化工学报 ›› 2021, Vol. 72 ›› Issue (8): 3933-3945.DOI: 10.11949/0438-1157.20201843

冯宇1,2,3( ),张鑫2,张曼2,王建成1,阎智锋2,李甫2,费鹏飞2,卢建军1,2,米杰1(

),张鑫2,张曼2,王建成1,阎智锋2,李甫2,费鹏飞2,卢建军1,2,米杰1( )

)

收稿日期:2020-12-16

修回日期:2021-03-30

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

冯宇,米杰

作者简介:冯宇(1991—),男,博士,讲师,基金资助:

Yu FENG1,2,3( ),Xin ZHANG2,Man ZHANG2,Jiancheng WANG1,Zhifeng YAN2,Fu LI2,Pengfei FEI2,Jianjun LU1,2,Jie MI1(

),Xin ZHANG2,Man ZHANG2,Jiancheng WANG1,Zhifeng YAN2,Fu LI2,Pengfei FEI2,Jianjun LU1,2,Jie MI1( )

)

Received:2020-12-16

Revised:2021-03-30

Online:2021-08-05

Published:2021-08-05

Contact:

Yu FENG,Jie MI

摘要:

煤在气化和燃烧过程中产生的气体污染物和颗粒物会转移到合成气和空气中,从而产生设备腐蚀和环境污染等问题。静电纺丝纤维具有可调控的、超细的直径,多孔的结构,超高的比表面积,可设计的形貌以及易于表面修饰等优点,在气体污染物脱除领域有着巨大的应用价值。介绍了静电纺丝的基本原理和发展现状,综述且简要分析了静电纺丝纳米纤维材料在PMs、CO2、NOx、H2S、SO2和VOCs等气体污染物脱除方面的应用及研究现状。最后,对电纺纤维在气体污染物脱除领域中更广泛、更深入的应用前景进行了展望。

中图分类号:

冯宇, 张鑫, 张曼, 王建成, 阎智锋, 李甫, 费鹏飞, 卢建军, 米杰. 静电纺丝纤维对煤基气体污染物脱除研究进展[J]. 化工学报, 2021, 72(8): 3933-3945.

Yu FENG, Xin ZHANG, Man ZHANG, Jiancheng WANG, Zhifeng YAN, Fu LI, Pengfei FEI, Jianjun LU, Jie MI. Research progress on the removal of coal based gas pollutants by electrospun fibers[J]. CIESC Journal, 2021, 72(8): 3933-3945.

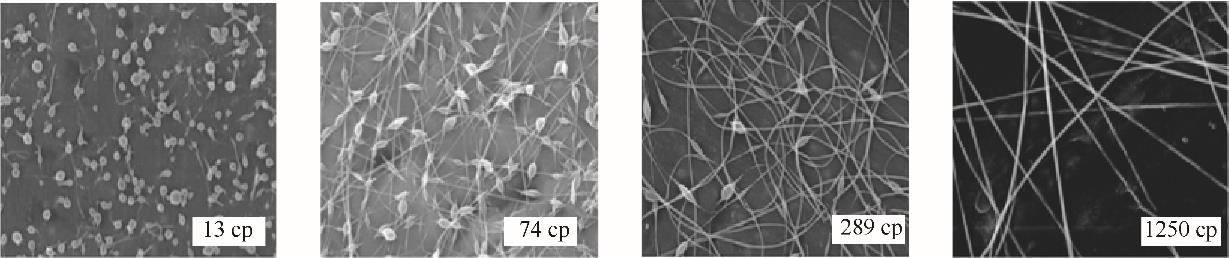

图5 电纺聚环氧乙烷纤维形态随溶液黏度增大的SEM图(从左至右依次增大)[44]

