化工学报 ›› 2022, Vol. 73 ›› Issue (7): 2874-2884.DOI: 10.11949/0438-1157.20220297

蔡楚玥1( ),方晓明1,2,张正国1,2,3(

),方晓明1,2,张正国1,2,3( ),凌子夜1,2

),凌子夜1,2

收稿日期:2022-03-02

修回日期:2022-04-24

出版日期:2022-07-05

发布日期:2022-08-01

通讯作者:

张正国

作者简介:蔡楚玥(1997—),女,硕士研究生,基金资助:

Chuyue CAI1( ),Xiaoming FANG1,2,Zhengguo ZHANG1,2,3(

),Xiaoming FANG1,2,Zhengguo ZHANG1,2,3( ),Ziye LING1,2

),Ziye LING1,2

Received:2022-03-02

Revised:2022-04-24

Online:2022-07-05

Published:2022-08-01

Contact:

Zhengguo ZHANG

摘要:

电子技术的高速发展对散热技术提出了更高的要求,热界面材料作为散热技术的关键材料之一,面临着提高热导率以及减小传热热阻的挑战。将垂直碳纳米管阵列(VACNTs)和固-液相变材料石蜡(PA)与硅橡胶(SR)复合,研制了一种新型VACNTs/PA/SR复合相变垫片。研究表明,通过磁场校准方法可以使表面改性的镀镍多壁CNTs在SR中实现垂直定向排列,所得VACNTs/SR垫片较CNTs随机排列的垫片具有更高的热导率,并确定VACNTs/SR垫片中CNTs的适宜含量为6%(质量),对应垫片的热导率可达0.71 W/(m·K)。对于固定CNTs含量为6%(质量)但PA含量不同的一系列VACNTs/PA/SR相变垫片,PA的添加量不大于12.5%(质量)时,相变垫片克服了液态PA的泄漏问题;相变垫片在PA发生固-液相变后表现出硬度显著下降,热阻减少可达55.14%,并具备优异的热可靠性。将最佳VACNTs/SR垫片样品及最佳VACNTs/PA/SR相变垫片样品进行散热性能对比发现,与使用VACNTs/SR垫片的情况相比,使用VACNTs/PA/SR相变垫片时的模拟芯片不仅在温度上升阶段的升温速率更小,而且当芯片温度达到平衡后对应的平衡温度也更低,降低了3.5℃,显示出更好的散热性能。VACNTs/PA/SR相变垫片优良的特性和散热性能使其在电子设备散热领域具有良好的应用前景。

中图分类号:

蔡楚玥, 方晓明, 张正国, 凌子夜. CNTs阵列增强石蜡/硅橡胶复合相变垫片的散热性能研究[J]. 化工学报, 2022, 73(7): 2874-2884.

Chuyue CAI, Xiaoming FANG, Zhengguo ZHANG, Ziye LING. Enhancing heat dissipation performance of paraffin/silicone rubber phase change thermal pad by introducing carbon nanotubes[J]. CIESC Journal, 2022, 73(7): 2874-2884.

图4 不同静置时间下样品在硅油中的分散情况照片A—CNTs; B—氧化CNTs; C—表面改性CNTs

Fig.4 Photographs of different CNTs dispersions at different storing durationsA—CNTs; B—acid treated CNTs; C—surface modified CNTs

| 样品 | w/% | Tm/℃ | Hm/(J/g) | Tf/℃ | Hf/(J/g) | η/% |

|---|---|---|---|---|---|---|

| PA | 100 | 49.0 | 199.1 | 52.4 | 198.7 | 100 |

| PCTIM-1 | 5.0 | 51.8 | 8.5 | 53.0 | 7.8 | 4.1 |

| PCTIM-2 | 7.5 | 51.0 | 12.9 | 52.2 | 12.1 | 6.3 |

| PCTIM-3 | 10.0 | 51.0 | 17.7 | 52.6 | 17.1 | 8.8 |

| PCTIM-4 | 12.5 | 50.5 | 23.7 | 53.2 | 23.2 | 11.8 |

| PCTIM-5 | 15.0 | 50.1 | 26.6 | 52.8 | 25.8 | 13.2 |

表1 含有不同质量分数PA相变垫片的相变特性

Table 1 Phase change characteristics of phase change thermal pads containing different mass fractions of PA

