化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5396-5401.DOI: 10.11949/0438-1157.20210436

张凯博1( ),徐晓明1,薛有宝1,万柳1,田威1,曾涛1(

),徐晓明1,薛有宝1,万柳1,田威1,曾涛1( ),张亚婷2

),张亚婷2

收稿日期:2021-03-29

修回日期:2021-05-25

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

曾涛

作者简介:张凯博(1994—),男,硕士,助理工程师,

Kaibo ZHANG1( ),Xiaoming XU1,Youbao XUE1,Liu WAN1,Wei TIAN1,Tao ZENG1(

),Xiaoming XU1,Youbao XUE1,Liu WAN1,Wei TIAN1,Tao ZENG1( ),Yating ZHANG2

),Yating ZHANG2

Received:2021-03-29

Revised:2021-05-25

Online:2021-10-05

Published:2021-10-05

Contact:

Tao ZENG

摘要:

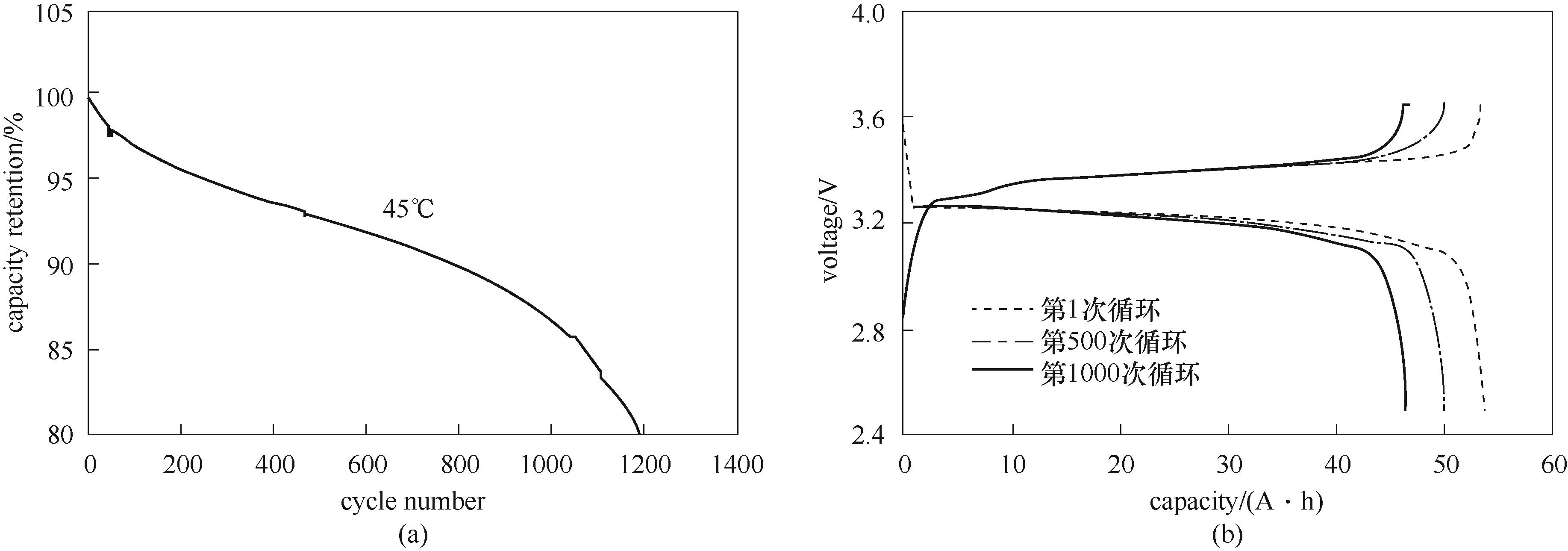

以电动汽车的方型LiFePO4/石墨动力实验电池为研究对象,探究其在45℃恒温箱下1C充放电循环的失效机理。通过对电池进行解剖,系统分析了电池循环前后正负极片的厚度、形貌、结构和克容量的变化。随着电池在45℃高温下循环,电解液分解以及Fe溶出损失、SEI膜再生长,消耗大量的活性锂,交流内阻增加导致电化学极化增大,活性锂消耗引起负极容量损失为6.7%,负极结构变化造成的容量损失为22.64%。结果表明石墨负极动力学性能的衰减是电池失效的主要因素。

中图分类号:

张凯博,徐晓明,薛有宝,万柳,田威,曾涛,张亚婷. LiFePO4锂离子动力电池45℃容量衰减机理[J]. 化工学报, 2021, 72(10): 5396-5401.