Fig.5 SEM images of electrospun polyethylene oxide fibers with increasing solution viscosity (increase from left to right) [44]

| 1 | Chan C K, Yao X H. Air pollution in mega cities in China[J]. Atmospheric Environment, 2008, 42(1): 1-42. |

| 2 | 潘玲颖, 麻林巍, 周喆, 等. 2030年中国煤电SO2和NOx排放总量的情况研究[J]. 动力工程学报, 2010, 30(5): 378-383. |

| Pan L Y, Ma L W, Zhou Z, et al. Scenario analysis on total SO2 and NOx emission of China's coal-fired power plants in 2030[J]. Journal of Chinese Society of Power Engineering, 2010, 30(5): 378-383. | |

| 3 | 何秋生, 范晓周, 王新明, 等. 煤焦化过程中颗粒物和二氧化硫的释放[J]. 地球与环境, 2007, 35(3): 279-283. |

| He Q S, Fan X Z, Wang X M, et al. Emissions of TSP and sulfur dioxide(SO2) from coal coking process[J]. Earth and Environment, 2007, 35(3): 279-283. | |

| 4 | 王志刚, 陶兆勇, 段贤勇, 等. 天然气净化厂SO2减排技术的应用及讨论[J]. 天然气与石油, 2017, 35(1): 60-63, 10. |

| Wang Z G, Tao Z Y, Duan X Y, et al. Application and discussion on SO2 emission reduction technology of natural gas purification plant[J]. Natural Gas and Oil, 2017, 35(1): 60-63, 10. | |

| 5 | Gholami F, Tomas M, Gholami Z, et al. Technologies for the nitrogen oxides reduction from flue gas: a review[J]. Science of the Total Environment, 2020, 714: 136712. |

| 6 | Ghose M K. Meeting the challenges of sustainable development of energy through clean coal technologies[J]. TIDEE (TERI Information Digest on Energy & Environment), 2013, 12(2): 169-182. |

| 7 | Im S I, Lee K B. Novel sorption-enhanced methanation with simultaneous CO2 removal for the production of synthetic natural gas[J]. Industrial & Engineering Chemistry Research, 2016, 55(34): 9244-9255. |

| 8 | 张国莲, 陈廷. 纳米纤维的研究现状及其应用[J]. 纺织导报, 2005, (1): 12-16, 18. |

| Zhang G L, Chen T. The research and application of nanometer fiber[J]. China Textile Leader, 2005, (1): 12-16, 18. | |

| 9 | Perez-Puyana V, Jiménez-Rosado M, Romero A, et al. Development of PVA/gelatin nanofibrous scaffolds for tissue engineering via electrospinning[J]. Materials Research Express, 2018, 5(3): 035401. |

| 10 | Si Y, Tang X M, Yu J Y, et al. Electrospun nanofibers: solving global issues[M]//Nanostructure Science and Technology. Berlin, Heidelberg: Springer, 2014: 3-38. |

| 11 | Chan S, Jankovic J, Susac D, et al. Electrospun carbon nanofiber catalyst layers for polymer electrolyte membrane fuel cells: structure and performance[J]. Journal of Power Sources, 2018, 392: 239-250. |

| 12 | Liu H, Gough C R, Deng Q Q, et al. Recent advances in electrospun sustainable composites for biomedical, environmental, energy, and packaging applications[J]. International Journal of Molecular Sciences, 2020, 21(11): 4019. |

| 13 | Motsoeneng T S, Mokoena T E, Mokhena T C, et al. Application of electrospun materials in filtration and sorbents[M]//Electrospun Materials and Their Allied Applications. Wiley Scrivener Publishing, 2020: 401-414. |

| 14 | Yi H H, Du C C, Ma Y Q, et al. A novel semi-dry method for the simultaneous removal of Hg and SO2 using spray drying absorption method[J]. Journal of Chemical Technology & Biotechnology, 2020, 95(5): 1431-1440. |

| 15 | Yang X L, Wang J W, Guo H T, et al. Structural design toward functional materials by electrospinning: a review[J]. e-Polymers, 2020, 20(1): 682-712. |

| 16 | Ryu H, Park J. Effects of electrospinning parameters on the fiber formation and application[J]. Transactions of the Korean Hydrogen and New Energy Society, 2018, 29(1): 71-80. |

| 17 | Tan R, Yang X, Shen Y J. Robot-aided electrospinning toward intelligent biomedical engineering[J]. Robotics and Biomimetics, 2017, 4(1): 17. |

| 18 | 刘呈坤. 静电纺丝技术的研究进展[J]. 合成纤维工业, 2012, 35(2): 53-56. |

| Liu C K. Research progress in electrospinning process[J]. China Synthetic Fiber Industry, 2012, 35(2): 53-56. | |

