化工学报 ›› 2022, Vol. 73 ›› Issue (10): 4780-4790.DOI: 10.11949/0438-1157.20220805

• 过程安全 • 上一篇

吴一1( ), 温小萍1(

), 温小萍1( ), 张素梅1, 郭志东2, 邓浩鑫1, 纪文涛3

), 张素梅1, 郭志东2, 邓浩鑫1, 纪文涛3

收稿日期:2022-06-08

修回日期:2022-07-05

出版日期:2022-10-05

发布日期:2022-11-02

通讯作者:

温小萍

作者简介:吴一(1998—),男,硕士研究生,414151937@qq.com

基金资助:

Yi WU1( ), Xiaoping WEN1(

), Xiaoping WEN1( ), Sumei ZHANG1, Zhidong GUO2, Haoxin DENG1, Wentao JI3

), Sumei ZHANG1, Zhidong GUO2, Haoxin DENG1, Wentao JI3

Received:2022-06-08

Revised:2022-07-05

Online:2022-10-05

Published:2022-11-02

Contact:

Xiaoping WEN

摘要:

为了研究垂直圆管内掺氢甲烷燃烧的不稳定性,自行搭建了上端为开口下端为闭口的透明圆形燃烧管道(半径

中图分类号:

吴一, 温小萍, 张素梅, 郭志东, 邓浩鑫, 纪文涛. 垂直圆管内掺氢甲烷燃烧不稳定性研究[J]. 化工学报, 2022, 73(10): 4780-4790.

Yi WU, Xiaoping WEN, Sumei ZHANG, Zhidong GUO, Haoxin DENG, Wentao JI. Study on combustion instability of hydrogen methane-doped in vertical circular tubes[J]. CIESC Journal, 2022, 73(10): 4780-4790.

