化工学报 ›› 2020, Vol. 71 ›› Issue (8): 3625-3632.DOI: 10.11949/0438-1157.20200357

收稿日期:2020-04-07

修回日期:2020-05-07

出版日期:2020-08-05

发布日期:2020-08-05

通讯作者:

牛胜利

作者简介:厉志鹏(1995—),男,硕士研究生,基金资助:

Zhipeng LI( ),Shengli NIU(

),Shengli NIU( ),Kuihua HAN,Chunmei LU

),Kuihua HAN,Chunmei LU

Received:2020-04-07

Revised:2020-05-07

Online:2020-08-05

Published:2020-08-05

Contact:

Shengli NIU

摘要:

借助分子模拟手段,研究了锌、镧、镁掺杂改性对钙铝基复合型金属氧化物催化酯交换的影响。构建了Al2O3(110)、CaO(100)以及锌、镧、镁掺杂改性的衍生模型。计算了不同改性氧化铝表面的掺杂结合能,分析了甲醇和乙酸甲酯在氧化钙及其衍生物表面的吸附过程,讨论了甲醇在Al2O3(110)及其衍生物表面的吸附过程及其Mulliken电荷密度的变化。结果表明,采用锌、镧、镁掺杂改性能强化钙铝复合型金属氧化物催化剂对甲醇的吸附性能,有助于催化酯交换反应的进行。

中图分类号:

厉志鹏, 牛胜利, 韩奎华, 路春美. 掺杂改性对钙铝基复合物酯交换催化剂吸附性能影响的分子模拟[J]. 化工学报, 2020, 71(8): 3625-3632.

Zhipeng LI, Shengli NIU, Kuihua HAN, Chunmei LU. Molecular simulation of the effect of doping modification on the adsorption properties of calcium-aluminum-based composites ester exchange catalysts[J]. CIESC Journal, 2020, 71(8): 3625-3632.

