, 闫子涵, 姚秀颖, 卢春喜. 提升管进料区内气体射流流动行为的调控及工业应用[J]. 化工学报, 2022, 73(6): 2496-2513. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号