CIESC Journal ›› 2023, Vol. 74 ›› Issue (1): 290-302.DOI: 10.11949/0438-1157.20221070

• Reviews and monographs • Previous Articles Next Articles

Xiang GUO( ), Jinshuo QIAO(

), Jinshuo QIAO( ), Zhenhua WANG, Wang SUN, Kening SUN(

), Zhenhua WANG, Wang SUN, Kening SUN( )

)

Received:2022-08-01

Revised:2022-11-01

Online:2023-03-20

Published:2023-01-05

Contact:

Jinshuo QIAO, Kening SUN

通讯作者:

乔金硕,孙克宁

作者简介:郭祥(1994—),男,博士研究生,guoxiang0658@163.com

基金资助:CLC Number:

Xiang GUO, Jinshuo QIAO, Zhenhua WANG, Wang SUN, Kening SUN. Progress of structure for carbon-fueled solid oxide fuel cells[J]. CIESC Journal, 2023, 74(1): 290-302.

郭祥, 乔金硕, 王振华, 孙旺, 孙克宁. 碳燃料固体氧化物燃料电池结构研究进展[J]. 化工学报, 2023, 74(1): 290-302.

Add to citation manager EndNote|Ris|BibTeX

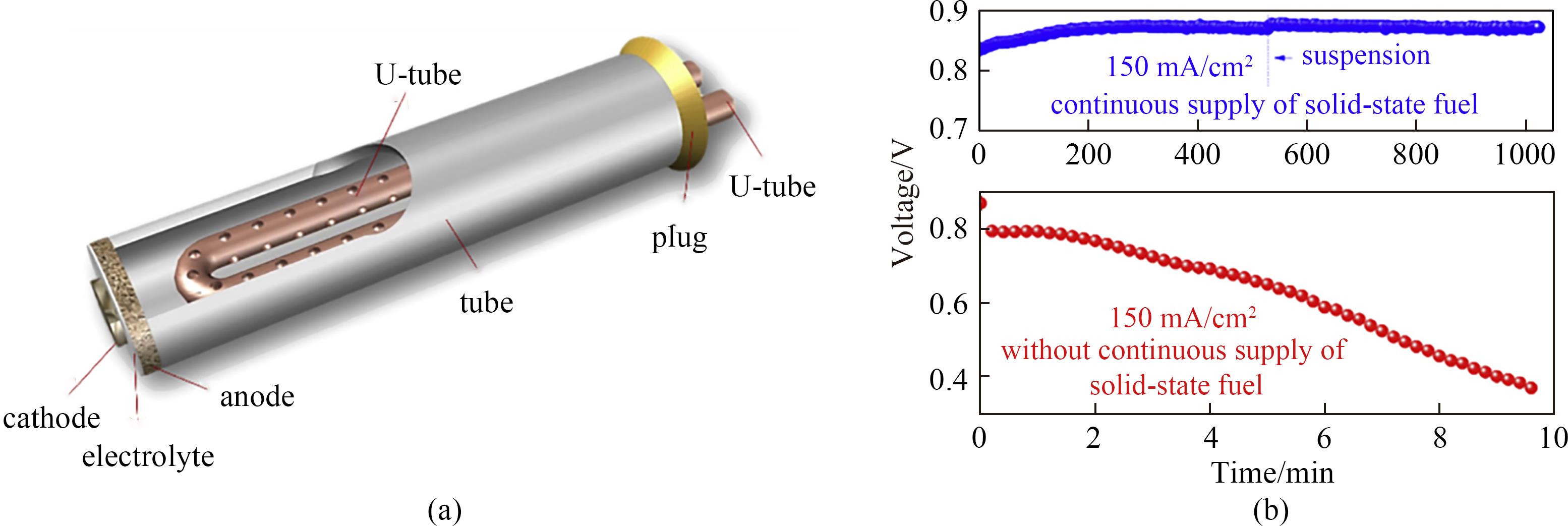

Fig.15 (a) U-shaped tubular continuous supply device; (b) Cell voltage as a function of time at 800℃ under a constant polarization current density of 150 mA/cm2 [84]

| 燃料 | 辅助剂 | 阳极 | 电解质 | 阴极 | 温度/℃ | 最大功率密度/(mW/cm2) |

|---|---|---|---|---|---|---|

| 褐煤[ | — | Ag-Gd0.1Ce0.9O2-δ | YSZ | Ag-Gd0.1Ce0.9O2-δ | 850 | 221 |

| 牙签炭[ | — | La0.3Sr0.7Fe0.7Ti0.3O3-δ (LSFT) | YSZ | La0.3Sr0.7Fe0.7Ti0.3O3-δ (LSFT) | 850 | 223 |

