化工学报 ›› 2021, Vol. 72 ›› Issue (4): 2156-2166.DOI: 10.11949/0438-1157.20201022

张秦意1( ),杨晓宏1,2(

),杨晓宏1,2( ),邓洪玲1,胡俊虎1,田瑞1,3

),邓洪玲1,胡俊虎1,田瑞1,3

收稿日期:2020-07-27

修回日期:2020-10-28

出版日期:2021-04-05

发布日期:2021-04-05

通讯作者:

杨晓宏

作者简介:张秦意(1997—),男,硕士研究生,基金资助:

ZHANG Qinyi1( ),YANG Xiaohong1,2(

),YANG Xiaohong1,2( ),DENG Hongling1,HU Junhu1,TIAN Rui1,3

),DENG Hongling1,HU Junhu1,TIAN Rui1,3

Received:2020-07-27

Revised:2020-10-28

Online:2021-04-05

Published:2021-04-05

Contact:

YANG Xiaohong

摘要:

设计并搭建了太阳能光热-光电方腔型膜蒸馏系统,为研究该系统机理与优化问题,首先以料液进口温度、流量、太阳辐照度为影响因子,膜通量、能耗为响应值,采用响应面法分析各影响因子与响应值间的关系;其次结合中心复合设计法设计实验工况,建立响应值与影响因子的二次多项式回归模型,通过方差分析、实验验证对所建立的模型进行可靠性分析;最后对响应值进行响应面分析与系统优化,获得了系统最佳运行工况和最优膜通量、能耗值,并进行了实验验证。结果表明,系统最佳工况为:料液进口温度为63℃,料液进口流量为232 L/h,太阳辐照度为700 W/m2,在此工况下实际膜通量达到7.28 L/(m2·h),高于预测值6.39 L/(m2·h),两者误差为12.23%,对应的能耗值为10.40 L/(kW·h)。

中图分类号:

张秦意, 杨晓宏, 邓洪玲, 胡俊虎, 田瑞. 基于响应面法光热-光电膜蒸馏系统优化研究[J]. 化工学报, 2021, 72(4): 2156-2166.

ZHANG Qinyi, YANG Xiaohong, DENG Hongling, HU Junhu, TIAN Rui. Study on optimization of thermal-photovoltaic membrane distillation system based on response surface methodology[J]. CIESC Journal, 2021, 72(4): 2156-2166.

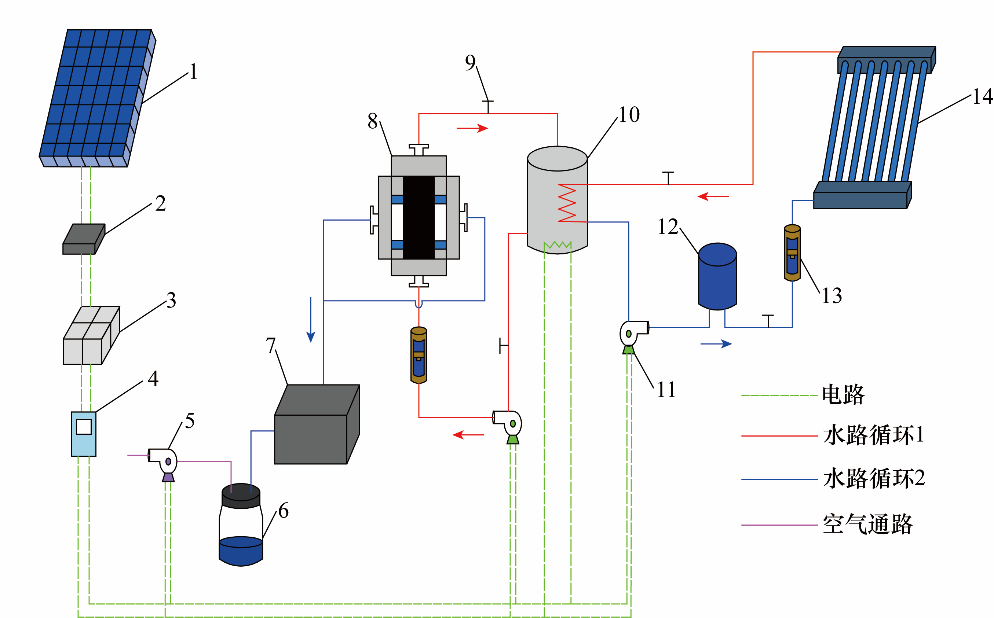

图1 太阳能光热-光电方腔型膜蒸馏系统1—光伏系统;2—控制器;3—蓄电池;4—电度表;5—真空泵;6—收集瓶;7—冷凝水箱;8—方腔型膜组件;9—阀门;10—保温水箱;11—循环泵;12—缓冲水箱;13—流量计;14—太阳集热器

