化工学报 ›› 2022, Vol. 73 ›› Issue (2): 612-621.DOI: 10.11949/0438-1157.20210838

李广1( ),庄大伟1,谢丽懿1,丁国良1(

),庄大伟1,谢丽懿1,丁国良1( ),郑立宇2,龙春仙2,江波2

),郑立宇2,龙春仙2,江波2

收稿日期:2021-06-22

修回日期:2021-12-13

出版日期:2022-02-05

发布日期:2022-02-18

通讯作者:

丁国良

作者简介:李广(1997—),男,硕士研究生,基金资助:

Guang LI1( ),Dawei ZHUANG1,Liyi XIE1,Guoliang DING1(

),Dawei ZHUANG1,Liyi XIE1,Guoliang DING1( ),Liyu ZHENG2,Chunxian LONG2,Bo JIANG2

),Liyu ZHENG2,Chunxian LONG2,Bo JIANG2

Received:2021-06-22

Revised:2021-12-13

Online:2022-02-05

Published:2022-02-18

Contact:

Guoliang DING

摘要:

R32作为低温室效应制冷剂得到广泛应用,空调器中循环的介质是制冷剂与润滑油的混合物,掌握R32-润滑油混合物的流动沸腾特性是R32空调器优化设计的关键。本文的目的是参照空调器实际运行工况,测试R32-润滑油混合物的管内流动沸腾换热特性,开发传热系数关联式。新搭建了具有防爆功能的R32-润滑油混合物管内换热性能测试台,采用换热管为7 mm铜管,测试的质流密度200~400 kg/(m2·s)、干度0.2~0.7、油浓度0~5%。实验结果表明,R32-润滑油混合物管内流动沸腾传热系数随质流密度的增大而增大;在中低干度下传热系数随油浓度的增大而增大,在高干度下随油浓度增大先增大后减小并于3%油浓度处取得最大值。基于混合物物性与流型开发了传热系数关联式,预测值与85%的实验数据的误差在±20%内。

中图分类号:

李广, 庄大伟, 谢丽懿, 丁国良, 郑立宇, 龙春仙, 江波. 含油R32管内流动沸腾换热特性测试及关联式开发[J]. 化工学报, 2022, 73(2): 612-621.

Guang LI, Dawei ZHUANG, Liyi XIE, Guoliang DING, Liyu ZHENG, Chunxian LONG, Bo JIANG. Experimental investigation and correlation development of flow boiling heat transfer characteristics of R32-oil mixture inside tube[J]. CIESC Journal, 2022, 73(2): 612-621.