| 工况 | 当量比 | CH4/% | H2/% | Air/% | 声速 | |

|---|---|---|---|---|---|---|

| 1 | 1 | 10 | 9.17 | 1.02 | 89.81 | 354 |

| 2 | 1 | 20 | 8.80 | 2.20 | 89.00 | 356 |

| 3 | 1 | 30 | 8.35 | 3.58 | 88.07 | 358 |

| 4 | 1 | 35 | 8.10 | 4.36 | 87.54 | 359 |

| 5 | 1 | 40 | 7.83 | 5.22 | 86.95 | 361 |

| 6 | 1 | 45 | 7.52 | 6.16 | 86.32 | 362 |

| 7 | 1 | 50 | 7.19 | 7.19 | 85.62 | 364 |

| 8 | 1 | 55 | 6.82 | 8.34 | 84.84 | 366 |

| 9 | 1 | 60 | 6.41 | 9.62 | 83.97 | 368 |

| 10 | 1 | 65 | 5.95 | 11.05 | 83.00 | 371 |

| 11 | 1 | 70 | 5.43 | 12.67 | 81.90 | 373 |

表1 实验工况

Table 1 Experimental conditions

| 工况 | 当量比 | CH4/% | H2/% | Air/% | 声速 | |

|---|---|---|---|---|---|---|

| 1 | 1 | 10 | 9.17 | 1.02 | 89.81 | 354 |

| 2 | 1 | 20 | 8.80 | 2.20 | 89.00 | 356 |

| 3 | 1 | 30 | 8.35 | 3.58 | 88.07 | 358 |

| 4 | 1 | 35 | 8.10 | 4.36 | 87.54 | 359 |

| 5 | 1 | 40 | 7.83 | 5.22 | 86.95 | 361 |

| 6 | 1 | 45 | 7.52 | 6.16 | 86.32 | 362 |

| 7 | 1 | 50 | 7.19 | 7.19 | 85.62 | 364 |

| 8 | 1 | 55 | 6.82 | 8.34 | 84.84 | 366 |

| 9 | 1 | 60 | 6.41 | 9.62 | 83.97 | 368 |

| 10 | 1 | 65 | 5.95 | 11.05 | 83.00 | 371 |

| 11 | 1 | 70 | 5.43 | 12.67 | 81.90 | 373 |

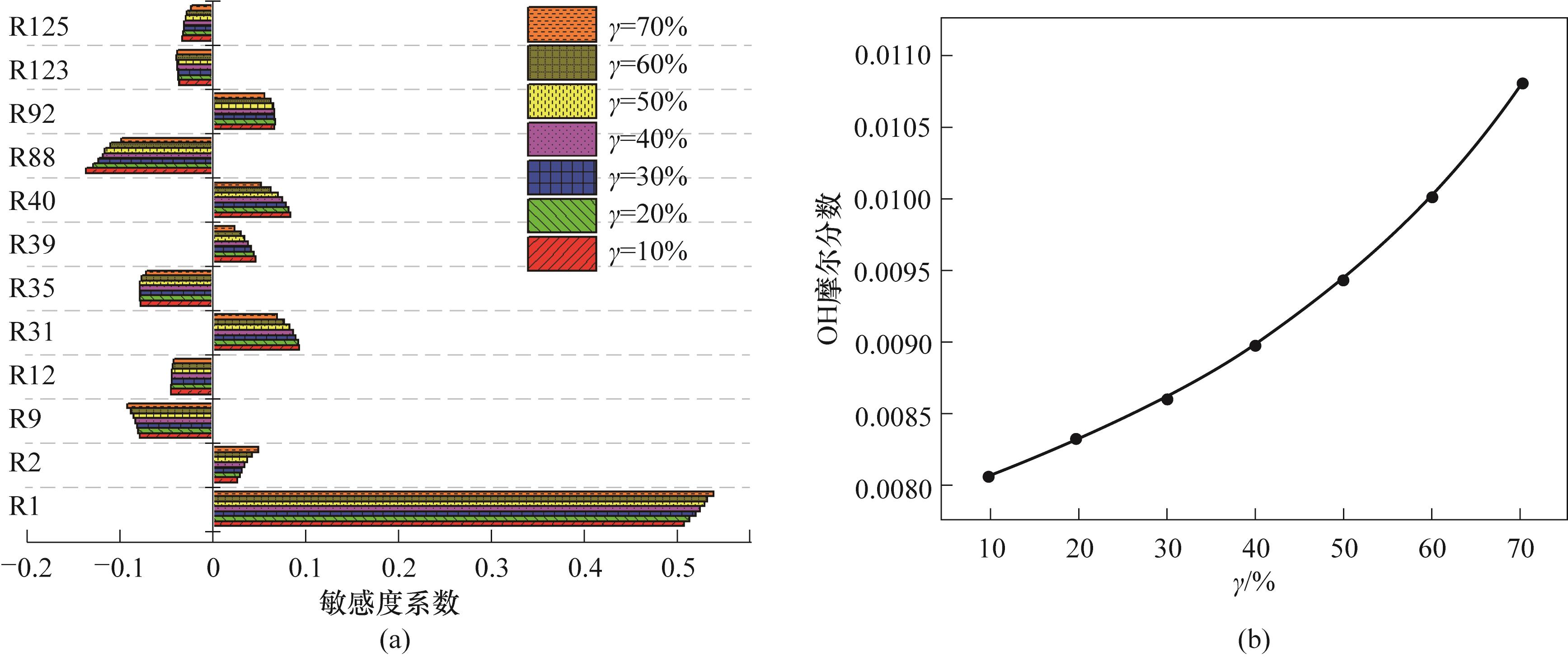

图11 主要链式反应的敏感度系数和OH自由基摩尔分数的最大值

Fig.11 The sensitivity coefficients for main chain reactions and the maximum value of the OH free radical molar fraction

