化工学报 ›› 2023, Vol. 74 ›› Issue (12): 5006-5015.DOI: 10.11949/0438-1157.20231188

收稿日期:2023-11-17

修回日期:2023-12-22

出版日期:2023-12-25

发布日期:2024-02-19

通讯作者:

汪秋英,张小亮

作者简介:陈佩佩(1998—),女,硕士研究生,chenpeipei17@163.com

基金资助:

Peipei CHEN( ), Qiuying WANG(

), Qiuying WANG( ), Zeqing XIAO, Sijia ZHOU, Xiaoliang ZHANG(

), Zeqing XIAO, Sijia ZHOU, Xiaoliang ZHANG( )

)

Received:2023-11-17

Revised:2023-12-22

Online:2023-12-25

Published:2024-02-19

Contact:

Qiuying WANG, Xiaoliang ZHANG

摘要:

石墨烯量子点(GQDs)作为新兴的零维石墨烯衍生物,与二维材料氧化石墨烯相比,具有尺寸更小、比表面积更大、亲水性更强等优势,作为膜分离材料近年来备受关注。分别以柠檬酸、木质素磺酸钠、葡萄糖为前体,采用一步水热法成功合成出GQD并组装成GQDs复合膜,系统探究了三种前体对GQDs复合膜的微观结构和渗透汽化脱盐性能的影响。采用UV-Vis、FTIR、XRD、TEM等表征手段对膜的结构和形貌进行了分析,结果表明:不同前体会影响GQDs的粒径大小和膜层间距d-spacing值,从而影响GQDs复合膜的表面微观结构和渗透汽化脱盐性能。三种前体中以柠檬酸为前体制备的CA-GQDs复合膜的脱盐性能最佳,30℃在3.5%(质量分数)NaCl溶液中优化制备的CA-GQDs复合膜的渗透通量高达37.36 kg·m-2·h-1(渗透率高达1.2×10-4 mol·m-2·s-1·Pa-1),盐截留率近乎100%。此外,该复合膜在进料液pH=2~12具有较好的耐酸碱稳定性,尤其是pH=8~11时盐截留率仍保持99.95%以上。

中图分类号:

陈佩佩, 汪秋英, 肖泽卿, 周思佳, 张小亮. 石墨烯量子点复合膜的调控制备:前体的影响[J]. 化工学报, 2023, 74(12): 5006-5015.

Peipei CHEN, Qiuying WANG, Zeqing XIAO, Sijia ZHOU, Xiaoliang ZHANG. Tailoring preparation of graphene quantum dot composite membranes: influence of precursors[J]. CIESC Journal, 2023, 74(12): 5006-5015.

