化工学报 ›› 2022, Vol. 73 ›› Issue (6): 2612-2621.DOI: 10.11949/0438-1157.20211519

刘怡琳1( ),李钰1(

),李钰1( ),余亚雄1,黄哲庆1,周强1,2,3(

),余亚雄1,黄哲庆1,周强1,2,3( )

)

收稿日期:2021-10-26

修回日期:2022-01-11

出版日期:2022-06-05

发布日期:2022-06-30

通讯作者:

李钰,周强

作者简介:刘怡琳(1997—),女,硕士研究生,基金资助:

Yilin LIU1( ),Yu LI1(

),Yu LI1( ),Yaxiong YU1,Zheqing HUANG1,Qiang ZHOU1,2,3(

),Yaxiong YU1,Zheqing HUANG1,Qiang ZHOU1,2,3( )

)

Received:2021-10-26

Revised:2022-01-11

Online:2022-06-05

Published:2022-06-30

Contact:

Yu LI,Qiang ZHOU

摘要:

颗粒聚团等介尺度结构在气固两相流中普遍存在,这些介尺度非均匀结构直接影响气固流动特性及气固接触效率,进而影响气固相间传热、传质及化学反应过程。在更适合工业大尺度气固传热模拟的粗网格方法中缺乏准确度高、简单易用且可以考虑介尺度非均匀结构影响的传热模型。采用计算流体力学-离散单元法(CFD-DEM)研究了气固两相流相间传热,为了保证气固相间持续传热,采用了两种维持气固相间传热温差的方法,并讨论了两种方法的优缺点。方法一:给气相能量方程添加热源项;方法二:每间隔一段时间重置气相温度,重置温度后气固两相自由传热,两种方法中均保持固相温度不变。结果表明聚团界面位置的局部单位体积气固传热量最大,重置温度方法在稀相和界面位置的局部单位体积传热量与总单位体积传热量之比大于热源项方法,而在浓相位置的局部单位体积传热量与总单位体积传热量之比小于热源项方法。通过过滤CFD-DEM计算数据,为重置温度方法构建了双参数(过滤固含率、过滤尺度)传热系数修正因子模型,通过先验分析评价了模型的表现,研究表明所构建模型在过滤网格尺度为5~40倍颗粒直径范围内优于文献中已有的双参数模型。

中图分类号:

刘怡琳, 李钰, 余亚雄, 黄哲庆, 周强. 基于重置温度方法的双参数介尺度气固传热模型构建[J]. 化工学报, 2022, 73(6): 2612-2621.

Yilin LIU, Yu LI, Yaxiong YU, Zheqing HUANG, Qiang ZHOU. Construction of two parameter mesoscale heat transfer model for gas-solid flow based on resetting temperature method[J]. CIESC Journal, 2022, 73(6): 2612-2621.

