化工学报 ›› 2022, Vol. 73 ›› Issue (12): 5672-5684.DOI: 10.11949/0438-1157.20221224

• 过程安全 • 上一篇

裴蓓1( ), 康亚祥1, 余明高2(

), 康亚祥1, 余明高2( ), 郭佳琪1, 韦双明1, 陈立伟1

), 郭佳琪1, 韦双明1, 陈立伟1

收稿日期:2022-09-07

修回日期:2022-10-31

出版日期:2022-12-05

发布日期:2023-01-17

通讯作者:

余明高

作者简介:裴蓓(1982—),女,博士,副教授,smart128@126.com

基金资助:

Bei PEI1( ), Yaxiang KANG1, Minggao YU2(

), Yaxiang KANG1, Minggao YU2( ), Jiaqi GUO1, Shuangming WEI1, Liwei CHEN1

), Jiaqi GUO1, Shuangming WEI1, Liwei CHEN1

Received:2022-09-07

Revised:2022-10-31

Online:2022-12-05

Published:2023-01-17

Contact:

Minggao YU

摘要:

利用20 L球爆炸实验平台,系统研究了不同点火延迟时间对CO2-超细水雾抑制瓦斯/煤尘爆炸特性的影响。结果表明:相比单一抑爆,在CO2-超细水雾作用下,随着点火延迟时间延长和水雾浓度增大,瓦斯/煤尘爆炸强度削弱,火焰传播速度降低,火焰亮度降低且出现下沉现象,火焰内部煤尘粒子运动状态由向心运动向旋转运动转换。10%CO2、306 g/m3超细水雾时,在1500 ms点火延迟时的最大爆炸压力和最大压力上升速率比无水雾时分别降低了6.79%和16.14%,最大爆炸压力来临时间延长了24.47%;10%CO2、204 g/m3超细水雾下,在2000 ms点火延迟时的最大爆炸压力和火焰平均速度比1000 ms点火延迟时分别降低了5.22%和37.5%,最大爆炸压力来临时间延长24.66%。研究结果为气液两相抑爆剂抑制瓦斯/煤尘爆炸控制参数的确定提供了技术指导。

中图分类号:

裴蓓, 康亚祥, 余明高, 郭佳琪, 韦双明, 陈立伟. 点火延迟时间对CO2-超细水雾的抑爆特性影响[J]. 化工学报, 2022, 73(12): 5672-5684.

Bei PEI, Yaxiang KANG, Minggao YU, Jiaqi GUO, Shuangming WEI, Liwei CHEN. Effect of ignition delay time on explosion suppression characteristics of CO2-ultra-fine water mist[J]. CIESC Journal, 2022, 73(12): 5672-5684.