| 分子 | 键 | 键长/ nm | |

|---|---|---|---|

| 本文 | 文献[ | ||

| 甲醇 | O—H | 0.097 | 0.096 |

| C—O | 0.143 | 0.143 | |

| C—H1/2/3 | 0.109/0.110/0.110 | 0.110/0.110/0.110 | |

| 乙酸甲酯 | C—O1/2 | 0.144/0.136 | 0.143/0.136 |

| C—C | 0.150 | 0.150 | |

C O O | 0.122 | 0.122 | |

| C—H1/2/3 | 0.109/0.109/0.109 | 0.109/0.109/0.109 | |

| C—H4/5/6 | 0.109/0.110/0.110 | 0.109/0.109/0.109 | |

表1 甲醇和乙酸甲酯的键长

Table 1 Bond length of methanol and methyl acetate

| 分子 | 键 | 键长/ nm | |

|---|---|---|---|

| 本文 | 文献[ | ||

| 甲醇 | O—H | 0.097 | 0.096 |

| C—O | 0.143 | 0.143 | |

| C—H1/2/3 | 0.109/0.110/0.110 | 0.110/0.110/0.110 | |

| 乙酸甲酯 | C—O1/2 | 0.144/0.136 | 0.143/0.136 |

| C—C | 0.150 | 0.150 | |

C O O | 0.122 | 0.122 | |

| C—H1/2/3 | 0.109/0.109/0.109 | 0.109/0.109/0.109 | |

| C—H4/5/6 | 0.109/0.110/0.110 | 0.109/0.109/0.109 | |

| 掺杂方式 | 掺杂结合能(kJ/mol) | |||

|---|---|---|---|---|

Ca, M=0 | Ca, M=Zn | Ca, M=La | Ca, M=Mg | |

| Ca 取代 Al3c-1, M 取代 Al5c-1 | 215.03 215.03 | 969.33 | 151.23 | 652.17 |

| Ca 取代 Al3c-1, M 取代 Al4c-1 | 982.20 | 284.34 | 688.67 | |

| Ca 取代 Al4c-1, M 取代 Al3c-1 | 294.06 294.06 | 1037.07 | 310.07 | 728.05 |

| Ca 取代 Al4c-1, M 取代 Al5c-1 | 893.98 | 228.42 | 721.49 | |

| Ca 取代 Al5c-1, M 取代 Al4c-1 | 214.50 214.50 | 970.12 | 242.60 | 676.59 |

| Ca 取代 Al5c-1, M 取代 Al3c-1 | 960.15 | 213.98 | 643.25 | |

表2 催化剂表面在不同情况下的掺杂结合能

Table 2 Dopant incorporation energy of catalysts surface under different conditions