| 反应序号 | 主要链式反应 | 反应序号 | 主要链式反应 |

|---|---|---|---|

| R1 | H+O2 | R39 | HCO+M |

| R2 | O+H2 | R40 | HCO+H2O |

| R9 | H+OH+M | R88 | CH3+H(+M) |

| R12 | H+O2(+M) | R92 | CH3+OH |

| R31 | CO+OH | R123 | CH4+H |

| R35 | HCO+H | R125 | CH4+OH |

表2 主要链式反应

Table 2 Main chain reactions

| 反应序号 | 主要链式反应 | 反应序号 | 主要链式反应 |

|---|---|---|---|

| R1 | H+O2 | R39 | HCO+M |

| R2 | O+H2 | R40 | HCO+H2O |

| R9 | H+OH+M | R88 | CH3+H(+M) |

| R12 | H+O2(+M) | R92 | CH3+OH |

| R31 | CO+OH | R123 | CH4+H |

| R35 | HCO+H | R125 | CH4+OH |

| 1 | Law C K. Combustion at a crossroads: status and prospects[J]. Proceedings of the Combustion Institute, 2007, 31(1): 1-29 |

| 2 | Park J W, Oh C B. Flame structure and global flame response to the equivalence ratios of interacting partially premixed methane and hydrogen flames[J]. International Journal of Hydrogen Energy, 2012, 37(9): 7877-7888. |

| 3 | Lee S D, Chung S H. On the structure and extinction of interacting lean methane/air premixed flames[J]. Combustion and Flame, 1994, 98(1/2): 80-92. |

| 4 | Verhelst S, Wallner T. Hydrogen-fueled internal combustion engines[J]. Progress in Energy and Combustion Science, 2009, 35(6): 490-527. |

| 5 | 余明高, 袁晨樵, 郑凯. 管道内障碍物对加氢甲烷爆炸特性的影响[J]. 化工学报, 2016, 67(12): 5311-5319. |

| Yu M G, Yuan C Q, Zheng K. Effects of hydrogen addition on explosion characteristics of gas under condition of obstacles[J]. CIESC Journal, 2016, 67(12): 5311-5319. | |

| 6 | Law C K, Kwon O C. Effects of hydrocarbon substitution on atmospheric hydrogen-air flame propagation[J]. International Journal of Hydrogen Energy, 2004, 29(8): 867-879. |

| 7 | Sánchez A L, Williams F A. Recent advances in understanding of flammability characteristics of hydrogen[J]. Progress in Energy and Combustion Science, 2014, 41: 1-55. |

| 8 | Okafor E C, Hayakawa A, Nagano Y, et al. Effects of hydrogen concentration on premixed laminar flames of hydrogen-methane-air[J]. International Journal of Hydrogen Energy, 2014, 39(5): 2409-2417. |

| 9 | Woolley R M, Fairweather M, Falle S A E G, et al. Prediction of confined, vented methane-hydrogen explosions using a computational fluid dynamic approach[J]. International Journal of Hydrogen Energy, 2013, 38(16): 6904-6914. |

| 10 | Wu Y, Wen X P, Guo Z D, et al. Experimental study on the propagation characteristics of hydrogen/methane/air premixed flames in a narrow channel[J]. International Journal of Hydrogen Energy, 2022, 47(9): 6377-6387. |

| 11 | Wen X P, Guo Z D, Wang F H, et al. Experimental study on the quenching process of methane/air deflagration flame with porous media[J]. Journal of Loss Prevention in the Process Industries, 2020, 65: 104121. |

| 12 | Wang F H, Chen W, Wen X P, et al. Numerical simulation and mechanism analysis of gas explosion suppression by ultrasonic water mist[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2019, 41(23): 2821-2833. |

| 13 | Landau L. On the theory of slow combustion[M]//Dynamics of Curved Fronts. Amsterdam: Elsevier, 1988: 403-411. |

| 14 | Landau L D, Lifshitz E M. Fluid Mechanics: Landau and Lifshitz: Course of Theoretical Physics[M]. Amsterdam: Elsevier, 2013. |

| 15 | Lieuwen T C. Unsteady Combustor Physics[M]. Cambridge: Cambridge University Press, 2021. |