| 煤样 | 水分/% (质量) | 灰分/% (质量) | 挥发分/% (质量) | 固定碳/% (质量) |

|---|---|---|---|---|

| 褐煤 | 4.15 | 11.75 | 35.02 | 49.08 |

表1 煤尘工业分析

Table 1 Industrial analysis of coal dust

| 煤样 | 水分/% (质量) | 灰分/% (质量) | 挥发分/% (质量) | 固定碳/% (质量) |

|---|---|---|---|---|

| 褐煤 | 4.15 | 11.75 | 35.02 | 49.08 |

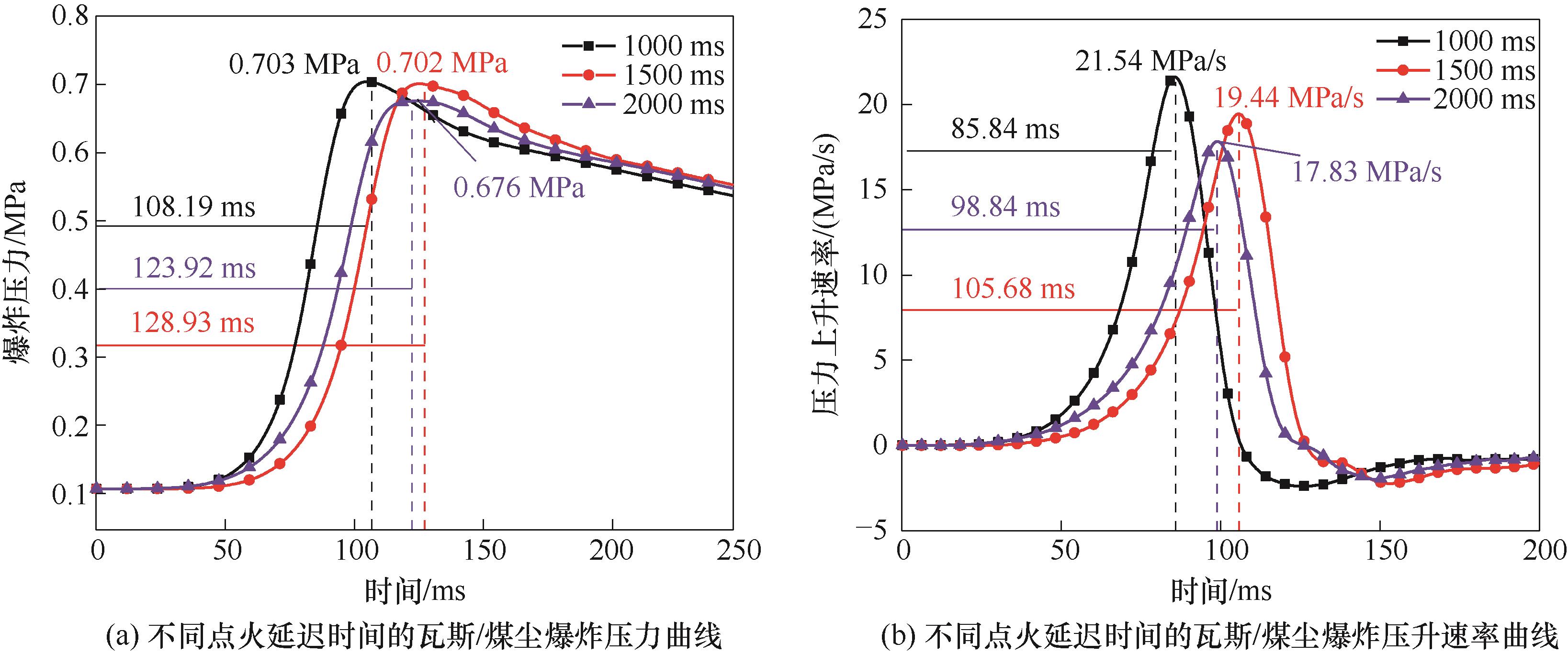

图3 不同点火延迟时间的瓦斯/煤尘爆炸压力曲线和压升速率曲线(0%CO2+0 g/m3 H2O)

Fig.3 Gas/coal dust explosion pressure curve and pressure rise rate curve with different ignition delay time(0%CO2+0 g/m3H2O)

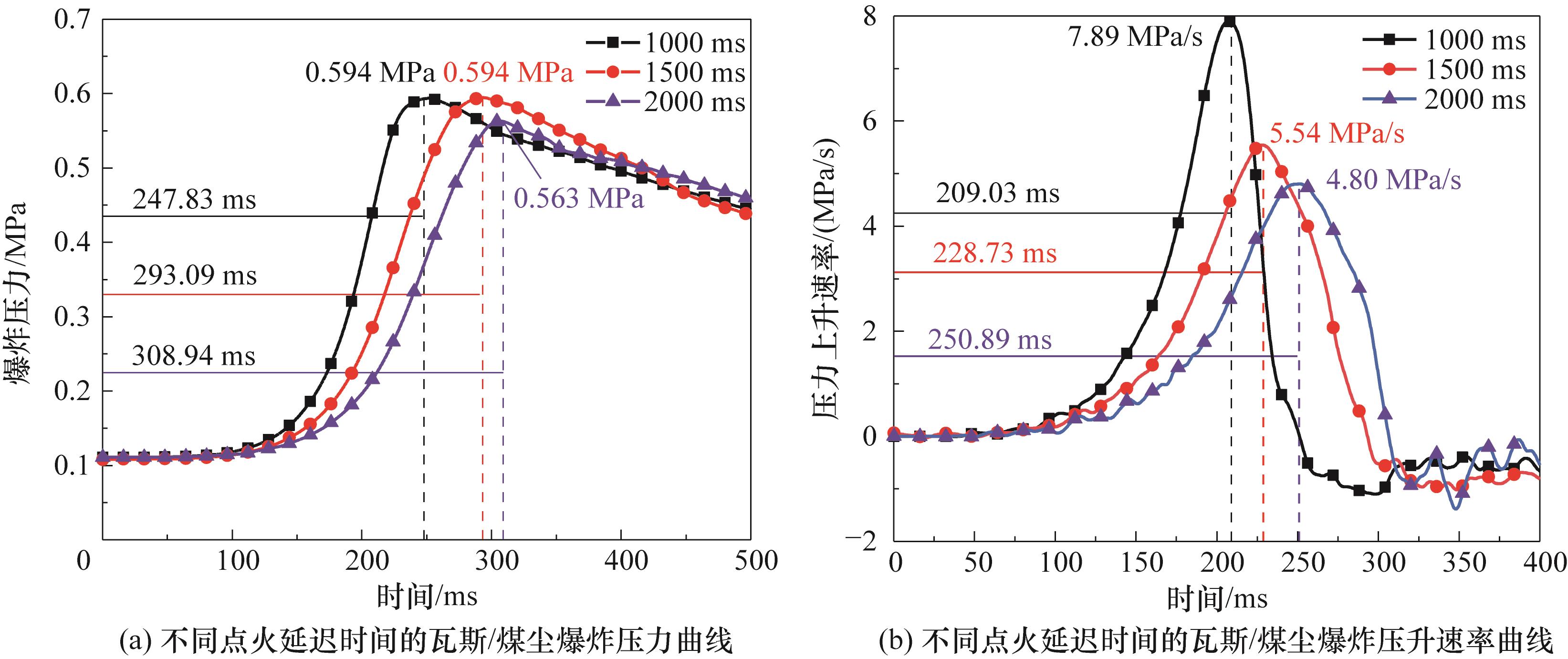

图4 不同点火延迟时间的瓦斯/煤尘爆炸压力曲线和压升速率曲线(10%CO2+204 g/m3H2O)