| 掺杂方式 | 掺杂结合能(kJ/mol) | |||

|---|---|---|---|---|

Ca, M=0 | Ca, M=Zn | Ca, M=La | Ca, M=Mg | |

| Ca 取代 Al3c-1, M 取代 Al5c-1 | 215.03 215.03 | 969.33 | 151.23 | 652.17 |

| Ca 取代 Al3c-1, M 取代 Al4c-1 | 982.20 | 284.34 | 688.67 | |

| Ca 取代 Al4c-1, M 取代 Al3c-1 | 294.06 294.06 | 1037.07 | 310.07 | 728.05 |

| Ca 取代 Al4c-1, M 取代 Al5c-1 | 893.98 | 228.42 | 721.49 | |

| Ca 取代 Al5c-1, M 取代 Al4c-1 | 214.50 214.50 | 970.12 | 242.60 | 676.59 |

| Ca 取代 Al5c-1, M 取代 Al3c-1 | 960.15 | 213.98 | 643.25 | |

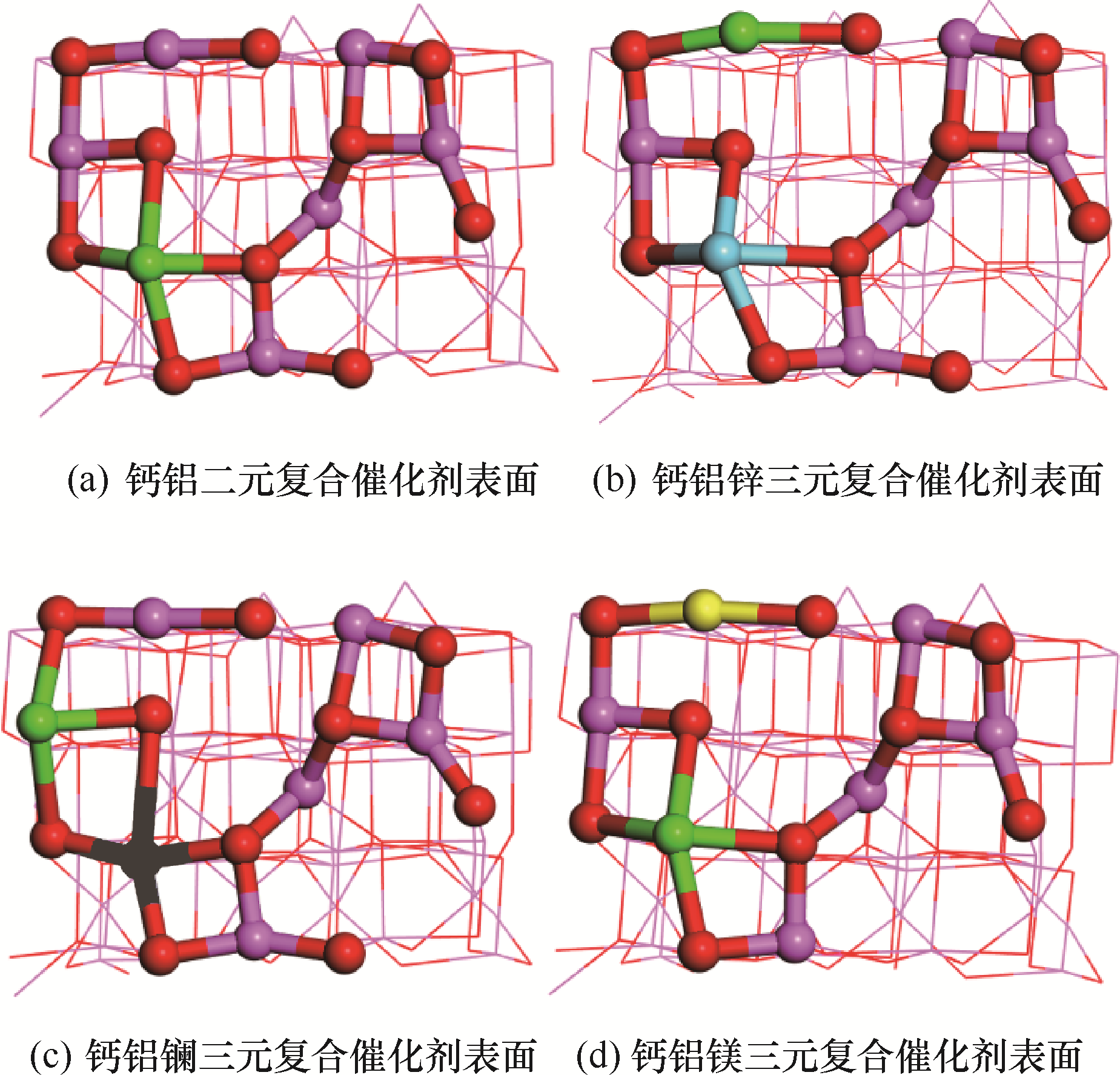

图3 掺杂改性后催化剂表面结构俯视图(红色为氧原子,粉色为铝原子,绿色为钙原子,黄色为镁原子,黑色为锌原子,蓝色为镧原子)

Fig.3 Top view of doped catalyst structure surfaces (O atoms are red, Al atoms are pink, Ca atoms are green, Mg atoms are yellow, Zn atoms are black and La atoms are blue)

| 吸附位置 | H—O键长/nm | H—M键长/nm | 吸附能/ (kJ/mol) |

|---|---|---|---|

| 钙催化剂表面 | 0.140 | 0.107 | -137.051 |

| 钙锌催化剂表面 | 0.151 | 0.103 | -164.094 |

| 钙镧催化剂表面 | 0.149 | 0.104 | -136.001 |

| 钙镁催化剂表面 | 0.148 | 0.105 | -158.318 |

表3 甲醇吸附在催化剂表面后的键长和吸附能

Table 3 Bond length and adsorption energy of methanol absorbed on catalyst surfaces

| 吸附位置 | H—O键长/nm | H—M键长/nm | 吸附能/ (kJ/mol) |

|---|---|---|---|

| 钙催化剂表面 | 0.140 | 0.107 | -137.051 |

| 钙锌催化剂表面 | 0.151 | 0.103 | -164.094 |

| 钙镧催化剂表面 | 0.149 | 0.104 | -136.001 |

| 钙镁催化剂表面 | 0.148 | 0.105 | -158.318 |

| 吸附位置 | C O键长/nm O键长/nm | 吸附能/(kJ/mol) |

|---|---|---|

| 钙催化剂表面 | 0.123 | -120.640 |

| 钙锌催化剂表面 | 0.123 | -135.102 |

| 钙镧催化剂表面 | 0.128 | -149.694 |

| 钙镁催化剂表面 | 0.122 | -100.801 |

表4 乙酸甲酯吸附在Ca-M催化剂表面后的键长和吸附能

Table 4 Bond length and adsorption energy of methyl acetate absorbed on Ca-M catalyst surfaces