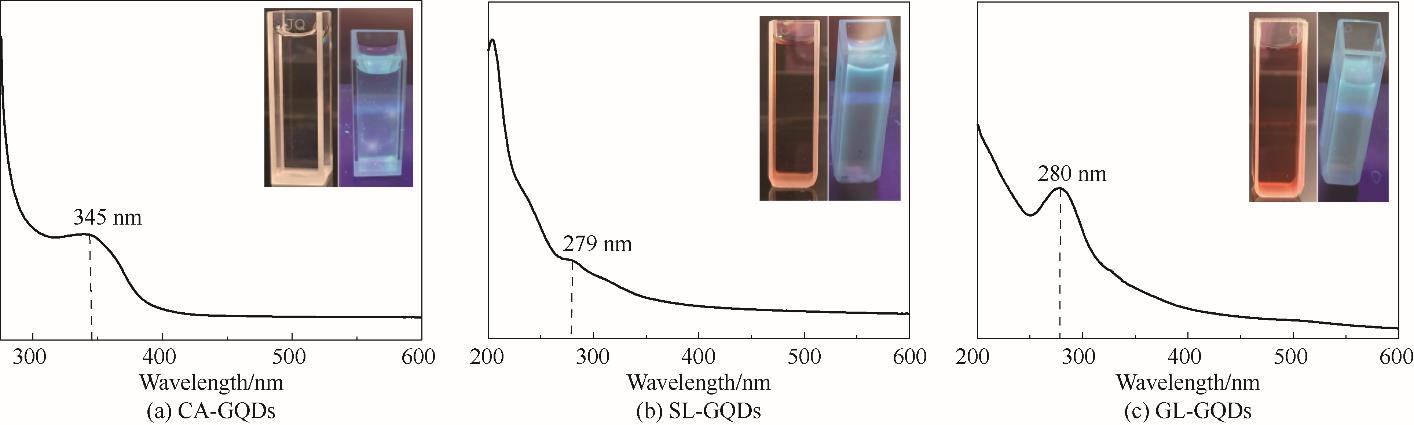

图2 不同前体制备GQDs溶液的UV-Vis谱及其光致发光照片[插图中分别为GQDs溶液在白炽灯(左)和365 nm紫外线(右)照射下光致发光照片]

Fig.2 UV-Vis spectra and photoluminescence photos of GQDs solutions prepared with different precursors [incandescent lamp (left) and 365 nm UV light (right) in the illustrations]

图4 不同前体制备GQDs的TEM形貌图和对应的粒径分布

Fig.4 TEM images and the corresponding particle size distribution (inset) of GQDs samples prepared with different precursors

图5 不同前体制备的GQDs在干态、湿态的XRD谱图及其对应的d-spacing值

Fig.5 XRD patterns in dry and wet states and the corresponding d-spacing of GQDs samples prepared with different precursors