Fig.4 Gas/coal dust explosion pressure curve and pressure rise rate curve with different ignition delay time(10%CO2+204 g/m3H2O)

图5 不同浓度超细水雾作用下的瓦斯/煤尘爆炸压力曲线和压升速率曲线(10%CO2+1500 ms)

Fig.5 Gas/coal dust explosion pressure curve and pressure rise rate curve under the action of different concentrations of ultra-fine water mist (10%CO2+1500 ms)

图6 不同体积分数CO2作用时的压力曲线和压力上升速率曲线(204 g/m3H2O+1500 ms)

Fig.6 Gas/coal dust explosion pressure curve and pressure rise rate curve under the action of different volume fraction of CO2(204 g/m3H2O+1500 ms)

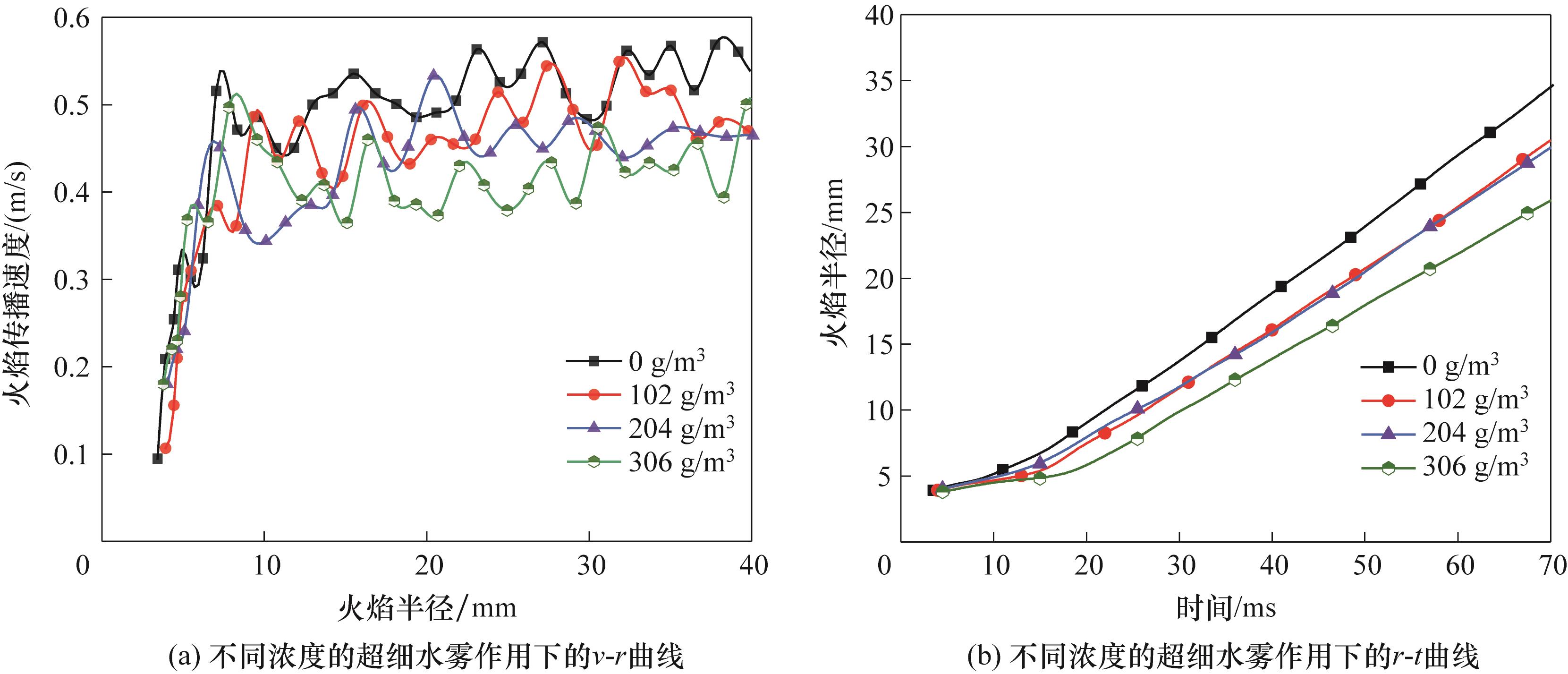

图10 不同浓度的超细水雾作用下的v-r和r-t曲线(6%CO2+1500 ms)

Fig.10 v-r and r-t curves under the action of different concentrations of ultra-fine water mist(6%CO2+1500 ms)

图11 不同浓度超细水雾作用下火焰平均速度随点火延迟时间的变化曲线(6%CO2)

