化工学报 ›› 2022, Vol. 73 ›› Issue (11): 5025-5038.DOI: 10.11949/0438-1157.20220963

龚海峰1( ), 罗鑫2, 彭烨2, 余保3, 杨阳1, 张浩华2

), 罗鑫2, 彭烨2, 余保3, 杨阳1, 张浩华2

收稿日期:2022-07-11

修回日期:2022-09-23

出版日期:2022-11-05

发布日期:2022-12-06

通讯作者:

龚海峰

作者简介:龚海峰(1979—),男,博士,教授,ghf79016@163.com

基金资助:

Haifeng GONG1( ), Xin LUO2, Ye PENG2, Bao YU3, Yang YANG1, Haohua ZHANG2

), Xin LUO2, Ye PENG2, Bao YU3, Yang YANG1, Haohua ZHANG2

Received:2022-07-11

Revised:2022-09-23

Online:2022-11-05

Published:2022-12-06

Contact:

Haifeng GONG

摘要:

工业废油脱水去固处理是其资源化工艺的重要环节,为高效地去除废油乳化液中的水和固体颗粒杂质,提出一种能够实现油-水-固相高效分离的异构旋流三相分离装置。装置结构及其参数是影响油-水-固三相分离效率的关键因素。于是,通过耦合多相流控制方程、群体平衡和稀疏颗粒条件下的颗粒追踪方程,忽略颗粒对整体质量守恒和动量守恒的影响,建立了异构旋流三相分离数值模型,通过模型考察了分离装置去固段结构对去固脱水效率的影响,并进一步优化了分离装置去固段的结构参数。计算与实验结果表明:装置去固段结构的变化会显著影响异构旋流三相分离装置的去固性能,对脱水率的影响不明显;最佳底流管、去固管和侧流管直径分别为6、15和6 mm时,装置侧流口的固体颗粒回收率和脱油率同时达到最高,可达87%以上,为设计研制高性能工业废油资源化装置提供理论和技术支撑。

中图分类号:

龚海峰, 罗鑫, 彭烨, 余保, 杨阳, 张浩华. 工业废油异构旋流三相分离装置去固结构及优化[J]. 化工学报, 2022, 73(11): 5025-5038.

Haifeng GONG, Xin LUO, Ye PENG, Bao YU, Yang YANG, Haohua ZHANG. Desolidification structure and optimization of specially-shaped hydrocyclone three-phase separation device for industrial waste oil[J]. CIESC Journal, 2022, 73(11): 5025-5038.

| Do/mm | Di/mm | Lo/mm | Ds/mm | D/mm | Dh/mm | Du/mm | Dw/mm | L0/mm | L1/mm | δ/mm | L3/mm | L4/mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18.0 | 12.0 | 45.0 | 70.0 | 26.0 | 4.0~8.0 | 3.0~9.0 | 11.0~19.0 | 124.7 | 305.5 | 25.0 | 100.0 | 50.0 |

表 1 异构旋流三相分离装置的结构参数

Table 1 Structural parameters of specially-shaped hydrocyclone three-phase separation device

| Do/mm | Di/mm | Lo/mm | Ds/mm | D/mm | Dh/mm | Du/mm | Dw/mm | L0/mm | L1/mm | δ/mm | L3/mm | L4/mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18.0 | 12.0 | 45.0 | 70.0 | 26.0 | 4.0~8.0 | 3.0~9.0 | 11.0~19.0 | 124.7 | 305.5 | 25.0 | 100.0 | 50.0 |

| ρo/(kg/m3) | ρw/(kg/m3) | ρp/(kg/m3) | μo/(mPa·s) | μw/(mPa·s) | dp/μm |

|---|---|---|---|---|---|

| 863 | 998.3 | 2650 | 16.807 | 1.003 | 50 |

表 2 物料参数

Table 2 Physical parameters

| ρo/(kg/m3) | ρw/(kg/m3) | ρp/(kg/m3) | μo/(mPa·s) | μw/(mPa·s) | dp/μm |

|---|---|---|---|---|---|

| 863 | 998.3 | 2650 | 16.807 | 1.003 | 50 |

图 6 异构旋流三相分离装置的数值结果与实验结果对比

Fig.6 Comparison of numerical results and experimental results of specially-shaped hydrocyclone three-phase separation device

