化工学报 ›› 2021, Vol. 72 ›› Issue (7): 3668-3679.DOI: 10.11949/0438-1157.20201893

蔡中杰1( ),田盼1,黄忠亮2,黄猛1,黄加乐1(

),田盼1,黄忠亮2,黄猛1,黄加乐1( ),詹国武2(

),詹国武2( ),李清彪1,3

),李清彪1,3

收稿日期:2020-12-22

修回日期:2021-03-02

出版日期:2021-07-05

发布日期:2021-07-05

通讯作者:

黄加乐,詹国武

作者简介:蔡中杰(1995—),男,硕士研究生,基金资助:

CAI Zhongjie1( ),TIAN Pan1,HUANG Zhongliang2,HUANG Meng1,HUANG Jiale1(

),TIAN Pan1,HUANG Zhongliang2,HUANG Meng1,HUANG Jiale1( ),ZHAN Guowu2(

),ZHAN Guowu2( ),LI Qingbiao1,3

),LI Qingbiao1,3

Received:2020-12-22

Revised:2021-03-02

Online:2021-07-05

Published:2021-07-05

Contact:

HUANG Jiale,ZHAN Guowu

摘要:

采用油菜花粉作为生物模板制备了具有多层次孔结构的ZnO,再通过浸渍还原法将Cu负载于ZnO上制备了具有不同结构的Cu/ZnO负载型催化剂(bio-CZ-500),研究发现在500℃条件下焙烧制备的bio-CZ-500催化剂在CO2加氢反应中经过100 h测试活性几乎不变,同时甲醇选择性高达81%。相比之下,无生物模板制备的Cu/ZnO催化剂显示出较低甲醇选择性(50%),且催化剂在12 h内快速失活。通过透射电镜、扫描电镜、氮气吸脱附、红外光谱、X射线衍射、X射线光电子能谱、接触角测试、程序升温等表征技术揭示了bio-CZ-500催化剂具有多级孔碳结构、丰富的Cu-ZnO活性界面和较高的水接触角。催化剂的弱亲水性加快了副产物水的扩散,促进了中间体分解制甲醇,同时抑制了铜颗粒的烧结失活,从而提高甲醇的选择性与催化剂的稳定性。该工作为制备高效稳定的Cu基工业催化剂提供了新方法。

中图分类号:

蔡中杰, 田盼, 黄忠亮, 黄猛, 黄加乐, 詹国武, 李清彪. 基于生物模板制备二氧化碳加氢反应的Cu/ZnO催化剂[J]. 化工学报, 2021, 72(7): 3668-3679.

CAI Zhongjie, TIAN Pan, HUANG Zhongliang, HUANG Meng, HUANG Jiale, ZHAN Guowu, LI Qingbiao. Preparation of Cu/ZnO nanocatalysts based on bio-templates for CO2 hydrogenation[J]. CIESC Journal, 2021, 72(7): 3668-3679.