Fig.11 Curve of flame average velocity changing with ignition delay time under the action of different concentrations of ultra-fine water mist (6%CO2)

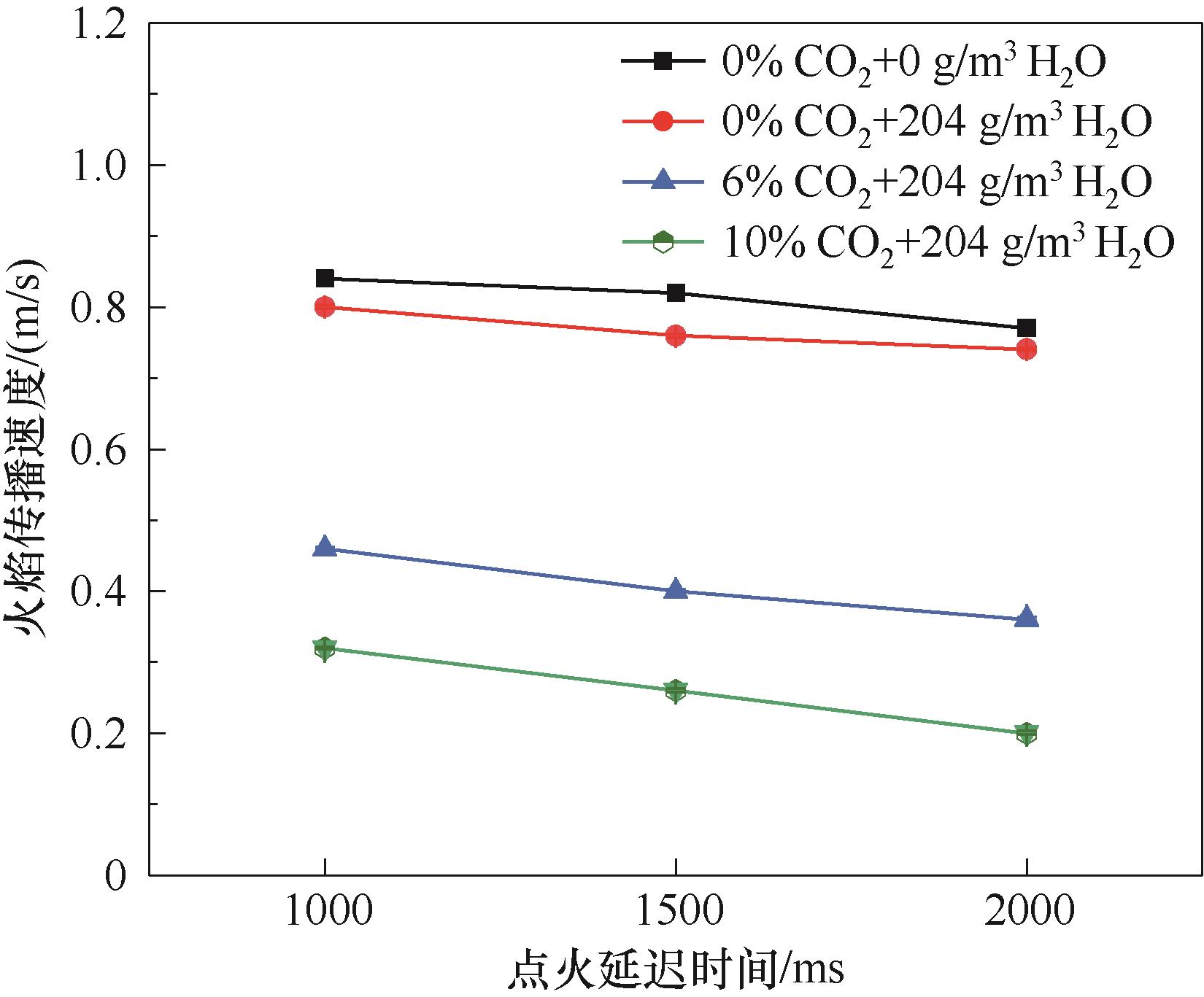

图12 不同CO2浓度作用下火焰平均速度随点火延迟时间的变化曲线(204 g/m3H2O)

Fig.12 Curve of flame average velocity changing with ignition delay time under the action of different concentrations of ultra-fine water mist (204 g/m3H2O)