| 参数 | 数值 |

|---|---|

| 颗粒直径 | 7.5×10-5 m |

| 计算域尺寸 | 240dp × 960dp× 6dp |

| 网格尺寸 | 2.5dp × 2.5dp × 3dp |

| 重力加速度 | 9.81 m/s2 |

| 颗粒密度 | 1500 kg/m3 |

| 法向弹性系数 | 5 N/m |

| 恢复系数 | 0.8 |

| 颗粒间碰撞的切向阻尼系数与法向阻尼系数之比 | 0.5 |

| 颗粒间摩擦系数 | 0.5 |

| 颗粒比热容 | 840 J/(kg·K) |

| 颗粒热导率 | 1.4 W/(m·K) |

| 气相密度 | 1.3 kg/m3 |

| 气相黏度 | 1.8×105 Pa·s |

| 气相比热容 | 1010 J/(kg·K) |

| 气相热导率 | 0.02552 W/(m·K) |

| 颗粒弛豫时间 | 0.026 s |

| 整体固含率 | 0.05 |

| 初始固相温度 | 0 K |

| 方法一初始气相温度 | 0.1 K |

| 方法二重置气相温度 | 1000 K |

| 颗粒数目 | 1.3201×105 |

| 曳力模型 | Gidaspow_blend |

表1 主要计算参数及设置

Table 1 Parameters and settings

| 参数 | 数值 |

|---|---|

| 颗粒直径 | 7.5×10-5 m |

| 计算域尺寸 | 240dp × 960dp× 6dp |