图 7 不同底流管直径的切向速度分布

Fig.7 Tangential velocity distributions of different underflow pipe diameters: (a) Tangential velocity distribution contour of different underflow pipe diameters at y=0 section; Tangential velocity distributions of different underflow pipe diameters on different sections: (b) z=100.0 mm; (c) z=200.0 mm

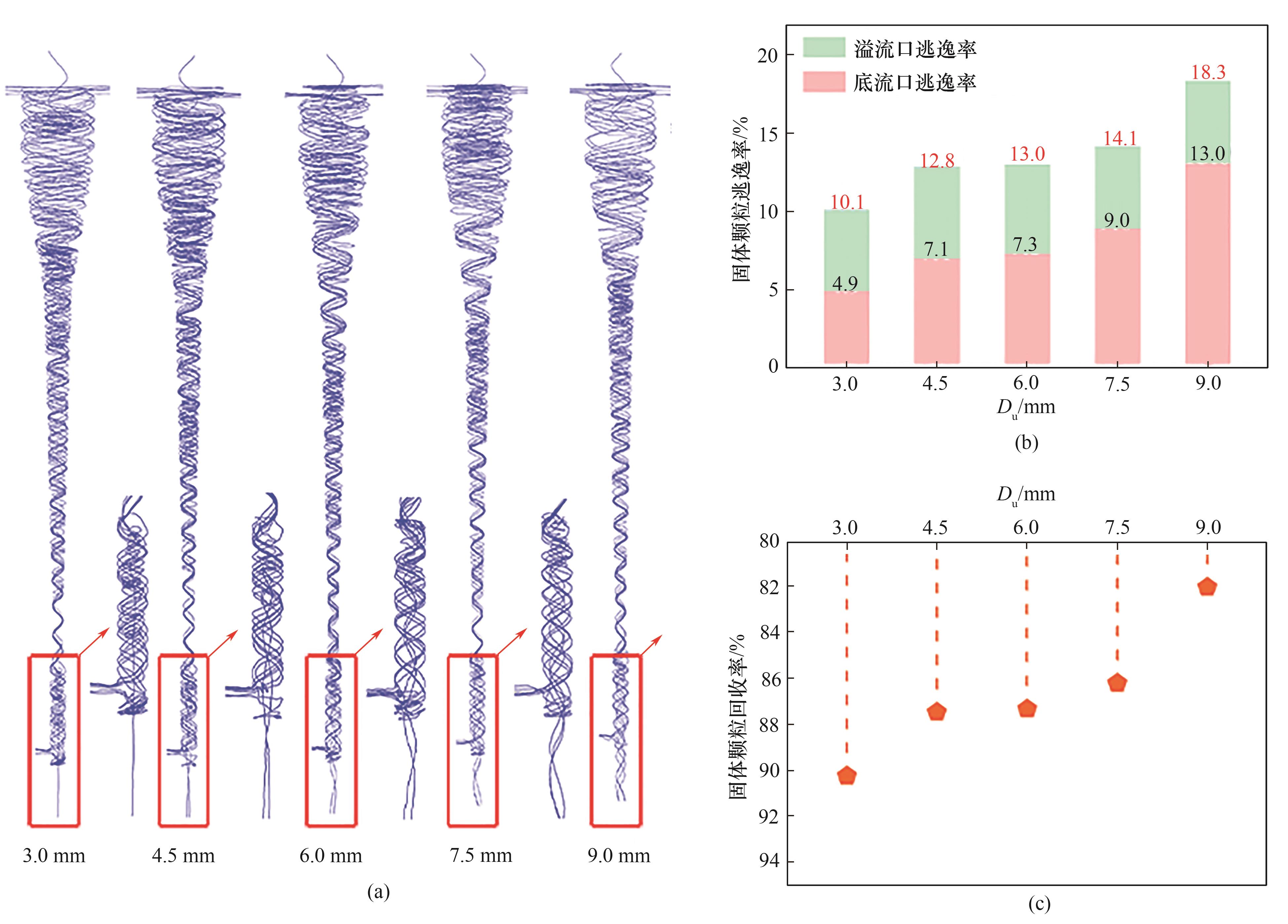

图 8 不同底流管直径的固体颗粒分布

Fig.8 Solid particle distribution of different underflow pipe diameters: (a) The trajectory of the solid particle of different underflow pipe diameters; (b) Solid particle escape rate of different underflow pipe diameters; (c) Solid particle recovery rate of different underflow pipe diameters