| 16 | Poinsot T. Prediction and control of combustion instabilities in real engines[J]. Proceedings of the Combustion Institute, 2017, 36(1): 1-28. |

| 17 | Searby G, Rochwerger D. A parametric acoustic instability in premixed flames[J]. Journal of Fluid Mechanics, 1991, 231: 529-543. |

| 18 | Searby G. Acoustic instability in premixed flames[J]. Combustion Science and Technology, 1992, 81(4/5/6): 221-231. |

| 19 | Clanet C, Searby G, Clavin P. Primary acoustic instability of flames propagating in tubes: cases of spray and premixed gas combustion[J]. Journal of Fluid Mechanics, 1999, 385: 157-197. |

| 20 | Aldredge R C, Killingsworth N J. Experimental evaluation of Markstein-number influence on thermoacoustic instability[J]. Combustion and Flame, 2004, 137(1/2): 178-197. |

| 21 | Yoon S H, Noh T J, Fujita O. Effects of Lewis number on generation of primary acoustic instability in downward-propagating flames[J]. Proceedings of the Combustion Institute, 2017, 36(1): 1603-1611. |

| 22 | Dubey A K, Koyama Y, Hashimoto N, et al. Experimental and theoretical study of secondary acoustic instability of downward propagating flames: higher modes and growth rates[J]. Combustion and Flame, 2019, 205: 316-326. |

| 23 | Dubey A K, Koyama Y, Hashimoto N, et al. Effect of geometrical parameters on thermo-acoustic instability of downward propagating flames in tubes[J]. Proceedings of the Combustion Institute, 2019, 37(2): 1869-1877. |

| 24 | 韦双明, 余明高, 裴蓓, 等. 三元混合气体燃料爆炸特性实验研究[J]. 化工学报, 2022, 73(1): 451-460. |

| Wei S M, Yu M G, Pei B, et al. Experimental study on explosion characteristics of ternary mixed gas fuel[J]. CIESC Journal, 2022, 73(1): 451-460. | |

| 25 | 郑立刚, 朱小超, 于水军, 等. 浓度和点火位置对氢气-空气预混气爆燃特性影响[J]. 化工学报, 2019, 70(1): 408-416. |

| Zheng L G, Zhu X C, Yu S J, et al. Effect of concentration and ignition position on characteristics of premixed hydrogen-air deflagration[J]. CIESC Journal, 2019, 70(1): 408-416. | |

| 26 | Beardsell G, Blanquart G. Impact of pressure fluctuations on the dynamics of laminar premixed flames[J]. Proceedings of the Combustion Institute, 2019, 37(2): 1895-1902. |

| 27 | Xiao H H, Wang Q S, He X C, et al. Experimental and numerical study on premixed hydrogen/air flame propagation in a horizontal rectangular closed duct[J]. International Journal of Hydrogen Energy, 2010, 35(3): 1367-1376. |

| 28 | Matalon M. Flame dynamics[J]. Proceedings of the Combustion Institute, 2009, 32(1): 57-82. |

| 29 | Jiménez C, Quinard J, Graña-Otero J, et al. Unsteady response of hydrogen and methane flames to pressure waves[J]. Combustion and Flame, 2012, 159(5): 1894-1908. |

| 30 | 时高龙, 温小萍, 王发辉, 等. 预混气体爆炸火焰与压力的耦合振荡特性[J]. 化工学报, 2019, 70(7): 2811-2818. |

| Shi G L, Wen X P, Wang F H, et al. Coupling oscillation characteristics of premixed gas explosion flame and pressure[J]. CIESC Journal, 2019, 70(7): 2811-2818. | |

| 31 | Emami S D, Rajabi M, Che Hassan C R, et al. Experimental study on premixed hydrogen/air and hydrogen-methane/air mixtures explosion in 90 degree bend pipeline[J]. International Journal of Hydrogen Energy, 2013, 38(32): 14115-14120. |