| 样品 | w/% | Tm/℃ | Hm/(J/g) | Tf/℃ | Hf/(J/g) | η/% |

|---|---|---|---|---|---|---|

| PA | 100 | 49.0 | 199.1 | 52.4 | 198.7 | 100 |

| PCTIM-1 | 5.0 | 51.8 | 8.5 | 53.0 | 7.8 | 4.1 |

| PCTIM-2 | 7.5 | 51.0 | 12.9 | 52.2 | 12.1 | 6.3 |

| PCTIM-3 | 10.0 | 51.0 | 17.7 | 52.6 | 17.1 | 8.8 |

| PCTIM-4 | 12.5 | 50.5 | 23.7 | 53.2 | 23.2 | 11.8 |

| PCTIM-5 | 15.0 | 50.1 | 26.6 | 52.8 | 25.8 | 13.2 |

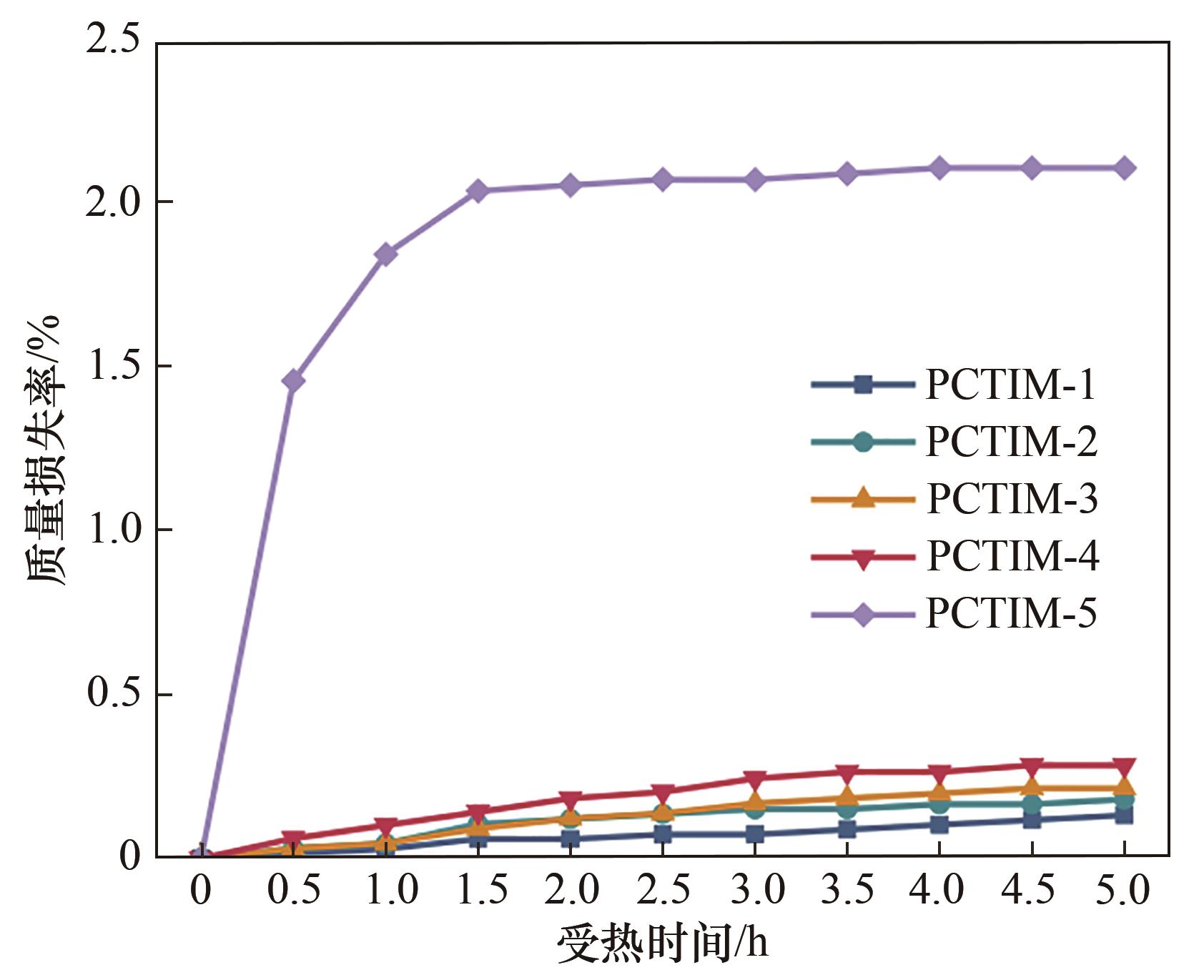

图9 不同PA质量分数的VACNTs/PA/SR相变垫片在加热过程中的质量损失率

Fig.9 Mass loss percentages of the phase change thermal pads containing different mass fractions of PA during the heating

图10 含有不同PA质量分数的VACNTs/PA/SR相变垫片的热导率、硬度及热阻

Fig.10 Thermal conductivity, hardness, and resistance of the thermal pads containing different mass fractions of PA under different temperature

图12 在不同功率下不使用垫片(空载)和使用不同垫片时模拟芯片的温升曲线

Fig.12 Temperature rise curves of the simulative chip when employing no thermal pads and the different thermal pads at different heating power

| 功率/W | T空载/℃ | TTIM/℃ | TPCTIM/℃ | ΔT/℃ |

|---|---|---|---|---|

| 100 | 141.0 | 130.6 | 129.5 | 1.1 |

| 30 | 109.1 | 98.2 | 96.5 | 1.7 |

| 20 | 81.4 | 71.9 | 69.8 | 2.1 |

| 10 | 57.0 | 48.7 | 45.2 | 3.5 |

表2 在不同功率下不使用(空载)和使用不同垫片时模拟芯片的平衡温度