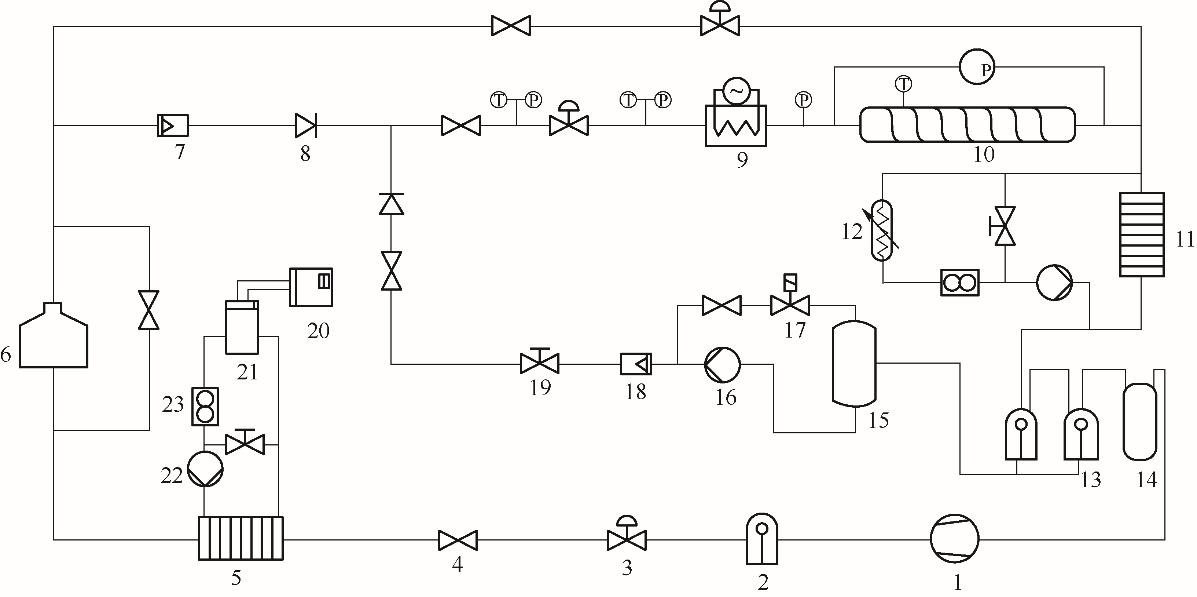

图1 实验台示意图1—压缩机;2—压缩机油分离器;3—气动调节阀;4—球阀;5—过冷器;6—制冷剂储液罐;7—制冷剂质量流量计;8—单向止回阀;9—预热器;10—测试段;11—过热器;12—电热水器;13—油分离器组;14—气液分离器;15—储油罐;16—高压油泵;17—微型调节阀;18—油质量流量计;19—针阀;20—冷水机组;21—水箱;22—水泵;23—体积流量计