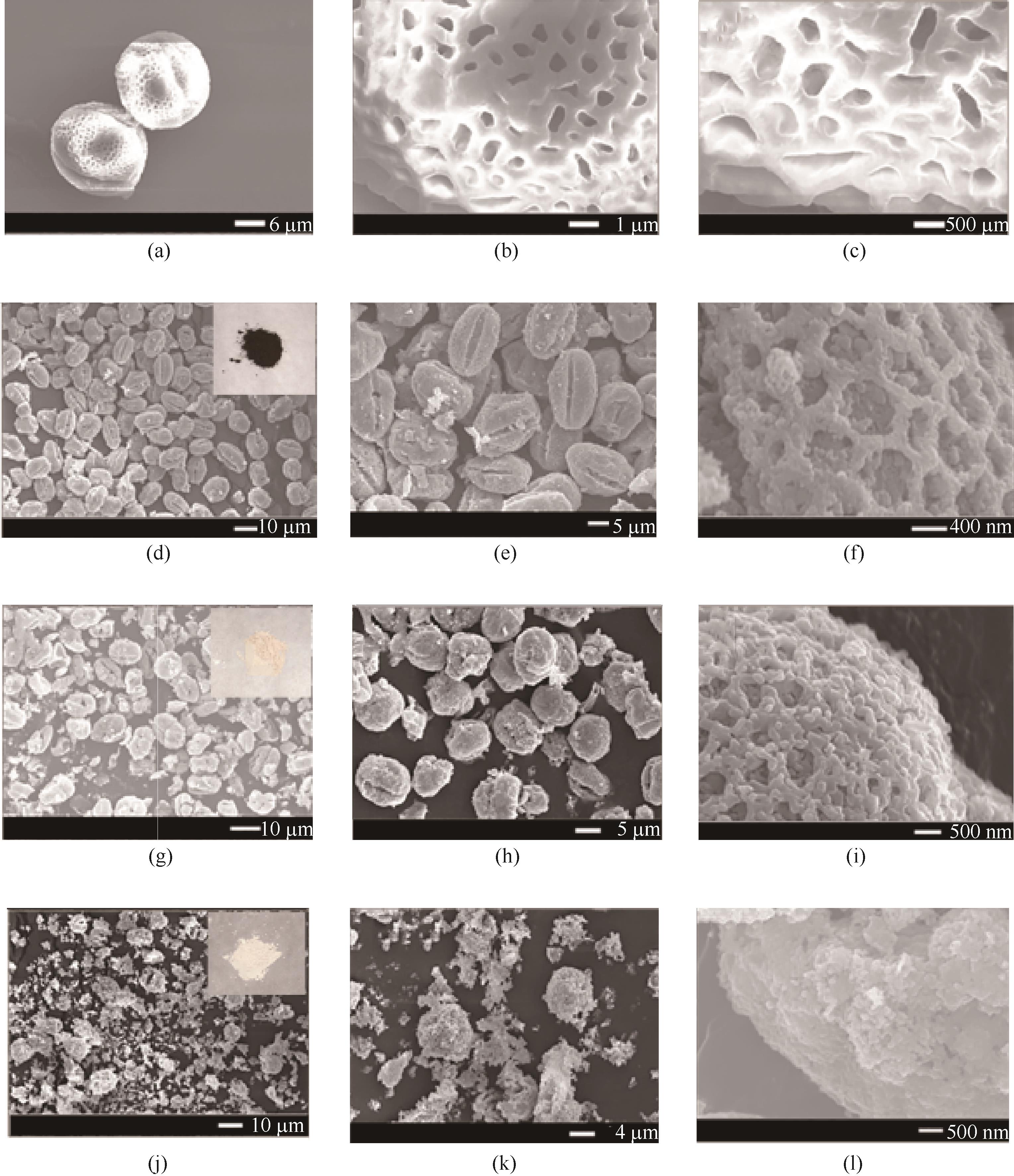

图2 原始花粉的扫描电镜图[(a)~(c)];不同焙烧温度下制备的bio-ZnO的扫描电镜图: 500℃[(d)~(f)],600℃[(g)~(i)],700℃[(j)~(l)][其中图(d)、(g)、(j)中插图分别为该焙烧后样品的照片]

Fig.2 Representative SEM images of the original pollen [(a)—(c)] and bio-ZnO obtained at the calcination temperature of 500℃[(d)—(f)], 600℃[(g)—(i)], and 700℃[(j)—(l)] [Insets in (d), (g), and (j) are photos of the calcined samples]