| 19 | 王艳芝. 静电纺丝技术发展简史及应用[J]. 合成纤维工业, 2018, 41(4): 52-57. |

| Wang Y Z. A brief history of electrospinning technology development and application[J]. China Synthetic Fiber Industry, 2018, 41(4): 52-57. | |

| 20 | Boys C V. On the production, properties, and some suggested uses of the finest threads[J]. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1887, 23(145): 489-499. |

| 21 | Zeleny J. The electrical discharge from liquid points, and a hydrostatic method of measuring the electric intensity at their surfaces[J]. Physical Review, 1914, 3(2): 69. |

| 22 | 葛自良, 毛骏健, 陆汝杰. 液体静电雾化现象及其应用[J]. 自然杂志, 2000, 22(1): 37-41. |

| Ge Z L, Mao J J, Lu R J. Liquid atomizing phenomenon subjected to the DC high voltage and its application[J]. Chinese Journal of Nature, 2000, 22(1): 37-41. | |

| 23 | Bailey A G. Electrostatic spraying of liquids[J]. Physics Bulletin, 1984, 35(4): 146-148. |

| 24 | Taylor G I. Disintegration of water drops in an electric field[J]. Proceedings of the Royal Society of London Series A Mathematical and Physical Sciences, 1964, 280(1382): 383-397. |

| 25 | Taylor G I. The force exerted by an electric field on a long cylindrical conductor[J]. Proceedings of the Royal Society of London Series A Mathematical and Physical Sciences, 1966, 291(1425): 145-158. |

| 26 | Taylor G I. Electrically driven jets[J]. Proceedings of the Royal Society of London Series A Mathematical and Physical Sciences, 1969, 313(1515): 453-475. |

| 27 | Reneker D H, Yarin A L, Fong H, et al. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning[J]. Journal of Applied Physics, 2000, 87(9): 4531-4547. |

| 28 | Hohman M M, Shin M, Rutledge G, et al. Electrospinning and electrically forced jets(Ⅰ): Stability theory[J]. Physics of Fluids, 2001, 13(8): 2201-2220. |

| 29 | Larsen G, Velarde-Ortiz R, Minchow K, et al. A method for making inorganic and hybrid (organic/inorganic) fibers and vesicles with diameters in the submicrometer and micrometer range via sol-gel chemistry and electrically forced liquid jets[J]. Journal of the American Chemical Society, 2003, 125(5): 1154-1155. |

| 30 | Li D, Wang Y L, Xia Y N. Electrospinning of polymeric and ceramic nanofibers as uniaxially aligned arrays[J]. Nano Letters, 2003, 3(8): 1167-1171. |

| 31 | Ghorani B, Russell S J, Goswami P. Controlled morphology and mechanical characterisation of electrospun cellulose acetate fibre webs[J]. International Journal of Polymer Science, 2013, 2013: 1-12. |

| 32 | Wang C, Hashimoto T. Self-organization in electrospun polymer solutions: from dissipative structures to ordered fiber structures through fluctuations[J]. Macromolecules, 2018, 51(12): 4502-4515. |

| 33 | He J X, Zhou Y M, Qi K, et al. Continuous twisted nanofiber yarns fabricated by double conjugate electrospinning[J]. Fibers and Polymers, 2013, 14(11): 1857-1863. |

| 34 | Minaei F, Ravandi S A H, Hejazi S M, et al. The fabrication and characterization of casein/PEO nanofibrous yarn via electrospinning[J]. e-Polymers, 2019, 19(1): 154-167. |

| 35 | Pillay V, Dott C, Choonara Y E, et al. A review of the effect of processing variables on the fabrication of electrospun nanofibers for drug delivery applications[J]. Journal of Nanomaterials, 2013, 2013: 1-22. |

| 36 | Chowdhury M, Stylios G. Effect of experimental parameters on the morphology of electrospun Nylon 6 fibres[J]. International Journal of Basic & Applied Sciences, 2010, 10(6): 116-131. |

| 37 | Prabu G T V, Dhurai B. A novel profiled multi-pin electrospinning system for nanofiber production and encapsulation of nanoparticles into nanofibers[J]. Scientific Reports, 2020, 10(1): 4302. |