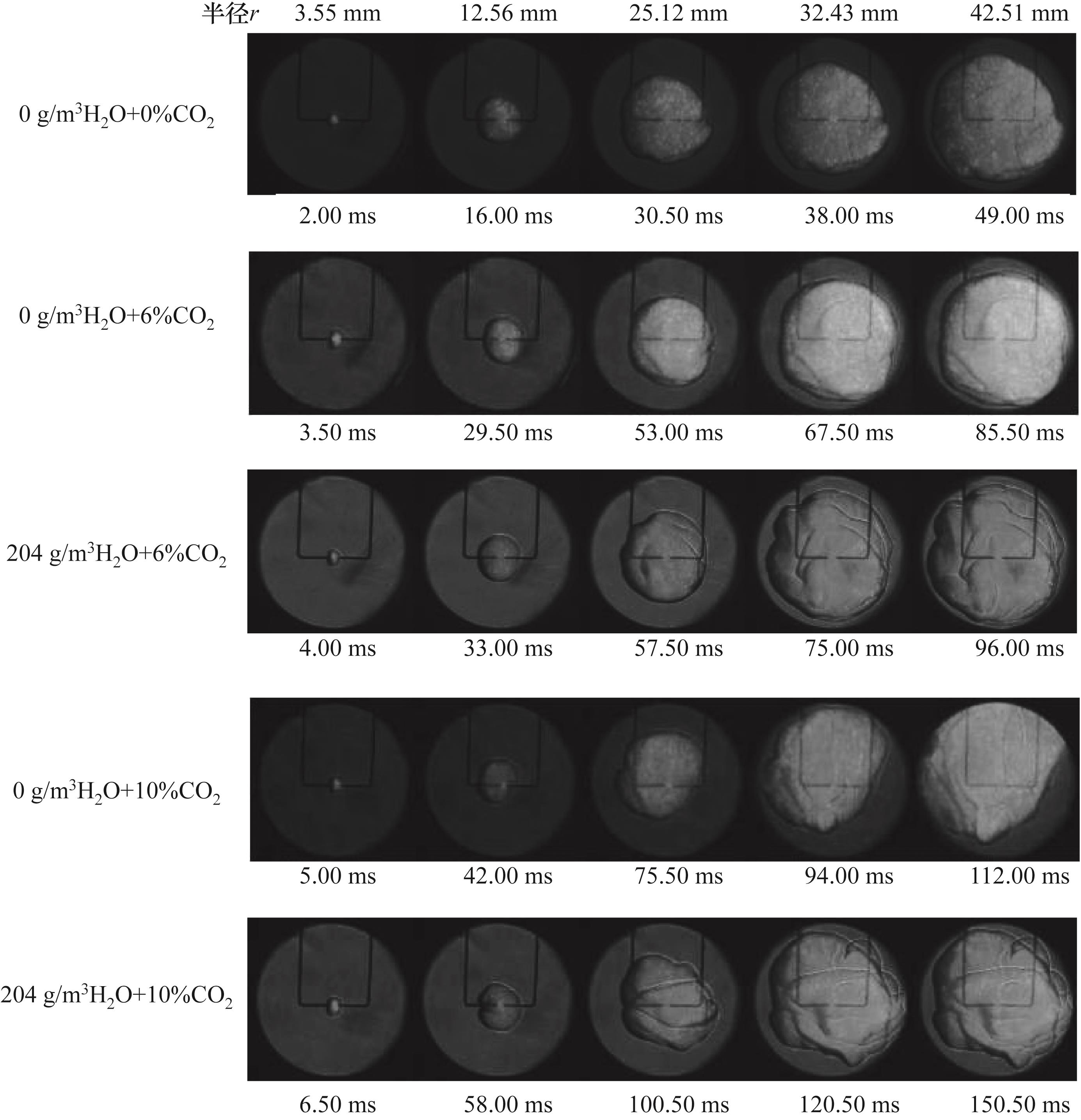

图14 不同浓度超细水雾下瓦斯/煤尘爆炸纹影图像(6%CO2+1500 ms)

Fig.14 Schlieren image of gas/coal dust explosion under different concentrations of ultra-fine water mist(6%CO2+1500 ms)

图15 不同条件CO2和超细水雾作用下的瓦斯/煤尘爆炸纹影图像(1500 ms)

Fig.15 Schlieren image of gas/coal dust explosion under different conditions of CO2 and ultra-fine water mist(1500 ms)