Table 2 Equilibrium temperatures of the simulative chip when employing no TIM and different TIMs at different heating power

| 功率/W | T空载/℃ | TTIM/℃ | TPCTIM/℃ | ΔT/℃ |

|---|---|---|---|---|

| 100 | 141.0 | 130.6 | 129.5 | 1.1 |

| 30 | 109.1 | 98.2 | 96.5 | 1.7 |

| 20 | 81.4 | 71.9 | 69.8 | 2.1 |

| 10 | 57.0 | 48.7 | 45.2 | 3.5 |

| 性能参数 | TIM-6 | PCTIM-4 |

|---|---|---|

| 热导率/(W/(m·K)) | 0.71 | 0.71 |

| 厚度/mm | 0.98 | 0.98 |

| 硬度/HA | 47.5 | 34.7 |

| 热阻/(K·cm2/W) | 19.1483 | 15.2650 |

表3 TIM-6和PCTIM-4的特性参数

Table 3 Characteristics of TIM-6 and PCTIM-4

| 性能参数 | TIM-6 | PCTIM-4 |

|---|---|---|

| 热导率/(W/(m·K)) | 0.71 | 0.71 |

| 厚度/mm | 0.98 | 0.98 |

| 硬度/HA | 47.5 | 34.7 |

| 热阻/(K·cm2/W) | 19.1483 | 15.2650 |

| 1 | 刘长青, 陈茂, 于伟. 热界面材料的研究进展[J]. 中国基础科学, 2018, 20(3): 13-27, 64. |

| Liu C Q, Chen M, Yu W. Progress in the research of thermal interface materials[J]. China Basic Science, 2018, 20(3): 13-27, 64. | |

| 2 | 高丽娜, 赵领. 温度应力下基于步进加速退化试验的电子器件寿命预测[J]. 电子元件与材料, 2014, 33(6): 72-76. |

| Gao L N, Zhao L. Life prediction of electronic equipments based on step-stress accelerated degradation test under temperature stress[J]. Electronic Components and Materials, 2014, 33(6): 72-76. | |