| 吸附位置 | C O键长/nm O键长/nm | 吸附能/(kJ/mol) |

|---|---|---|

| 钙催化剂表面 | 0.123 | -120.640 |

| 钙锌催化剂表面 | 0.123 | -135.102 |

| 钙镧催化剂表面 | 0.128 | -149.694 |

| 钙镁催化剂表面 | 0.122 | -100.801 |

| 吸附位置 | H—O键长/nm | 吸附能/(kJ/mol) |

|---|---|---|

| 钙铝催化剂表面 | 0.097 | -105.020 |

| 钙铝锌催化剂表面 | 0.098 | -122.873 |

| 钙铝镧催化剂表面 | 0.098 | -147.816 |

| 钙铝镁催化剂表面 | 0.098 | -259.662 |

表5 甲醇吸附在Ca-Al-M催化剂表面后的键长和吸附能

Table 5 Bond length and adsorption energy of methanol absorbed on Ca-Al-M catalyst surfaces

| 吸附位置 | H—O键长/nm | 吸附能/(kJ/mol) |

|---|---|---|

| 钙铝催化剂表面 | 0.097 | -105.020 |

| 钙铝锌催化剂表面 | 0.098 | -122.873 |

| 钙铝镧催化剂表面 | 0.098 | -147.816 |

| 钙铝镁催化剂表面 | 0.098 | -259.662 |

| 吸附位置 | Mulliken电荷/e | ||||||

|---|---|---|---|---|---|---|---|

| H(O-H) | O | C | H1 | H2 | H3 | 总计 | |

| 纯甲醇 | 0.253 | -0.507 | 0.145 | 0.029 | 0.029 | 0.050 | 0 |

| 钙铝催化剂表面 | 0.327 | -0.601 | -0.018 | 0.105 | 0.115 | 0.119 | 0.047 |

| 钙铝锌催化剂表面 | 0.379 | -0.623 | -0.029 | 0.100 | 0.110 | 0.126 | 0.063 |

| 钙铝镧催化剂表面 | 0.405 | -0.635 | -0.024 | 0.108 | 0.113 | 0.124 | 0.091 |

| 钙铝镁催化剂表面 | 0.353 | -0.596 | -0.051 | 0.111 | 0.115 | 0.121 | 0.053 |

表6 甲醇吸附在Ca-Al-M催化剂表面的Mulliken电荷布局

Table 6 Mulliken atomic charge populations for methanol adsorption on Ca-Al-M catalyst surfaces

| 吸附位置 | Mulliken电荷/e | ||||||

|---|---|---|---|---|---|---|---|

| H(O-H) | O | C | H1 | H2 | H3 | 总计 | |

| 纯甲醇 | 0.253 | -0.507 | 0.145 | 0.029 | 0.029 | 0.050 | 0 |

| 钙铝催化剂表面 | 0.327 | -0.601 | -0.018 | 0.105 | 0.115 | 0.119 | 0.047 |

| 钙铝锌催化剂表面 | 0.379 | -0.623 | -0.029 | 0.100 | 0.110 | 0.126 | 0.063 |

| 钙铝镧催化剂表面 | 0.405 | -0.635 | -0.024 | 0.108 | 0.113 | 0.124 | 0.091 |

| 钙铝镁催化剂表面 | 0.353 | -0.596 | -0.051 | 0.111 | 0.115 | 0.121 | 0.053 |

| 1 | Niu S L, Zhang X Y, Ning Y L, et al. Dolomite incorporated with cerium to enhance the stability in catalyzing transesterification for biodiesel production[J]. Renewable Energy, 2020, 154: 107-116. |

| 2 | Pavlovic S M, Marinkovic D M, Kostic M D, et al. A CaO/zeolite-based catalyst obtained from waste chicken eggshell and coal fly ash for biodiesel production[J]. Fuel, 2020, 267: 117171. |

| 3 | Isabela C M, Stefan G S, Vasile P. Theoretical aspects of methyl acetate and methanol activation on MgO(100) and (501) catalyst surfaces with application in FAME production[J]. Applied Surface Science, 2017, 392: 920-928. |