| 38 | Haider A, Haider S, Kang I K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology[J]. Arabian Journal of Chemistry, 2018, 11(8): 1165-1188. |

| 39 | Haider S, Al-Zeghayer Y, Ahmed Ali F A, et al. Highly aligned narrow diameter chitosan electrospun nanofibers[J]. Journal of Polymer Research, 2013, 20(4): 1-11. |

| 40 | Koski A, Yim K, Shivkumar S. Effect of molecular weight on fibrous PVA produced by electrospinning[J]. Materials Letters, 2004, 58(3/4): 493-497. |

| 41 | Tan E P S, Ng S Y, Lim C T. Tensile testing of a single ultrafine polymeric fiber[J]. Biomaterials, 2005, 26(13): 1453-1456. |

| 42 | Burger C, Hsiao B S, Chu B. Nanofibrous materials and their applications[J]. Annual Review of Materials Research, 2006, 36(1): 333-368. |

| 43 | Xiao S L, Shen M W, Ma H, et al. Fabrication of water-stable electrospun polyacrylic acid-based nanofibrous mats for removal of copper (II) ions in aqueous solution[J]. Journal of Applied Polymer Science, 2010, 116(4): 2409-2417. |

| 44 | Luzio A, Canesi E V, Bertarelli C, et al. Electrospun polymer fibers for electronic applications[J]. Materials (Basel, Switzerland), 2014, 7(2): 906-947. |

| 45 | Hayati I, Bailey A I, Tadros T F. Investigations into the mechanisms of electrohydrodynamic spraying of liquids (I): Effect of electric field and the environment on pendant drops and factors affecting the formation of stable jets and atomization[J]. Journal of Colloid and Interface Science, 1987, 117(1): 205-221. |

| 46 | Yao Y T, Wei H Q, Wang J J, et al. Fabrication of hybrid membrane of electrospun polycaprolactone and polyethylene oxide with shape memory property[J]. Composites Part B: Engineering, 2015, 83: 264-269. |

| 47 | Okutan N, Terzi P, Altay F. Affecting parameters on electrospinning process and characterization of electrospun gelatin nanofibers[J]. Food Hydrocolloids, 2014, 39: 19-26. |

| 48 | Megelski S, Stephens J S, Chase D B, et al. Micro- and nanostructured surface morphology on electrospun polymer fibers[J]. Macromolecules, 2002, 35(22): 8456-8466. |

| 49 | Bakar S S, Fong K C, Eleyas A, et al. Effect of voltage and flow rate electrospinning parameters on polyacrylonitrile electrospun fibers[J]. IOP Conference Series: Materials Science and Engineering, 2018, 318: 012076. |

| 50 | Matabola K P, Moutloali R M. The influence of electrospinning parameters on the morphology and diameter of poly(vinyledene fluoride) nanofibers— effect of sodium chloride[J]. Journal of Materials Science, 2013, 48(16): 5475-5482. |

| 51 | Mo X M, Xu C Y, Kotaki M, et al. Electrospun P(LLA-CL) nanofiber: a biomimetic extracellular matrix for smooth muscle cell and endothelial cell proliferation[J]. Biomaterials, 2004, 25(10): 1883-1890. |

| 52 | Zhao S L, Wu X H, Wang L G, et al. Electrospinning of ethyl-cyanoethyl cellulose/tetrahydrofuran solutions[J]. Journal of Applied Polymer Science, 2004, 91(1): 242-246. |

| 53 | Pelipenko J, Kristl J, Janković B, et al. The impact of relative humidity during electrospinning on the morphology and mechanical properties of nanofibers[J]. International Journal of Pharmaceutics, 2013, 456(1): 125-134. |

| 54 | Bae H S, Haider A, Selim K M K, et al. Fabrication of highly porous PMMA electrospun fibers and their application in the removal of phenol and iodine[J]. Journal of Polymer Research, 2013, 20(7): 1-7. |

| 55 | Mit-Uppatham C, Nithitanakul M, Supaphol P. Ultrafine electrospun polyamide-6 fibers: effect of solution conditions on morphology and average fiber diameter[J]. Macromolecular Chemistry and Physics, 2004, 205(17): 2327-2338. |