| 活性炭[ | 5%(质量分数)BaCO3 | Ag-GDC | YSZ | Ag-GDC | 850 | 328.4 |

| 低硫(0.15%)阿拉斯加煤[ | CO2吹扫 | Ni-YSZ | YSZ | 钙钛矿 | 930 | 450 |

| 小麦秸秆炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 187 |

| 玉米芯炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 204 |

| 甘蔗渣炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 260 |

| 活性炭[ | — | La0.8Sr0.2Fe0.9Nb0.1O3-δ | ScSZ | LSM/ScSZ | 850 | 302.8 |

| 玉米秸秆炭[ | — | La0.8Sr0.2Fe0.9Nb0.1O3-δ | ScSZ | LSM/ScSZ | 850 | 218.5 |

| 石墨[ | Ar | Pt | YSZ | Pt | 950 | 16.8 |

| 活性炭[ | Li2CO3+K2CO3 Ar | Ni-SDC | SDC | Ba0.5Sr0.5Co0.8Fe0.2O3-δ | 750 | 158.3 |

| 废旧纸箱制炭[ | — | La0.3Sr0.7Fe0.7Ti0.3O3-δ | SSZ | La0.3Sr0.7Fe0.7Ti0.3O3-δ | 850 | 308.7 |

| 海带炭[ | — | Ag-GDC | YSZ | Ag-GDC | 850 | 285 |

| 核桃壳炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 800 | 205 |

| 兰花树叶炭[ | — | Ag-GDC | YSZ | Ag-GDC | 850 | 212 |

| 活性炭[ | — | Ni/Fe-YSZ | YSZ | La0.6Sr0.4Co0.2Fe0.8O3-GDC | 800 | 425~529 |

| 工业焦炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 850 | 217 |

| 小麦秸秆炭[ | Ca | Ag-GDC | YSZ | Ag-GDC | 800 | 258 |

| 椰壳炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 800 | 274 |

| 活性炭[ | Li2CO3+K2CO3 Ar | (PrBa)0.95Fe1.4Cu0.4Nb0.2O5+δ | LSGM | La0.6Sr0.4Co0.2Fe0.8O3 | 800 | 431 |

Table 1 Fuels and electrodes of direct carbon fuel cells

| 燃料 | 辅助剂 | 阳极 | 电解质 | 阴极 | 温度/℃ | 最大功率密度/(mW/cm2) |

|---|---|---|---|---|---|---|

| 褐煤[ | — | Ag-Gd0.1Ce0.9O2-δ | YSZ | Ag-Gd0.1Ce0.9O2-δ | 850 | 221 |

| 牙签炭[ | — | La0.3Sr0.7Fe0.7Ti0.3O3-δ (LSFT) | YSZ | La0.3Sr0.7Fe0.7Ti0.3O3-δ (LSFT) | 850 | 223 |

| 活性炭[ | 5%(质量分数)BaCO3 | Ag-GDC | YSZ | Ag-GDC | 850 | 328.4 |

| 低硫(0.15%)阿拉斯加煤[ | CO2吹扫 | Ni-YSZ | YSZ | 钙钛矿 | 930 | 450 |

| 小麦秸秆炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 187 |

| 玉米芯炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 204 |

| 甘蔗渣炭[ | — | Ag-Ce0.8Gd0.2O1.9 | YSZ | Ag-Ce0.8Gd0.2O1.9 | 800 | 260 |

| 活性炭[ | — | La0.8Sr0.2Fe0.9Nb0.1O3-δ | ScSZ | LSM/ScSZ | 850 | 302.8 |

| 玉米秸秆炭[ | — | La0.8Sr0.2Fe0.9Nb0.1O3-δ | ScSZ | LSM/ScSZ | 850 | 218.5 |

| 石墨[ | Ar | Pt | YSZ | Pt | 950 | 16.8 |

| 活性炭[ | Li2CO3+K2CO3 Ar | Ni-SDC | SDC | Ba0.5Sr0.5Co0.8Fe0.2O3-δ | 750 | 158.3 |

| 废旧纸箱制炭[ | — | La0.3Sr0.7Fe0.7Ti0.3O3-δ | SSZ | La0.3Sr0.7Fe0.7Ti0.3O3-δ | 850 | 308.7 |

| 海带炭[ | — | Ag-GDC | YSZ | Ag-GDC | 850 | 285 |

| 核桃壳炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 800 | 205 |

| 兰花树叶炭[ | — | Ag-GDC | YSZ | Ag-GDC | 850 | 212 |

| 活性炭[ | — | Ni/Fe-YSZ | YSZ | La0.6Sr0.4Co0.2Fe0.8O3-GDC | 800 | 425~529 |

| 工业焦炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 850 | 217 |

| 小麦秸秆炭[ | Ca | Ag-GDC | YSZ | Ag-GDC | 800 | 258 |

| 椰壳炭[ | Fe | Ag-GDC | YSZ | Ag-GDC | 800 | 274 |

| 活性炭[ | Li2CO3+K2CO3 Ar | (PrBa)0.95Fe1.4Cu0.4Nb0.2O5+δ | LSGM | La0.6Sr0.4Co0.2Fe0.8O3 | 800 | 431 |