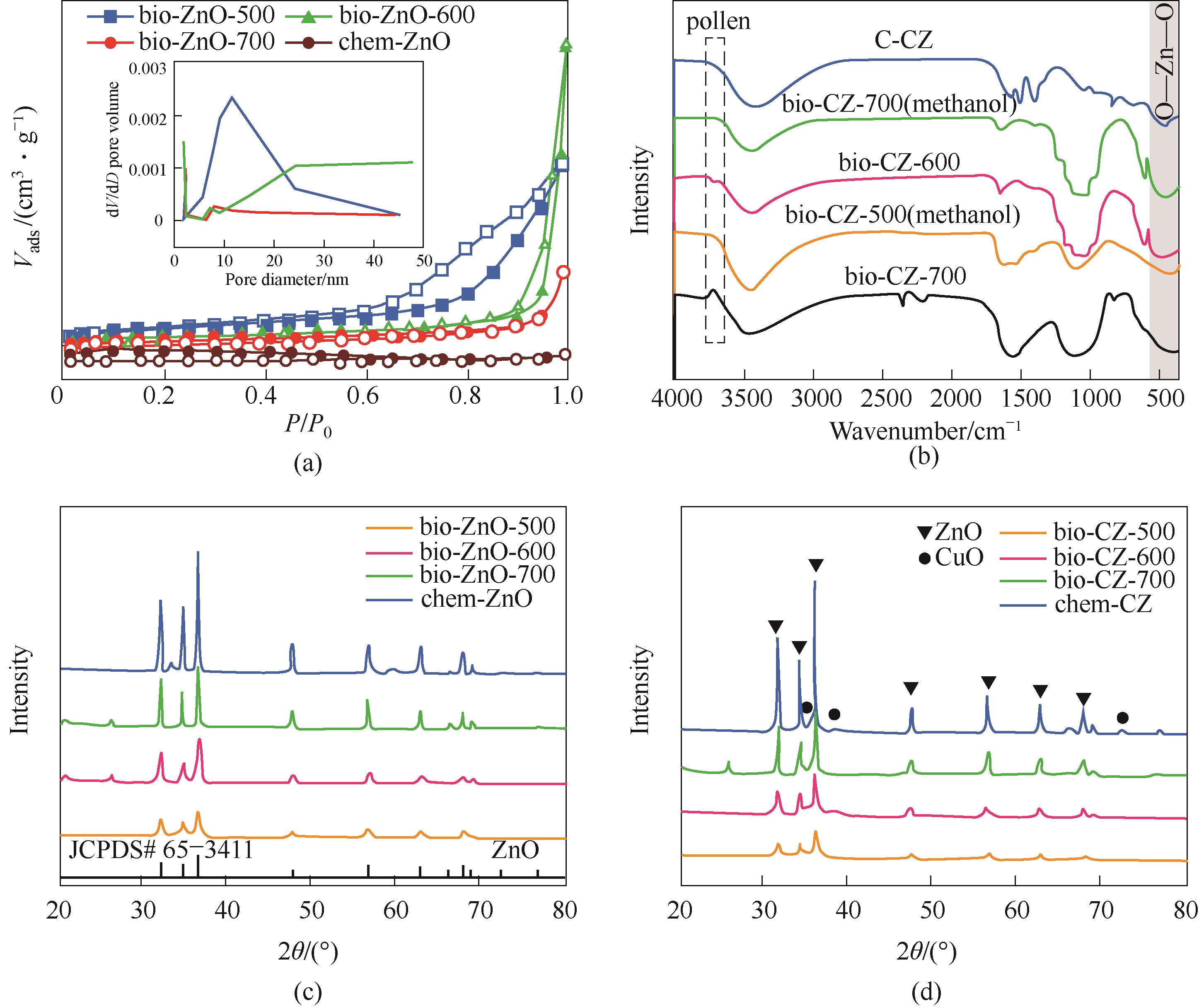

图4 不同样品的氮气吸脱附曲线(内插图为孔径分布)(a);红外谱图(methanol表示甲醇洗涤样品) (b); ZnO载体的XRD谱图(c);负载Cu后催化剂的XRD谱图(d)

Fig.4 N2 physisorption isotherms of different samples(inset shows corresponding pore size distribution curves) (a); FTIR spectra (b); XRD patterns of ZnO support samples (c); XRD patterns of catalyst samples (d)

图6 反应温度对两种催化剂活性的影响(内插图为催化剂相应的模型)(a);Cu/Zn摩尔比对bio-CZ-500催化性能的影响(b);四种催化剂的活性评价结果(c);bio-CZ-500与chem-CZ催化剂的稳定性评价结果(图中实心图例代表bio-CZ-500,空心图例代表chem-CZ)(d)

Fig.6 Effect of reaction temperature on the catalytic performance of bio-CZ-500 and chem-CZ (insets are the structure model) (a); The effect of different molar ratios on the catalytic performance of bio-CZ-500 (b); Comparisons of catalytic performance of four catalysts (c); Long-term stability test of bio-CZ-500 and chem-CZ catalysts during 100 h on stream (the soild symbols represent bio-CZ-500 and hollow symbols represent chem-CZ) (d)

图7 反应前的bio-CZ-500催化剂的透射电镜图[(a)~(c)];反应前的chem-CZ催化剂的透射电镜图[(d)~(f)];[其中图(b)、(e)中内插图为Cu颗粒的粒径分布]

Fig.7 Representative TEM images of fresh bio-CZ-500 catalyst[(a)—(c)] and fresh chem-CZ catalyst[(d)—(f)][Insets in (b), (e) show the particle size distributions of Cu nanoparticles]

图8 反应后的bio-CZ-500催化剂的TEM图[(a)~(c)];反应后的chem-CZ催化剂的TEM图[(d)~(f)][其中图(b)、(e)中的内插图为Cu颗粒的粒径分布]