| 4 | Isabela C M, Stefan G S, Vasile P. Effect of Ca and Sr in MgO(100) on the activation of methanol and methyl acetate[J]. Catalysis Today, 2018, 306: 207-214. |

| 5 | Ran W, Lin S H, Rempel G L, et al. Synthesis and properties of UV curable waterborne polyurethane acrylate nanocomposite films based on the surface modification of gamma-Al2O3[J]. Polymer Korea, 2017, 41(3): 385-393. |

| 6 | Vivian V T, Thaisa A M, Elisabete M A. Cu and Ni catalysts supported on γ-Al2O3 and SiO2 assessed in glycerol steam reforming reaction[J]. Journal of the Brazilian Chemical Society, 2015, 26(1):22-31. |

| 7 | Bercic G, Levec J. Intrinsic and global reaction-rate of methanol dehydration over gamma-Al2O3 pellets[J]. Ind. Eng. Chem. Res., 1992, 31: 1035-1040. |

| 8 | 张弛成, 洪业, 陈立芳, 等. 负载型钯团簇上氢分子吸附和解离吸附的密度泛函理论[J]. 化工学报, 2017, 68(2): 694-701. |

| Zhang C C, Hong Y, Chen L F, et al. Density functional theory of molecular and dissociative adsorption of hydrogen on supported palladium clusters[J]. CIESC Journal, 2017, 68(2): 694-701. | |

| 9 | Nunes A L B, Castilhos F. Chemical interesterification of soybean oil and methyl acetate to FAME using CaO as catalyst[J]. Fuel, 2020, 267: 117264. |

| 10 | 胡雪玲, 韦藤幼, 吴炼, 等. 改性膨润土催化麻疯树油酯交换反应动力学及生物柴油纯化[J]. 化工学报, 2015, 66(8): 3113-3119. |

| Hu X L, Wei T Y, Wu L, et al. Kinetics of jatropha oil transesterification catalyzed by modified bentonite and biodiesel purification[J]. CIESC Journal, 2015, 66(8): 3113-3119. | |

| 11 | Zheng L, Xia S, Lu X, et al. Transesterification of glycerol with dimethyl carbonate over calcined Ca-Al hydrocalumite[J]. Chinese Journal of Catalysis, 2015, 36(10): 1759-1765. |

| 12 | Tang S K, Wang L P, Zhang Y, et al. Study on preparation of Ca/Al/Fe3O4 magnetic composite solid catalyst and its application in biodiesel transesterification[J]. Fuel Processing Technology, 2012, 95: 84-89. |

| 13 | Ngamcharussrivichai C, Totarat P, Bunyakiat K. Ca and Zn mixed oxide as a heterogeneous base catalyst for transesterification of palm kernel oil[J]. Applied Catalysis A General, 2008, 341(1/2): 77-85. |

| 14 | Zhao S, Niu S L, Yu H W, et al. Experimental investigation on biodiesel production through transesterification promoted by the La-dolomite catalyst[J]. Fuel, 2019, 257: 116092. |

| 15 | 颜姝丽, 鲁厚芳, 姜利寒, 等. 固体碱催化剂用于油脂甲醇酯交换反应制备生物柴油[J]. 化工学报, 2007, 58(10): 2506-2512. |

| Yan S L, Lu H F, Jiang L H, et al. Solid base catalysts for transesterification of oil with methanol to produce biodiesel[J]. Journal of Chemical Industry and Engineering (China),2007, 58(10): 2506-2512. | |

| 16 | 李晓红, 杨云峰. Ca-Zn-Al-O固体碱的制备、表征及其油脂醇解催化活性[J]. 中国油脂, 2016, 41(12): 65-68. |

| Li X H, Yang Y F. Preparation and characterization of Ca-Zn-Al-O solid base and its catalytic activity in oil alcoholysis[J]. China Oils and Fats, 2016, 41(12): 65-68. | |