| 网格尺寸 | 2.5dp × 2.5dp × 3dp |

| 重力加速度 | 9.81 m/s2 |

| 颗粒密度 | 1500 kg/m3 |

| 法向弹性系数 | 5 N/m |

| 恢复系数 | 0.8 |

| 颗粒间碰撞的切向阻尼系数与法向阻尼系数之比 | 0.5 |

| 颗粒间摩擦系数 | 0.5 |

| 颗粒比热容 | 840 J/(kg·K) |

| 颗粒热导率 | 1.4 W/(m·K) |

| 气相密度 | 1.3 kg/m3 |

| 气相黏度 | 1.8×105 Pa·s |

| 气相比热容 | 1010 J/(kg·K) |

| 气相热导率 | 0.02552 W/(m·K) |

| 颗粒弛豫时间 | 0.026 s |

| 整体固含率 | 0.05 |

| 初始固相温度 | 0 K |

| 方法一初始气相温度 | 0.1 K |

| 方法二重置气相温度 | 1000 K |

| 颗粒数目 | 1.3201×105 |

| 曳力模型 | Gidaspow_blend |

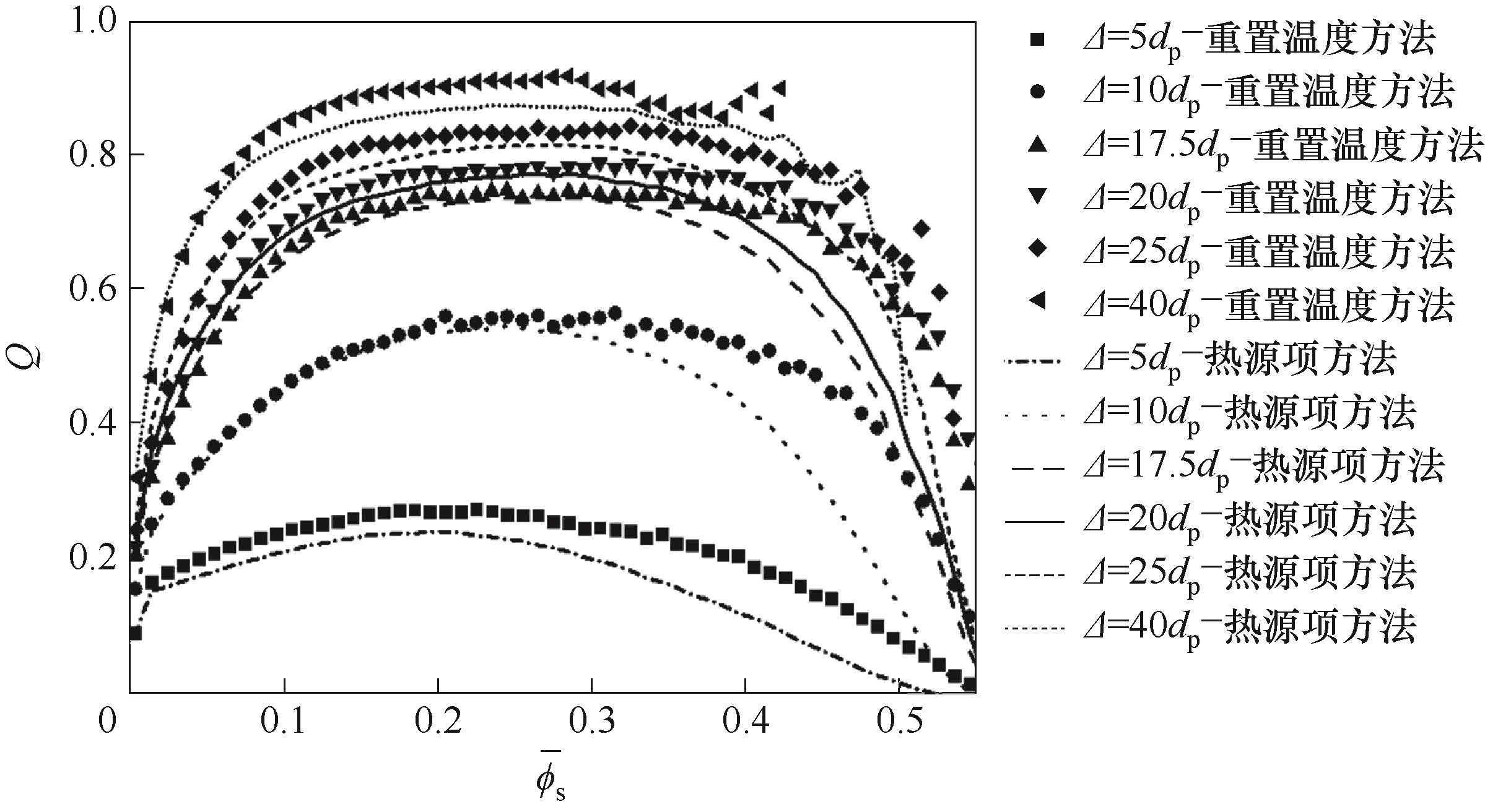

图8 两种方法在不同尺度下获得的Q的平均值随过滤固含率的变化

Fig.8 The average value of Q obtained by the two methods varied with the filtered solid volume fraction at different filter sizes