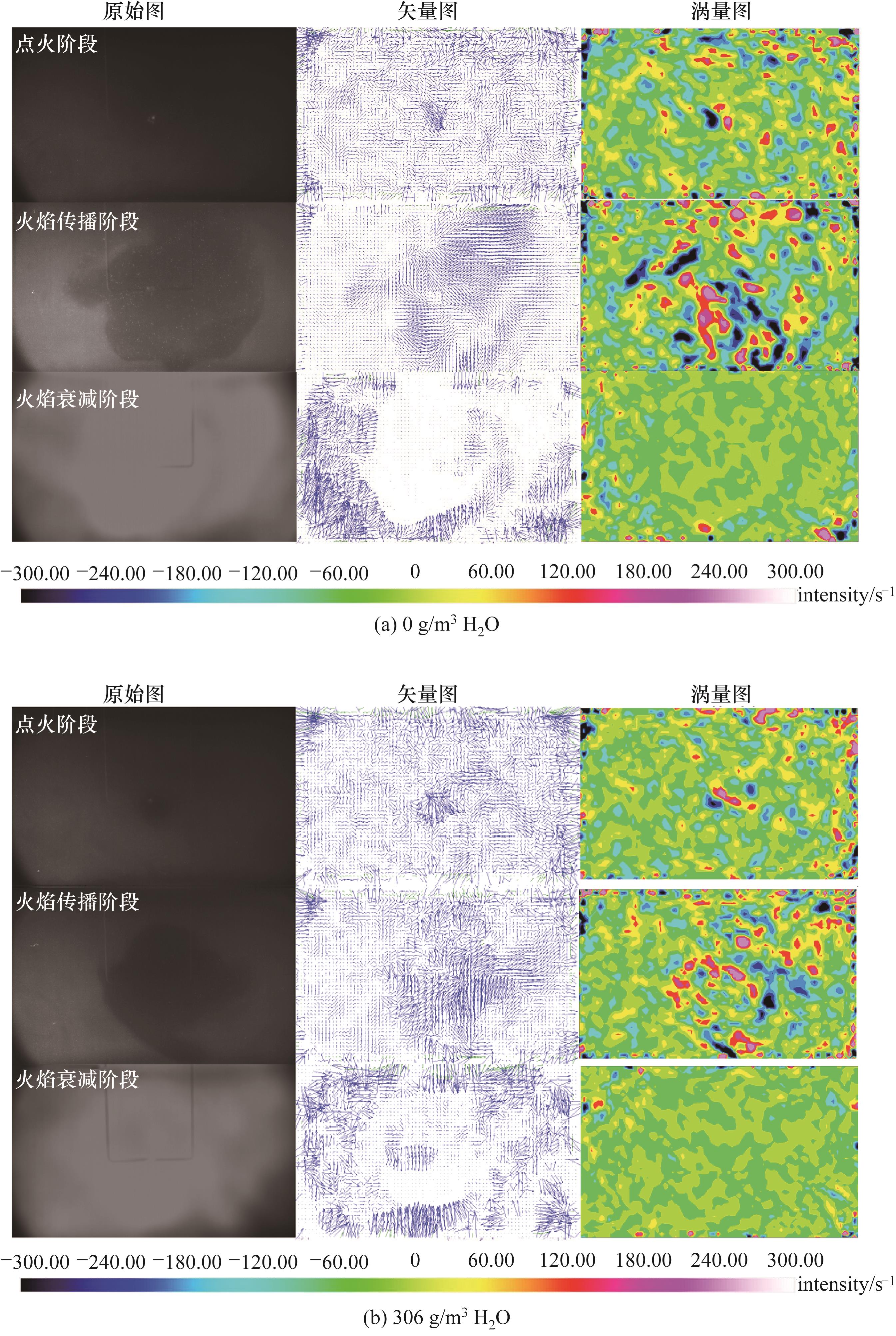

图17 不同浓度超细水雾下瓦斯/煤尘爆炸流场图(10%CO2+1500 ms)

Fig.17 Flow field diagram of gas/coal dust explosion under different concentrations of ultra-fine water mist(10%CO2+1500 ms)

| 1 | 司荣军, 李润之, 苏岱峰. 煤尘云质量浓度对瓦斯爆炸压力影响的试验研究[J]. 安全与环境学报, 2018, 18(5): 1796-1798. |

| Si R J, Li R Z, Su D F. Investigation of the influence of the coal dust cloud on the gas explosion pressure[J]. Journal of Safety and Environment, 2018, 18(5): 1796-1798. | |

| 2 | 裴蓓, 张子阳, 潘荣锟, 等. 不同强度冲击波诱导沉积煤尘爆炸火焰传播特性[J]. 煤炭学报, 2021, 46(2): 498-506. |

| Pei B, Zhang Z Y, Pan R K, et al. Flame propagation characteristics of deposited coal dust explosion induced by shock waves of different intensities[J]. Journal of China Coal Society, 2021, 46(2): 498-506. | |

| 3 | 王博, 苟瑞君, 阚润哲. 煤尘粒径对瓦斯煤尘爆炸的影响研究[J]. 中北大学学报(自然科学版), 2019, 40(1): 79-83, 89. |

| Wang B, Gou R J, Kan R Z. Study on the influence of particle size of coal dust on gas and coal dust explosion[J]. Journal of North University of China (Natural Science Edition), 2019, 40(1): 79-83, 89. | |

| 4 | 裴蓓, 朱知印, 余明高, 等. 瓦斯/煤尘爆炸初期复合火焰加速及灾害强化机制分析[J]. 工程热物理学报, 2021, 42(7): 1879-1886. |

| Pei B, Zhu Z Y, Yu M G, et al. Analysis on the acceleration of composite flame and the strengthening mechanism of disaster in the initial stage of gas/coal dust explosion[J]. Journal of Engineering Thermophysics, 2021, 42(7): 1879-1886. | |

| 5 | 景国勋, 邵泓源, 吴昱楼, 等. 不同煤种对瓦斯煤尘爆炸影响的实验研究[J]. 煤矿安全, 2020, 51(5): 1-5. |

| Jing G X, Shao H Y, Wu Y L, et al. Experimental study on the influence of different coal species on gas and coal dust explosion[J]. Safety in Coal Mines, 2020, 51(5): 1-5. | |