| 17 | Liao Y, Li F, Dai X, et al. Solid base catalysts derived from Ca-M-Al (M = Mg, La, Ce, Y) layered double hydroxides for dimethyl carbonate synthesis by transesterification of methanol with propylene carbonate[J]. Chinese Journal of Catalysis, 2017, 38(11): 1860-1869. |

| 18 | Eliane D, Jane E, Reem H, et al. Biodiesel production from refined sunflower oil over Ca-Mg-Al catalysts: effect of the composition and the thermal treatment[J]. Renewable Energy, 2020,146: 1242-1248. |

| 19 | Liu Z M, Li J H, Seong I W, et al. Density functional theory studies of NO and NO2 adsorption on Al2O3 supported SnO2 cluster[J]. Catalysis Letters, 2013, 143: 912-918. |

| 20 | 臧丽莉. Al2O3表面吸附小分子的第一性原理研究[D]. 福州: 福州大学, 2011. |

| Zang L L. First-principles studies on the adsorptions of small molecules on the Al2O3 surfaces[D]. Fuzhou: Fuzhou University, 2011. | |

| 21 | Digne M, Sautet P, Raybaud P, et al. Use of DFT to achieve a rational understanding of acid–basic properties of γ-alumina surfaces[J]. Journal of Catalysis, 2004, 226(1): 54-68. |

| 22 | Gao H W. DFT study of the adsorption properties of single Pt, Pd, Ag, In and Sn on the γ-Al2O3(110) surface[J]. Chemical Physics Letters, 2016, 657: 11-17. |

| 23 | Song Z, Wang B, Yu J, et al. Adsorption properties of CO, H2 and CH4 over Pd/gamma-Al2O3 catalyst: a density functional study[J]. Applied Surface Science, 2016, 387(30): 341-350. |

| 24 | 薛继龙, 方镭, 罗伟, 等. Cu-Pt-Au三元合金催化水煤气变换反应的密度泛函研究[J]. 燃料化学学报, 2019, 47(6): 688-696. |

| Xue J L, Fang L, Luo W, et al. Density functional study of water gas shift reaction catalyzed by Cu-Pt-Au ternary alloy[J]. Journal of Fuel Chemistry and Technology, 2019, 47(6): 688-696. | |

| 25 | 梁志永, 覃吴, 石司默, 等. 化学链燃烧中Co掺杂改性Fe2O3(104)载氧体反应特性[J]. 工程科学与技术, 2019, 51(6): 28-35. |

| Liang Z Y, Qin W, Shi S M, et al. Modification of Co-doping on reaction properties of Fe2O3(104) oxygen carrier during chemical looping combustion[J]. Advanced Engineering Sciences, 2019, 51(6): 28-35. | |

| 26 | 杨涛, 曹蕃, 刘利军, 等. 掺杂Ce/Zr对γ-Al2O3(110)表面的影响[J]. 燃烧科学与技术, 2017, 23(6): 542-546. |

| Yang T, Cao F, Liu L J, et al. Impact of Ce/Zr doping on γ-Al2O3(110) surface[J]. Journal of Combustion Science and Technology, 2017, 23(6): 542-546. | |

| 27 | 石磊, 于悦, 王吉宇, 等. 酯交换法合成碳酸甲乙酯研究进展[J]. 燃料化学学报, 2019, 47(12): 1504-1521. |

| Shi L, Yu Y, Wang J Y, et al. Recent advances of studies in ethyl methyl carbonate synthesis via transesterification process[J]. Journal of Fuel Chemistry and Technology, 2019, 47(12): 1504-1521. | |

| 28 | 付希. CaO-ZnO固体碱催化剂的制备及其催化大豆油酯交换反应的性能[J]. 石油化工, 2017, 46(5): 552-557. |

| Fu X. Preparation of CaO-ZnO solid base catalysts and their catalytic performances for transesterification of soybean oil[J]. Petrochemical Technology, 2017, 46(5): 552-557. | |