| 56 | De Vrieze S, Van Camp T, Nelvig A, et al. The effect of temperature and humidity on electrospinning[J]. Journal of Materials Science, 2009, 44(5): 1357-1362. |

| 57 | Yang A K, Cai L L, Zhang R F, et al. Thermal management in nanofiber-based face mask[J]. Nano Letters, 2017, 17(6): 3506-3510. |

| 58 | Liu K, Liu C, Hsu P C, et al. Core-shell nanofibrous materials with high particulate matter removal efficiencies and thermally triggered flame retardant properties[J]. ACS Central Science, 2018, 4(7): 894-898. |

| 59 | Lee S, Cho A R, Park D, et al. Reusable polybenzimidazole nanofiber membrane filter for highly breathable PM2.5 dust proof mask[J]. ACS Applied Materials & Interfaces, 2019, 11(3): 2750-2757. |

| 60 | Wang C Y, Wu S Y, Jian M Q, et al. Silk nanofibers as high efficient and lightweight air filter[J]. Nano Research, 2016, 9(9): 2590-2597. |

| 61 | Liu B W, Zhang S C, Wang X L, et al. Efficient and reusable polyamide-56 nanofiber/nets membrane with bimodal structures for air filtration[J]. Journal of Colloid and Interface Science, 2015, 457: 203-211. |

| 62 | Kim S J, Nam Y S, Rhee D M, et al. Preparation and characterization of antimicrobial polycarbonate nanofibrous membrane[J]. European Polymer Journal, 2007, 43(8): 3146-3152. |

| 63 | Jeong S, Cho H, Han S, et al. High efficiency, transparent, reusable, and active PM2.5 filters by hierarchical Ag nanowire percolation network[J]. Nano Letters, 2017, 17(7): 4339-4346. |

| 64 | Cho B M, Nam Y S, Cheon J Y, et al. Residual charge and filtration efficiency of polycarbonate fibrous membranes prepared by electrospinning[J]. Journal of Applied Polymer Science, 2015, 132(1): 41340. |

| 65 | Yeom B Y, Shim E, Pourdeyhimi B. Boehmite nanoparticles incorporated electrospun Nylon-6 nanofiber web for new electret filter media[J]. Macromolecular Research, 2010, 18(9): 884-890. |

| 66 | 胡敏, 仲兆祥, 邢卫红. 纳米纤维膜在空气净化中的应用研究进展[J]. 化工进展, 2018, 37(4): 1305-1313. |

| Hu M, Zhong Z X, Xing W H. Development of nanofiber membrane for air purification[J]. Chemical Industry and Engineering Progress, 2018, 37(4): 1305-1313. | |

| 67 | Leung W F, Hung C H, Yuen P T. Effect of face velocity, nanofiber packing density and thickness on filtration performance of filters with nanofibers coated on a substrate[J]. Separation and Purification Technology, 2010, 71(1): 30-37. |

| 68 | Selling G W, Woods K K. Improved isolation of zein from corn gluten meal using acetic acid and isolate characterization as solvent[J]. Cereal Chemistry, 2008, 85(2): 202-206. |

| 69 | Ozden D, Basal G. Polyamide 6/chitosan nanofiber coated HEPA filter for bioaerosol control[J]. Industria Textila, 2017, 68(6): 427-434. |

| 70 |

Kadam V, Truong Y B, Kyratzis I L, et al. Nanofibres for clean air breathing[J]. Journal of the Institution of Engineers (India): Series E, 2021. doi:10.1007/540034-021-00207-3.

DOI |

| 71 | Zhang Y F, Guan J M, Wang X F, et al. Balsam-pear-skin-like porous polyacrylonitrile nanofibrous membranes grafted with polyethyleneimine for postcombustion CO2 capture[J]. ACS Applied Materials & Interfaces, 2017, 9(46): 41087-41098. |

| 72 | Ullah R, Atilhan M, Anaya B, et al. Investigation of ester- and amide-linker-based porous organic polymers for carbon dioxide capture and separation at wide temperatures and pressures[J]. ACS Applied Materials & Interfaces, 2016, 8(32): 20772-20785. |

| 73 | Fu Y, Wang Z Q, Li S Z, et al. Functionalized covalent triazine frameworks for effective CO2 and SO2 removal[J]. ACS Applied Materials & Interfaces, 2018, 10(42): 36002-36009. |