| 1 | Cao T Y, Huang K, Shi Y X, et al. Recent advances in high-temperature carbon-air fuel cells[J]. Energy & Environmental Science, 2017, 10(2): 460-490. |

| 2 | Cui C, Li S B, Gong J Y, et al. Review of molten carbonate-based direct carbon fuel cells[J]. Materials for Renewable and Sustainable Energy, 2021, 10(2): 1-24. |

| 3 | Ma M J, Yang X X, Qiao J S, et al. Progress and challenges of carbon-fueled solid oxide fuel cells anode[J]. Journal of Energy Chemistry, 2021, 56: 209-222. |

| 4 | 艾承燚, 乔金硕, 王振华, 等. 原位析出纳米合金的PrBaFe2O6- δ 基阳极构筑及其在固体碳燃料电池中的应用研究[J]. 化工学报, 2022, 73(8): 3708-3719. |

| Ai C Y, Qiao J S, Wang Z H, et al. Investigation on PrBaFe2O6- δ anode material with in situ FeNi nanoparticle in direct carbon solid oxide fuel cell[J]. CIESC Journal, 2022, 73(8): 3708-3719. | |

| 5 | Cao D X, Sun Y, Wang G L. Direct carbon fuel cell: fundamentals and recent developments[J]. Journal of Power Sources, 2007, 167(2): 250-257. |

| 6 | Jiang C R, Ma J J, Corre G, et al. Challenges in developing direct carbon fuel cells[J]. Chemical Society Reviews, 2017, 46(10): 2889-2912. |

| 7 | Dong Y X, Xing L, Li X F, et al. A membrane-less molten hydroxide direct carbon fuel cell with fuel continuously supplied at low temperatures: a modeling and experimental study[J]. Applied Energy, 2022, 324: 119585. |

| 8 | Wejrzanowski T, Cwieka K, Skibinski J, et al. Metallic foam supported electrodes for molten carbonate fuel cells[J]. Materials & Design, 2020, 193: 108864. |

| 9 | Wu H, Xiao J, Zeng X Y, et al. A high performance direct carbon solid oxide fuel cell—a green pathway for brown coal utilization[J]. Applied Energy, 2019, 248: 679-687. |

| 10 | Jiang C R, Ma J J, Bonaccorso A D, et al. Demonstration of high power, direct conversion of waste-derived carbon in a hybrid direct carbon fuel cell[J]. Energy and Environmental Science, 2012, 5: 6973-6980. |

| 11 | Giddey S, Kulkarni A, Munnings C, et al. Performance evaluation of a tubular direct carbon fuel cell operating in a packed bed of carbon[J]. Energy, 2014, 68: 538-547. |

| 12 | Gong S Q, Zeng H Y, Lin J, et al. A robust flat-chip solid oxide fuel cell coupled with catalytic partial oxidation of methane[J]. Journal of Power Sources, 2018, 402: 124-132. |

| 13 | Somalu M R, Muchtar A, Daud W R W, et al. Screen-printing inks for the fabrication of solid oxide fuel cell films: a review[J]. Renewable and Sustainable Energy Reviews, 2017, 75: 426-439. |

| 14 | Yang R J, Lee M C, Chang J C, et al. Fabrication and characterization of a Sm0.2Ce0.8O1.9 electrolyte film by the spin-coating method for a low-temperature anode-supported solid oxide fuel cells[J]. Journal of Power Sources, 2012, 206: 111-118. |

| 15 | Gurauskis J. Deposition via dip coating technique of dense yttrium stabilized zirconia layers[J]. International Journal of Applied Ceramic Technology, 2013, 10(1): 79-86. |

| 16 | Tanhaei M, Mozammel M. Yttria-stabilized zirconia thin film electrolyte deposited by EB-PVD on porous anode support for SOFC applications[J]. Ceramics International, 2017, 43(3): 3035-3042. |

| 17 | Choi H, Cho G Y, Cha S W. Fabrication and characterization of anode supported YSZ/GDC bilayer electrolyte SOFC using dry press process[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2014, 1(2): 95-99. |

| 18 | Sivasankaran V, Combemale L, Pera M C, et al. Initial preparation and characterization of single step fabricated intermediate temperature solid oxide fuel cells (IT-SOFC)[J]. Fuel Cells, 2014, 14(3): 533-536. |

| 19 | Sinha A, Miller D N, Irvine J T S. Development of novel anode material for intermediate temperature SOFC (IT-SOFC)[J]. Journal of Materials Chemistry A, 2016, 4(28): 11117-11123. |

| 20 | Liu J, Yuan H, Qiao J S, et al. Hierarchical hollow nanofiber networks for high-performance hybrid direct carbon fuel cells[J]. Journal of Materials Chemistry A, 2017, 5(33): 17216-17220. |