| 6 | Li Y, Xu H L, Wang X S. Experimental study on the influence of initial pressure on explosion of methane-coal dust mixtures[J]. Procedia Engineering, 2013, 62: 980-984. |

| 7 | Kundu S K, Zanganeh J, Eschebach D, et al. Explosion severity of methane-coal dust hybrid mixtures in a ducted spherical vessel[J]. Powder Technology, 2018, 323: 95-102. |

| 8 | Garcia-Agreda A, Benedetto A D, Russo P, et al. Dust/gas mixtures explosion regimes[J]. Powder Technology, 2011, 205(1/2/3): 81-86. |

| 9 | Cao W G, Zhou Z H, Li W J, et al. Under-expansion jet flame propagation characteristics of premixed H2/air in explosion venting[J]. International Journal of Hydrogen Energy, 2021, 46(78): 38913-38922. |

| 10 | Cao W G, Zhou Z H, Zhou W, et al. The flow field behaviours of under-expansion jet flame in premixed hydrogen/air explosion venting[J]. International Journal of Hydrogen Energy, 2022, 47(18): 10420-10430. |

| 11 | Cao W G, Qin Q F, Cao W, et al. Experimental and numerical studies on the explosion severities of coal dust/air mixtures in a 20-L spherical vessel[J]. Powder Technology, 2017, 310: 17-23. |

| 12 | Jiao F Y, Zhang H R, Li W J, et al. Experimental and numerical study of the influence of initial temperature on explosion limits and explosion process of syngas-air mixtures[J]. International Journal of Hydrogen Energy, 2022, 47(52): 22261-22272. |

| 13 | 王晓彬. 点火延迟时间对甲烷煤尘爆炸特性的影响[J]. 煤矿安全, 2020, 51(3): 23-27. |

| Wang X B. Effect of ignition delay time on explosion characteristics of methane and coal dust hybrid mixtures[J]. Safety in Coal Mines, 2020, 51(3): 23-27. | |

| 14 | 李雨成, 刘天奇, 周西华. 煤尘爆炸最大压力随点火延迟时间的时序性分析[J]. 中国安全科学学报, 2016, 26(5): 30-34. |

| Li Y C, Liu T Q, Zhou X H. Time series analysis of maximum pressure of coal dust explosion as a function of ignition delay time[J]. China Safety Science Journal, 2016, 26(5): 30-34. | |

| 15 | Wang S Y, Shi Z C, Peng X, et al. Effect of the ignition delay time on explosion severity parameters of coal dust/air mixtures[J]. Powder Technology, 2019, 342: 509-516. |

| 16 | 袁旌杰, 伍毅, 陈瑜, 等. 点火延迟时间对粉尘最大爆炸压力测定影响的研究[J]. 中国安全科学学报, 2010, 20(3): 65-69. |

| Yuan J J, Wu Y, Chen Y, et al. Effect of ignition delay time on measurement of maximum explosion pressure of dusts[J]. China Safety Science Journal, 2010, 20(3): 65-69. | |

| 17 | Song Y F, Zhang Q. Quantitative research on gas explosion inhibition by water mist[J]. Journal of Hazardous Materials, 2019, 363: 16-25. |

| 18 | Jing Q, Wang D, Liu Q M, et al. Inhibition effect and mechanism of ultra-fine water mist on CH4/air detonation: quantitative research based on CFD technology[J]. Process Safety and Environmental Protection, 2021, 148: 75-92. |

| 19 | Blanchard E, Boulet P, Fromy P, et al. Experimental and numerical study of the interaction between water mist and fire in an intermediate test tunnel[J]. Fire Technology, 2014, 50(3): 565-587. |

| 20 | 李振峰, 王天政, 安安, 等. 细水雾抑制煤尘与瓦斯爆炸实验[J]. 西安科技大学学报, 2011, 31(6): 698-702, 707. |

| Li Z F, Wang T Z, An A, et al. Experiment on inhibiting the gas and coal dust explosion by water mist[J]. Journal of Xi'an University of Science and Technology, 2011, 31(6): 698-702, 707. | |

| 21 | Zhang P P, Zhou Y H, Cao X Y, et al. Mitigation of methane/air explosion in a closed vessel by ultrafine water fog[J]. Safety Science, 2014, 62: 1-7. |

| 22 | Cao X Y, Ren J J, Zhou Y H, et al. Suppression of methane/air explosion by ultrafine water mist containing sodium chloride additive[J]. Journal of Hazardous Materials, 2015, 285: 311-318. |

| 23 | 陈彪, 冯萧, 张皓天, 等. 超细水雾抑制甲烷-煤尘复合爆炸的实验研究[J]. 消防科学与技术, 2021, 40(7): 1046-1051. |

| Chen B, Feng X, Zhang H T, et al. Experimental study on suppression of methane-coal dust compound explosion by ultra-fine water mist[J]. Fire Science and Technology, 2021, 40(7): 1046-1051. | |