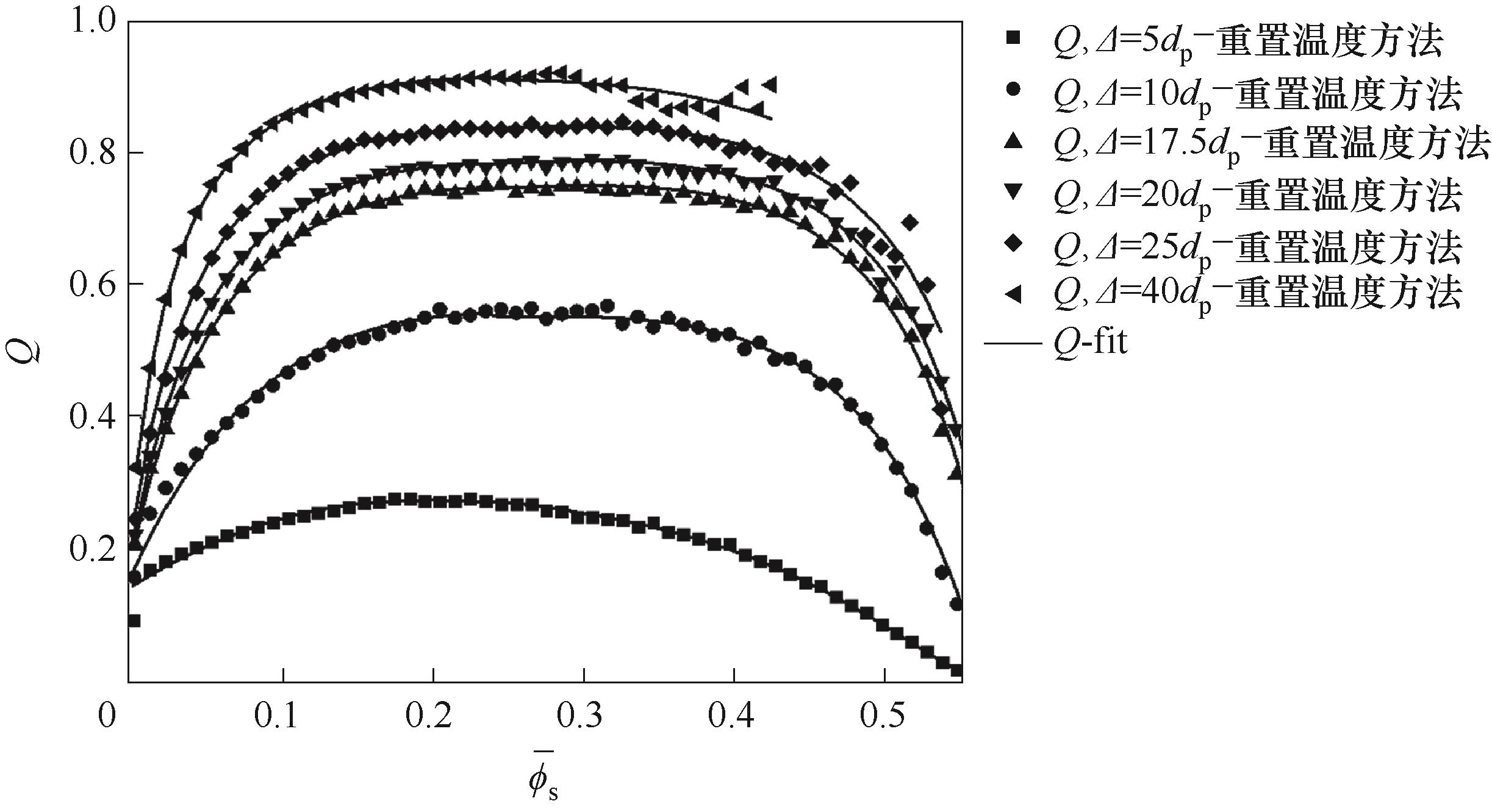

图9 重置温度方法下介尺度模型拟合Q和真实Q随过滤固含率的变化

Fig.9 The variation of fitting Q obtained by the mesoscale model and real Q with the filtered solid volume fraction under the resetting temperature method

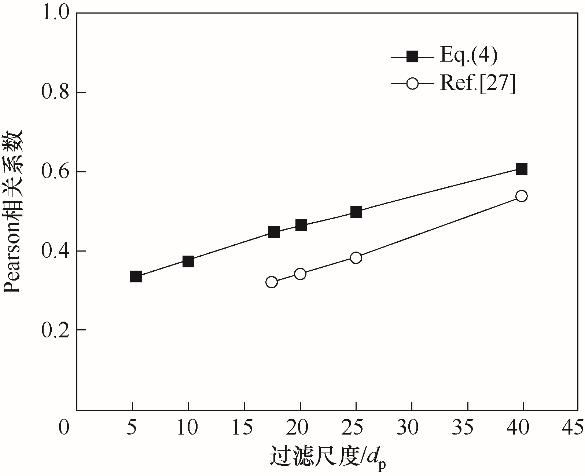

图10 不同过滤尺度下模型预测值(Qpredict)与粗网格过滤值(Qexact)的Pearson相关系数

Fig.10 Pearson correlation coefficients between Qpredict and Qexact under different filter sizes

图11 不同过滤尺度下模型预测值(Qpredict)与粗网格过滤值(Qexact)相对误差的概率密度分布

Fig.11 The probability density distribution(PDF) of relative errors between Qpredict and Qexact at different filter sizes

| 1 | Tavassoli H, Peters E A J F, Kuipers J A M. Direct numerical simulation of non-isothermal flow through dense bidisperse random arrays of spheres[J]. Powder Technology, 2017, 314: 291-298. |

| 2 | Agrawal K, Loezos P N, Syamlal M, et al. The role of meso-scale structures in rapid gas–solid flows[J]. Journal of Fluid Mechanics, 2001, 445: 151-185. |

| 3 | Li J H, Kwauk M. Multiscale nature of complex fluid-particle systems[J]. Industrial & Engineering Chemistry Research, 2001, 40(20): 4227-4237. |

| 4 | Helland E, Bournot H, Occelli R, et al. Drag reduction and cluster formation in a circulating fluidised bed[J]. Chemical Engineering Science, 2007, 62(1/2): 148-158. |

| 5 | Sundaresan S. Modeling the hydrodynamics of multiphase flow reactors: current status and challenges[J]. AIChE Journal, 2000, 46(6): 1102-1105. |