| 21 | Ma M J, Yang X X, Ren R Z, et al. Honeycombed porous, size-matching architecture for high-performance hybrid direct carbon fuel cell anode[J]. ACS Applied Materials & Interfaces, 2020, 12(27): 30411-30419. |

| 22 | Lee A C, Li S W, Mitchell R E, et al. Conversion of solid carbonaceous fuels in a fluidized bed fuel cell[J]. Electrochemical and Solid-State Letters, 2008, 11(2): B20. |

| 23 | Wang W, Liu Z J, Zhang Y P, et al. A direct carbon solid oxide fuel cell stack on a single electrolyte plate fabricated by tape casting technique[J]. Journal of Alloys and Compounds, 2019, 794: 294-302. |

| 24 | Chen Q Y, Qiu Q Y, Yan X M, et al. A compact and seal-less direct carbon solid oxide fuel cell stack stepping into practical application[J]. Applied Energy, 2020, 278: 115657. |

| 25 | Li G D, Gou Y J, Qiao J S, et al. Recent progress of tubular solid oxide fuel cell: from materials to applications[J]. Journal of Power Sources, 2020, 477: 228693. |

| 26 | Li T, Wu Z T, Li K. Co-extrusion of electrolyte/anode functional layer/anode triple-layer ceramic hollow fibres for micro-tubular solid oxide fuel cells-electrochemical performance study[J]. Journal of Power Sources, 2015, 273: 999-1005. |

| 27 | Liu R Z, Zhao C H, Li J L, et al. A novel direct carbon fuel cell by approach of tubular solid oxide fuel cells[J]. Journal of Power Sources, 2010, 195(2): 480-482. |

| 28 | Xie Y M, Tang Y B, Liu J. An Al2O3-doped YSZ electrolyte-supporting solid oxide fuel cell fabricated by dip-coating and its direct operation on carbon fuel[J]. ECS Transactions, 2013, 57(1): 3039-3048. |

| 29 | Xie Y M, Wang X Q, Liu J, et al. Fabrication and performance of tubular electrolyte-supporting direct carbon solid oxide fuel cell by dip coating technique[J]. Acta Physico-Chimica Sinica, 2017, 33(2): 386-392. |

| 30 | Xie Y M, Cai W Z, Xiao J, et al. Electrochemical gas-electricity cogeneration through direct carbon solid oxide fuel cells[J]. Journal of Power Sources, 2015, 277: 1-8. |

| 31 | 王晓强, 刘江, 谢永敏, 等. 可用作便携式电源的高性能直接碳固体氧化物燃料电池组(英文)[J]. 物理化学学报, 2017(8):1614-1620. |

| Wang X Q, Liu J, Xie Y M, et al. A high performance direct carbon solid oxide fuel cell stack for portable applications[J]. Acta Physico-Chimica Sinica, 2017(8):1614-1620. | |

| 32 | Yang B B, Ran R, Zhong Y J, et al. A carbon-air battery for high power generation[J]. Angewandte Chemie International Edition, 2015, 54(12): 3722-3725. |

| 33 | Bai Y H, Wang C L, Ding J, et al. Direct operation of cone-shaped anode-supported segmented-in-series solid oxide fuel cell stack with methane[J]. Journal of Power Sources, 2010, 195(12): 3882-3886. |

| 34 | Bai Y H, Liu Y, Tang Y B, et al. Direct carbon solid oxide fuel cell—a potential high performance battery[J]. International Journal of Hydrogen Energy, 2011, 36(15): 9189-9194. |

| 35 | Yu F Y, Zhang Y P, Yu L, et al. All-solid-state direct carbon fuel cells with thin yttrium-stabilized-zirconia electrolyte supported on nickel and iron bimetal-based anodes[J]. International Journal of Hydrogen Energy, 2016, 41(21): 9048-9058. |

| 36 | Wang C Q, Lü Z, Su C X, et al. Effects of discharge mode and fuel treating temperature on the fuel utilization of direct carbon solid oxide fuel cell[J]. International Journal of Hydrogen Energy, 2019, 44(2): 1174-1181. |

| 37 | Bae Y, Lee S, Hong J. The effect of anode microstructure and fuel utilization on current relaxation and concentration polarization of solid oxide fuel cell under electrical load change[J]. Energy Conversion and Management, 2019, 201: 112152. |

| 38 | Xie Y M, Li J L, Hou J X, et al. Direct use of coke in a solid oxide fuel cell[J]. Journal of Fuel Chemistry and Technology, 2018, 46(10): 1168-1174. |

| 39 | Wu W, Zhang Y, Ding D, et al. A high-performing direct carbon fuel cell with a 3D architectured anode operated below 600℃[J]. Advanced Materials (Deerfield Beach, Fla.), 2018, 30(4): 1704745. |