Fig.8 TEM images of spent bio-CZ-500 catalyst[(a)—(c)] and spent chem-CZ catalyst[(d)—(f)] [Insets in (b), (e) show the particle size distributions of Cu nanoparticles]

| 1 | 金涌, 周禹成, 胡山鹰. 低碳理念指导的煤化工产业发展探讨[J]. 化工学报, 2012, 63(1): 3-8. |

| Jin Y, Zhou Y C, Hu S Y. Discussion on development of coal chemical industry using low-carbon concept[J]. CIESC Journal, 2012, 63(1): 3-8. | |

| 2 | 刘昌俊, 郭秋婷, 叶静云, 等. 二氧化碳转化催化剂研究进展及相关问题思考[J]. 化工学报, 2016, 67(1): 6-13. |

| Liu C J, Guo Q T, Ye J Y, et al. Perspective on catalyst investigation for CO2 conversion and related issues[J]. CIESC Journal, 2016, 67(1): 6-13. | |

| 3 | 巩金龙. CO2化学转化研究进展概述[J]. 化工学报, 2017, 68(4): 1282-1285. |

| Gong J L. A brief overview on recent progress on chemical conversion of CO2[J]. CIESC Journal, 2017, 68(4): 1282-1285. | |

| 4 | Liu Y T, Deng D H, Bao X H. Catalysis for selected C1 chemistry[J]. Chem, 2020, 6(10): 2497-2514. |

| 5 | 石磊, 张婉莹, 王玉鑫, 等. 低温甲醇合成研究进展[J]. 化工学报, 2015, 66(9): 3333-3340. |

| Shi L, Zhang W Y, Wang Y X, et al. Research developments of low-temperature methanol synthesis[J]. CIESC Journal, 2015, 66(9): 3333-3340. | |

| 6 | 邵光印, 张玉龙, 张征湃, 等. 不同硅铝比ZSM-5负载铁基催化剂二氧化碳加氢性能[J]. 化工学报, 2017, 68(2): 670-678. |

| Shao G Y, Zhang Y L, Zhang Z P, et al. CO2 hydrogenation over Fe catalysts supported on ZSM-5 zeolite with different ratios of Si/Al[J]. CIESC Journal, 2017, 68(2): 670-678. | |

| 7 | Jiang X, Nie X W, Guo X W, et al. Recent advances in carbon dioxide hydrogenation to methanol via heterogeneous catalysis[J]. Chemical Reviews, 2020, 120(15): 7984-8034. |

| 8 | Cai Z J, Dai J J, Li W, et al. Pd supported on MIL-68(In)-derived In2O3 nanotubes as superior catalysts to boost CO2 hydrogenation to methanol[J]. ACS Catalysis, 2020, 10(22): 13275-13289. |

| 9 | Liu X, Zhan G W, Wu J Y, et al. Preparation of integrated CuO/ZnO/OS nanocatalysts by using acid-etched oyster shells as a support for CO2 hydrogenation[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(18): 7162-7173. |

| 10 | Zhao F G, Zhan G W, Zhou S F. Intercalation of laminar Cu–Al LDHs with molecular TCPP(M) (M = Zn, Co, Ni, and Fe) towards high-performance CO2 hydrogenation catalysts[J]. Nanoscale, 2020, 12(24): 13145-13156. |

| 11 | 胡菊, 潘亚林, 黎汉生, 等. 铈改性甲醇合成铜基催化剂的制备及其性能[J]. 化工学报, 2014, 65(7): 2770-2775. |

| Hu J, Pan Y L, Li H S, et al. Preparation and properties of cerium modified Cu-based catalysts for methanol synthesis[J]. CIESC Journal, 2014, 65(7): 2770-2775. | |

| 12 | Kattel S, Liu P, Chen J G. Tuning selectivity of CO2 hydrogenation reactions at the metal/oxide interface[J]. J. Am. Chem. Soc., 2017, 139(29): 9739-9754. |

| 13 | Kattel S, Ramirez P J, Chen J G, et al. Active sites for CO2 hydrogenation to methanol on Cu/ZnO catalysts[J]. Science, 2017, 355(6331):1296-1299. |

| 14 | Behrens M, Studt F, Kasatkin I, et al. The active site of methanol synthesis over Cu/ZnO/Al2O3 industrial catalysts[J]. Science, 2012, 336(6083): 893-897. |