Kaibo ZHANG,Xiaoming XU,Youbao XUE,Liu WAN,Wei TIAN,Tao ZENG,Yating ZHANG. Analysis of mechanism of capacity attenuation of LiFePO4 lithium-ion power battery at 45℃[J]. CIESC Journal, 2021, 72(10): 5396-5401.

图1 LiFePO4/石墨动力电池在45℃下的容量衰减曲线(a)和不同循环次数的恒流充放电曲线(b)

Fig.1 Capacity decay curve (a) and constant current charge-discharge curves of different cycles (b) of LiFePO4/graphite power battery at 45℃

| 电池 | 电解液 | 正极片厚度/μm | 负极片厚度/μm |

|---|---|---|---|

| 新鲜电池 | 大量 | 168 | 116 |

| 失效电池 | 无 | 184 | 142 |

表1 新鲜电池与失效电池的电解液、极片厚度对比

Table 1 Comparison of electrolyte and electrode thickness between fresh and failed batteries

| 电池 | 电解液 | 正极片厚度/μm | 负极片厚度/μm |

|---|---|---|---|

| 新鲜电池 | 大量 | 168 | 116 |

| 失效电池 | 无 | 184 | 142 |

| 电池 | Rs/mΩ | RSEI/mΩ | Rct/mΩ |

|---|---|---|---|

| 循环前 | 0.69 | 0.86 | 1.34 |

| 循环后 | 0.68 | 1.15 | 1.86 |

表2 电池测试前后的EIS拟合数据

Table 2 EIS fitting data before and after battery test

| 电池 | Rs/mΩ | RSEI/mΩ | Rct/mΩ |

|---|---|---|---|

| 循环前 | 0.69 | 0.86 | 1.34 |

| 循环后 | 0.68 | 1.15 | 1.86 |

| 正极 | 新鲜电池容量 | 失效电池容量 | ||

|---|---|---|---|---|

| 充电 | 放电 | 充电 | 放电 | |

| 样品1 | 3.77 | 3.78 | 3.19 | 3.23 |

| 样品2 | 3.78 | 3.78 | 3.23 | 3.24 |

| 平均容量/(mA·h) | 3.77 | 3.78 | 3.21 | 3.24 |

| 平均克容量/(mA·h/g) | 151.34 | 152.48 | 140.10 | 143.82 |

表3 新鲜电池与失效电池正极/Li半电池的平均容量

Table 3 Average capacity of fresh and failed battery cathodes/Li half-cell of LiFePO4

| 正极 | 新鲜电池容量 | 失效电池容量 | ||

|---|---|---|---|---|

| 充电 | 放电 | 充电 | 放电 | |

| 样品1 | 3.77 | 3.78 | 3.19 | 3.23 |

| 样品2 | 3.78 | 3.78 | 3.23 | 3.24 |

| 平均容量/(mA·h) | 3.77 | 3.78 | 3.21 | 3.24 |

| 平均克容量/(mA·h/g) | 151.34 | 152.48 | 140.10 | 143.82 |

| 负极 | 新鲜电池容量 | 失效电池容量 | ||

|---|---|---|---|---|

| 充电 | 放电 | 充电 | 放电 | |

| 样品1 | 3.27 | 3.29 | 2.74 | 2.79 |

| 样品2 | 3.25 | 3.27 | 2.71 | 2.73 |

| 平均容量/(mA·h) | 3.26 | 3.28 | 2.72 | 2.76 |

| 平均克容量/(mA·h/g) | 288.14 | 290.25 | 203.6 | 224.53 |

表4 新鲜电池与失效电池负极/Li半电池的容量

Table 4 Average capacity of fresh and failed battery anodes/Li half-cell of graphite

| 负极 | 新鲜电池容量 | 失效电池容量 | ||

|---|---|---|---|---|

| 充电 | 放电 | 充电 | 放电 | |

| 样品1 | 3.27 | 3.29 | 2.74 | 2.79 |

| 样品2 | 3.25 | 3.27 | 2.71 | 2.73 |

| 平均容量/(mA·h) | 3.26 | 3.28 | 2.72 | 2.76 |

| 平均克容量/(mA·h/g) | 288.14 | 290.25 | 203.6 | 224.53 |

| 1 | Sharma S S, Manthiram A. Towards more environmentally and socially responsible batteries[J]. Energy & Environmental Science, 2020, 13(11): 4087-4097. |