Fig.1 Schematic diagram of experimental apparatus

| 项目 | 数值 |

|---|---|

| 蒸发温度/℃ | -5、5、15 |

| 干度 | 0.2、0.4、0.6、0.7 |

| 质流密度/(kg/(m2·s)) | 200、300、400 |

| 管径/mm | 7 |

| 润滑油浓度/% | 0、1、3、5 |

表1 实验工况

Table 1 Test conditions of the experimental rig

| 项目 | 数值 |

|---|---|

| 蒸发温度/℃ | -5、5、15 |

| 干度 | 0.2、0.4、0.6、0.7 |

| 质流密度/(kg/(m2·s)) | 200、300、400 |

| 管径/mm | 7 |

| 润滑油浓度/% | 0、1、3、5 |

| 测量参数 | 测量仪器 | 测量范围 | 测量精度 |

|---|---|---|---|

| 制冷剂温度 | 5TC-TT-K-36型热电偶 | -10~25℃ | ±0.05℃ |

| 冷取水温度 | 5TC-TT-K-36型热电偶 | 5~10℃ | ±0.05℃ |

| 加热水温度 | 5TC-TT-K-36型热电偶 | 30~50℃ | ±0.05℃ |

| 制冷剂压力 | CX3051/G/HT/5M压力变 送器 | 1500 kPa | ±0.1% |

| 润滑油压力 | CX3051/G/HT/5M压力变 送器 | 3000 kPa | ±0.5% |

| 制冷剂压降 | 3051S2CD3A2E12A1AB4K5M5压差变送器 | 0~50 kPa | ±0.04% |

| 制冷剂质量流量 | E+H科式流量计 | 5.1~17.1 g/s | ±0.05% |

| 润滑油质量流量 | OVAL科式流量计 | 0~0.257 g/s | ±0.015% |

| 冷却水体积流量 | LWGY-12BAGS1/U/NE/NT体积流量计 | 0.48~39.6 L/min | ±0.5% |

| 加热水体积流量 | LWGY-12BAGS1/U/NE/NT体积流量计 | 0.48~39.6 L/min | ±0.5% |

表2 参数测量仪器及精度

Table 2 Measuring instrument and uncertainties

| 测量参数 | 测量仪器 | 测量范围 | 测量精度 |

|---|---|---|---|

| 制冷剂温度 | 5TC-TT-K-36型热电偶 | -10~25℃ | ±0.05℃ |

| 冷取水温度 | 5TC-TT-K-36型热电偶 | 5~10℃ | ±0.05℃ |

| 加热水温度 | 5TC-TT-K-36型热电偶 | 30~50℃ | ±0.05℃ |

| 制冷剂压力 | CX3051/G/HT/5M压力变 送器 | 1500 kPa | ±0.1% |

| 润滑油压力 | CX3051/G/HT/5M压力变 送器 | 3000 kPa | ±0.5% |

| 制冷剂压降 | 3051S2CD3A2E12A1AB4K5M5压差变送器 | 0~50 kPa | ±0.04% |

| 制冷剂质量流量 | E+H科式流量计 | 5.1~17.1 g/s | ±0.05% |

| 润滑油质量流量 | OVAL科式流量计 | 0~0.257 g/s | ±0.015% |

| 冷却水体积流量 | LWGY-12BAGS1/U/NE/NT体积流量计 | 0.48~39.6 L/min | ±0.5% |

| 加热水体积流量 | LWGY-12BAGS1/U/NE/NT体积流量计 | 0.48~39.6 L/min | ±0.5% |

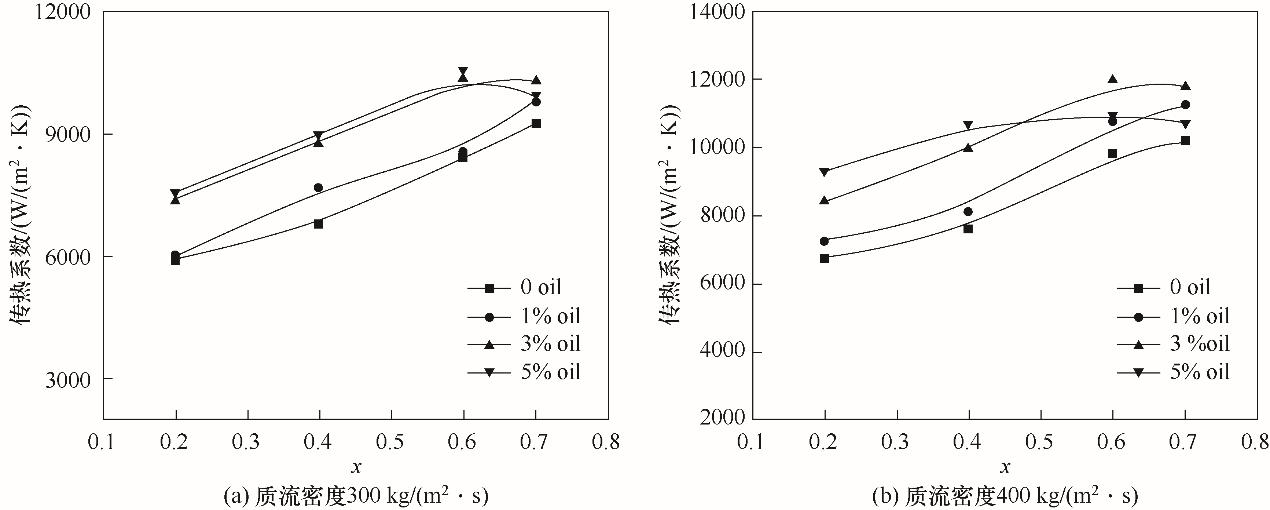

图3 蒸发温度15℃ R32-润滑油混合物传热系数随干度和油浓度的变化

Fig.3 Heat transfer coefficient of R32-oil mixture plotted as a function of oil concentration and vapor quality at 15℃ evaporation temperature