| 6 | Wang S Y, Yin L J, Lu H L, et al. Numerical analysis of interphase heat and mass transfer of cluster in a circulating fluidized bed[J]. Powder Technology, 2009, 189(1): 87-96. |

| 7 | Wang S, Luo K, Hu C S, et al. CFD-DEM simulation of heat transfer in fluidized beds: model verification, validation, and application[J]. Chemical Engineering Science, 2019, 197: 280-295. |

| 8 | Baltussen M W, Buist K A, Peters E A J F, et al. Multiscale modelling of dense gas-particle flows[J]. Advances in Chemical Engineering, 2018, 53: 1-52. |

| 9 | Igci Y, Andrews A T, Sundaresan S, et al. Filtered two-fluid models for fluidized gas-particle suspensions[J]. AIChE Journal, 2008, 54(6): 1431-1448. |

| 10 | Igci Y, Sundaresan S. Constitutive models for filtered two-fluid models of fluidized gas-particle flows[J]. Industrial & Engineering Chemistry Research, 2011, 50(23): 13190-13201. |

| 11 | 王维, 洪坤, 鲁波娜, 等. 流态化模拟: 基于介尺度结构的多尺度CFD[J]. 化工学报, 2013, 64(1): 95-106. |

| Wang W, Hong K, Lu B N, et al. Fluidized bed simulation: structure-dependent multiscale CFD[J]. CIESC Journal, 2013, 64(1): 95-106. | |

| 12 | Cloete J H, Cloete S, Radl S, et al. On the choice of closure complexity in anisotropic drag closures for filtered Two Fluid Models[J]. Chemical Engineering Science, 2019, 207: 379-396. |

| 13 | Li J, Kwauk M. Particle-Fluid Two-Phase Flow: the Energy-Minimization Multi-Scale Method[M]. Beijing: Metallurgy Industry Press, 1994. |

| 14 | Yang N, Wang W, Ge W, et al. Simulation of heterogeneous structure in a circulating fluidized-bed riser by combining the two-fluid model with the EMMS approach[J]. Industrial & Engineering Chemistry Research, 2004, 43(18): 5548-5561. |

| 15 | Wang W, Li J H. Simulation of gas-solid two-phase flow by a multi-scale CFD approach—extension of the EMMS model to the sub-grid level[J]. Chemical Engineering Science, 2007, 62(1/2): 208-231. |

| 16 | Sundaresan S, Ozel A, Kolehmainen J. Toward constitutive models for momentum, species, and energy transport in gas-particle flows[J]. Annual Review of Chemical and Biomolecular Engineering, 2018, 9: 61-81. |

| 17 | Gao X, Li T W, Sarkar A, et al. Development and validation of an enhanced filtered drag model for simulating gas-solid fluidization of Geldart A particles in all flow regimes[J]. Chemical Engineering Science, 2018, 184: 33-51. |

| 18 | Jiang M, Chen X, Zhou Q. A gas pressure gradient-dependent subgrid drift velocity model for drag prediction in fluidized gas–particle flows[J]. AIChE Journal, 2020, 66(4): e16884. |

| 19 | Dong W G, Wang W, Li J H. A multiscale mass transfer model for gas-solid riser flows(Ⅰ):Sub-grid model and simple tests[J]. Chemical Engineering Science, 2008, 63(10): 2798-2810. |

| 20 | Hou B L, Li H Z. Relationship between flow structure and transfer coefficients in fast fluidized beds[J]. Chemical Engineering Journal, 2010, 157(2/3): 509-519. |

| 21 | 鲁波娜, 程从礼, 鲁维民, 等. 基于多尺度模型的MIP提升管反应历程数值模拟[J]. 化工学报, 2013, 64(6): 1983-1992. |

| Lu B N, Cheng C L, Lu W M, et al. Numerical simulation of reaction process in MIP riser based on multi-scale model[J]. CIESC Journal, 2013, 64(6): 1983-1992. | |

