CIESC Journal ›› 2024, Vol. 75 ›› Issue (5): 2081-2090.DOI: 10.11949/0438-1157.20240143

• Process safety • Previous Articles

Jing LI1( ), Fangfang ZHANG1, Shuaishuai WANG1, Jianhua XU1, Pengyuan ZHANG1,2(

), Fangfang ZHANG1, Shuaishuai WANG1, Jianhua XU1, Pengyuan ZHANG1,2( )

)

Received:2024-01-30

Revised:2024-03-18

Online:2024-06-25

Published:2024-05-25

Contact:

Pengyuan ZHANG

李静1( ), 张方芳1, 王帅帅1, 徐建华1, 张朋远1,2(

), 张方芳1, 王帅帅1, 徐建华1, 张朋远1,2( )

)

通讯作者:

张朋远

作者简介:李静(1991—),女,硕士,助教,jltiffany@163.com

基金资助:CLC Number:

Jing LI, Fangfang ZHANG, Shuaishuai WANG, Jianhua XU, Pengyuan ZHANG. Effect of cavity structure on flammability limit of n-butane partially premixed flame[J]. CIESC Journal, 2024, 75(5): 2081-2090.

李静, 张方芳, 王帅帅, 徐建华, 张朋远. 凹腔结构对正丁烷部分预混火焰可燃极限的影响[J]. 化工学报, 2024, 75(5): 2081-2090.

