化工学报 ›› 2021, Vol. 72 ›› Issue (S1): 482-493.DOI: 10.11949/0438-1157.20201771

收稿日期:2020-12-09

修回日期:2021-01-15

出版日期:2021-06-20

发布日期:2021-06-20

通讯作者:

王志刚,谭小耀

作者简介:陈晨(1995—),女,硕士研究生,基金资助:

CHEN Chen( ),WANG Mingming,WANG Zhigang(

),WANG Mingming,WANG Zhigang( ),TAN Xiaoyao(

),TAN Xiaoyao( )

)

Received:2020-12-09

Revised:2021-01-15

Online:2021-06-20

Published:2021-06-20

Contact:

WANG Zhigang,TAN Xiaoyao

摘要:

采用纺丝-烧结技术制备了具有内表面致密皮层的外支撑式金属镍非对称中空纤维膜,并用于乙醇自热重整(EATR)制氢,研究了温度、进料流速、吹扫气流速、水醇比(S/C)以及氧醇比(O2/C)等操作条件对膜制氢性能的影响。结果表明,金属镍非对称中空纤维膜既具有优异的EATR催化活性,又有良好的透氢性能。在500~1000℃、S/C=4、O2/C=0.8的条件下乙醇可完全转化,H2产率和H2渗透通量可分别达到81.59%和13.99 mmol/(m2·s),增加进料中氧气含量可显著抑制膜表面积炭,但同时也会降低氢气产率和一氧化碳选择性。

中图分类号:

陈晨, 王明明, 王志刚, 谭小耀. 镍基非对称中空纤维膜用于乙醇自热重整制氢[J]. 化工学报, 2021, 72(S1): 482-493.

CHEN Chen, WANG Mingming, WANG Zhigang, TAN Xiaoyao. Hydrogen production by ethanol autothermal reforming using nickel-based asymmetric hollow fiber membranes[J]. CIESC Journal, 2021, 72(S1): 482-493.

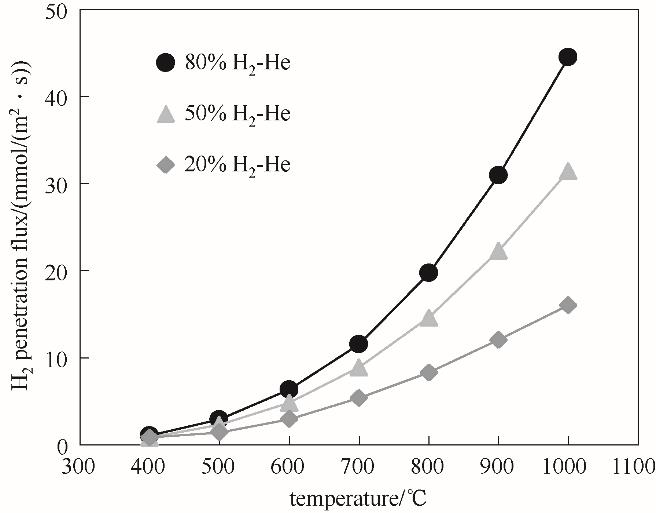

图3 不同进料浓度下镍中空纤维膜的H2渗透通量与温度的关系(H2-He进料速率= 30 ml/min;N2吹扫速率= 60 ml/min)

Fig.3 H2 permeation flux of Ni hollow fiber membrane as a function of temperature at different feed concentrations (H2-He feed rate=30 ml/min; N2 sweep rate=60 ml/min)

图4 镍中空纤维膜反应器和空白反应器中乙醇自热重整反应乙醇转化率、H2产率,MR产物浓度和Blank产物浓度随温度的变化(反应条件:S/C=4,O2/C=0.8,无吹扫气,进料流速为13 μl/min)

Fig.4 Ethanol autothermal reforming in Ni hollow fiber membrane reactor and blank reactor at different temperatures, ethanol conversion, hydrogen yield, product concentration of MR and Blank (Reaction conditions: S/C=4, O2/C=0.8, no sweep gas, feed flow rate=13 μl/min)

图5 不同吹扫气流速对乙醇自热重整反应乙醇转化率、H2产率、CO选择性和H2渗透通量的影响(反应条件:S/C=4,O2/C=0.8,吹扫气流速分别为0、30、50、70 ml/min,进料流速为13 μl/min)

Fig.5 Effect of sweep gas flow rate on ethanol conversion, hydrogen yield, CO selectivity and hydrogen penetration flux at different temperatures (Reaction conditions: S/C=4, O2/C=0.8, sweep gas flow rate=0,30,50,70 ml/min, feed flow rate=13 μl/min)