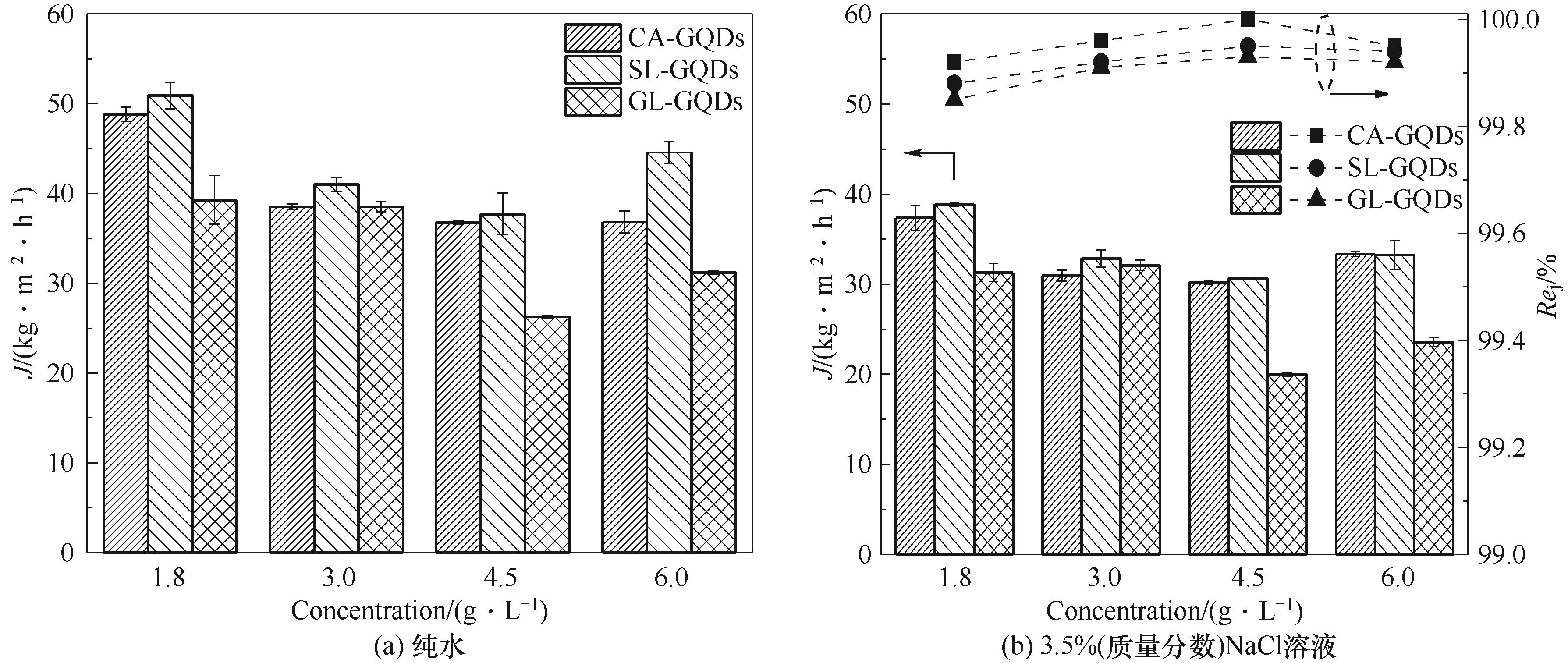

图6 前体及其浸涂浓度对GQDs复合膜脱盐性能的影响

Fig.6 Effect of precursors and dip-coating concentrations on the desalination performance of GQDs composite membranes towards pure water and 3.5% (mass) NaCl solution at 30℃

图7 浸涂次数和浸涂液pH对CA-GQDs复合膜脱盐性能的影响

Fig.7 Effect of dip-coating times and pH in dip-coating solution on the desalination performance of CA-GQDs composite membranes towards pure water and 3.5% (mass) NaCl solution at 30℃