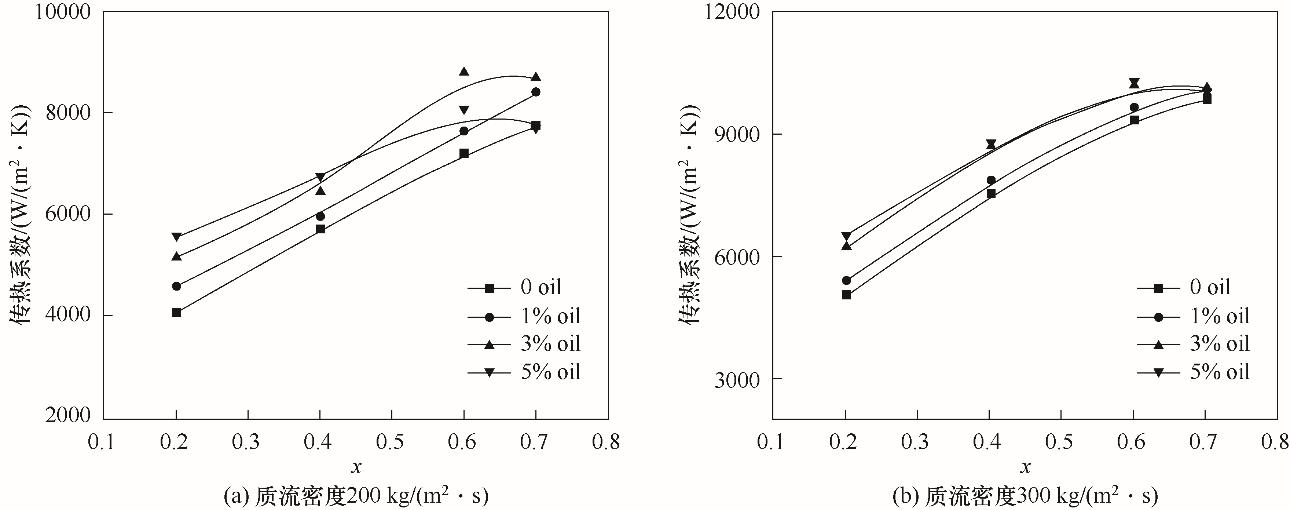

图4 蒸发温度5℃ R32-润滑油混合物传热系数随干度和油浓度的变化

Fig.4 Heat transfer coefficient of R32-oil mixture plotted as a function of oil concentration and vapor quality at 5℃ evaporation temperature

图5 蒸发温度-5℃ R32-润滑油混合物传热系数随干度和油浓度的变化

Fig.5 Heat transfer coefficient of R32-oil mixture plotted as a function of oil concentration and vapor quality at -5℃ evaporation temperature

| 1 | Shu H W, Bie X, Zhang H L, et al. Natural heat transfer air-conditioning terminal device and its system configuration for ultra-low energy buildings[J]. Renewable Energy, 2020, 154: 1113-1121. |

| 2 | Huang D S, Tu W B, Zhang X M, et al. Using Taguchi method to obtain the optimal design of heat dissipation mechanism for electronic component packaging[J]. Microelectronics Reliability, 2016, 65: 131-141. |

| 3 | Yang Q, Zhao J Q, Huang Y P, et al. A diamond made microchannel heat sink for high-density heat flux dissipation[J]. Applied Thermal Engineering, 2019, 158: 113804. |

| 4 | 吴文翔, 韩小渠, 周志杰, 等. 循环转轮空调系统变工况除湿特性[J]. 化工学报, 2020, 71: 355-360. |

| Wu W X, Han X Q, Zhou Z J, et al. Dehumidification characteristics of recirculated desiccant wheel dehumidification system under variable working conditions[J]. CIESC Journal, 2020, 71: 355-360. | |

| 5 | 吴志光, 马虎根, 蔡祖恢. R32/R134a在水平内螺纹管内流动沸腾强化特性的分析与研究[J]. 化工学报, 2005, 56(2): 239-242. |

| Wu Z G, Ma H G, Cai Z H. Convective heat transfer of R32/R134a inside horizontal microfin tubes[J]. Journal of Chemical Industry and Engineering (China), 2005, 56(2): 239-242. | |

| 6 | Liu L S, Dou Y W, Yao B, et al. Historical and projected HFC-410A emission from room air conditioning sector in China[J]. Atmospheric Environment, 2019, 212: 194-200. |

| 7 | 邱琳祯, 谷波, 缪梦华. R32热力学性质计算模型及其分析[J]. 化工学报, 2019, 70(6): 2075-2082. |

| Qiu L Z, Gu B, Miao M H. Calculation model and analysis of thermodynamic properties of R32 refrigerant[J]. CIESC Journal, 2019, 70(6): 2075-2082. | |

| 8 | 金梧凤, 于斌, 高攀, 等. R32与新型PVE油的互溶性及其对空调性能的影响[J]. 化工学报, 2018, 69(4): 1631-1637. |

| Jin W F, Yu B, Gao P, et al. Effect of solubility between R32 and new PVE oil on performance of air conditioning system[J]. CIESC Journal, 2018, 69(4): 1631-1637. | |

| 9 | Jin W F, Gao P, Zheng Y F. Experimental study on ventilation effect on concentration distribution of R32 leaking from floor type air conditioner[J]. Energy Procedia, 2017, 105: 4627-4634. |