| 24 | 常新明, 张红军, 魏垂胜, 等. 细水雾粒径对管内瓦斯爆炸特性的影响机理研究[J]. 河南理工大学学报(自然科学版), 2021, 40(5): 8-15. |

| Chang X M, Zhang H J, Wei C S, et al. Study on the influence mechanism of fine water mist particle size on gas explosion characteristics in pipe[J]. Journal of Henan Polytechnic University (Natural Science), 2021, 40(5): 8-15. | |

| 25 | 余明高, 安安, 游浩. 细水雾抑制管道瓦斯爆炸的实验研究[J]. 煤炭学报, 2011, 36(3): 417-422. |

| Yu M G, An A, You H. Experimental study on inhibiting the gas explosion by water spray in tube[J]. Journal of China Coal Society, 2011, 36(3): 417-422. | |

| 26 | Wei S M, Yu M G, Pei B, et al. Suppression of CO2 and H2O on the cellular instability of premixed methane/air flame[J]. Fuel, 2020, 264: 116862. |

| 27 | Pei B, Zhu Z Y, Yang S J, et al. Evaluation of the suppression effect on the flame intensification of ethanol fire by N2 twin-fluid water mist containing KQ compound additive[J]. Process Safety and Environmental Protection, 2021, 149: 289-298. |

| 28 | Tousif M, Harish A, Kumaran S M, et al. Numerical study of interaction of coal dust with premixed fuel-lean methane-air flames[J]. Advanced Powder Technology, 2020, 31(9): 3833-3844. |

| 29 | 李海涛, 陈晓坤, 邓军, 等. 湍流状态下竖直管道内甲烷-煤尘预混特征及爆炸过程数值模拟[J]. 煤炭学报, 2018, 43(6): 1769-1779. |

| Li H T, Chen X K, Deng J, et al. Numerical simulation on the premix properties and explosion process of methane/coal dust mixture in a vertical pipeline under turbulent flow[J]. Journal of China Coal Society, 2018, 43(6): 1769-1779. | |

| 30 | 李庆钊, 翟成, 吴海进, 等. 基于20L球形爆炸装置的煤尘爆炸特性研究[J]. 煤炭学报, 2011, 36(S1): 119-124. |

| Li Q Z, Zhai C, Wu H J, et al. Investigation on coal dust explosion characteristics using 20 L explosion sphere vessels[J]. Journal of China Coal Society, 2011, 36(S1): 119-124. |

| [1] | 代宝民, 王启龙, 刘圣春, 张佳宁, 李鑫海, 宗凡迪. 非共沸工质辅助过冷CO2冷热联供系统的热力学性能分析[J]. 化工学报, 2023, 74(S1): 64-73. |

| [2] | 杨天阳, 邹慧明, 周晖, 王春磊, 田长青. -30℃电动汽车补气式CO2热泵制热性能实验研究[J]. 化工学报, 2023, 74(S1): 272-279. |

| [3] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [4] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [5] | 李贵贤, 曹阿波, 孟文亮, 王东亮, 杨勇, 周怀荣. 耦合固体氧化物电解槽的CO2制甲醇过程设计与评价研究[J]. 化工学报, 2023, 74(7): 2999-3009. |

| [6] | 杨灿, 孙雪琦, 尚明华, 张建, 张香平, 曾少娟. 相变离子液体体系吸收分离CO2的研究现状及展望[J]. 化工学报, 2023, 74(4): 1419-1432. |

| [7] | 赵焕娟, 刘婧, 周冬雷, 林敏. 多孔材料对氢气爆轰的抑制作用[J]. 化工学报, 2023, 74(2): 968-976. |

| [8] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [9] | 王峰, 张顺鑫, 余方博, 刘亚, 郭烈锦. 光催化CO2还原制碳氢燃料系统优化策略研究[J]. 化工学报, 2023, 74(1): 29-44. |

| [10] | 党迎喜, 谈朋, 刘晓勤, 孙林兵. 辐射冷却和太阳能加热驱动的CO2变温捕获[J]. 化工学报, 2023, 74(1): 469-478. |

| [11] | 鲁军辉, 李俊明. H2O-CO2、H2O-N2、H2O-He水平管外自然对流凝结换热特性研究[J]. 化工学报, 2022, 73(9): 3870-3879. |

| [12] | 王燕, 何佳, 杨晶晶, 林晨迪, 纪文涛. 草酸盐和碳酸氢盐抑制聚乙烯粉尘爆炸特性[J]. 化工学报, 2022, 73(9): 4207-4216. |

| [13] | 裴仁花, 王永洪, 张新儒, 李晋平. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| [14] | 郭丹, 方雨洁, 许一寒, 李致远, 黄守莹, 王胜平, 马新宾. 乙烷和二氧化碳催化转化的研究进展[J]. 化工学报, 2022, 73(8): 3406-3416. |

| [15] | 王立维, 王娟娟, 王永洪, 张新儒, 李晋平. 聚乙烯胺/Cu3(BTC)2-MMT-NH2混合基质膜的制备及气体传递性能[J]. 化工学报, 2022, 73(7): 3068-3077. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号