Fig.1 Solar thermal-photovoltaic square cavity membrane distillation system

| 膜丝平均 孔径/μm | 膜丝内、外径/mm | 膜丝长度/mm | 膜面积/m2 | 孔隙率/% |

|---|---|---|---|---|

| 0.2 | 0.6/1.0 | 65 | 0.1 | 60 |

表1 膜组件参数

Table 1 Parameters of membrane module

| 膜丝平均 孔径/μm | 膜丝内、外径/mm | 膜丝长度/mm | 膜面积/m2 | 孔隙率/% |

|---|---|---|---|---|

| 0.2 | 0.6/1.0 | 65 | 0.1 | 60 |

| 温度点 | 流量点 | 名称 |

|---|---|---|

| 1 | 1 | 集热器入口 |

| 2 | 1 | 集热器出口 |

| 3 | 3 | 膜组件入口 |

| 4 | 3 | 膜组件出口 |

表2 测点名称

Table 2 Name of measuring point

| 温度点 | 流量点 | 名称 |

|---|---|---|

| 1 | 1 | 集热器入口 |

| 2 | 1 | 集热器出口 |

| 3 | 3 | 膜组件入口 |

| 4 | 3 | 膜组件出口 |

| 测量参数 | 测量仪器 |

|---|---|

| 温度 | DTM411数字温度显示仪 |

| 流量 | LZB-25玻璃转子流量计 |

| 真空度 | 真空表 |

| 电导率 | DDS-307电导率仪 |

| 产水量 | JA31002电子天平 |

表3 测量参数及仪器

Table 3 Parameters and instruments of measurement

| 测量参数 | 测量仪器 |

|---|---|

| 温度 | DTM411数字温度显示仪 |

| 流量 | LZB-25玻璃转子流量计 |

| 真空度 | 真空表 |

| 电导率 | DDS-307电导率仪 |

| 产水量 | JA31002电子天平 |

| 自变量 | 编码 | 水平 | ||||

|---|---|---|---|---|---|---|

| -α | -1 | 0 | 1 | +α | ||

| T/℃ | X1 | 52 | 55 | 59 | 63 | 65 |

| Qf/(L/h) | X2 | 31 | 100 | 200 | 300 | 368 |

| I/(W/m2) | X3 | 163 | 300 | 500 | 700 | 836 |

表4 影响因子编码水平

Table 4 The code levels of influence factors

| 自变量 | 编码 | 水平 | ||||

|---|---|---|---|---|---|---|

| -α | -1 | 0 | 1 | +α | ||

| T/℃ | X1 | 52 | 55 | 59 | 63 | 65 |

| Qf/(L/h) | X2 | 31 | 100 | 200 | 300 | 368 |

| I/(W/m2) | X3 | 163 | 300 | 500 | 700 | 836 |

| 实验编号 | 实验 类型① | T/℃ | Qf/(L/h) | I/(W/m2) | 响应值 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 实际值 | 编码值 | 实际值 | 编码值 | 实际值 | 编码值 | J/(L/(m2·h)) | Ec/(kW·h) | W/(L/(kW·h)) | ||