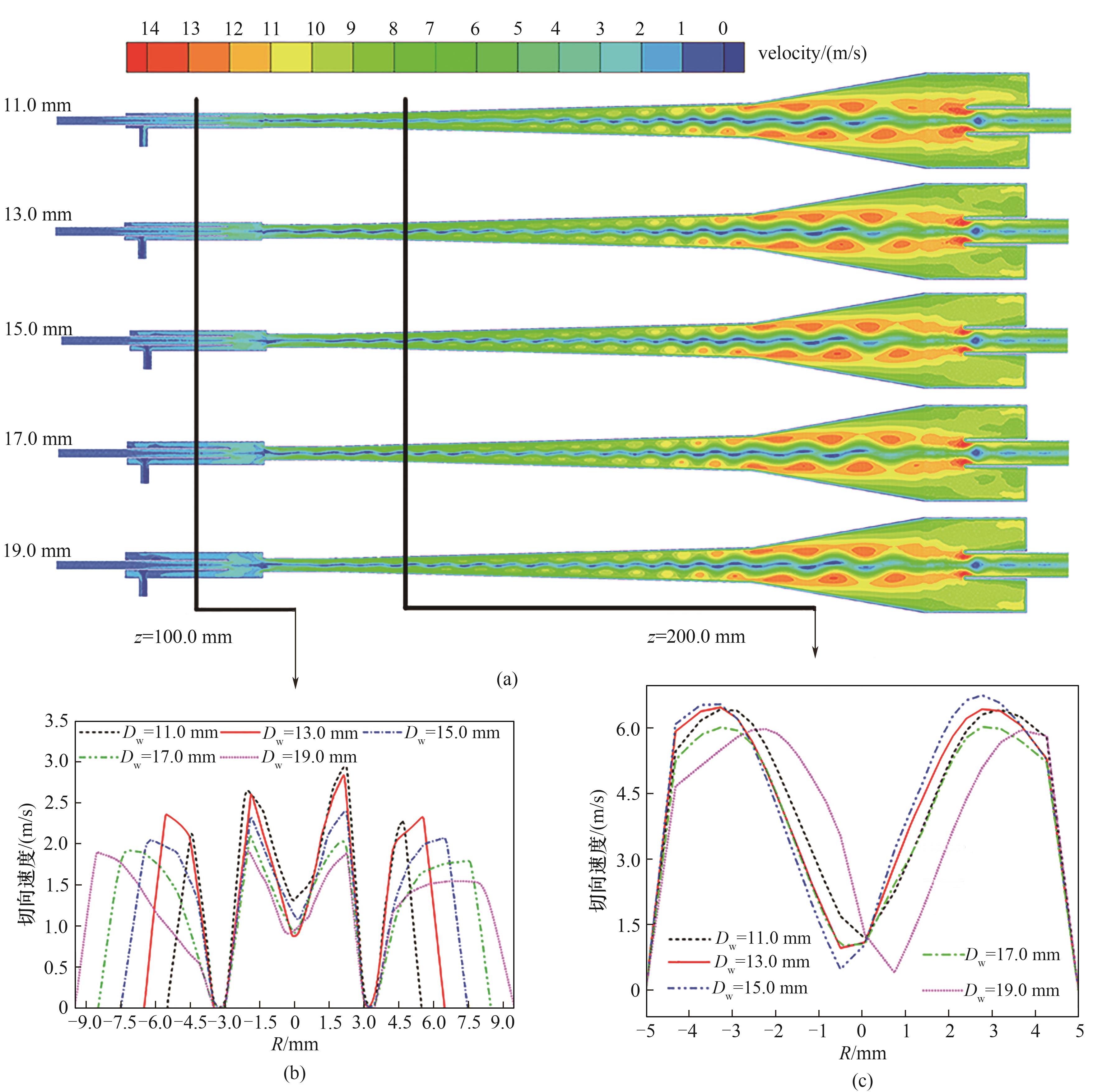

图 10 不同去固管直径的切向速度分布

Fig.10 Tangential velocity distributions of different desolidification pipe diameters: (a) Tangential velocity distribution contour of different desolidification pipe diameters at y=0 section; Tangential velocity distributions of different underflow pipe diameters on different sections: (b) z=100.0 mm, (c) z=200.0 mm

图 11 不同去固管直径条件下的固体颗粒运动轨迹

Fig.11 Solid particle distribution of different desolidification pipe diameters: (a) The trajectory of the solid particle of different desolidification pipe diameters; (b) Solid particle escape rate of different desolidification pipe diameters; (c) Solid particle recovery rate of different desolidification pipe diameters

图 13 不同侧流管直径的切向速度分布

Fig.13 Tangential velocity distributions of different sideflow pipe diameters: (a) Tangential velocity distribution contour of different sideflow pipe diameters at y=0 section; Tangential velocity distributions of different sideflow pipe diameters on different sections: (b) z=100.0 mm, (c) z=200.0 mm

图 14 不同侧流管直径下的固体颗粒运动轨迹

Fig.14 Solid particle distribution of different sideflow pipe diameters: (a) The trajectory of the solid particle of different sideflow pipe diameters; (b) Solid particle escape rate of different sideflow pipe diameters; (c) Solid particle recovery rate of different sideflow pipe diameters

| 1 | 龚海峰, 戴飞, 余保, 等. 高压脉冲电场-旋流离心场联合破乳脱水装置与试验[J]. 现代化工, 2018, 38(4): 178-181. |