| 40 | Bian W J, Wu W, Orme C J, et al. Direct carbon fuel cells: dual 3D ceramic textile electrodes: fast kinetics for carbon oxidation reaction and oxygen reduction reaction in direct carbon fuel cells at reduced temperatures[J]. Advanced Functional Materials, 2020, 30(19): 2070119. |

| 41 | Zhou W, Jiao Y, Li S D, et al. Anodes for carbon-fueled solid oxide fuel cells[J]. ChemElectroChem, 2016, 3(2): 193-203. |

| 42 | Duan N Q, Xue Y, Ma J Y, et al. Liquid antimony-silver alloys as anodes for direct carbon solid oxide fuel cells[J]. Journal of Power Sources, 2018, 397: 170-176. |

| 43 | Tao T, McPhee W, Koslowske M, et al. Liquid tin anode SOFC for direct fuel conversion-impact of coal and JP-8 impurities[J]. ECS Transactions, 2009, 25(2): 1115-1124. |

| 44 | Cao T Y, Song P D, Shi Y X, et al. Carbonate-tin composite liquid anode for solid oxide direct carbon fuel cell[J]. International Journal of Hydrogen Energy, 2017, 42(9): 6324-6331. |

| 45 | Jayakumar A, Lee S, Hornés A, et al. A comparison of molten Sn and Bi for solid oxide fuel cell anodes[J]. Journal of the Electrochemical Society, 2010, 157(3): B365. |

| 46 | Jayakumar A, Vohs J M, Gorte R J. Molten-metal electrodes for solid oxide fuel cells[J]. Industrial & Engineering Chemistry Research, 2010, 49(21): 10237-10241. |

| 47 | Jayakumar A, Küngas R, Roy S, et al. A direct carbon fuel cell with a molten antimony anode[J]. Energy & Environmental Science, 2011, 4(10): 4133. |

| 48 | Jayakumar A, Javadekar A, Gissinger J, et al. The stability of direct carbon fuel cells with molten Sb and Sb-Bi alloy anodes[J]. AIChE Journal, 2013, 59(9): 3342-3348. |

| 49 | Cao T Y, Shi Y X, Cai N S. Liquid antimony anode fluidization within a tubular direct carbon fuel cell[J]. Journal of the Electrochemical Society, 2015, 163(3): F127-F131. |

| 50 | Duan N Q, Cao Y, Hua B, et al. Tubular direct carbon solid oxide fuel cells with molten antimony anode and refueling feasibility[J]. Energy, 2016, 95: 274-278. |

| 51 | Duan N Q, Tan Y, Yan D, et al. Biomass carbon fueled tubular solid oxide fuel cells with molten antimony anode[J]. Applied Energy, 2016, 165: 983-989. |

| 52 | Ma J Y, Duan N Q, Han Y, et al. Hot corrosion of yttria-stabilized zirconia by liquid antimony and antimony oxide[J]. Journal of Power Sources, 2019, 434: 226764. |

| 53 | Cao T Y, Song P D, Shi Y X, et al. Oxy-combustion of coal in liquid-antimony-anode solid oxide fuel cell system[J]. Proceedings of the Combustion Institute, 2019, 37(3): 2841-2848. |

| 54 | Han Y, Ma J Y, Duan N Q, et al. Enhanced resistance of gadolinium-doped cerium oxide to liquid antimony and antimony oxide corrosions by addition of iron oxide[J]. Journal of Power Sources, 2020, 455: 227970. |

| 55 | Javadekar A, Jayakumar A, Pujara R, et al. Molten silver as a direct carbon fuel cell anode[J]. Journal of Power Sources, 2012, 214: 239-243. |

| 56 | Jafri N, Wong W Y, Doshi V, et al. A review on production and characterization of biochars for application in direct carbon fuel cells[J]. Process Safety and Environmental Protection, 2018, 118: 152-166. |

| 57 | Jain S L, Nabae Y, Lakeman B J, et al. Solid state electrochemistry of direct carbon/air fuel cells[J]. Solid State Ionics, 2008, 179(27/28/29/30/31/32): 1417-1421. |

| 58 | Wu Y Z, Su C, Zhang C M, et al. A new carbon fuel cell with high power output by integrating with in situ catalytic reverse Boudouard reaction[J]. Electrochemistry Communications, 2009, 11(6): 1265-1268. |

| 59 | Irvine J, Fuentes Cuesta A, Mottram A, et al. Utilisation of coal in direct carbon fuel cells[J]. ECS Transactions, 2015, 68(1): 2681-2684. |

| 60 | Liu J, Qiao J S, Yuan H, et al. Ni modified Ce(Mn, Fe)O2 cermet anode for high-performance direct carbon fuel cell[J]. Electrochimica Acta, 2017, 232: 174-181. |