图6 不同蒸汽/乙醇比对乙醇自热重整反应乙醇转化率、H2产率、CO选择性和H2渗透通量的影响(反应条件:S/C=3、4、5、6,O2/C=0.8,吹扫气流速为30 ml/min,进料流速为13 μl/min)

Fig.6 Effect of S/C on ethanol conversion, hydrogen yield, CO selectivity and hydrogen penetration flux at different temperatures (Reaction conditions: S/C=3,4,5,6, O2/C=0.8, sweep gas flow rate=30 ml/min, feed flow rate=13 μl/min)

图7 不同氧气/乙醇比对乙醇自热重整反应乙醇转化率、H2产率、CO选择性和H2渗透通量的影响(反应条件:S/C=4,O2/C=0、0.5、0.8、1,吹扫气流速为30 ml/min,进料流速为13 μl/min)

Fig.7 Effect of O2/C on ethanol conversion, hydrogen yield, CO selectivity and hydrogen penetration flux at different temperatures (Reaction conditions: S/C=4, O2/C=0,0.5,0.8,1, sweep gas flow rate=30 ml/min, feed flow rate=13 μl/min)

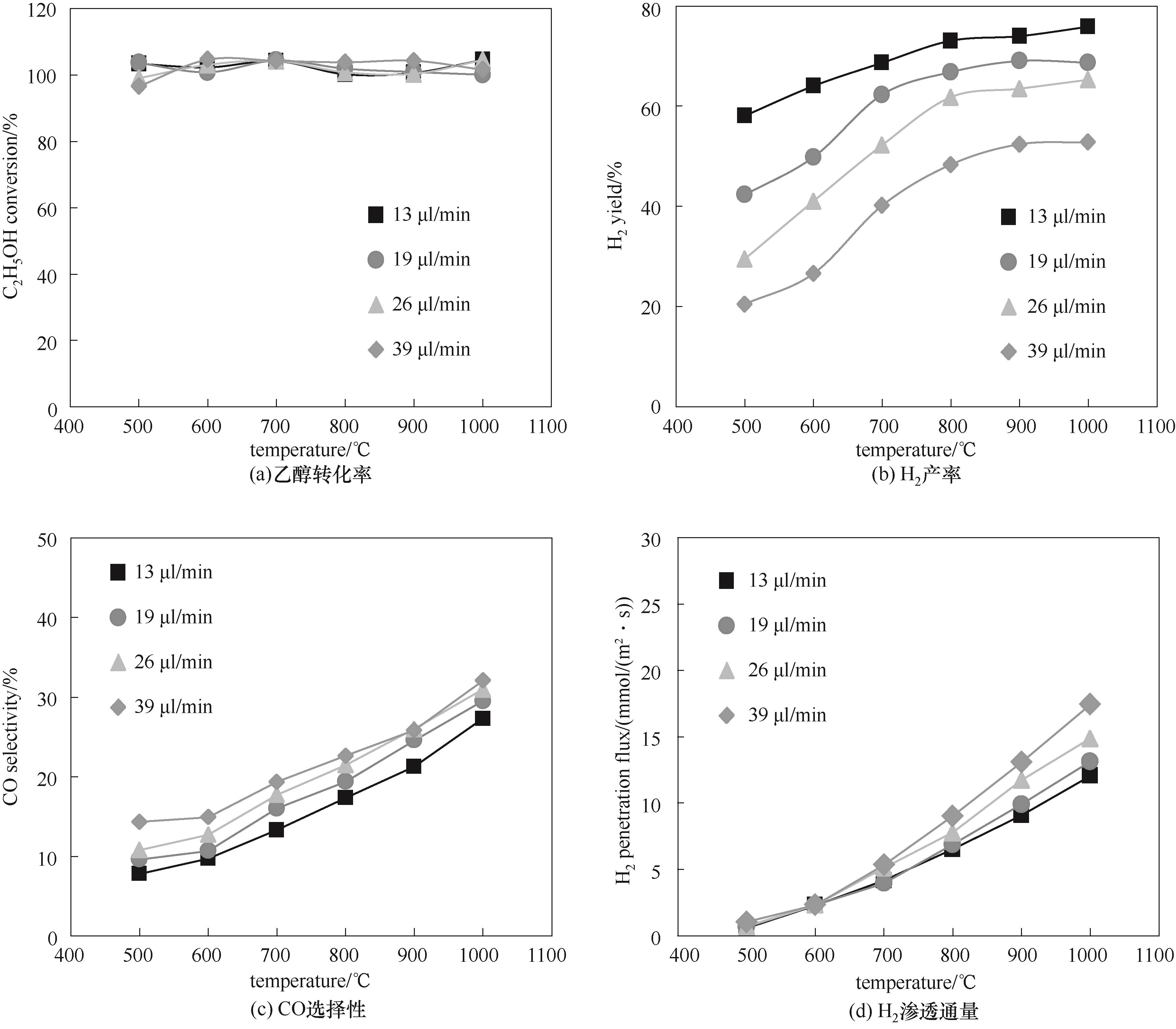

图8 不同进料流速对乙醇自热重整反应乙醇转化率、H2产率、CO选择性和H2渗透通量的影响(反应条件:S/C=4,O2/C=0.8,吹扫气流速为30 ml/min,进料流速分别为13、19、26、39 μl/min)