| 32 | Vaezi V, Aldredge R C. Laminar-flame instabilities in a Taylor-couette combustor[J]. Combustion and Flame, 2000, 121(1/2): 356-366. |

| 33 | Taniyama Y, Fujita O. Initiation and formation of the corrugated structure leading to the self-turbulization of downward propagating flames in a combustion tube with external laser absorption[J]. Combustion and Flame, 2014, 161(6): 1558-1565. |

| 34 | Diao S T, Wen X P, Guo Z D, et al. Experimental study of explosion dynamics of syngas flames in the narrow channel[J]. International Journal of Hydrogen Energy, 2022, 47(40): 17808-17820. |

| 35 | Ibrahim S S, Masri A R. The effects of obstructions on overpressure resulting from premixed flame deflagration[J]. Journal of Loss Prevention in the Process Industries, 2001, 14(3): 213-221. |

| 36 | Yanez J, Kuznetsov M, Grune J. Flame instability of lean hydrogen-air mixtures in a smooth open-ended vertical channel[J]. Combustion and Flame, 2015, 162(7): 2830-2839. |

| 37 | Wang H, You X Q, Joshi A V, et al. USC mech version Ⅱ. High-temperature combustion reaction model of H2/CO/ C1-C4 compounds[DB/OL]. (2007-05)[2022-06-08]. Ⅱ.htm. |

| 38 | 熊小鹤, 丁艳军, 操晓波, 等. 基于激波管装置的乙烯氧化实验研究与动力学机理分析[J]. 物理化学学报, 2016, 32(6): 1416-1423. |

| Xiong X H, Ding Y J, Cao X B, et al. Ethylene oxidation experimental study and kinetic mechanism analysis based on shock tube[J]. Acta Physico-Chimica Sinica, 2016, 32(6): 1416-1423. | |

| 39 | Yoon S H, Noh T J, Fujita O. Onset mechanism of primary acoustic instability in downward-propagating flames[J]. Combustion and Flame, 2016, 170: 1-11. |

| 40 | Sharma D, Mahapatra S, Garnayak S, et al. Development of the reduced chemical kinetic mechanism for combustion of H2/CO/C1-C4 hydrocarbons[J]. Energy & Fuels, 2021, 35(1): 718-742. |

| 41 | Pelcé P, Rochwerger D. Vibratory instability of cellular flames propagating in tubes[J]. Journal of Fluid Mechanics, 1992, 239: 293-307. |

| 42 | 王发辉, 孙悦, 温小萍, 等. 富氧条件下不同泄爆面积对CH4燃烧诱导快速相变的影响[J]. 安全与环境学报, 2021, 21(1): 109-116. |

| Wang F H, Sun Y, Wen X P, et al. Impact of the different venting areas on the combustion induced rapid phase transition(CRPT) by CH4/N2/O2-enriched mixture[J]. Journal of Safety and Environment, 2021, 21(1): 109-116. | |

| 43 | Guo Z D, Wen X P, Zhang S M, et al. Experimental study on the combustion-induced rapid phase transition of syngas/air mixtures under different conditions[J]. International Journal of Hydrogen Energy, 2020, 45(38): 19948-19955. |

| 44 | Di Benedetto A, Cammarota F, Di Sarli V, et al. Combustion-induced rapid-phase transition (cRPT) in CH4/CO2/O2-enriched mixtures[J]. Energy & Fuels, 2012, 26(8): 4799-4803. |

| 45 | Basco A, Cammarota F, Di Sarli V, et al. Theoretical analysis of anomalous explosion behavior for H2/CO/O2/N2 and CH4/O2/N2/CO2 mixtures in the light of combustion-induced rapid phase transition[J]. International Journal of Hydrogen Energy, 2015, 40(25): 8239-8247. |

| 46 | Nie B S, Yang L L, Ge B Q, et al. Chemical kinetic characteristics of methane/air mixture explosion and its affecting factors[J]. Journal of Loss Prevention in the Process Industries, 2017, 49: 675-682. |