| 61 | Li S B, Jiang C R, Liu J, et al. Mechanism of enhanced performance on a hybrid direct carbon fuel cell using sawdust biofuels[J]. Journal of Power Sources, 2018, 383: 10-16. |

| 62 | Xu H R, Chen B, Zhang H C, et al. Experimental and modeling study of high performance direct carbon solid oxide fuel cell with in situ catalytic steam-carbon gasification reaction[J]. Journal of Power Sources, 2018, 382: 135-143. |

| 63 | Xu X Y, Zhou W, Liang F L, et al. A comparative study of different carbon fuels in an electrolyte-supported hybrid direct carbon fuel cell[J]. Applied Energy, 2013, 108: 402-409. |

| 64 | Tang Y B, Liu J. Effect of anode and Boudouard reaction catalysts on the performance of direct carbon solid oxide fuel cells[J]. International Journal of Hydrogen Energy, 2010, 35(20): 11188-11193. |

| 65 | Cai W Z, Liu J, Yu F Y, et al. A high performance direct carbon solid oxide fuel cell fueled by Ca-loaded activated carbon[J]. International Journal of Hydrogen Energy, 2017, 42(33): 21167-21176. |

| 66 | Fuente-Cuesta A, Jiang C R, Arenillas A, et al. Role of coal characteristics in the electrochemical behaviour of hybrid direct carbon fuel cells[J]. Energy & Environmental Science, 2016, 9(9): 2868-2880. |

| 67 | Xie Y M, Tang Y B, Liu J. A verification of the reaction mechanism of direct carbon solid oxide fuel cells[J]. Journal of Solid State Electrochemistry, 2013, 17(1): 121-127. |

| 68 | Lin J, Chen L, Liu T, et al. The beneficial effects of straight open large pores in the support on steam electrolysis performance of electrode-supported solid oxide electrolysis cell[J]. Journal of Power Sources, 2018, 374: 175-180. |

| 69 | Zhou M Y, Wang X Q, Zhang Y P, et al. Effect of counter diffusion of CO and CO2 between carbon and anode on the performance of direct carbon solid oxide fuel cells[J]. Solid State Ionics, 2019, 343: 115127. |

| 70 | Feng J, Qiao J S, Sun W, et al. Characteristic and preparation of Ce0.5Zr0.5O2 as the anode support for solid oxide fuel cells by phase inversion technology[J]. International Journal of Hydrogen Energy, 2015, 40(37): 12784-12789. |

| 71 | Li Y H, Chen L, Zhang L, et al. Millimeter tubular solid oxide electrolysis cells with modified asymmetric hydrogen electrode[J]. International Journal of Hydrogen Energy, 2016, 41(10): 5209-5214. |

| 72 | He W, Huang H, Gao J F, et al. Phase-inversion tape casting and oxygen permeation properties of supported ceramic membranes[J]. Journal of Membrane Science, 2014, 452: 294-299. |

| 73 | Huang H, Lin J, Wang Y L, et al. Facile one-step forming of NiO and yttrium-stabilized zirconia composite anodes with straight open pores for planar solid oxide fuel cell using phase-inversion tape casting method[J]. Journal of Power Sources, 2015, 274: 1114-1117. |

| 74 | Shi N, Su F, Huan D M, et al. Performance and DRT analysis of P-SOFCs fabricated using new phase inversion combined tape casting technology[J]. Journal of Materials Chemistry A, 2017, 5(37): 19664-19671. |

| 75 | Yang Y, Liu F S, Han X, et al. Highly efficient and stable fuel-catalyzed dendritic microchannels for dilute ethanol fueled solid oxide fuel cells[J]. Applied Energy, 2022, 307: 118222. |

| 76 | Gu D G, Shi N, Yu F, et al. Asymmetric anode substrate fabricated by phase inversion process and its interface modification for solid oxide fuel cells[J]. Journal of Alloys and Compounds, 2018, 742: 20-28. |

| 77 | Chen S N, Gu D G, Zheng Y F, et al. Enhanced performance of NiO-3YSZ planar anode-supported SOFC with an anode functional layer[J]. Journal of Materials Science, 2020, 55(1): 88-98. |

| 78 | Shi N, Xie Y, Yang Y, et al. Infiltrated Ni0.08Co0.02CeO2- x @Ni0.8Co0.2 catalysts for a finger-like anode in direct methane-fueled solid oxide fuel cells[J]. ACS Applied Materials & Interfaces, 2021, 13(4): 4943-4954. |

| 79 | Wang M M, Li N Z, Wang Z X, et al. Electrochemical performance and redox stability of solid oxide fuel cells supported on dual-layered anodes of Ni-YSZ cermet and Ni-Fe alloy[J]. International Journal of Hydrogen Energy, 2022, 47(8): 5453-5461. |

| 80 | Liu T, Wang Y, Zhang Y X, et al. Steam electrolysis in a solid oxide electrolysis cell fabricated by the phase-inversion tape casting method[J]. Electrochemistry Communications, 2015, 61: 106-109. |