Add to citation manager EndNote|Ris|BibTeX

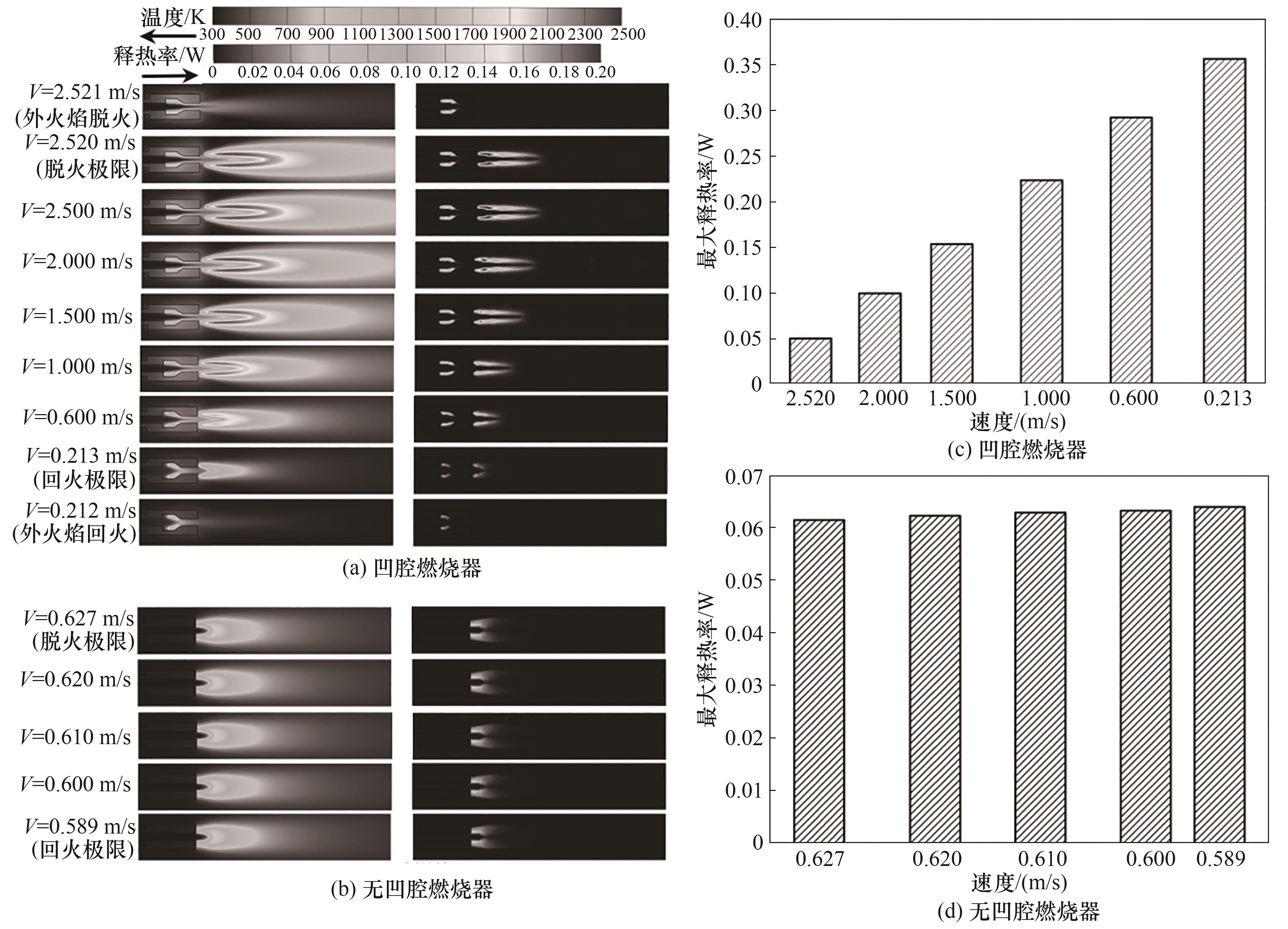

Fig.4 Distributions of temperature and heat release for cavity (a) and non-cavity burners (b), and maximum heat release at different velocity for cavity (c) and non-cavity burners (d)