| 1 | O1 | 63 | 1 | 100 | -1 | 300 | -1 | 4.76 | 0.63 | 7.555556 |

| 2 | O2 | 63 | 1 | 300 | 1 | 700 | 1 | 5.34 | 0.49 | 10.89796 |

| 3 | O3 | 63 | 1 | 300 | 1 | 300 | -1 | 3.899 | 0.51 | 7.645098 |

| 4 | O4 | 63 | 1 | 100 | -1 | 700 | 1 | 4.9599 | 0.706 | 7.025354 |

| 5 | O5 | 55 | -1 | 300 | 1 | 300 | -1 | 1.9136 | 0.97 | 1.972784 |

| 6 | O6 | 55 | -1 | 100 | -1 | 700 | 1 | 2.4683 | 0.765 | 3.226536 |

| 7 | O7 | 55 | -1 | 300 | 1 | 700 | 1 | 3.2175 | 0.52 | 6.1875 |

| 8 | O8 | 55 | -1 | 100 | -1 | 300 | -1 | 2.4157 | 0.61 | 3.960164 |

| 9 | S1 | 65 | 1.68 | 200 | 0 | 500 | 0 | 7.7961 | 0.57 | 13.67737 |

| 10 | S2 | 52 | -1.68 | 200 | 0 | 500 | 0 | 0.6939 | 0.735 | 0.944082 |

| 11 | S3 | 59 | 0 | 368 | 1.68 | 500 | 0 | 3.5467 | 0.57 | 6.222281 |

| 12 | S4 | 59 | 0 | 31 | -1.68 | 500 | 0 | 1.0266 | 0.52 | 1.974231 |

| 13 | S5 | 59 | 0 | 200 | 0 | 836 | 1.68 | 4.904 | 0.61 | 8.039344 |

| 14 | S6 | 59 | 0 | 200 | 0 | 163 | -1.68 | 3.0409 | 0.53 | 5.737547 |

| 15 | C1 | 59 | 0 | 200 | 0 | 500 | 0 | 4.4908 | 0.645 | 6.962481 |

| 16 | C2 | 59 | 0 | 200 | 0 | 500 | 0 | 4.567 | 0.623 | 7.330658 |

| 17 | C3 | 59 | 0 | 200 | 0 | 500 | 0 | 4.63 | 0.68 | 6.808824 |

| 18 | C4 | 59 | 0 | 200 | 0 | 500 | 0 | 4.74 | 0.71 | 6.676056 |

| 19 | C5 | 59 | 0 | 200 | 0 | 500 | 0 | 4.831 | 0.59 | 8.188136 |

| 20 | C6 | 59 | 0 | 200 | 0 | 500 | 0 | 4.765 | 0.632 | 7.539557 |

表5 CCD实验设计及结果

Table 5 Experimental design and results of CCD

| 实验编号 | 实验 类型① | T/℃ | Qf/(L/h) | I/(W/m2) | 响应值 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 实际值 | 编码值 | 实际值 | 编码值 | 实际值 | 编码值 | J/(L/(m2·h)) | Ec/(kW·h) | W/(L/(kW·h)) | ||