| 15 | 应卫勇, 房鼎业, 姚佩芳, 等. 甲醇合成铜基催化剂硫化氢中毒研究(Ⅰ):硫化氢中毒本征失活动力学[J]. 化工学报, 1992, 43(2): 133-138. |

| Ying W Y, Fang D Y, Yao P F, et al. Hydrogen sulfide poisoning of methanol synthesis Cu-based catalyst (I): Intrinsic deactivation kinetics[J]. Journal of Chemical Industry and Engineering (China), 1992, 43(2): 133-138. | |

| 16 | Lunkenbein T, Schumann J, Behrens M, et al. Formation of a ZnO overlayer in industrial Cu/ZnO/Al2O3 catalysts induced by strong metal-support interactions[J]. Angew. Chem. Int. Ed. Engl., 2015, 54(15): 4544-4548. |

| 17 | Behrens M, Furche A, Kasatkin I, et al. The potential of microstructural optimization in metal/oxide catalysts: higher intrinsic activity of copper by partial embedding of copper nanoparticles[J]. ChemCatChem, 2010, 2(7): 816-818. |

| 18 | Behrens M. Meso- and nano-structuring of industrial Cu/ZnO/(Al2O3) catalysts[J]. Journal of Catalysis, 2009, 267(1): 24-29. |

| 19 | Sun Y H, Chen L M, Bao Y F, et al. Roles of nitrogen species on nitrogen-doped CNTs supported Cu- ZrO2 system for carbon dioxide hydrogenation to methanol[J]. Catalysis Today, 2018, 307: 212-223. |

| 20 | Wang Y H, Gao W G, Li K Z, et al. Strong evidence of the role of H2O in affecting methanol selectivity from CO2 hydrogenation over Cu-ZnO-ZrO2 [J]. Chem, 2020, 6(2): 419-430. |

| 21 | Wang Y, Kattel S, Gao W, et al. Exploring the ternary interactions in Cu-ZnO-ZrO2 catalysts for efficient CO2 hydrogenation to methanol[J]. Nature Communications, 2019, 10(1): 1166. |

| 22 | 姜霞, 李雯, 郭云龙, 等. 生物模板法制备金属氧化物及其催化应用研究进展[J]. 化工进展, 2019, 38(1): 485-494. |

| Jiang X, Li W, Guo Y L, et al. Progress on bio-templated synthesis of metal oxides and their catalytic applications[J]. Chemical Industry and Engineering Progress, 2019, 38(1): 485-494. | |

| 23 | Liu X, Dai J J, Li W, et al. Green fabrication of integrated Au/CuO/oyster shell nanocatalysts with oyster shells as alternative supports for CO oxidation[J]. ACS Sustainable Chemistry & Engineering, 2019,7(21): 17768-17777. |

| 24 | 陈彰旭,郑炳云,李先学, 等. 模板法制备纳米材料研究进展[J]. 化工进展, 2010, 29(1): 94-99. |

| Chen Z X, Zheng B Y, Li X X, et al. Progress in the preparation of nanomaterials employing template method[J]. Chemical Industry and Engineering Progress, 2010, 29(1): 94-99. | |

| 25 | Wang K C, Li W, Huang J J, et al. Enhanced active site extraction from perovskite LaCoO3 using encapsulated PdO for efficient CO2 methanation[J]. Journal of Energy Chemistry, 2021, 53: 9-19. |

| 26 | Li W, Wang K C, Zhan G W, et al. Hydrogenation of CO2 to dimethyl ether over tandem catalysts based on biotemplated hierarchical ZSM-5 and Pd/ZnO[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(37): 14058-14070. |

| 27 | Jiang X, Liu Y, Hao H J, et al. Rape pollen-templated synthesis of C,N self-doped hierarchical TiO2 for selective hydrogenation of 1, 3-butadiene[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(1): 882-888. |

| 28 | Pustovarenko A, Dikhtiarenko A, Bavykina A, et al. Metal-organic framework-derived synthesis of cobalt indium catalysts for the hydrogenation of CO2 to methanol[J]. ACS Catalysis, 2020, 10(9): 5064-5076. |

| 29 | Schumann J, Eichelbaum M, Lunkenbein T, et al. Promoting strong metal support interaction: doping ZnO for enhanced activity of Cu/ZnO:M (M = Al, Ga, Mg) catalysts[J]. ACS Catalysis, 2015, 5(6): 3260-3270. |