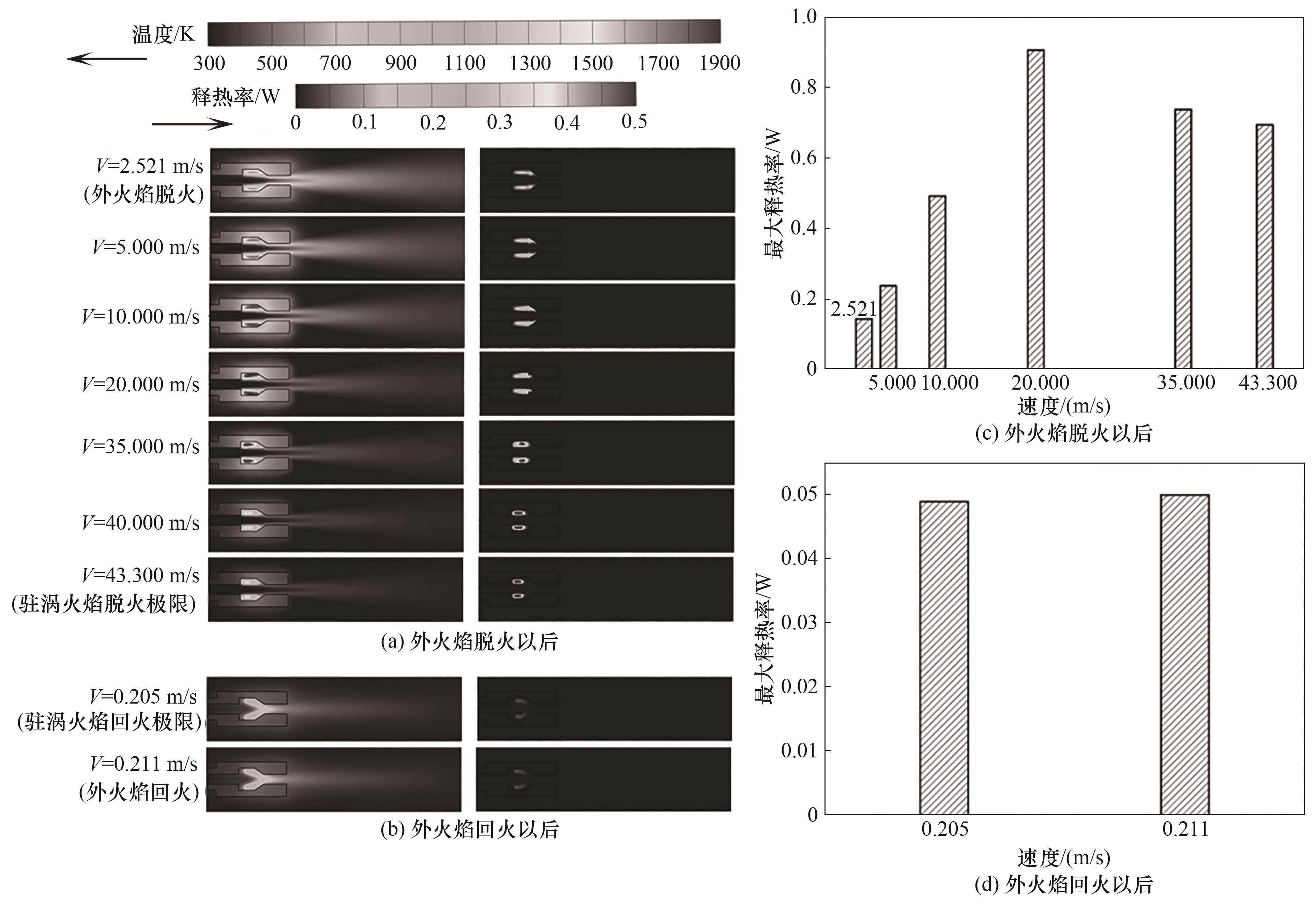

Fig.6 Distributions of temperature and heat release of trapped vortex flame after blowoff (a)/flashback (b) of external flame for cavity burner, and maximum heat release at different velocity for blowoff (c)/flashback (d) of external flame

| 1 | 曾海翔, 王平, Prashant Shrotriya, 等. 带有局部熄火现象的部分预混火焰大涡模拟研究[J]. 上海交通大学学报, 2022, 56(1): 35-44. |

| Zeng H X, Wang P, Shrotriya P, et al. Large eddy simulation of partially premixed flame with local extinction phenomenon[J]. Journal of Shanghai Jiao Tong University, 2022, 56(1): 35-44. | |

| 2 | 张鲁栋. 部分预混火焰中自由基和碳氧比的模拟及实验检测研究[D]. 武汉: 华中科技大学, 2021. |

| Zhang L D. Experimental measurement and simulation of radicals and carbon-to-oxygen atom ratio in partially premixed flames[D].Wuhan: Huazhong University of Science and Technology, 2021. | |

| 3 | 余志健, 杨旸. 部分预混燃烧室热声不稳定及火焰结构实验分析[J]. 航空动力学报, 2022, 37(12): 2851-2864. |

| Yu Z J, Yang Y. Investigation of thermo-acoustic instabilities and flame structures in a partially premixed combustor[J]. Journal of Aerospace Power, 2022, 37(12): 2851-2864. | |

| 4 | Özdemir İ B. Simulation of turbulent combustion in a self-aerated domestic gas oven[J]. Applied Thermal Engineering, 2017, 113: 160-169. |

| 5 | Yan B, Li B, Baudoin E, et al. Structures and stabilization of low calorific value gas turbulent partially premixed flames in a conical burner[J]. Experimental Thermal and Fluid Science, 2010, 34(3): 412-419. |

| 6 | Keramiotis C, Founti M A. An experimental investigation of stability and operation of a biogas fueled porous burner[J]. Fuel, 2013, 103: 278-284. |

| 7 | Aggarwal S K. Extinction of laminar partially premixed flames[J]. Progress in Energy and Combustion Science, 2009, 35(6): 528-570. |

| 8 | Zhang P Y, Kang Y H, Huang X M, et al. Effects of H2 addition on flammability dynamics and extinction physics of dimethyl ether in laminar spherical diffusion flame[J]. ACS Omega, 2020, 5(34): 21579-21592. |

| 9 | Zhang P Y, Kang Y H, Huang X M, et al. Study on effect of hydrogen addition on extinction dynamics of dimethyl ether spherical diffusion flame[J]. International Journal of Hydrogen Energy, 2020, 45(19): 11350-11367. |

| 10 | Guo L, Zhai M, Xu S J, et al. Flame characteristics of methane/air with hydrogen addition in the micro confined combustion space[J]. International Journal of Hydrogen Energy, 2022, 47(44): 19319-19337. |

| 11 | Kang Y H, Shuang W, Jiang X C, et al. Study on effect of dimethyl ether addition on combustion characteristics of turbulent methane/air jet diffusion flame[J]. Fuel Processing Technology, 2017, 159: 421-435. |

| 12 | Yang W M, Chou S K, Shu C, et al. Combustion in micro-cylindrical combustors with and without a backward facing step[J]. Applied Thermal Engineering, 2002, 22(16): 1777-1787. |

| 13 | Tan Y, Jiaqiang E, Chen J W, et al. Investigation on combustion characteristics and thermal performance of a three rearward-step structure micro combustor fueled by premixed hydrogen/air[J]. Renewable Energy, 2022, 186: 486-504. |

| 14 | Yan Y F, Yan H Y, Zhang L, et al. Numerical investigation on combustion characteristics of methane/air in a micro-combustor with a regular triangular pyramidbluff body[J]. International Journal of Hydrogen Energy, 2018, 43(15): 7581-7590. |