| 1 | O1 | 63 | 1 | 100 | -1 | 300 | -1 | 4.76 | 0.63 | 7.555556 |

| 2 | O2 | 63 | 1 | 300 | 1 | 700 | 1 | 5.34 | 0.49 | 10.89796 |

| 3 | O3 | 63 | 1 | 300 | 1 | 300 | -1 | 3.899 | 0.51 | 7.645098 |

| 4 | O4 | 63 | 1 | 100 | -1 | 700 | 1 | 4.9599 | 0.706 | 7.025354 |

| 5 | O5 | 55 | -1 | 300 | 1 | 300 | -1 | 1.9136 | 0.97 | 1.972784 |

| 6 | O6 | 55 | -1 | 100 | -1 | 700 | 1 | 2.4683 | 0.765 | 3.226536 |

| 7 | O7 | 55 | -1 | 300 | 1 | 700 | 1 | 3.2175 | 0.52 | 6.1875 |

| 8 | O8 | 55 | -1 | 100 | -1 | 300 | -1 | 2.4157 | 0.61 | 3.960164 |

| 9 | S1 | 65 | 1.68 | 200 | 0 | 500 | 0 | 7.7961 | 0.57 | 13.67737 |

| 10 | S2 | 52 | -1.68 | 200 | 0 | 500 | 0 | 0.6939 | 0.735 | 0.944082 |

| 11 | S3 | 59 | 0 | 368 | 1.68 | 500 | 0 | 3.5467 | 0.57 | 6.222281 |

| 12 | S4 | 59 | 0 | 31 | -1.68 | 500 | 0 | 1.0266 | 0.52 | 1.974231 |

| 13 | S5 | 59 | 0 | 200 | 0 | 836 | 1.68 | 4.904 | 0.61 | 8.039344 |

| 14 | S6 | 59 | 0 | 200 | 0 | 163 | -1.68 | 3.0409 | 0.53 | 5.737547 |

| 15 | C1 | 59 | 0 | 200 | 0 | 500 | 0 | 4.4908 | 0.645 | 6.962481 |

| 16 | C2 | 59 | 0 | 200 | 0 | 500 | 0 | 4.567 | 0.623 | 7.330658 |

| 17 | C3 | 59 | 0 | 200 | 0 | 500 | 0 | 4.63 | 0.68 | 6.808824 |

| 18 | C4 | 59 | 0 | 200 | 0 | 500 | 0 | 4.74 | 0.71 | 6.676056 |

| 19 | C5 | 59 | 0 | 200 | 0 | 500 | 0 | 4.831 | 0.59 | 8.188136 |

| 20 | C6 | 59 | 0 | 200 | 0 | 500 | 0 | 4.765 | 0.632 | 7.539557 |

| 来源 | 自由度 | 平方和 | 均方 | F值 | P值 | R2 | R2adj | AP |

|---|---|---|---|---|---|---|---|---|

| 模型 | 9 | 46.25 | 5.14 | 9.2 | 0.0009 | 0.8922 | 0.7952 | 10.21 |

| 残差 | 10 | 5.59 | 0.56 | — | — | — | — | — |

| 总和 | 19 | 51.84 | — | — | — | — | — | — |

表6 膜通量响应面模型方差分析

Table 6 Variance analysis of RSM model of the membrane flux

| 来源 | 自由度 | 平方和 | 均方 | F值 | P值 | R2 | R2adj | AP |

|---|---|---|---|---|---|---|---|---|

| 模型 | 9 | 46.25 | 5.14 | 9.2 | 0.0009 | 0.8922 | 0.7952 | 10.21 |

| 残差 | 10 | 5.59 | 0.56 | — | — | — | — | — |

| 总和 | 19 | 51.84 | — | — | — | — | — | — |

| 来源 | 自由度 | 平方和 | 均方 | F值 | P值 | R2 | R2adj | AP |

|---|---|---|---|---|---|---|---|---|

| 模型 | 9 | 159.29 | 17.7 | 15.72 | 0.0001 | 0.934 | 0.8746 | 13.85 |

| 残差 | 10 | 11.26 | 1.13 | — | — | — | — | — |

| 总和 | 19 | 170.55 | — | — | — | — | — | — |

表7 能耗响应面模型方差分析

Table 7 Variance analysis of RSM model of the energy consumption

| 来源 | 自由度 | 平方和 | 均方 | F值 | P值 | R2 | R2adj | AP |

|---|---|---|---|---|---|---|---|---|

| 模型 | 9 | 159.29 | 17.7 | 15.72 | 0.0001 | 0.934 | 0.8746 | 13.85 |

| 残差 | 10 | 11.26 | 1.13 | — | — | — | — | — |

| 总和 | 19 | 170.55 | — | — | — | — | — | — |

| T/℃ | Qf/(L/h) | I/(W/m2) | J/(L/(m2·h)) | 误差/% | |

|---|---|---|---|---|---|

| 预测值 | 实验值 | ||||

| 63 | 232 | 700 | 6.39 | 7.28 | 12.23 |

表8 系统在最佳工况下的J最优值

Table 8 The optimal membrane flux under optimal operating conditions

| T/℃ | Qf/(L/h) | I/(W/m2) | J/(L/(m2·h)) | 误差/% | |

|---|---|---|---|---|---|

| 预测值 | 实验值 | ||||

| 63 | 232 | 700 | 6.39 | 7.28 | 12.23 |

| 名称 | 价格/元 |

|---|---|

| 集热器及配件 | 850 |

| 光伏板及配件 | 940 |

| 膜组件 | 3000 |

| 循环、真空泵 | 520 |

| 管道 | 168 |

| 保温水箱 | 550 |

| 运行维护成本 | 500 |

表9 系统投资估算

Table 9 Investment estimation of the system

| 名称 | 价格/元 |

|---|---|

| 集热器及配件 | 850 |

| 光伏板及配件 | 940 |

| 膜组件 | 3000 |

| 循环、真空泵 | 520 |

| 管道 | 168 |

| 保温水箱 | 550 |

| 运行维护成本 | 500 |

| 1 | Yang H, Fu M X, Zhan Z L, et al. Study on combined freezing-based desalination processes with microwave treatment[J]. Desalination, 2020, 475: 114201. |