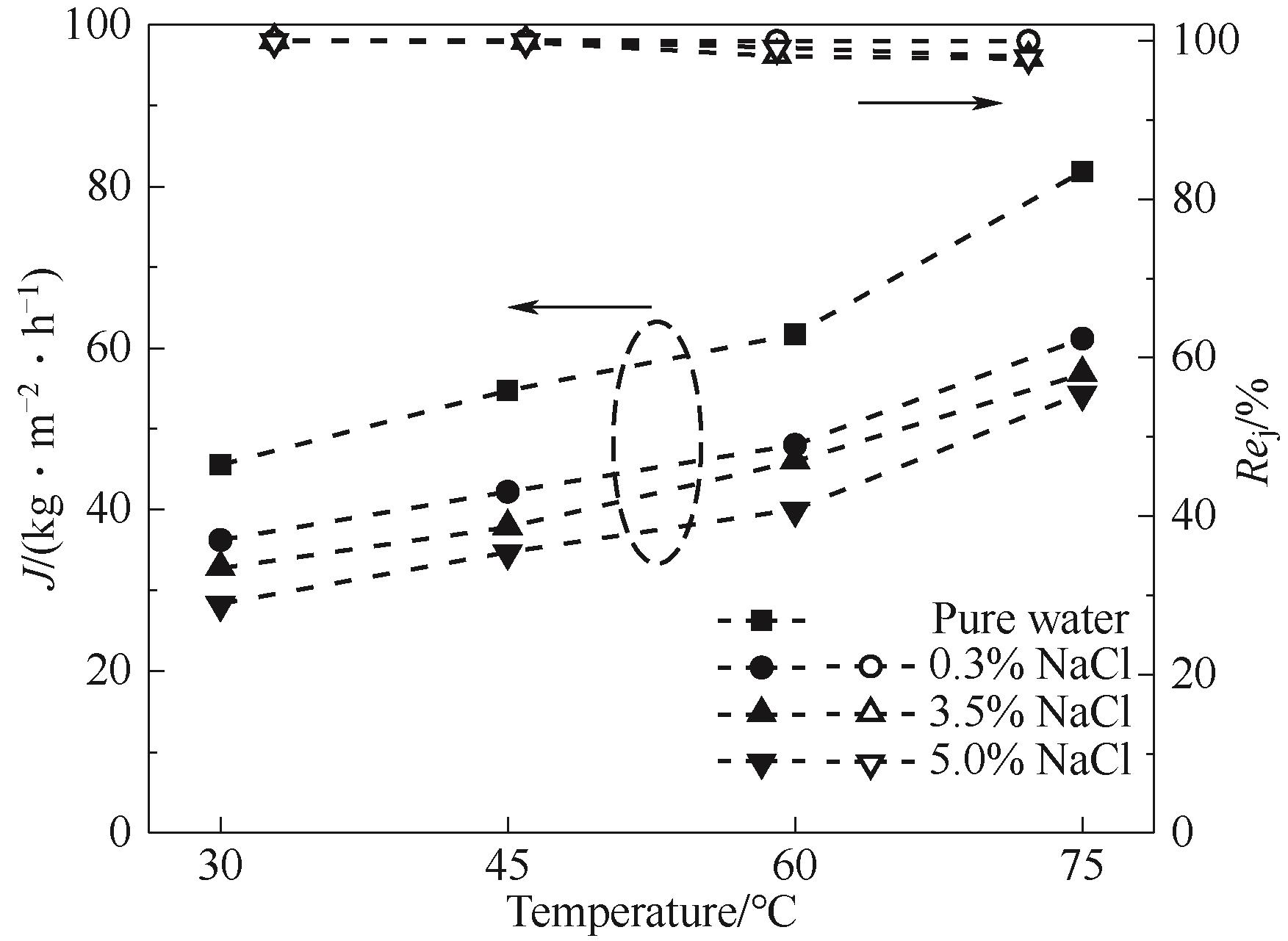

图8 测试温度对CA-GQDs复合膜在不同浓度NaCl溶液中的脱盐性能影响

Fig.8 Effect of feed temperature on the desalination performance of CA-GQDs composite membranes towards pure water and NaCl solutions with different concentrations

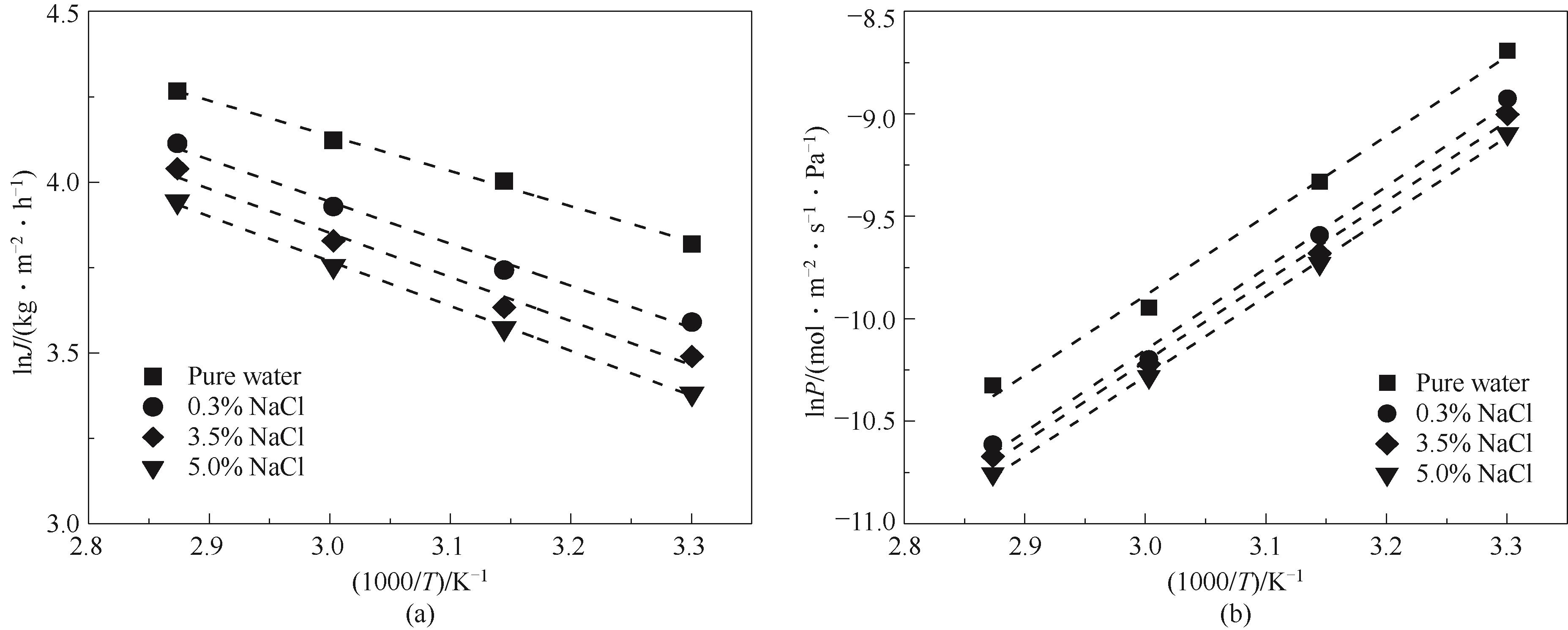

图9 CA-GQDs复合膜的渗透通量和渗透率与温度的Arrhenius关系曲线

Fig.9 Arrhenius plots of temperature dependent permeation flux and permeance of GQDs composite membranes towards pure water and NaCl solutions with different concentrations