| 74 | Liu Y Y, Ghimire P, Jaroniec M. Copper benzene-1, 3, 5-tricarboxylate (Cu-BTC) metal-organic framework (MOF) and porous carbon composites as efficient carbon dioxide adsorbents[J]. Journal of Colloid and Interface Science, 2019, 535: 122-132. |

| 75 | Inonu Z, Keskin S, Erkey C. An emerging family of hybrid nanomaterials: metal-organic framework/aerogel composites[J]. ACS Applied Nano Materials, 2018, 1(11): 5959-5980. |

| 76 | Querejeta N, García S, Álvarez-Gutiérrez N, et al. Measuring heat capacity of activated carbons for CO2 capture[J]. Journal of CO2 Utilization, 2019, 33: 148-156. |

| 77 | Iqbal N, Wang X F, Ge J L, et al. Cobalt oxide nanoparticles embedded in flexible carbon nanofibers: attractive material for supercapacitor electrodes and CO2 adsorption[J]. RSC Advances, 2016, 6(57): 52171-52179. |

| 78 | Ali N, Babar A A, Zhang Y F, et al. Porous, flexible, and core-shell structured carbon nanofibers hybridized by tin oxide nanoparticles for efficient carbon dioxide capture[J]. Journal of Colloid and Interface Science, 2020, 560: 379-387. |

| 79 | Qu H L, Wei S Y, Guo Z H. Coaxial electrospun nanostructures and their applications[J]. Journal of Materials Chemistry A, 2013, 1(38): 11513. |

| 80 | Zainab G, Babar A A, Ali N, et al. Electrospun carbon nanofibers with multi-aperture/opening porous hierarchical structure for efficient CO2 adsorption[J]. Journal of Colloid and Interface Science, 2020, 561: 659-667. |

| 81 | Wang M X, Huang Z H, Shen K, et al. Catalytically oxidation of NO into NO2 at room temperature by graphitized porous nanofibers[J]. Catalysis Today, 2013, 201: 109-114. |

| 82 | Marani D, Silva R H, Dankeaw A, et al. Effect of the sol-gel conditions on the morphology and SCR performance of electrospun V-W-TiO2 catalysts[J]. Journal of Physics and Chemistry of Solids, 2018, 118: 255-261. |

| 83 | Gao C, Xiao B, Shi J W, et al. Comprehensive understanding the promoting effect of Dy-doping on MnFeOx nanowires for the low-temperature NH3-SCR of NOx: an experimental and theoretical study[J]. Journal of Catalysis, 2019, 380: 55-67. |

| 84 | Rodriguez N M, Kim M S, Baker R T K. Carbon nanofibers: a unique catalyst support medium[J]. The Journal of Physical Chemistry, 1994, 98(50): 13108-13111. |

| 85 | Wang M X, Huang Z H, Shimohara T, et al. NO removal by electrospun porous carbon nanofibers at room temperature[J]. Chemical Engineering Journal, 2011, 170(2/3): 505-511. |

| 86 | Bajaj B, Joh H I, Jo S M, et al. Enhanced reactive H2S adsorption using carbon nanofibers supported with Cu/CuxO nanoparticles[J]. Applied Surface Science, 2018, 429: 253-257. |

| 87 | Kim S, Bajaj B, Byun C K, et al. Preparation of flexible zinc oxide/carbon nanofiber webs for mid-temperature desulfurization[J]. Applied Surface Science, 2014, 320: 218-224. |

| 88 | Ucar N, Alptoğa Ö, Önen A, et al. Improvement of SO2 adsorption capacity of fiber web surface produced from continuous graphene oxide fiber[J]. The Journal of the Textile Institute, 2019, 110(3): 358-367. |

| 89 | Mochida I, Korai Y, Shirahama M, et al. Removal of SOx and NOx over activated carbon fibers[J]. Carbon, 2000, 38(2): 227-239. |

| 90 | Song X F, Wang Z J, Li Z Y, et al. Ultrafine porous carbon fibers for SO2 adsorption via electrospinning of polyacrylonitrile solution[J]. Journal of Colloid and Interface Science, 2008, 327(2): 388-392. |