| 10 | Jia L Z, Jin W F, Zhang Y. Analysis of indoor environment safety with R32 leaking from a running air conditioner[J]. Procedia Engineering, 2015, 121: 1605-1612. |

| 11 | 金梧凤, 贾利芝, 张燕. 空调送风速度和送风角度对可燃性冷媒R32泄漏扩散规律的影响[J]. 化工学报, 2015, 66(6): 2351-2358. |

| Jin W F, Jia L Z, Zhang Y. Effect of air supply velocity and angle on R32 leakage and diffusion[J]. CIESC Journal, 2015, 66(6): 2351-2358. | |

| 12 | 陈景祥, 李蔚, 朱华, 等. 三维双侧强化管内R410A蒸发换热特性[J]. 化工学报, 2018, 69: 76-81. |

| Chen J X, Li W, Zhu H, et al. Evaporation heat transfer performance of R410A inside 3-D double-enhanced tubes[J]. CIESC Journal, 2018, 69: 76-81. | |

| 13 | 唐亚林, 舒碧芬, 杨瑞林. R32家用变频空调器制冷剂充注量优化[J]. 制冷与空调, 2018, 18(6): 37-40, 66. |

| Tang Y L, Shu B F, Yang R L. Optimization on refrigerant charge amount of R32 household frequency-conversion air conditioner[J]. Refrigeration and Air-Conditioning, 2018, 18(6): 37-40, 66. | |

| 14 | 李云翔, 张蕾, 刘春慧. 双蒸发温度空调系统热力学分析[C]//2020年中国家用电器技术大会论文集. 宁波, 2020: 938-942. |

| Li Y X, Zhang L, Liu C H. Thermodynamic analysis on air conditioning system with double evaporating temperatures[C]// China Home Appliance Technology Conference 2020. Ningbo, 2020: 938-942. | |

| 15 | 陈裕博, 杨昭, 翟瑞, 等. R290/R1234yf与矿物油的互溶性测试及评价方法[J]. 化工学报, 2019, 70(9): 3248-3255. |

| Chen Y B, Yang Z, Zhai R, et al. Miscibility measurement and evaluation method of R290/R1234yf with mineral oil[J]. CIESC Journal, 2019, 70(9): 3248-3255. | |

| 16 | 刘蕴青, 崔勇, 陈引生. 压缩机带油率对空调系统性能影响研究[J]. 低温与超导, 2019, 47(11): 82-85, 90. |

| Liu Y Q, Cui Y, Chen Y S. Study on the effect of oil-carrying rate of compressor on the performance of air conditioning system[J]. Cryogenics & Superconductivity, 2019, 47(11): 82-85, 90. | |

| 17 | 邱金友, 张华, 钟绍庚, 等. R32/油混合物管内两相流动摩擦压降模型预测研究[J]. 低温与超导, 2019, 47(1): 72-76. |

| Qiu J Y, Zhang H, Zhong S G, et al. Investigation on prediction of two-phase frictional pressure drop for R32/oil mixture inside tube[J]. Cryogenics & Superconductivity, 2019, 47(1): 72-76. | |

| 18 | 胡海涛, 丁国良, 汪振策, 等. R410A-油混合物在7 mm直强化管和C形强化管内流动沸腾的摩擦压降特性[J]. 化工学报, 2007, 58(8): 1905-1910. |

| Hu H T, Ding G L, Wang Z C, et al. Frictional pressure drop characteristics of R410A-oil mixture flow boiling in 7 mm straight and C-shape enhanced tubes[J]. Journal of Chemical Industry and Engineering (China), 2007, 58(8): 1905-1910. | |

| 19 | Huang X C, Ding G L, Hu H T, et al. Influence of oil on flow condensation heat transfer of R410A inside 4.18 mm and 1.6 mm inner diameter horizontal smooth tubes[J]. International Journal of Refrigeration, 2010, 33(1): 158-169. |

| 20 | 张丹亭, 陶乐仁, 李庆普, 等. R32在水平强化管内的流动沸腾换热特性研究[J]. 热能动力工程, 2019, 34(3): 97-102, 133. |