| Solution | Ej/(kJ·mol-1) | Ep/(kJ·mol-1) | (Ej-Ep)/(kJ·mol-1) | ΔHv/(kJ·mol-1)[ |

|---|---|---|---|---|

| Pure water | 8.57±0.38 | -32.33±1.73 | 40.90 | 40.71—46.48 |

| 0.3% NaCl | 10.24±0.62 | -33.22±1.45 | 43.46 | 40.69—46.34 |

| 3.5% NaCl | 10.73±0.95 | -32.49±1.16 | 43.22 | 40.67—45.96 |

| 5.0% NaCl | 10.91±0.30 | -32.37±0.54 | 43.28 | 40.66—45.74 |

表1 CA-GQDs复合膜渗透汽化脱盐过程的活化能

Table 1 Activation energy of CA-GQDs composite membranes for pervaporation desalination processes

| Solution | Ej/(kJ·mol-1) | Ep/(kJ·mol-1) | (Ej-Ep)/(kJ·mol-1) | ΔHv/(kJ·mol-1)[ |

|---|---|---|---|---|

| Pure water | 8.57±0.38 | -32.33±1.73 | 40.90 | 40.71—46.48 |

| 0.3% NaCl | 10.24±0.62 | -33.22±1.45 | 43.46 | 40.69—46.34 |

| 3.5% NaCl | 10.73±0.95 | -32.49±1.16 | 43.22 | 40.67—45.96 |

| 5.0% NaCl | 10.91±0.30 | -32.37±0.54 | 43.28 | 40.66—45.74 |

| 1 | Yan Y X, Manickam S, Lester E, et al. Synthesis of graphene oxide and graphene quantum dots from miscanthus via ultrasound-assisted mechano-chemical cracking method[J]. Ultrasonics Sonochemistry, 2021, 73: 105519. |

| 2 | Li X M, Rui M C, Song J Z, et al. Carbon and graphene quantum dots for optoelectronic and energy devices: a review[J]. Advanced Functional Materials, 2015, 25(31): 4929-4947. |

| 3 | 刘嘉玮, 郝雨峰, 苏延磊. 石墨烯量子点纳滤膜的仿生修饰及稳定性研究[J]. 化工学报, 2021, 72(6): 3390-3398. |

| Liu J W, Hao Y F, Su Y L. Biomimetic modification and stability of graphene quantum dots nanofiltration membranes[J]. CIESC Journal, 2021, 72(6): 3390-3398. | |

| 4 | Li H T, Kang Z H, Liu Y, et al. Carbon nanodots: synthesis, properties and applications[J]. Journal of Materials Chemistry, 2012, 22(46): 24230-24253. |

| 5 | 韩威, 詹俊, 石红, 等. 氮和硫双掺杂石墨烯量子点的合成及其性能研究[J]. 化工学报, 2021, 72(S1): 530-538. |

| Han W, Zhan J, Shi H, et al. Synthesis and properties of nitrogen and sulfur codoped graphene quantum dots[J]. CIESC Journal, 2021, 72(S1): 530-538. | |

| 6 | Chen W F, Lv G, Hu W M, et al. Synthesis and applications of graphene quantum dots: a review[J]. Nanotechnology Reviews, 2018, 7(2): 157-185. |

| 7 | Sun J W, Jia W, Guo J X, et al. Amino-embedded carbon quantum dots incorporated thin-film nanocomposite membrane for desalination by pervaporation[J]. Desalination, 2022, 533: 115742. |

| 8 | Zhang Y, Song J, Shi B B, et al. Graphene oxide membranes with an enlarged interlaminar nanochannel through functionalized quantum dots for pervaporative water-selective transport[J]. Separation and Purification Technology, 2022, 292: 120975. |