| 15 | Fan A W, Wan J L, Liu Y, et al. The effect of the blockage ratio on the blow-off limit of a hydrogen/air flame in a planar micro-combustor with a bluff body[J]. International Journal of Hydrogen Energy, 2013, 38(26): 11438-11445. |

| 16 | Yang X, Yang W M, Dong S K, et al. Flame stability analysis of premixed hydrogen/air mixtures in a swirl micro-combustor[J]. Energy, 2020, 209: 118495. |

| 17 | Gao W, Yan Y F, Huang L J, et al. Numerical comparison of premixed H2/air combustion characteristic of three types of micro cavity-combustors with guide vanes, bluff body, guide vanes and bluff body respectively[J]. International Journal of Hydrogen Energy, 2021, 46(47): 24382-24394. |

| 18 | Liu Y, Fan A W, Yao H, et al. Numerical investigation of filtration gas combustion in a mesoscale combustor filled with inert fibrous porous medium[J]. International Journal of Heat and Mass Transfer, 2015, 91: 18-26. |

| 19 | Liu Y, Fan A W, Yao H, et al. A numerical investigation on the effect of wall thermal conductivity on flame stability and combustion efficiency in a mesoscale channel filled with fibrous porous medium[J]. Applied Thermal Engineering, 2016, 101: 239-246. |

| 20 | Wan J L, Yang W, Fan A W, et al. A numerical investigation on combustion characteristics of H2/air mixture in a micro-combustor with wall cavities[J]. International Journal of Hydrogen Energy, 2014, 39(15): 8138-8146. |

| 21 | Su Y, Song J L, Chai J L, et al. Numerical investigation of a novel micro combustor with double-cavity for micro-thermophotovoltaic system[J]. Energy Conversion and Management, 2015, 106: 173-180. |

| 22 | Kang Y H, Wei S, Zhang P Y, et al. Detailed multi-dimensional study on NO x formation and destruction mechanisms in dimethyl ether/air diffusion flame under the moderate or intense low-oxygen dilution (MILD) condition[J]. Energy, 2017, 119: 1195-1211. |

| 23 | Kang Y H, Wang Q H, Lu X F, et al. Experimental and numerical study on NO x and CO emission characteristics of dimethyl ether/air jet diffusion flame[J]. Applied Energy, 2015, 149: 204-224. |

| 24 | Choi M, Park Y, Li X Z, et al. Study on flame structures and emission characteristics according to various swirl combinations and fuel compositions in a CH4/H2/CO syngas swirl-stabilized combustor[J]. Fuel, 2019, 253: 887-903. |

| 25 | Kuo C H, Ronney P D. Numerical modeling of non-adiabatic heat-recirculating combustors[J]. Proceedings of the Combustion Institute, 2007, 31(2): 3277-3284. |

| 26 | He Z Q, Yan Y F, Zhao T, et al. Parametric study of inserting internal spiral fins on the micro combustor performance for thermophotovoltaic systems[J]. Renewable and Sustainable Energy Reviews, 2022, 165: 112595. |

| 27 | He Z Q, Yan Y F, Fang R M, et al. Numerical investigation of a novel micro combustor with a central and bilateral slotted blunt body[J]. International Journal of Hydrogen Energy, 2021, 46(45): 23564-23579. |

| 28 | He Z Q, Zhang L, Li X Q, et al. Heat transfer enhancement and pressure loss analysis of hydrogen-fueled microcombustor with slinky projection shape channel for micro-thermophotovoltaic system[J]. Energy, 2023, 283: 129119. |

| 29 | Zhang P Y, Kang Y H, Huang X M, et al. Comparative study on the dimethyl ether combustion characteristics in normal and inverse diffusion spherical flame geometries[J]. ACS Omega, 2020, 5(38): 24654-24665. |

| 30 | 王天天, 张海, 张扬, 等. 掺氢天然气在燃气锅炉和灶具中的回火风险分析[J]. 力学与实践, 2022, 44(3): 543-553. |

| Wang T T, Zhang H, Zhang Y, et al. Flashback risk analysis of hydrogen-enriched natural gas in boilers and domestic appliances[J]. Mechanics in Engineering, 2022, 44(3): 543-553. | |

| 31 | Kim T Y, Kim H K, Ku J W, et al. A heat-recirculating combustor with multiple injectors for thermophotovoltaic power conversion[J]. Applied Energy, 2017, 193: 174-181. |