| 47 | 余明高, 栾鹏鹏, 郑凯, 等. 管道内预混合成气爆炸特性[J]. 化工学报, 2018, 69(10): 4486-4494. |

| Yu M G, Luan P P, Zheng K, et al. Characteristics of premixed syngas/air explosion in horizontal duct[J]. CIESC Journal, 2018, 69(10): 4486-4494. | |

| 48 | Zheng K, Yu M G, Zheng L G, et al. Experimental study on premixed flame propagation of hydrogen/methane/air deflagration in closed ducts[J]. International Journal of Hydrogen Energy, 2017, 42(8): 5426-5438. |

| 49 | Yao Z F, Deng H X, Zhao W L, et al. Experimental study on explosion characteristics of premixed syngas/air mixture with different ignition positions and opening ratios[J]. Fuel, 2020, 279: 118426. |

| 50 | Clanet C, Searby G. On the“tulip flame”phenomenon[J]. Combustion and Flame, 1996, 105(1/2): 225-238. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 刘晓洋, 喻健良, 侯玉洁, 闫兴清, 张振华, 吕先舒. 螺旋微通道对掺氢甲烷爆轰传播的影响[J]. 化工学报, 2023, 74(7): 3139-3148. |

| [3] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [4] | 周小文, 杜杰, 张战国, 许光文. 基于甲烷脉冲法的Fe2O3-Al2O3载氧体还原特性研究[J]. 化工学报, 2023, 74(6): 2611-2623. |

| [5] | 胡晗, 杨亮, 李春晓, 刘道平. 天然烟浸滤液水合物法储甲烷动力学研究[J]. 化工学报, 2023, 74(3): 1313-1321. |

| [6] | 高靖博, 孙强, 李青, 王逸伟, 郭绪强. 考虑水合物结构转变的含氢气体水合物相平衡模型[J]. 化工学报, 2023, 74(2): 666-673. |

| [7] | 彭晓婉, 郭笑楠, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8浆液法分离CH4/N2的双吸收-吸附塔工艺流程建模与模拟[J]. 化工学报, 2023, 74(2): 784-795. |

| [8] | 廖珊珊, 张少刚, 陶骏骏, 刘家豪, 汪金辉. 竖直射流火撞击障碍管道数值模拟分析[J]. 化工学报, 2022, 73(9): 4226-4234. |

| [9] | 杜峰, 尹思琦, 罗辉, 邓文安, 李传, 黄振薇, 王文静. H2在Mo x S y 团簇上吸附解离的尺寸效应研究[J]. 化工学报, 2022, 73(9): 3895-3903. |

| [10] | 沈嘉辉, 王侃宏, 郁达伟, 胡大洲, 魏源送. 游离氨调理污泥厌氧消化优化产甲烷过程与强化有机物释放[J]. 化工学报, 2022, 73(9): 4147-4155. |

| [11] | 宋健斐, 孙立强, 解明, 魏耀东. 旋风分离器内气相旋转流不稳定性的实验研究[J]. 化工学报, 2022, 73(7): 2858-2864. |

| [12] | 唐翠萍, 张雅楠, 梁德青, 李祥. 聚乙烯己内酰胺链端改性及其对甲烷水合物形成的抑制作用研究[J]. 化工学报, 2022, 73(5): 2130-2139. |

| [13] | 张欣, 周利, 王诗慧, 吉旭, 毕可鑫. 考虑原油性质波动的炼厂氢气网络集成优化[J]. 化工学报, 2022, 73(4): 1631-1646. |

| [14] | 张淑君, 王诗慧, 张欣, 吉旭, 戴一阳, 党亚固, 周利. 集成轻烃回收单元代理模型的氢气网络多目标优化[J]. 化工学报, 2022, 73(4): 1658-1672. |

| [15] | 闫帅, 杨家宝, 龚岩, 郭庆华, 于广锁. CO2稀释对甲烷反扩散火焰结构的影响研究[J]. 化工学报, 2022, 73(3): 1335-1342. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号