| 2 | Zheng Y J, Hatzell K B. Technoeconomic analysis of solar thermal desalination[J]. Desalination, 2020, 474: 114168. |

| 3 | Bendevis P, Karam A, Laleg-Kirati T M. Optimal model-free control of solar thermal membrane distillation system[J]. Computers & Chemical Engineering, 2020, 133: 106622. |

| 4 | Jaradat A Q, Gharaibeh S, Abu Irjei M. The application of solar distillation technique as a mean for olive mill wastewater management[J]. Water and Environment Journal, 2018, 32(1): 134-140. |

| 5 | Manchanda H, Kumar M. Study of water desalination techniques and a review on active solar distillation methods[J]. Environmental Progress & Sustainable Energy, 2018, 37(1): 444-464. |

| 6 | 丁春立, 林帝出, 王德武, 等. 电纺及疏水改性制备CA/SiNPs-FAS超疏水复合膜及膜蒸馏脱盐研究[J]. 化工学报, 2018, 69(4): 1774-1782. |

| Ding C L, Lin D C, Wang D W, et al. Preparation of superhydrophobic CA/SiNPs-FAS electrospun nanofibrous membranes for direct contact membrane distillation[J]. CIESC Journal, 2018, 69(4): 1774-1782. | |

| 7 | 刘羊九, 韩吉田, 王云山, 等. 直接接触式膜蒸馏用于处理含盐溶液的实验研究[J]. 化工学报, 2018, 69: 246-251. |

| Liu Y J, Han J T, Wang Y S, et al. Experimental study on saline solution by direct contact membrane distillation[J]. CIESC Journal, 2018, 69: 246-251. | |

| 8 | Moejes S N, van Wonderen G J, Bitter J H, et al. Assessment of air gap membrane distillation for milk concentration[J]. Journal of Membrane Science, 2020, 594: 117403. |

| 9 | Yang H C, Zhong W W, Hou J W, et al. Janus hollow fiber membrane with a mussel-inspired coating on the lumen surface for direct contact membrane distillation[J]. Journal of Membrane Science, 2017, 523: 1-7. |

| 10 | Mansour S, Giwa A, Hasan S W. Novel graphene nanoplatelets-coated polyethylene membrane for the treatment of reject brine by pilot-scale direct contact membrane distillation: an optimization study[J]. Desalination, 2018, 441: 9-20. |

| 11 | 姜晓滨, 孙国鑫, 贺高红. 高效膜蒸馏结晶过程的研究进展[J]. 化工学报, 2020, 71(9): 3905-3918. |

| Jiang X B, Sun G X, He G H. Research progress of high-efficiency membrane distillation crystallization process[J]. CIESC Journal, 2020, 71(9): 3905-3918. | |

| 12 | 白炳林, 杨晓宏, 田瑞, 等. 太阳能光热-光电中空纤维真空膜蒸馏系统理论与实验研究[J]. 化工学报, 2019, 70(9): 3517-3526. |

| Bai B L, Yang X H, Tian R, et al. Theoretical and experimental research on solar thermal-photovoltaic hollow fiber vacuum membrane distillation system[J]. CIESC Journal, 2019, 70(9): 3517-3526. | |

| 13 | Fath H E S, Elsherbiny S M, Hassan A A, et al. PV and thermally driven small-scale, stand-alone solar desalination systems with very low maintenance needs[J]. Desalination, 2008, 225(1/2/3): 58-69. |

| 14 | Drioli E, Ali A, Macedonio F. Membrane distillation: recent developments and perspectives[J]. Desalination, 2015, 356: 56-84. |

| 15 | Alkhudhiri A, Darwish N, Hilal N. Membrane distillation: a comprehensive review[J]. Desalination, 2012, 287: 2-18. |

| 16 | Tong X, Liu S, Chen Y S, et al. Thermodynamic analysis of a solar thermal facilitated membrane seawater desalination process[J]. Journal of Cleaner Production, 2020, 256: 120398. |

| 17 | Li W P, Chen Y Q, Yao L, et al. Fe3O4/PVDF-HFP photothermal membrane with in situ heating for sustainable, stable and efficient pilot-scale solar-driven membrane distillation[J]. Desalination, 2020, 478: 114288. |