| 3 | 汪琦玮. 热界面材料的界面热阻问题研究[D]. 武汉: 华中科技大学, 2019. |

| Wang Q W. Study on the interfacial thermal resistance of thermal interface materials[D]. Wuhan: Huazhong University of Science and Technology, 2019. | |

| 4 | 侯思雨, 闫焕焕, 任芳, 等. 高分子复合材料导热性能的研究进展[J]. 合成材料老化与应用, 2020, 49(6): 135-138, 83. |

| Hou S Y, Yan H H, Ren F, et al. Research progress on thermal conducting polymer composites[J]. Synthetic Materials Aging and Application, 2020, 49(6): 135-138, 83. | |

| 5 | Liu C Q, Chen C, Yu W, et al. Thermal properties of a novel form-stable phase change thermal interface materials olefin block copolymer/paraffin filled with Al2O3 [J]. International Journal of Thermal Sciences, 2020, 152: 106293. |

| 6 | Mao D S, Chen J H, Ren L L, et al. Spherical core-shell Al@Al2O3 filled epoxy resin composites as high-performance thermal interface materials[J]. Composites Part A: Applied Science and Manufacturing, 2019, 123: 260-269. |

| 7 | Barshutina M N, Volkov V S, Arsenin A V, et al. Silicone composites with CNT/graphene hybrid fillers: a review[J]. Materials (Basel, Switzerland), 2021, 14(9): 2418. |

| 8 | Kim P, Shi L, Majumdar A, et al. Thermal transport measurements of individual multiwalled nanotubes[J]. Physical Review Letters, 2001, 87(21): 215502. |

| 9 | 桑亚非, 赫玉欣, 张丽, 等. 长链硅烷偶联剂对多壁碳纳米管表面改性研究[J]. 化工新型材料, 2017, 45(3): 69-71. |

| Sang Y F, He Y X, Zhang L, et al. Long chain silane coupling agent used for surface modification of multi-walled carbon nanotubes[J]. New Chemical Materials, 2017, 45(3): 69-71. | |

| 10 | Li M, Chen M R, Wu Z S, et al. Carbon nanotube grafted with polyalcohol and its influence on the thermal conductivity of phase change material[J]. Energy Conversion and Management, 2014, 83: 325-329. |

| 11 | Li M, Guo Q G, Chen Q W. Thermal conductivity improvement of heat-storage composite filled with milling modified carbon nanotubes[J]. International Journal of Green Energy, 2019, 16(15): 1617-1623. |

| 12 | Ganguli S, Roy A K, Wheeler R, et al. Superior thermal interface via vertically aligned carbon nanotubes grown on graphite foils[J]. Journal of Materials Research, 2013, 28(7): 933-939. |

| 13 | Huang H, Liu C , Wu Y, et al. Aligned carbon nanotube composite films for thermal management[J]. Advanced Materials, 2005, 17(13): 1652-1656. |

| 14 | Yu H T, Feng Y Y, Chen C, et al. Thermally conductive, self-healing, and elastic Polyimide@Vertically aligned carbon nanotubes composite as smart thermal interface material[J]. Carbon, 2021, 179: 348-357. |

| 15 | Peacock M A, Roy C K, Hamilton M C, et al. Characterization of transferred vertically aligned carbon nanotubes arrays as thermal interface materials[J]. International Journal of Heat and Mass Transfer, 2016, 97: 94-100. |

| 16 | Sakamoto H, Fujiwara I, Takamura E, et al. Nanofiber-guided orientation of electrospun carbon nanotubes and fabrication of aligned CNT electrodes for biodevice applications[J]. Materials Chemistry and Physics, 2020, 245: 122745. |

| 17 | Wu G, Zhan H, Shi Q Q, et al. Full on-line preparation of polymer composites reinforced with aligned carbon nanotubes[J]. Composites Science and Technology, 2020, 200: 108472. |

| 18 | Sharma A, Tripathi B, Vijay Y K. Dramatic improvement in properties of magnetically aligned CNT/polymer nanocomposites[J]. Journal of Membrane Science, 2010, 361(1/2): 89-95. |