| 81 | Li Y H, Li P, Hu B B, et al. A nanostructured ceramic fuel electrode for efficient CO2/H2O electrolysis without safe gas[J]. Journal of Materials Chemistry A, 2016, 4(23): 9236-9243. |

| 82 | Zheng M H, Wang S, Yang Y, et al. Barium carbonate as a synergistic catalyst for the H2O/CO2 reduction reaction at Ni-yttria stabilized zirconia cathodes for solid oxide electrolysis cells[J]. Journal of Materials Chemistry A, 2018, 6(6): 2721-2729. |

| 83 | Li N Z, Wang L M, Wang M M, et al. Ni-cermet with straight pore paths as cathode for solid oxide electrolysis cell enabling energy-efficient and coking-resistant conversion of CO2 [J]. Journal of Power Sources, 2022, 518: 230787. |

| 84 | Zhu X B, Li Y Q, Lü Z. Continuous conversion of biomass wastes in a La0.75Sr0.25Cr0.5Mn0.5O3- δ based carbon-air battery[J]. International Journal of Hydrogen Energy, 2016, 41(9): 5057-5062. |

| 85 | Zhang J, Ricote S, Hendriksen P V, et al. Advanced materials for thin-film solid oxide fuel cells: recent progress and challenges in boosting the device performance at low temperatures[J]. Advanced Functional Materials, 2022, 32(22): 2111205. |

| 86 | Tang H Q, Yu F Y, Wang Y S, et al. Enhancing the power output of direct carbon solid oxide fuel cell using Ba-loaded activated carbon fuel[J]. Energy Technology, 2019, 7(4): 1800885. |

| 87 | Gür T M, Homel M, Virkar A. High performance solid oxide fuel cell operating on dry gasified coal[J]. Journal of Power Sources, 2010, 195: 1085-1090. |

| 88 | Qiu Q Y, Zhou M Y, Cai W Z, et al. A comparative investigation on direct carbon solid oxide fuel cells operated with fuels of biochar derived from wheat straw, corncob, and bagasse[J]. Biomass and Bioenergy, 2019, 121: 56-63. |

| 89 | Li J W, Wei B, Wang C Q, et al. High-performance and stable La0.8Sr0.2Fe0.9Nb0.1O3- δ anode for direct carbon solid oxide fuel cells fueled by activated carbon and corn straw derived carbon[J]. International Journal of Hydrogen Energy, 2018, 43(27): 12358-12367. |

| 90 | Kim J P, Lim H, Jeon C H, et al. Performance evaluation of tubular fuel cells fuelled by pulverized graphite[J]. Journal of Power Sources, 2010, 195(22): 7568-7573. |

| 91 | Wang C Q, Lü Z, Li J W, et al. Efficient use of waste carton for power generation, tar and fertilizer through direct carbon solid oxide fuel cell[J]. Renewable Energy, 2020, 158: 410-420. |

| 92 | Wu H, Xiao J, Hao S R, et al. In-situ catalytic gasification of kelp-derived biochar as a fuel for direct carbon solid oxide fuel cells[J]. Journal of Alloys and Compounds, 2021, 865: 158922. |

| 93 | Xie Y M, Xiao J, Liu Q S, et al. Highly efficient utilization of walnut shell biochar through a facile designed portable direct carbon solid oxide fuel cell stack[J]. Energy, 2021, 227: 120456. |

| 94 | Cai W Z, Zhou Q, Xie Y M, et al. A direct carbon solid oxide fuel cell operated on a plant derived biofuel with natural catalyst[J]. Applied Energy, 2016, 179: 1232-1241. |

| 95 | Cai W Z, Liu J, Liu P P, et al. A direct carbon solid oxide fuel cell fueled with char from wheat straw[J]. International Journal of Energy Research, 2019, 43(7): 2468-2477. |

| 96 | 丘倩媛, 陈倩阳, 刘志军, 等. 以椰壳生物质炭为燃料的直接炭固体氧化物燃料电池[J]. 燃料化学学报, 2019, 47(3): 352-360. |

| Qiu Q Y, Chen Q Y, Liu Z J, et al. Biochar derived from coconut as fuel for the direct carbon solid oxide fuel cell[J]. Journal of Fuel Chemistry and Technology, 2019, 47(3): 352-360. | |

| 97 | Ma M J, Qiao J S, Yang X X, et al. Enhanced stability and catalytic activity on layered perovskite anode for high-performance hybrid direct carbon fuel cells[J]. ACS Applied Materials & Interfaces, 2020, 12(11): 12938-12948. |

| 98 | Cai W Z, Zhou Q, Xie Y M, et al. A facile method of preparing Fe-loaded activated carbon fuel for direct carbon solid oxide fuel cells[J]. Fuel, 2015, 159: 887-893. |