| 2 | Li J, Zhou Y, Zheng Y Y, et al. Preparation and properties of LiFePO4 cathode material for lithium ion power battery[J]. Advanced Materials Research, 2011, 239: 302-305. |

| 3 | 许于, 陈怡沁, 周静红, 等. LiFePO4锂离子电池的数值模拟: 正极材料颗粒粒径的影响[J]. 化工学报, 2020, 71(2): 821-830. |

| Xu Y, Chen Y Q, Zhou J H, et al. Numerical simulation of lithium-ion battery with LiFePO4 as cathode material: effect of particle size[J]. CIESC Journal, 2020, 71(2): 821-830. | |

| 4 | Bian X L, Liu L C, Yan J Y, et al. An open circuit voltage-based model for state-of-health estimation of lithium-ion batteries: model development and validation[J]. Journal of Power Sources, 2020, 448: 227401. |

| 5 | Naumann M, Spingler F B, Jossen A. Analysis and modeling of cycle aging of a commercial LiFePO4/graphite cell[J]. Journal of Power Sources, 2020, 451: 227666. |

| 6 | Wu F, Tan G Q, Chen R J, et al. Novel solid-state Li/LiFePO4 battery configuration with a ternary nanocomposite electrolyte for practical applications[J]. Advanced Materials, 2011, 23(43): 5081-5085. |

| 7 | Nishimura S I, Natsui R, Yamada A. Superstructure in the metastable intermediate-phase Li2/3FePO4 accelerating the lithium battery cathode reaction[J]. Angewandte Chemie International Edition, 2015, 54(31): 8939-8942. |

| 8 | Wang J, Liu P, Hicks-Garner J, et al. Cycle-life model for graphite-LiFePO4 cells[J]. Journal of Power Sources, 2011, 196(8): 3942-3948. |

| 9 | Huang S J, Huang B G, Pai F S. Fast charge strategy based on the characterization and evaluation of LiFePO4 batteries[J]. IEEE Transactions on Power Electronics, 2013, 28(4): 1555-1562. |

| 10 | Sivakumar M, Muruganantham R, Subadevi R. Synthesis of surface modified LiFePO4 cathode material via polyol technique for high rate lithium secondary battery[J]. Applied Surface Science, 2015, 337: 234-240. |

| 11 | Thomas J, Castro E B, Milocco R, et al. Performance of LiFePO4/C and carbon fibers composite as cathodes in lithium-ion batteries and battery modeling[J]. ECS Transactions, 2014, 48(1): 129-133. |

| 12 | Lim J, Gim J, Song J J, et al. Direct formation of LiFePO4/graphene composite via microwave-assisted polyol process[J]. Journal of Power Sources, 2016, 304: 354-359. |

| 13 | Shi M, Li R W, Liu Y L. In situ preparation of LiFePO4/C with unique copolymer carbon resource for superior performance lithium-ion batteries[J]. Journal of Alloys and Compounds, 2021, 854: 157162. |

| 14 | Gu M, Shi W, Zheng J M, et al. Probing the failure mechanism of nanoscale LiFePO4 for Li-ion batteries[J]. Applied Physics Letters, 2015, 106(20): 159-171. |

| 15 | Lu L G, Han X B, Li J Q, et al. A review on the key issues for lithium-ion battery management in electric vehicles[J]. Journal of Power Sources, 2013, 226: 272-288. |

| 16 | Wen J W, Yu Y, Chen C H. A review on lithium-ion batteries safety issues: existing problems and possible solutions[J]. Materials Express, 2012, 2(3): 197-212. |

| 17 | Gannett C N, Melecio-Zambrano L, Theibault M J, et al. Organic electrode materials for fast-rate, high-power battery applications[J]. Materials Reports: Energy, 2021, 1(1): 100008. |

| 18 | Song H S, Cao Z, Chen X, et al. Capacity fade of LiFePO4/graphite cell at elevated temperature[J]. Journal of Solid State Electrochemistry, 2013, 17(3): 599-605. |

| 19 | 刘伯峥, 徐晓明, 曾涛, 等. 高镍三元正极材料锂离子电池45℃容量衰减[J]. 电池, 2020, 50(5): 458-461. |

| Liu B Z, Xu X M, Zeng T, et al. Capacity fading of nickel-rich ternary cathode material Li-ion battery at 45℃[J]. Battery Bimonthly, 2020, 50(5): 458-461. | |