| Gong H F, Dai F, Yu B, et al. Equipment and experiment for demulsification and dewatering by combining high voltage pulsed electric field with swirl centrifugal field[J]. Modern Chemical Industry, 2018, 38(4): 178-181. | |

| 2 | Geras’kina E V, Matkivskaya Y O, Chukhmanov E P, et al. Viscosity modifiers based on vinyl isobutyl ether copolymers for lubricating oils[J]. Russian Journal of Applied Chemistry, 2014, 87(11): 1649-1653. |

| 3 | 张贤明, 焦昭杰, 贾玉梅, 等. 工业污染废润滑油再生技术[J]. 环境科学与技术, 2008, 31(3): 39-42. |

| Zhang X M, Jiao Z J, Jia Y M, et al. Regeneration techniques of waste lubricating oil[J]. Environmental Science & Technology, 2008, 31(3): 39-42. | |

| 4 | Zolfaghari R, Fakhru’l-Razi A, Abdullah L C, et al. Demulsification techniques of water-in-oil and oil-in-water emulsions in petroleum industry[J]. Separation and Purification Technology, 2016, 170: 377-407. |

| 5 | Kang W L, Yin X, Yang H B, et al. Demulsification performance, behavior and mechanism of different demulsifiers on the light crude oil emulsions[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2018, 545: 197-204. |

| 6 | 段继海, 黄帅彪, 高昶, 等. 锥体开缝对水力旋流器固液分离性能的影响[J]. 化工学报, 2019, 70(5): 1823-1831. |

| Duan J H, Huang S B, Gao C, et al. Influence of slit structure in hydrocyclone conical section on solid-liquid separation performance[J]. CIESC Journal, 2019, 70(5): 1823-1831. | |