Fig.8 Effect of feed flow rate on ethanol conversion, hydrogen yield, CO selectivity and hydrogen permeation flux at different temperatures (Reaction conditions: S/C=4, O/C=0.8, sweep gas flow rate=30 ml/min, feed flow rate=13,19,26,39 μl/min)

图10 ESR、EATR氢气渗透测试后镍中空纤维膜的形貌(a)、(b),ESR、EATR氢气渗透测试前后镍中空纤维的EDS映射(c)和元素分析(d)

Fig.10 Morphology of Ni hollow fiber membranes after ESR (a) and EATR (b) hydrogen permeation tests; EDS mappings (c) and EDS patterns (d) of nickel hollow fiber membranes before and after ESR and EATR hydrogen permeation tests

| 1 | Ni M, Leung D Y C, Leung M K H. A review on reforming bio-ethanol for hydrogen production [J]. International Journal of Hydrogen Energy, 2007, 32(15): 3238-3247. |

| 2 | Lin H Q, He Z J, Sun Z, et al. CO2-selective membranes for hydrogen production and CO2 capture (I): Membrane development [J]. Journal of Membrane Science, 2014, 457: 149-161. |

| 3 | Mazloomi K, Gomes C. Hydrogen as an energy carrier: prospects and challenges [J]. Renewable and Sustainable Energy Reviews, 2012, 16(5): 3024-3033. |

| 4 | Spallina V, Matturro G, Ruocco C, et al. Direct route from ethanol to pure hydrogen through autothermal reforming in a membrane reactor: experimental demonstration, reactor modelling and design [J]. Energy, 2018, 143: 666-681. |

| 5 | Conte M, Iacobazzi A, Ronchetti M, et al. Hydrogen economy for a sustainable development: state-of-the-art and technological perspectives [J]. Journal of Power Sources, 2001, 100(1/2): 171-187. |

| 6 | Lin W H, Liu Y C, Chang H F. Hydrogen production from oxidative steam reforming of ethanol in a palladium-silver alloy composite membrane reactor [J]. Journal of the Chinese Institute of Chemical Engineers, 2008, 39(5): 435-440. |

| 7 | Lin W H, Liu Y C, Chang H F. Autothermal reforming of ethanol in a Pd-Ag/Ni composite membrane reactor [J]. International Journal of Hydrogen Energy, 2010, 35(23): 12961-12969. |

| 8 | Weng S F, Wang Y H, Lee C S. Autothermal steam reforming of ethanol over La2Ce2-xRuxO7 (x = 0~0.35) catalyst for hydrogen production [J]. Applied Catalysis B: Environmental, 2013, 134/135: 359-366. |

| 9 | Iulianelli A, Palma V, Bagnato G, et al. From bioethanol exploitation to high grade hydrogen generation: steam reforming promoted by a Co-Pt catalyst in a Pd-based membrane reactor [J]. Renewable Energy, 2018, 119: 834-843. |

| 10 | Graschinsky C, Giunta P, Amadeo N, et al. Thermodynamic analysis of hydrogen production by autothermal reforming of ethanol [J]. International Journal of Hydrogen Energy, 2012, 37(13): 10118-10124. |

| 11 | Guil-López R, Navarro R M, Peña M A, et al. Hydrogen production by oxidative ethanol reforming on Co, Ni and Cu ex-hydrotalcite catalysts [J]. International Journal of Hydrogen Energy, 2011, 36(2): 1512-1523. |

| 12 | Espinal R, Anzola A, Adrover E, et al. Durable ethanol steam reforming in a catalytic membrane reactor at moderate temperature over cobalt hydrotalcite [J]. International Journal of Hydrogen Energy, 2014, 39(21): 10902-10910. |

| 13 | Cheng Y S, Peña M A, Fierro J L, et al. Performance of alumina, zeolite, palladium, Pd-Ag alloy membranes for hydrogen separation from Towngas mixture [J]. Journal of Membrane Science, 2002, 204(1/2): 329-340. |