| 20 | Zhou X, Huang J, Pan Z Q, et al. Impedance characterization of lithium-ion batteries aging under high-temperature cycling: importance of electrolyte-phase diffusion[J]. Journal of Power Sources, 2019, 426: 216-222. |

| 21 | Duffner F, Kronemeyer N, Tübke J, et al. Post-lithium-ion battery cell production and its compatibility with lithium-ion cell production infrastructure[J]. Nature Energy, 2021, 6(2): 123-134. |

| 22 | 马洪运, 姚晓辉, 妙孟姚, 等. 高镍正极材料(LiNi0.83Co0.12Mn0.05O2)45℃循环失效机理研究[J]. 电化学, 2020, 26(3): 431-440. |

| Ma H Y, Yao X H, Miao M Y, et al. Degradation mechanism of LiNi0.83Co0.12Mn0.05O2 cycled at 45 ℃[J]. Journal of Eelectrochemistry, 2020, 26(3): 431-440. | |

| 23 | Ouyang D X, Weng J W, Chen M Y, et al. Impact of high-temperature environment on the optimal cycle rate of lithium-ion battery[J]. Journal of Energy Storage, 2020, 28: 101242. |

| 24 | Shim J, Kostecki R, Richardson T, et al. Electrochemical analysis for cycle performance and capacity fading of a lithium-ion battery cycled at elevated temperature[J]. Journal of Power Sources, 2002, 112(1): 222-230. |

| 25 | Zhang Y T, Zhang K B, Jia K L, et al. Facile synthesis 2D hierarchical structure of ultrahigh nitrogen-doped porous carbon graphene nanosheets as high-efficiency lithium-ion battery anodes[J]. Materials Chemistry and Physics, 2020, 251: 123043. |

| 26 | Agubra V A, Fergus J W, Fu R J, et al. Analysis of effects of the state of charge on the formation and growth of the deposit layer on graphite electrode of pouch type lithium ion polymer batteries[J]. Journal of Power Sources, 2014, 270: 213-220. |

| 27 | 郑勇, 李建玲, 王新东. 磷酸铁锂/石墨动力电池的高温衰减机制研究[J]. 材料导报, 2016, 30(10): 15-18, 32. |

| Zheng Y, Li J L, Wang X D. Capacity fading mechanism of LiFePO4/graphite power battery at high temperature[J]. Materials Review, 2016, 30(10): 15-18, 32. | |

| 28 | Wang D Y, Wu X D, Wang Z X, et al. Cracking causing cyclic instability of LiFePO4 cathode material[J]. Journal of Power Sources, 2005, 140(1): 125-128. |

| 29 | 王振, 李建玲, 王康康, 等. 磷酸铁锂/石墨动力电池衰退机理分析[J]. 稀有金属与硬质合金, 2020, 48(3): 60-66. |

| Wang Z, Li J L, Wang K K, et al. Analysis of capacity fading mechanisms of LiFePO4/graphite power battery[J]. Rare Metals and Cemented Carbides, 2020, 48(3): 60-66. | |

| 30 | Zhang Y, Zhang R L, Xu F F, et al. Surface structures, crystal orientation, and electrochemical behavior of modified LiFePO4 by novel strategies[J]. Energy Technology, 2019, 7(10): 1900385. |

| 31 | 孔令丽, 张克军, 夏晓萌, 等. 高电压锂离子电池高温浮充性能影响因素分析与改善[J]. 储能科学与技术, 2019, 8(6): 1165-1170. |

| Kong L L, Zhang K J, Xia X M, et al. Analysis and improvement of high temperature floating charge performance for high voltage lithium ion batteries[J]. Energy Storage Science and Technology, 2019, 8(6): 1165-1170. | |

| 32 | Kim D, Park S, Chae O B, et al. Re-deposition of manganese species on spinel LiMn2O4 electrode after Mn dissolution[J]. Journal of the Electrochemical Society, 2012, 159(3): A193-A197. |

| 33 | Li W S. Review—an unpredictable hazard in lithium-ion batteries from transition metal ions: dissolution from cathodes, deposition on anodes and elimination strategies[J]. Journal of the Electrochemical Society, 2020, 167(9): 090514. |

| [1] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [4] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [5] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [6] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [7] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [8] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [9] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [10] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [11] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [12] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [13] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [14] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [15] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号