| 18 | Li G P, Lu L. Modeling and performance analysis of a fully solar-powered stand-alone sweeping gas membrane distillation desalination system for island and coastal households[J]. Energy Conversion and Management, 2020, 205: 112375. |

| 19 | 李洪建. 太阳能空气隙膜蒸馏系统的实验研究[D]. 呼和浩特: 内蒙古工业大学, 2016. |

| Li H J. Experimental study on solar air gap membrane distillation[D]. Hohhot: Inner Mongolia University of Tehchnology, 2016. | |

| 20 | Ebadi M, Mozdianfard M R, Aliabadi M. Employing full factorial design and response surface methodology for optimizing direct contact membrane distillation operational conditions in desalinating the rejected stream of a reverse osmosis unit at Esfahan refinery–Iran[J]. Water Supply, 2019, 19(2): 492-501. |

| 21 | Liu J, Liu M L, Guo H, et al. Mass transfer in hollow fiber vacuum membrane distillation process based on membrane structure[J]. Journal of Membrane Science, 2017, 532: 115-123. |

| 22 | Zhu H L, Wang H J, Wang F, et al. Preparation and properties of PTFE hollow fiber membranes for desalination through vacuum membrane distillation[J]. Journal of Membrane Science, 2013, 446: 145-153. |

| 23 | Çelebican Ö, İnci İ, Baylan N. Modeling and optimization of formic acid adsorption by multiwall carbon nanotube using response surface methodology[J]. Journal of Molecular Structure, 2020, 1203: 127312. |

| 24 | Saha P, Waghmare D. Parametric optimization for autogenous butt laser welding of sub-millimeter thick SS 316 sheets using central composite design[J]. Optics & Laser Technology, 2020, 122: 105833. |

| 25 | Ayan E, Baylan N, Çehreli S. Optimization of reactive extraction of propionic acid with ionic liquids using central composite design[J]. Chemical Engineering Research and Design, 2020, 153: 666-676. |

| 26 | Machrouhi A, Alilou H, Farnane M, et al. Statistical optimization of activated carbon from Thapsia transtagana stems and dyes removal efficiency using central composite design[J]. Journal of Science: Advanced Materials and Devices, 2019, 4(4): 544-553. |

| 27 | de Sodipo B K, Aziz A A. Optimization of sonochemical method of functionalizing Amino-Silane on superparamagnetic iron oxide nanoparticles using Central Composite Design[J]. Ultrasonics Sonochemistry, 2020, 64: 104856. |

| 28 | Zhou B X, Wang T, Li C, et al. Multi-objective optimization of the preparation parameters of the powdered activated coke for SO2 adsorption using response surface methodology[J]. Journal of Analytical and Applied Pyrolysis, 2020, 146: 104776. |

| 29 | 张绮钰, 童乐, 岳晨. 液隙式热泵膜蒸馏海水淡化系统的热力性能分析[J]. 过程工程学报,2020, 20(11): 1265-1272. |

| Zhang Q Y, Tong L, Yue C. Thermal performance analysis of seawater desalination system based on liquid gap heat pump membrane distillation [J]. Chin. J. Process Eng., 2020, 20(11): 1265-1272. | |

| 30 | Singh V, Belova L, Singh B, et al. Biodiesel production using a novel heterogeneous catalyst, magnesium zirconate (Mg2Zr5O12): process optimization through response surface methodology (RSM)[J]. Energy Conversion and Management, 2018, 174: 198-207. |

| 31 | Sharma D, Yadav K D, Kumar S. Biotransformation of flower waste composting: optimization of waste combinations using response surface methodology[J]. Bioresource Technology, 2018, 270: 198-207. |

| 32 | Zarzoum K, Zhani K, Ben Bacha H, et al. Experimental parametric study of membrane distillation unit using solar energy[J]. Solar Energy, 2019, 188: 1274-1282. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [3] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [4] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [5] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [6] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [7] | 傅予, 刘兴翀, 王瀚雨, 李海敏, 倪亚飞, 邹文静, 雷月, 彭永姗. F3EACl修饰层对钙钛矿太阳能电池性能提升的研究[J]. 化工学报, 2023, 74(8): 3554-3563. |

| [8] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [9] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [10] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [11] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [12] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [13] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [14] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [15] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号