| 22 | Shu Z, Wang J W, Zhou Q, et al. Evaluation of multifluid model for heat transfer behavior of binary gas-solid flow in a downer reactor[J]. Powder Technology, 2015, 281: 34-48. |

| 23 | Guo L, Capecelatro J. The role of clusters on heat transfer in sedimenting gas-solid flows[J]. International Journal of Heat and Mass Transfer, 2019, 132: 1217-1230. |

| 24 | Lane W A, Sarkar A, Sundaresan S, et al. Sub-grid models for heat transfer in gas-particle flows with immersed horizontal cylinders[J]. Chemical Engineering Science, 2016, 151: 7-15. |

| 25 | Lane W A, Ryan E M. Verification, validation, and uncertainty quantification of a sub-grid model for heat transfer in gas-particle flows with immersed horizontal cylinders[J]. Chemical Engineering Science, 2018, 176: 409-420. |

| 26 | Rauchenzauner S, Schneiderbauer S. A dynamic spatially averaged two-fluid model for heat transport in moderately dense gas-particle flows[J]. Physics of Fluids, 2020, 32(6): 063307. |

| 27 | Agrawal K, Holloway W, Milioli C C, et al. Filtered models for scalar transport in gas-particle flows[J]. Chemical Engineering Science, 2013, 95: 291-300. |

| 28 | Huang Z Q, Zhang C, Jiang M, et al. Development of a filtered interphase heat transfer model based on fine-grid simulations of gas–solid flows[J]. AIChE Journal, 2020, 66(1): e16755. |

| 29 | Li Y, Yu Y X, Zhang C, et al. Improved filtered mesoscale interphase heat transfer model[J]. Particuology, 2021, 57: 176-186. |

| 30 | Lei H, Zhu L T, Luo Z H. Study of filtered interphase heat transfer using highly resolved CFD–DEM simulations[J]. AIChE Journal, 2021, 67(4): e17121. |

| 31 | Capecelatro J, Desjardins O, Fox R O. Numerical study of collisional particle dynamics in cluster-induced turbulence[J]. Journal of Fluid Mechanics, 2014, 747: R2. |

| 32 | Ozel A, Kolehmainen J, Radl S, et al. Fluid and particle coarsening of drag force for discrete-parcel approach[J]. Chemical Engineering Science, 2016, 155: 258-267. |

| 33 | Garg R, Galvin J, Li T W, et al. Open-source MFIX-DEM software for gas-solids flows(Ⅰ): Verification studies[J]. Powder Technology, 2012, 220: 122-137. |

| 34 | Hou Q F, Zhou Z Y, Yu A B. Computational study of heat transfer in a bubbling fluidized bed with a horizontal tube[J]. AIChE Journal, 2012, 58(5): 1422-1434. |

| 35 | Gunn D J. Transfer of heat or mass to particles in fixed and fluidised beds[J]. International Journal of Heat and Mass Transfer, 1978, 21(4): 467-476. |

| 36 | Yu Y X, Li Y, Jiang M, et al. Meso-scale drag model designed for coarse-grid Eulerian-Lagrangian simulation of gas-solid flows[J]. Chemical Engineering Science, 2020, 223: 115747. |

| 37 | Ozel A, Gu Y L, Milioli C C, et al. Towards filtered drag force model for non-cohesive and cohesive particle-gas flows[J]. Physics of Fluids, 2017, 29(10): 103308. |

| 38 | Wang J W, van der Hoef M A, Kuipers J A M. Why the two-fluid model fails to predict the bed expansion characteristics of Geldart A particles in gas-fluidized beds: a tentative answer[J]. Chemical Engineering Science, 2009, 64(3): 622-625. |

| 39 | Fullmer W D, Hrenya C M. Quantitative assessment of fine-grid kinetic-theory-based predictions of mean-slip in unbounded fluidization[J]. AIChE Journal, 2016, 62(1): 11-17. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [4] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [5] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [6] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [7] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [8] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [9] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [10] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [11] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [12] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [13] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [14] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [15] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号