| 7 | 刘鸿雁, 韩天龙, 王亚, 等. 水力旋流器新型出口挡板结构对分离性能的影响[J]. 化工学报, 2018, 69(5): 2081-2088. |

| Liu H Y, Han T L, Wang Y, et al. Influence of new outlet configurations with baffle on hydrocycloneon separation performance[J]. CIESC Journal, 2018, 69(5): 2081-2088. | |

| 8 | Bednarski S, Listewnik J. Hydrocyclones for simultaneous removal of oil and solid particles from ships’oily waters[J]. Filtration & Separation, 1988, 25(2): 92-97. |

| 9 | Seureau J, Ma B F, Aurelle Y, et al. Three-phase cyclone separator: US5332500[P]. 1994-07-26. |

| 10 | Wang B, Yu A B. Numerical study of the gas-liquid-solid flow in hydrocyclones with different configuration of vortex finder[J]. Chemical Engineering Journal, 2008, 135(1/2): 33-42. |

| 11 | Qiu Z, Gong H F, Peng Y, et al. Influence of different type of inlet pipe on the separation characteristic of double-field coupling demulsification and dewatering device[J]. Separation Science and Technology, 2022, 57(11): 1813-1824. |

| 12 | Saidi M, Maddahian R, Farhanieh B. Numerical investigation of cone angle effect on the flow field and separation efficiency of deoiling hydrocyclones[J]. Heat and Mass Transfer, 2013, 49(2): 247-260. |

| 13 | Tian J Y, Ni L, Song T, et al. Numerical study of foulant-water separation using hydrocyclones enhanced by reflux device: effect of underflow pipe diameter[J]. Separation and Purification Technology, 2019, 215: 10-24. |

| 14 | Noroozi S, Hashemabadi S H. CFD analysis of inlet chamber body profile effects on de-oiling hydrocyclone efficiency[J]. Chemical Engineering Research and Design, 2011, 89(7): 968-977. |

| 15 | Li S, Li R N, Nicolleau F C G A, et al. Study on oil-water two-phase flow characteristics of the hydrocyclone under periodic excitation[J]. Chemical Engineering Research and Design, 2020, 159: 215-224. |

| 16 | Kuang S B, Chu K W, Yu A B, et al. Numerical study of liquid-gas-solid flow in classifying hydrocyclones: effect of feed solids concentration[J]. Minerals Engineering, 2012, 31: 17-31. |

| 17 | Li F, Liu P K, Yang X H, et al. Numerical simulation on the effects of different inlet pipe structures on the flow field and seperation performance in a hydrocyclone[J]. Powder Technology, 2020, 373: 254-266. |

| 18 | Azadi M, Azadi M, Mohebbi A. A CFD study of the effect of cyclone size on its performance parameters[J]. Journal of Hazardous Materials, 2010, 182(1/2/3): 835-841. |

| 19 | Jing J Q, Zhang S J, Qin M, et al. Numerical simulation study of offshore heavy oil desanding by hydrocyclones[J]. Separation and Purification Technology, 2021, 258: 118051. |

| 20 | 崔岩, 王建军, 孙茂生, 等. 水力旋流除砂器内液-固两相流动试验与数值模拟[J]. 石油机械, 2015, 43(11): 123-128. |

| Cui Y, Wang J J, Sun M S, et al. Experiment and numerical simulation on the liquid-solid flow in hydrocyclone desander[J]. China Petroleum Machinery, 2015, 43(11): 123-128. | |

| 21 | Tian J Y, Wang H L, Lv W J, et al. Enhancement of pollutants hydrocyclone separation by adjusting back pressure ratio and pressure drop ratio[J]. Separation and Purification Technology, 2020, 240: 116604. |

| 22 | Ni L, Tian J Y, Zhao J N. Experimental study of the effect of underflow pipe diameter on separation performance of a novel de-foulant hydrocyclone with continuous underflow and reflux function[J]. Separation and Purification Technology, 2016, 171: 270-279. |

| 23 | Zhang Q L, Hui X R, Yan L, et al. Numerical simulation of the tar mist and dust movement process in a low-temperature dry distillation furnace[J]. Journal of Chemistry, 2020, 2020: 2356038. |