| 9 | Shao D D, Wang L, Yan X Y, et al. Amine-carbon quantum dots (CQDs-NH2) tailored polymeric loose nanofiltration membrane for precise molecular separation[J]. Chemical Engineering Research and Design, 2021, 171: 237-246. |

| 10 | Sun W G, Zhang N, Li Q, et al. Bioinspired lignin-based loose nanofiltration membrane with excellent acid, fouling, and chlorine resistances toward dye/salt separation[J]. Journal of Membrane Science, 2023, 670: 121372. |

| 11 | 任炼, 张鑫涛, 赵丽萍, 等. 碳源选择对荧光碳量子点光致发光性能的影响[J]. 化学与黏合, 2016, 38(5): 366-368. |

| Ren L, Zhang X T, Zhao L P, et al. Effect of different carbon sources on the photoluminescence properties of fluorescent carbon quantum dots[J]. Chemistry and Adhesion, 2016, 38(5): 366-368. | |

| 12 | Zhu Y, Zhang X J, Zhang L M, et al. Membranes constructed with zero-dimension carbon quantum dots for CO2 separation[J]. Journal of Membrane Science, 2022, 664: 121086. |

| 13 | Liu W, Ning C X, Sang R R, et al. Lignin-derived graphene quantum dots from phosphous acid-assisted hydrothermal pretreatment and their application in photocatalysis[J]. Industrial Crops and Products, 2021, 171: 113963. |

| 14 | Behzadi F, Saievar-Iranizad E, Bayat A. One step synthesis of graphene quantum dots, graphene nanosheets and carbon nanospheres: investigation of photoluminescence properties[J]. Materials Research Express, 2019, 6(10): 105615. |

| 15 | 张锐, 邵琦, 张华宇, 等. 硼掺杂二氧化硅杂化膜的制备及渗透汽化脱盐性能[J]. 化工学报, 2021, 72(4): 2317-2327. |

| Zhang R, Shao Q, Zhang H Y, et al. Fabrication of boron-doped hybrid silica membranes for pervaporation desalination[J]. CIESC Journal, 2021, 72(4): 2317-2327. | |

| 16 | Zhang H Y, Wen J L, Shao Q, et al. Fabrication of La/Y-codoped microporous organosilica membranes for high-performance pervaporation desalination[J]. Journal of Membrane Science, 2019, 584: 353-363. |

| 17 | Dong Y Q, Shao J W, Chen C Q, et al. Blue luminescent graphene quantum dots and graphene oxide prepared by tuning the carbonization degree of citric acid[J]. Carbon, 2012, 50(12): 4738-4743. |

| 18 | Shehab M, Ebrahim S, Soliman M. Graphene quantum dots prepared from glucose as optical sensor for glucose[J]. Journal of Luminescence, 2017, 184: 110-116. |

| 19 | Achadu O J, Nyokong T. Interaction of graphene quantum dots with 4-acetamido-2, 2, 6, 6-tetramethylpiperidine-oxyl free radicals: a spectroscopic and fluorimetric study[J]. Journal of Fluorescence, 2016, 26(1):283-295. |

| 20 | Gu W T, Zhang W, Li X M, et al. Graphene sheets from worm-like exfoliated graphite[J]. Journal of Materials Chemistry, 2009, 19(21): 3367-3369. |

| 21 | Li L L, Wu G H, Yang G H, et al. Focusing on luminescent graphene quantum dots: current status and future perspectives[J]. Nanoscale, 2013, 5(10): 4015-4039. |

| 22 | Zheng H, Mou Z H, Lim Y J, et al. Incorporating ionic carbon dots in polyamide nanofiltration membranes for high perm-selectivity and antifouling performance[J]. Journal of Membrane Science, 2023, 672: 121401. |

| 23 | Wu D H, Gao A R, Zhao H T, et al. Pervaporative desalination of high-salinity water[J]. Chemical Engineering Research and Design, 2018, 136: 154-164. |

| 24 | Halakoo E, Feng X S. Layer-by-layer assembly of polyethyleneimine/graphene oxide membranes for desalination of high-salinity water via pervaporation[J]. Separation and Purification Technology, 2020, 234: 116077. |

| 25 | Baker R W, Wijmans J G, Huang Y. Permeability, permeance and selectivity: a preferred way of reporting pervaporation performance data[J]. Journal of Membrane Science, 2010, 348(1/2): 346-352. |