| 29 | Yan S, Kim M, Mohan S, et al. Effects of preparative parameters on the structure and performance of Ca–La metal oxide catalysts for oil transesterification[J]. Applied Catalysis A General, 2010, 373(1/2): 104-111. |

| 30 | 王广欣, 颜姝丽, 周重文, 等. 用于生物柴油的钙镁催化剂的制备及其活性评价[J]. 中国油脂, 2005, 30(10): 64-67. |

| Wang G X, Yan S L, Zhou C W, et al. Preparation and activity measurement of CaO/MgO catalyst for biodiesel fuel production[J]. China Oils and Fats, 2005, 30(10): 64-67. | |

| 31 | 万艳春, 王玉军, 骆广生. 并流滴加法制备大孔容纤维状γ-氧化铝[J]. 化工学报, 2018, 69(11): 4840-4847. |

| Wan Y C, Wang Y J, Luo G S. Preparation of fibrous γ-alumina with large pore volume via co-current dropwise addition method[J]. CIESC Journal, 2018, 69(11): 4840-4847. | |

| 32 | Norhasyimah M K, Wan Azelee W A B, Rusmidah A. Catalytic optimization and physicochemical studies over Zn/Ca/Al2O3 catalyst for transesterification of low grade cooking oil[J]. Energy Conversion and Management, 2017, 137: 113-120. |

| 33 | Syamsuddin Y, Murat M N, Hameed B H. Transesterification of jatropha oil with dimethyl carbonate to produce fatty acid methyl ester over reusable Ca-La-Al mixed-oxide catalyst[J]. Energy Conversion and Management, 2015, 106: 1356-1361. |

| 34 | Gao L, Teng G, Lv J, et al. Biodiesel synthesis catalyzed by the KF/Ca-Mg-Al hydrotalcite base catalyst[J]. Energy & Fuels, 2010, 24(1): 646-651. |

| 35 | Liu R Q. Adsorption and dissociation of H2O on Au(111) surface: a DFT study[J]. Computational and Theoretical Chemistry, 2013, 1019: 141-145. |

| 36 | 孟庆森. 甲醇氧化羰基合成碳酸二甲酯反应机理的DFT研究[D]. 天津: 天津大学, 2013. |

| Meng Q S. Reaction mechanism for methanol oxycarbonylation to form dimethyl carbonate: a DFT approach[D]. Tianjin: Tianjin University, 2013. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [3] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [4] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [5] | 赵佳佳, 田世祥, 李鹏, 谢洪高. SiO2-H2O纳米流体强化煤尘润湿性的微观机理研究[J]. 化工学报, 2023, 74(9): 3931-3945. |

| [6] | 盛冰纯, 于建国, 林森. 铝基锂吸附剂分离高钠型地下卤水锂资源过程研究[J]. 化工学报, 2023, 74(8): 3375-3385. |

| [7] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [8] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [9] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [10] | 陈吉, 洪泽, 雷昭, 凌强, 赵志刚, 彭陈辉, 崔平. 基于分子动力学的焦炭溶损反应及其机理研究[J]. 化工学报, 2023, 74(7): 2935-2946. |

| [11] | 董明, 徐进良, 刘广林. 超临界水非均质特性分子动力学研究[J]. 化工学报, 2023, 74(7): 2836-2847. |

| [12] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [13] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [14] | 王新悦, 王俊杰, 曹思贤, 王翠, 李灵坤, 吴宏宇, 韩静, 吴昊. 玻璃内包材界面修饰对机械应力诱导的单克隆抗体聚集体形成的影响[J]. 化工学报, 2023, 74(6): 2580-2588. |

| [15] | 刘远超, 蒋旭浩, 邵钶, 徐一帆, 钟建斌, 李耑. 几何尺寸及缺陷对石墨炔纳米带热输运特性的影响[J]. 化工学报, 2023, 74(6): 2708-2716. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号