| 30 | van den Berg R, Prieto G, Korpershoek G, et al. Structure sensitivity of Cu and CuZn catalysts relevant to industrial methanol synthesis[J]. Nature Communications, 2016, 7: 13057. |

| 31 | Huang C L,Wen J J, Sun Y H, et al. CO2 hydrogenation to methanol over Cu/ZnO plate model catalyst: effects of reducing gas induced Cu nanoparticle morphology[J]. Chemical Engineering Journal, 2019, 374: 221-230. |

| 32 | 凌晨, 蒋新, 汪志勇, 等. 微反应器中的混合对Cu-ZnO催化剂微结构形成过程的影响[J]. 化工学报, 2018, 69(2): 718-724. |

| Ling C, Jiang X, Wang Z Y, et al. Influence of mixing inside microreactor on microstructural evolution of Cu-ZnO catalyst[J]. CIESC Journal, 2018, 69(2): 718-724. | |

| 33 | Liao F L, Huang Y Q, Ge J W, et al. Morphology-dependent interactions of ZnO with Cu nanoparticles at the materials' interface in selective hydrogenation of CO2 to CH3OH[J]. Angew. Chem. Int. Ed. Engl., 2011, 50(9): 2162-2165. |

| 34 | 曹晨熙, 陈天元, 丁晓旭, 等. 负载型铟基催化剂二氧化碳加氢动力学研究[J]. 化工学报, 2019, 70(10): 3985-3993. |

| Cao C X, Chen T Y, Ding X X, et al. Kinetics study on supported indium-based catalysts in carbon dioxide hydrogenation[J]. CIESC Journal, 2019, 70(10): 3985-3993. | |

| 35 | Zhao F G, Fan L L, Xu K J, et al. Hierarchical sheet-like Cu/Zn/Al nanocatalysts derived from LDH/MOF composites for CO2 hydrogenation to methanol[J]. Journal of CO2 Utilization, 2019, 33: 222-232. |

| 36 | Liu T K, Hong X L, Liu G L. In situ generation of the Cu@3D-ZrOx framework catalyst for selective methanol synthesis from CO2/H2[J]. ACS Catalysis, 2020, 10(1): 93-102. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [3] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [4] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [5] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [6] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [7] | 徐文超, 孙志高, 李翠敏, 李娟, 黄海峰. 静态条件下表面活性剂E-1310对HCFC-141b水合物生成的影响[J]. 化工学报, 2023, 74(5): 2179-2185. |

| [8] | 王子健, 柯明, 李佳涵, 李舒婷, 孙巾茹, 童燕兵, 赵治平, 刘加英, 任璐. 短b轴ZSM-5分子筛制备方法及应用研究进展[J]. 化工学报, 2023, 74(4): 1457-1473. |

| [9] | 刘润竹, 储甜甜, 张孝阿, 王成忠, 张军营. α,ω-端羟基亚苯基氟硅聚合物的合成及性能[J]. 化工学报, 2023, 74(3): 1360-1369. |

| [10] | 陈向上, 马振杰, 任希华, 贾悦, 吕晓龙, 陈华艳. 三维网络萃取膜的制备及传质效率研究[J]. 化工学报, 2023, 74(3): 1126-1133. |

| [11] | 杨宏欣, 李兴亚, 葛亮, 徐铜文. 含哌啶阳离子侧长链型一/二价阴离子选择性分离膜的制备[J]. 化工学报, 2022, 73(8): 3739-3748. |

| [12] | 宋健斐, 孙立强, 解明, 魏耀东. 旋风分离器内气相旋转流不稳定性的实验研究[J]. 化工学报, 2022, 73(7): 2858-2864. |

| [13] | 朱江伟, 马鹏飞, 杜晓, 杨言言, 郝晓刚, 罗善霞. 基于可变价NiFe-LDH/rGO对磷酸根离子的特异性电控分离[J]. 化工学报, 2022, 73(7): 3057-3067. |

| [14] | 徐珂, 史国强, 薛冬峰. 无机杂化钙钛矿团簇材料:介尺度钙钛矿材料发光性质研究[J]. 化工学报, 2022, 73(6): 2748-2756. |

| [15] | 宋超宇, 熊亚选, 张金花, 金宇贺, 药晨华, 王辉祥, 丁玉龙. 污泥焚烧炉渣基定型复合相变储热材料的制备和性能[J]. 化工学报, 2022, 73(5): 2279-2287. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号