| 99 | Yu X K, Shi Y X, Wang H J, et al. Using potassium catalytic gasification to improve the performance of solid oxide direct carbon fuel cells: experimental characterization and elementary reaction modeling[J]. Journal of Power Sources, 2014, 252: 130-137. |

| 100 | Xie Y M, Lu Z B, Ma C C, et al. High-performance gas-electricity cogeneration using a direct carbon solid oxide fuel cell fueled by biochar derived from camellia oleifera shells[J]. International Journal of Hydrogen Energy, 2020, 45(53): 29322-29330. |

| 101 | Li X, Zhu Z H, Chen J L, et al. Surface modification of carbon fuels for direct carbon fuel cells[J]. Journal of Power Sources, 2009, 186(1): 1-9. |

| [1] | Cheng CHENG, Zhongdi DUAN, Haoran SUN, Haitao HU, Hongxiang XUE. Lattice Boltzmann simulation of surface microstructure effect on crystallization fouling [J]. CIESC Journal, 2023, 74(S1): 74-86. |

| [2] | Yepin CHENG, Daqing HU, Yisha XU, Huayan LIU, Hanfeng LU, Guokai CUI. Application of ionic liquid-based deep eutectic solvents for CO2 conversion [J]. CIESC Journal, 2023, 74(9): 3640-3653. |

| [3] | Yali HU, Junyong HU, Suxia MA, Yukun SUN, Xueyi TAN, Jiaxin HUANG, Fengyuan YANG. Development of novel working fluid and study on electrochemical characteristics of reverse electrodialysis heat engine [J]. CIESC Journal, 2023, 74(8): 3513-3521. |

| [4] | Mengmeng ZHANG, Dong YAN, Yongfeng SHEN, Wencui LI. Effect of electrolyte types on the storage behaviors of anions and cations for dual-ion batteries [J]. CIESC Journal, 2023, 74(7): 3116-3126. |

| [5] | Jiali GE, Tuxiang GUAN, Xinmin QIU, Jian WU, Liming SHEN, Ningzhong BAO. Synthesis of FeF3 nanoparticles covered by vertical porous carbon for high performance Li-ion battery cathode [J]. CIESC Journal, 2023, 74(7): 3058-3067. |

| [6] | Chunyu LIU, Huanyu ZHOU, Yue MA, Changtao YUE. Drying characteristics and mathematical model of CaO-conditioned oil sludge [J]. CIESC Journal, 2023, 74(7): 3018-3027. |

| [7] | Yuanhao QU, Wenyi DENG, Xiaodan XIE, Yaxin SU. Study on electro-osmotic dewatering of sludge assisted by activated carbon/graphite [J]. CIESC Journal, 2023, 74(7): 3038-3050. |

| [8] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [9] | Zhen LONG, Jinhang WANG, Junjie REN, Yong HE, Xuebing ZHOU, Deqing LIANG. Experimental study on inhibition effect of natural gas hydrate formation by mixing ionic liquid with PVCap [J]. CIESC Journal, 2023, 74(6): 2639-2646. |

| [10] | Ruikang LI, Yingying HE, Weipeng LU, Yuanyuan WANG, Haodong DING, Yongming LUO. Study on the electrochemical enhanced cobalt-based cathode to activate peroxymonosulfate [J]. CIESC Journal, 2023, 74(5): 2207-2216. |

| [11] | Xu GUO, Yongzheng ZHANG, Houbing XIA, Na YANG, Zhenzhen ZHU, Jingyao QI. Research progress in the removal of water pollutants by carbon-based materials via electrooxidation [J]. CIESC Journal, 2023, 74(5): 1862-1874. |

| [12] | Zheng ZHANG, Yongping HE, Haidong SUN, Rongzi ZHANG, Zhengping SUN, Jinlan CHEN, Yixuan ZHENG, Xiao DU, Xiaogang HAO. Electrochemically switched ion exchange device with serpentine flow field for selective extraction of lithium [J]. CIESC Journal, 2023, 74(5): 2022-2033. |

| [13] | Chenxin LI, Yanqiu PAN, Liu HE, Yabin NIU, Lu YU. Carbon membrane model based on carbon microcrystal structure and its gas separation simulation [J]. CIESC Journal, 2023, 74(5): 2057-2066. |

| [14] | Chengze WANG, Kaili GU, Jinhua ZHANG, Jianxuan SHI, Yiwei LIU, Jinxiang LI. Sulfidation couples with aging to enhance the reactivity of zerovalent iron toward Cr(Ⅵ) in water [J]. CIESC Journal, 2023, 74(5): 2197-2206. |

| [15] | Laiming LUO, Jin ZHANG, Zhibin GUO, Haining WANG, Shanfu LU, Yan XIANG. Simulation and experiment of high temperature polymer electrolyte membrane fuel cells stack in the 1—5 kW range [J]. CIESC Journal, 2023, 74(4): 1724-1734. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||