| 91 | Yang R, Liu J H, Li S M. Preparation and characterization of in-site regenerated TiO2-ACFs photocatalyst[J]. International Journal of Minerals, Metallurgy, and Materials, 2011, 18(3): 357-363. |

| 92 | Gaur V, Asthana R, Verma N. Removal of SO2 by activated carbon fibers in the presence of O2 and H2O[J]. Carbon, 2006, 44(1): 46-60. |

| 93 | Yu H Q, Wu Y B, Song T B, et al. Preparation of metal oxide doped ACNFs and their adsorption performance for low concentration SO2[J]. International Journal of Minerals, Metallurgy, and Materials, 2013, 20(11): 1102-1106. |

| 94 | Zhang X Y, Gao B, Creamer A E, et al. Adsorption of VOCs onto engineered carbon materials: a review[J]. Journal of Hazardous Materials, 2017, 338: 102-123. |

| 95 | Kadam V, Truong Y B, Easton C, et al. Electrospun polyacrylonitrile/β-cyclodextrin composite membranes for simultaneous air filtration and adsorption of volatile organic compounds[J]. ACS Applied Nano Materials, 2018, 1(8): 4268-4277. |

| 96 | Blissett R S, Rowson N A. A review of the multi-component utilisation of coal fly ash[J]. Fuel, 2012, 97: 1-23. |

| 97 | Ge J C, Kim J Y, Yoon S K, et al. Fabrication of low-cost and high-performance coal fly ash nanofibrous membranes via electrospinning for the control of harmful substances[J]. Fuel, 2019, 237: 236-244. |

| 98 | Kang S M, Hwang J. Fabrication of hollow activated carbon nanofibers (HACNFs) containing manganese oxide catalyst for toluene removal via two-step process of electrospinning and thermal treatment[J]. Chemical Engineering Journal, 2020, 379: 122315. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [3] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [4] | 盛冰纯, 于建国, 林森. 铝基锂吸附剂分离高钠型地下卤水锂资源过程研究[J]. 化工学报, 2023, 74(8): 3375-3385. |

| [5] | 吕龙义, 及文博, 韩沐达, 李伟光, 高文芳, 刘晓阳, 孙丽, 王鹏飞, 任芝军, 张光明. 铁基导电材料强化厌氧去除卤代有机污染物:研究进展及未来展望[J]. 化工学报, 2023, 74(8): 3193-3202. |

| [6] | 张建华, 陈萌萌, 孙雅雯, 彭永臻. 部分短程硝化同步除磷耦合Anammox实现生活污水高效脱氮除磷[J]. 化工学报, 2023, 74(5): 2147-2156. |

| [7] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [8] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [9] | 肖川宝, 李林洋, 刘武锋, 钟年丙, 解泉华, 钟登杰, 常海星. 光催化与离子交换吸附耦合有效去除2,4,6-三氯苯酚[J]. 化工学报, 2023, 74(4): 1587-1597. |

| [10] | 潘煜, 王子航, 王佳韵, 王如竹, 张华. 基于可得然-氯化锂复合吸附剂的除湿换热器热湿性能研究[J]. 化工学报, 2023, 74(3): 1352-1359. |

| [11] | 李敏, 阎雪茹, 刘新磊. 苯并咪唑连接聚合物吸附剂和膜研究进展[J]. 化工学报, 2023, 74(2): 599-616. |

| [12] | 仇鹏, 韩洋, 许建良, 王辅臣, 代正华. 用于预测气流床煤气化的EDC模型参数研究[J]. 化工学报, 2023, 74(1): 428-437. |

| [13] | 陈晨, 杨倩, 陈云, 张睿, 刘冬. 不同氧浓度下煤挥发分燃烧的化学动力学研究[J]. 化工学报, 2022, 73(9): 4133-4146. |

| [14] | 刘振宇. 煤地下气化低效的化学反应工程根源:滞留层及通道中的传质与反应[J]. 化工学报, 2022, 73(8): 3299-3306. |

| [15] | 朱莲峰, 王超, 张梦娟, 刘方正, 贾鑫, 安萍, 许光文, 韩振南. 水蒸气/氧流化床两段煤气化制备低焦油合成气工艺实验[J]. 化工学报, 2022, 73(8): 3720-3730. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号