| [1] | Juan LI, Yaowen CAO, Zhangyu ZHU, Lei SHI, Jia LI. Numerical study and structural optimization of microchannel flow and heat transfer characteristics of bionic homocercal fin microchannels [J]. CIESC Journal, 2024, 75(5): 1802-1815. |

| [2] | Jinshan WANG, Shixue WANG, Yu ZHU. Influence of cooling surface temperature difference on the high temperature proton-exchange membrane fuel cell performance [J]. CIESC Journal, 2024, 75(5): 2026-2035. |

| [3] | Yifei LI, Xinyu DONG, Weishu WANG, Lu LIU, Yifan ZHAO. Numerical study on heat transfer of dry ice sublimation spray cooling on the surface of micro-ribbed plate [J]. CIESC Journal, 2024, 75(5): 1830-1842. |

| [4] | Fan LIU, Yuantong ZHANG, Cheng TAO, Chengyu HU, Xiaoping YANG, Jinjia WEI. Performance of manifold microchannel liquid cooling [J]. CIESC Journal, 2024, 75(5): 1777-1786. |

| [5] | Yingtao WU, Lihan FEI, Xiangdong KONG, Zhi WANG, Chenglong TANG, Zuohua HUANG. Hypergolic ignition characteristics and propulsion performance of imidazolium dicyanamide ionic liquids blended with furfuryl alcohol [J]. CIESC Journal, 2024, 75(5): 2017-2025. |

| [6] | Lei XIE, Yongsheng XU, Mei LIN. Comparative study on single-phase flow and heat transfer of different cross-section rib-soft tail structures [J]. CIESC Journal, 2024, 75(5): 1787-1801. |

| [7] | Wenya WANG, Wei ZHANG, Xiaoling LOU, Ruofei ZHONG, Bingbing CHEN, Junxian YUN. Multi-microtubes formation and simulation of nanocellulose-embedded cryogel microspheres [J]. CIESC Journal, 2024, 75(5): 2060-2071. |

| [8] | Jin ZHANG, Zhibin GUO, Laiming LUO, Shanfu LU, Yan XIANG. Design and performance of 5 kW reforming methanol high temperature proton exchange membrane fuel cell system [J]. CIESC Journal, 2024, 75(4): 1697-1704. |

| [9] | Mingze SUN, Helai HUANG, Zhiqiang NIU. Pt-based oxygen reduction reaction catalysts: from single crystal electrode to nanostructured extended surface [J]. CIESC Journal, 2024, 75(4): 1256-1269. |

| [10] | Binbin FENG, Mingjia LU, Zhihong HUANG, Yiwen CHANG, Zhiming CUI. Application and optimization of carbon supports in proton exchange membrane fuel cells [J]. CIESC Journal, 2024, 75(4): 1469-1484. |

| [11] | Xudong JIA, Bolong YANG, Qian CHENG, Xueli LI, Zhonghua XIANG. Preparation of high-efficiency iron-cobalt bimetallic site oxygen reduction electrocatalysts by step-by-step metal loading method [J]. CIESC Journal, 2024, 75(4): 1578-1593. |

| [12] | Zhouyang SHEN, Kang XUE, Qing LIU, Chengxiang SHI, Jijun ZOU, Xiangwen ZHANG, Lun PAN. Research progress on endothermic nanofluid fuels [J]. CIESC Journal, 2024, 75(4): 1167-1182. |

| [13] | Xiaoying JI, Yuan ZHENG, Xiaopeng LI, Zhen YANG, Wei ZHANG, Shirui QIU, Qianying ZHANG, Canghai LUO, Dongpeng SUN, Dong CHEN, Dongliang LI. Controlled preparation of droplets, particles and capsules by microfluidics and their applications [J]. CIESC Journal, 2024, 75(4): 1455-1468. |

| [14] | Haoqi CHEN, Bohui SHI, Qi PENG, Qi KANG, Shangfei SONG, Haiyuan YAO, Haihong CHEN, Haihao WU, Jing GONG. Phase equilibrium calculation of acid/alcohol hydrocarbon and water system based on stability analysis [J]. CIESC Journal, 2024, 75(3): 789-800. |

| [15] | Shiliang GU, Boren TAN, Quanzhong CHENG, Weijie YAO, Zhipeng DONG, Feng XU, Yong WANG. Numerical simulation of hydraulic characteristics in axial flow pump type mixer [J]. CIESC Journal, 2024, 75(3): 815-822. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||