| Zhang D T, Tao L R, Li Q P, et al. Study on the convective heat transfer of R32 inside horizontal enhanced tubes[J]. Journal of Engineering for Thermal Energy and Power, 2019, 34(3): 97-102, 133. | |

| 21 | Lillo G, Mastrullo R, Mauro A W, et al. Flow boiling of R32 in a horizontal stainless steel tube with 6.00 mm ID. Experiments, assessment of correlations and comparison with refrigerant R410A[J]. International Journal of Refrigeration, 2019, 97: 143-156. |

| 22 | Zhu Y, Wu X M, Zhao R. R32 flow boiling in horizontal mini channels(Part Ⅱ): Flow-pattern based prediction methods for heat transfer and pressure drop[J]. International Journal of Heat and Mass Transfer, 2017, 115: 1233-1244. |

| 23 | Schlager L M, Pate M B, Bergles A E. Heat transfer and pressure drop performance of smooth and internally finned tubes with oil and refrigerant 22 mixtures[J]. ASHRAE Transactions, 1989, 95(2): 160-169. |

| 24 | Wei W J, Ding G L, Hu H T, et al. Influence of lubricant oil on heat transfer performance of refrigerant flow boiling inside small diameter tubes(Part Ⅱ): Correlations[J]. Experimental Thermal and Fluid Science, 2007, 32(1): 77-84. |

| 25 | Cawte H, Sanders D A, Poland G A. Effect of lubricating oil contamination on evaporation in refrigerants R12 and R22[J]. International Journal of Energy Research, 1996, 20(8): 663-679. |

| 26 | Hambraeus K. Heat transfer of oil-contaminated HFC134a in a horizontal evaporator[J]. International Journal of Refrigeration, 1995, 18(2): 87-99. |

| 27 | Hu H T, Ding G L, Wei W J, et al. Heat transfer characteristics of R410A-oil mixture flow boiling inside a 7 mm straight smooth tube[J]. Experimental Thermal and Fluid Science, 2008, 32(3): 857-869. |

| 28 | Tichy J A, Duval W M B, Macken N A. Experimental investigation of heat transfer in forced-convection evaporation of oil-refrigerant mixtures[J]. Ashrae Transactions, 1986, 92 (2A): 450-460. |

| 29 | Eckels S J, Doerr T M, Pate M B. In-tube heat transfer and pressure drop of R-134a and ester lubricant mixtures in a smooth tube and a micro-fin tube(part I): Evaporation[J]. ASHRAE Transactions, 1994, 100(2): 265-282. |

| 30 | Eckels S J, Doerr T M, Pate M B. Heat transfer coefficients and pressure drops for R-134a and an ester lubricant mixture in a smooth tube and a micro-fin tube[J]. ASHRAE Transactions, 1998, 104 (1A): 366-375. |

| 31 | Hu H T, Ding G L, Wang K J. Measurement and correlation of frictional two-phase pressure drop of R410A/POE oil mixture flow boiling in a 7 mm straight micro-fin tube[J]. Applied Thermal Engineering, 2008, 28(11/12): 1272-1283. |

| 32 | Kattan N, Thome J R, Favrat D. Flow boiling in horizontal tubes(part 3): Development of a new heat transfer model based on flow pattern[J]. Journal of Heat Transfer, 1998, 120(1): 156-165. |

| 33 | Youbi-Idrissi M, Bonjour J, Terrier M F, et al. Oil presence in an evaporator: experimental validation of a refrigerant/oil mixture enthalpy calculation model[J]. International Journal of Refrigeration, 2004, 27(3): 215-224. |

| 34 | Moffat R J. Describing the uncertainties in experimental results[J]. Experimental Thermal and Fluid Science, 1988, 1(1): 3-17. |

| 35 | 胡海涛. R410A-润滑油混合物管内流动沸腾换热和压降特性的研究[D]. 上海: 上海交通大学, 2008. |

| Hu H T. Heat transfer and pressure drop of R410A-oil mixture flow boiling inside tubes[D]. Shanghai: Shanghai Jiao Tong University, 2008. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [4] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [5] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [6] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [7] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [8] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [9] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [10] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [11] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [12] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [13] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [14] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [15] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号