| 19 | Haibat J, Ceneviva S, Spencer M P, et al. Preliminary demonstration of energy-efficient fabrication of aligned CNT-polymer nanocomposites using magnetic fields[J]. Composites Science and Technology, 2017, 152: 27-35. |

| 20 | Liu Z R, Chung D D L. Boron nitride particle filled paraffin wax as a phase-change thermal interface material[J]. Journal of Electronic Packaging, 2006, 128(4): 319-323. |

| 21 | 仝兴存, 安兵, 吕卫文, 等. 电子封装热管理先进材料[M]. 北京:国防工业出版社, 2016. |

| Tong X C, An B, Lyu W W, et al. Advanced Materials for Thermal Management of Electronic Packaging[M]. Beijing: National Defense Industry Press, 2016. | |

| 22 | 邓志军, 万炜涛, 陈田安. 一种橡胶改性的相变导热界面材料及制备方法: 105441034A[P]. 2019-07-26. |

| Deng Z J, Wan W T, Chen T A. Rubber modified phase change heat conduction interface material and preparation method: 105441034A[P]. 2019-07-26. | |

| 23 | 史剑, 吴晓琳, 符显珠, 等. 复合相变垫片研究进展[J]. 材料导报, 2015, 29(1): 151-156. |

| Shi J, Wu X L, Fu X Z, et al. Research progress of phase change thermal interface materials[J]. Materials Review, 2015, 29(1): 151-156. | |

| 24 | Aoyagi Y, Leong C K, Chung D D L. Polyol-based phase-change thermal interface materials[J]. Journal of Electronic Materials, 2006, 35(3): 416-424. |

| 25 | Lee S Y, Singh P, Mahajan R L. Role of oxygen functional groups for improved performance of graphene-silicone composites as a thermal interface material[J]. Carbon, 2019, 145: 131-139. |

| 26 | Feng J, Liu Z J, Zhang D Q, et al. Phase change materials coated with modified graphene-oxide as fillers for silicone rubber used in thermal interface applications[J]. New Carbon Materials, 2019, 34(2): 188-195. |

| 27 | Feng C P, Yang L Y, Yang J, et al. Recent advances in polymer-based thermal interface materials for thermal management: a mini-review[J]. Composites Communications, 2020, 22: 100528. |

| 28 | Zhang Y F, Li W, Huang J H, et al. Expanded graphite/paraffin/silicone rubber as high temperature form-stabilized phase change materials for thermal energy storage and thermal interface materials[J]. Materials (Basel, Switzerland), 2020, 13(4): 894. |

| 29 | 李庆威. 碳纳米管热传导研究[D]. 北京: 清华大学, 2010. |

| Li Q W. Studies on thermal conductance of carbon nanotubes[D]. Beijing: Tsinghua University, 2010. | |

| 30 | Feng Y, Zhu J, Tang D W. Dependence of carbon nanotube array-silicon interface thermal conductance on array arrangement and filling fraction[J]. Applied Thermal Engineering, 2018, 145: 667-673. |

| 31 | Feng Y, Zhu J, Tang D W. Effect of van der Waals forces on thermal conductance at the interface of a single-wall carbon nanotube array and silicon[J]. AIP Advances, 2014, 4(12): 127118. |

| 32 | Zhou W X, Cheng Y, Chen K Q, et al. Thermal conductivity of amorphous materials[J]. Advanced Functional Materials, 2020, 30(8): 1903829. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [4] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [5] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [6] | 申利梅, 胡博兴, 谢雨霏, 曾伟豪, 张晓屿. 超薄平板热管传热性能的实验研究[J]. 化工学报, 2023, 74(S1): 198-205. |

| [7] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [8] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [9] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [10] | 吴延鹏, 刘乾隆, 田东民, 陈凤君. 相变材料与热管耦合的电子器件热管理研究进展[J]. 化工学报, 2023, 74(S1): 25-31. |

| [11] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [12] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [13] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [14] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [15] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号