| 26 | Yang G, Xie Z L, Cran M, et al. Enhanced desalination performance of poly(vinyl alcohol)/carbon nanotube composite pervaporation membranes via interfacial engineering[J]. Journal of Membrane Science, 2019, 579: 40-51. |

| 27 | Feng B, Xu K, Huang A S. Covalent synthesis of three-dimensional graphene oxide framework (GOF) membrane for seawater desalination[J]. Desalination, 2016, 394: 123-130. |

| 28 | Zhao X Y, Tong Z Q, Liu X F, et al. Facile preparation of polyamide-graphene oxide composite membranes for upgrading pervaporation desalination performances of hypersaline solutions[J]. Industrial & Engineering Chemistry Research, 2020, 59(26): 12232-12238. |

| 29 | Liang B, Zhan W, Qi G G, et al. High performance graphene oxide/polyacrylonitrile composite pervaporation membranes for desalination applications[J]. Journal of Materials Chemistry A, 2015, 3(9): 5140-5147. |

| 30 | Song Y M, Li R, Pan F S, et al. Ultrapermeable graphene oxide membranes with tunable interlayer distances via vein-like supramolecular dendrimers[J]. Journal of Materials Chemistry A, 2019, 7(31): 18642-18652. |

| 31 | Sun J W, Qian X W, Wang Z H, et al. Tailoring the microstructure of poly(vinyl alcohol)-intercalated graphene oxide membranes for enhanced desalination performance of high-salinity water by pervaporation[J]. Journal of Membrane Science, 2020, 599: 117838. |

| 32 | Cao Z S, Zeng S X, Xu Z, et al. Ultrathin ZSM-5 zeolite nanosheet laminated membrane for high-flux desalination of concentrated brines[J]. Science Advances, 2018, 4(11): eaau8634. |

| 33 | Liang B, Pan K, Li L, et al. High performance hydrophilic pervaporation composite membranes for water desalination[J]. Desalination, 2014, 347: 199-206. |

| 34 | Li L, Hou J W, Ye Y, et al. Composite PVA/PVDF pervaporation membrane for concentrated brine desalination: salt rejection, membrane fouling and defect control[J]. Desalination, 2017, 422: 49-58. |

| 35 | Prihatiningtyas I, Gebreslase G A, van der Bruggen B. Incorporation of Al2O3 into cellulose triacetate membranes to enhance the performance of pervaporation for desalination of hypersaline solutions[J]. Desalination, 2020, 474: 114198. |

| 36 | Wang Q Z, Lu Y Y, Li N. Preparation, characterization and performance of sulfonated poly(styrene-ethylene/butylene-styrene) block copolymer membranes for water desalination by pervaporation[J]. Desalination, 2016, 390: 33-46. |

| 37 | Prihatiningtyas I, Li Y, Hartanto Y, et al. Effect of solvent on the morphology and performance of cellulose triacetate membrane/cellulose nanocrystal nanocomposite pervaporation desalination membranes[J]. Chemical Engineering Journal, 2020, 388: 124216. |

| 38 | Drobek M, Yacou C, Motuzas J, et al. Long term pervaporation desalination of tubular MFI zeolite membranes[J]. Journal of Membrane Science, 2012, 415/416: 816-823. |

| 39 | He Y, Cui X M, Liu X D, et al. Preparation of self-supporting NaA zeolite membranes using geopolymers[J]. Journal of Membrane Science, 2013, 447: 66-72. |

| 40 | Reino Olegário da Silva D A, Bosmuler Zuge L C, de Paula Scheer A. Preparation and characterization of a novel green silica/PVA membrane for water desalination by pervaporation[J]. Separation and Purification Technology, 2020, 247: 116852. |

| 41 | Xie Z L, Hoang M, Duong T, et al. Sol-gel derived poly(vinyl alcohol)/maleic acid/silica hybrid membrane for desalination by pervaporation[J]. Journal of Membrane Science, 2011, 383(1/2): 96-103. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [3] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [4] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [5] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [6] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [7] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [8] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [9] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [10] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [11] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [12] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [13] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [14] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [15] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号