| 14 | Paiman S H, Rahman M A, Othman M H D, et al. Morphological study of yttria-stabilized zirconia hollow fibre membrane prepared using phase inversion/sintering technique [J]. Ceramics International, 2015, 41(10): 12543-12553. |

| 15 | Tan X Y, Liu Y T, Li K. Preparation of LSCF ceramic hollow-fiber membranes for oxygen production by a phase-inversion/sintering technique [J]. Industrial & Engineering Chemistry Research, 2005, 44(1): 61-66. |

| 16 | Lytkina A A, Orekhova N V, Ermilova M M, et al. Ru Rh based catalysts for hydrogen production via methanol steam reforming in conventional and membrane reactors [J]. International Journal of Hydrogen Energy, 2019, 44(26): 13310-13322. |

| 17 | Haag S, Burgard M, Ernst B. Pure nickel coating on a mesoporous alumina membrane: preparation by electroless plating and characterization [J]. Surface and Coatings Technology, 2006, 201(6): 2166-2173. |

| 18 | Zhang K, Gade S K, Way J D. Effects of heat treatment in air on hydrogen sorption over Pd-Ag and Pd-Au membrane surfaces [J]. Journal of Membrane Science, 2012, 403/404: 78-83. |

| 19 | Maneerung T, Hidajat K, Kawi S. Ultra-thin (<1 μm) internally-coated Pd-Ag alloy hollow fiber membrane with superior thermal stability and durability for high temperature H2 separation [J]. Journal of Membrane Science, 2014, 452: 127-142. |

| 20 | Wang M M, Zhou Y L, Tan X Y, et al. Nickel hollow fiber membranes for hydrogen separation from reformate gases and water gas shift reactions operated at high temperatures [J]. Journal of Membrane Science, 2019, 575: 89-97. |

| 21 | Ryi S K, Park J S, Choi S H, et al. Fabrication and characterization of metal porous membrane made of Ni powder for hydrogen separation [J]. Separation and Purification Technology, 2006, 47(3): 148-155. |

| 22 | Ernst B, Haag S, Burgard M. Permselectivity of a nickel/ceramic composite membrane at elevated temperatures: a new prospect in hydrogen separation? [J]. Journal of Membrane Science, 2007, 288(1/2): 208-217. |

| 23 | Lee S K, Ohn Y G, Noh S J. Measurement of hydrogen permeation through nickel in the elevated temperature range of 450 — 850℃ [J]. Journal of the Korean Physical Society, 2013, 63(10): 1955-1961. |

| 24 | Wang Z G, Kathiraser Y, Kawi S. High performance oxygen permeable membranes with Nb-doped BaBi0.05Co0.95O3-δ perovskite oxides [J]. Journal of Membrane Science, 2013, 431: 180-186. |

| 25 | Tan X Y, Liu Y T, Li K. Mixed conducting ceramic hollow-fiber membranes for air separation [J]. AIChE Journal, 2005, 51(7): 1991-2000. |

| 26 | Wang Z G, Kathiraser Y, Soh T, et al. Ultra-high oxygen permeable BaBiCoNb hollow fiber membranes and their stability under pure CH4 atmosphere [J]. Journal of Membrane Science, 2014, 465: 151-158. |

| 27 | Liu Y T, Li K. Preparation of SrCe0.95Yb0.05O3-α hollow fibre membranes: study on sintering processes [J]. Journal of Membrane Science, 2005, 259(1/2): 47-54. |

| 28 | Wang M M, Tan X Y, Wang X B, et al. Asymmetric nickel hollow fibres as the catalytic membrane reactor for CO2 hydrogenation into syngas [J]. Chemical Communications, 2019, 55(29): 4226-4229. |

| 29 | Cross A, Miller J T, Danghyan V, et al. Highly active and stable Ni-Cu supported catalysts prepared by combustion synthesis for hydrogen production from ethanol [J]. Applied Catalysis A: General, 2019, 572: 124-133. |

| 30 | Ogo S, Sekine Y. Recent progress in ethanol steam reforming using non-noble transition metal catalysts: a review [J]. Fuel Processing Technology, 2020, 199: 106238. |

| 31 | Jia H Y, Zhang J X, Yu J F, et al. Efficient H2 production via membrane-assisted ethanol steam reforming over Ir/CeO2 catalyst [J]. International Journal of Hydrogen Energy, 2019, 44(45): 24733-24745. |

| 32 | Jin Y, Rui Z B, Tian Y, et al. Autothermal reforming of ethanol in dense oxygen permeation membrane reactor [J]. Catalysis Today, 2016, 264: 214-220. |

| [1] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [2] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [3] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [4] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [5] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [6] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [7] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [8] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [9] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [10] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [11] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [12] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [13] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [14] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [15] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号