| 24 | Santati S, Thongsri J, Sarntima P. Modified small-volume jet nebulizer based on CFD simulation and its clinical outcomes in small asthmatic children[J]. Journal of Healthcare Engineering, 2019, 2019: 2524583. |

| 25 | Tang B, Xu Y X, Song X F, et al. Numerical study on the relationship between high sharpness and configurations of the vortex finder of a hydrocyclone by central composite design[J]. Chemical Engineering Journal, 2015, 278: 504-516. |

| 26 | Ye J X, Xu Y X, Song X F, et al. Numerical modelling and multi-objective optimization of the novel hydrocyclone for ultra-fine particles classification[J]. Chemical Engineering Science, 2019, 207: 1072-1084. |

| 27 | 王剑刚, 张艳红, 白兆圆, 等. 进口尺寸对旋转流场分离特征的影响[J]. 化工学报, 2014, 65(1): 205-212. |

| Wang J G, Zhang Y H, Bai Z Y, et al. Effects of inlet size on separation flow field inside hydrocyclone[J]. CIESC Journal, 2014, 65(1): 205-212. | |

| 28 | Cheng J C, Li Q, Yang C, et al. CFD-PBE simulation of a bubble column in OpenFOAM[J]. Chinese Journal of Chemical Engineering, 2018, 26(9): 1773-1784. |

| 29 | Luo H A, Svendsen H F. Theoretical model for drop and bubble breakup in turbulent dispersions[J]. AIChE Journal, 1996, 42(5): 1225-1233. |

| 30 | Zhang Y, Wang Y, Li F, et al. Optimal design of the linkage between two downhole hydrocyclones in series[C]//Proceedings of ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering. San Francisco, 2014. |

| 31 | Gong H F, Yang Y, Yu B, et al. Coalescence characteristics of droplets dispersed in oil subjected to electric and centrifugal fields[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 648: 129398. |

| 32 | Tian J Y, Ni L, Song T, et al. CFD simulation of hydrocyclone-separation performance influenced by reflux device and different vortex-finder lengths[J]. Separation and Purification Technology, 2020, 233: 116013. |

| 33 | 王志斌, 陈文梅, 褚良银, 等. 旋流分离器中固体颗粒随机轨道的数值模拟及分离特性分析[J]. 机械工程学报, 2006, 42(6): 34-39. |

| Wang Z B, Chen W M, Chu L Y, et al. Numerical simulation of particale motion trajectory in a hydrocyclone using a stochastic trajectory model[J]. Chinese Journal of Mechanical Engineering, 2006, 42(6): 34-39. | |

| 34 | Gong H F, Yu B, Dai F, et al. Simulation on performance of a demulsification and dewatering device with coupling double fields: swirl centrifugal field and high-voltage electric field[J]. Separation and Purification Technology, 2018, 207: 124-132. |

| 35 | Vakamalla T R, Kumbhar K S, Gujjula R, et al. Computational and experimental study of the effect of inclination on hydrocyclone performance[J]. Separation and Purification Technology, 2014, 138: 104-117. |

| 36 | Gong H F, Li W L, Zhang X M, et al. Effects of droplet dynamic characteristics on the separation performance of a demulsification and dewatering device coupling electric and centrifugal fields[J]. Separation and Purification Technology, 2021, 257: 117905. |

| 37 | Sun X M, Wei L. Liquid-solid hydrocyclone numerical simulation and separation efficiency analysis[J]. Advanced Materials Research, 2014, 1037: 103-106. |

| [1] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [2] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [3] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [4] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [5] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [6] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [7] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [8] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [9] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [10] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [11] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [12] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [13] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [14] | 何晓崐, 刘锐, 薛园, 左然. MOCVD生长AlN单晶薄膜的气相和表面化学反应综述[J]. 化工学报, 2023, 74(7): 2800-2813. |

| [15] | 董明, 徐进良, 刘广林. 超临界水非均质特性分子动力学研究[J]. 化工学报, 2023, 74(7): 2836-2847. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号