化工学报 ›› 2022, Vol. 73 ›› Issue (6): 2589-2602.DOI: 10.11949/0438-1157.20220452

张文龙1,2( ),宁尚雷1,2,靳海波1,2(

),宁尚雷1,2,靳海波1,2( ),马磊1,2,何广湘1,2,杨索和1,2,郭晓燕1,2,张荣月1,2

),马磊1,2,何广湘1,2,杨索和1,2,郭晓燕1,2,张荣月1,2

收稿日期:2022-03-30

修回日期:2022-06-01

出版日期:2022-06-05

发布日期:2022-06-30

通讯作者:

靳海波

作者简介:张文龙(1995—),男,硕士研究生,基金资助:

Wenlong ZHANG1,2( ),Shanglei NING1,2,Haibo JIN1,2(

),Shanglei NING1,2,Haibo JIN1,2( ),Lei MA1,2,Guangxiang HE1,2,Suohe YANG1,2,Xiaoyan GUO1,2,Rongyue ZHANG1,2

),Lei MA1,2,Guangxiang HE1,2,Suohe YANG1,2,Xiaoyan GUO1,2,Rongyue ZHANG1,2

Received:2022-03-30

Revised:2022-06-01

Online:2022-06-05

Published:2022-06-30

Contact:

Haibo JIN

摘要:

通过二维和三维CFD-PBM耦合模型对空气-醋酸体系中流体力学参数进行数值模拟,采用表面张力修正曳力模型与聚并模型,考察了醋酸浓度对鼓泡塔内气含率、气泡大小分布及轴向液速等参数的影响,与差压法、光纤探针和电阻层析成像技术(ERT)测量的实验数据进行了对比,并讨论分析了气含率和气泡直径等流体力学参数的模拟结果。结果表明,醋酸浓度在70%~80%(质量分数)范围内平均气含率存在最大值,且平均气含率的预测值在±10%误差内,三维模拟结果和ERT实验值吻合较好,说明修正后的模型在不同浓度醋酸体系中具有较好的预测性。

中图分类号:

张文龙,宁尚雷,靳海波,马磊,何广湘,杨索和,郭晓燕,张荣月. 鼓泡塔内空气-醋酸体系流体力学参数的CFD-PBM耦合模型数值模拟[J]. 化工学报, 2022, 73(6): 2589-2602.

Wenlong ZHANG,Shanglei NING,Haibo JIN,Lei MA,Guangxiang HE,Suohe YANG,Xiaoyan GUO,Rongyue ZHANG. Numerical simulation of hydrodynamic parameters with air-acetic acid system using CFD-PBM coupled model[J]. CIESC Journal, 2022, 73(6): 2589-2602.

| Ug/(m/s) | Concentration/%(mass) | σ/σ0 | Ce | αexp | αsim | Error/% |

|---|---|---|---|---|---|---|

| 0.047 | 50 | 1.44 | 1.20 | 0.120 | 0.113 | -6.19 |

| 0.071 | 50 | 1.44 | 1.15 | 0.152 | 0.158 | 3.95 |

| 0.094 | 50 | 1.44 | 1.10 | 0.185 | 0.201 | 8.65 |

| 0.047 | 60 | 1.36 | 1.15 | 0.139 | 0.130 | -6.92 |

| 0.071 | 60 | 1.36 | 1.10 | 0.174 | 0.177 | 1.72 |

| 0.094 | 60 | 1.36 | 1.05 | 0.212 | 0.221 | 4.25 |

| 0.047 | 70 | 1.29 | 1.10 | 0.143 | 0.141 | -1.40 |

| 0.071 | 70 | 1.29 | 1.05 | 0.182 | 0.187 | 2.75 |

| 0.094 | 70 | 1.29 | 1.00 | 0.220 | 0.232 | 5.45 |

| 0.047 | 80 | 1.20 | 1.05 | 0.140 | 0.134 | -6.83 |

| 0.071 | 80 | 1.20 | 1.00 | 0.174 | 0.182 | 4.60 |

| 0.094 | 80 | 1.20 | 0.95 | 0.207 | 0.226 | 9.17 |

| 0.047 | 90 | 1.11 | 1.00 | 0.121 | 0.116 | -4.13 |

| 0.071 | 90 | 1.11 | 0.95 | 0.160 | 0.165 | 3.13 |

| 0.094 | 90 | 1.11 | 0.90 | 0.195 | 0.208 | 6.67 |

| 0.047 | 100 | 1.00 | 0.95 | 0.117 | 0.108 | -7.70 |

| 0.071 | 100 | 1.00 | 0.90 | 0.153 | 0.155 | 1.31 |

| 0.094 | 100 | 1.00 | 0.85 | 0.193 | 0.199 | 3.11 |

表1 聚并系数的修正

Table 1 Correction of the coalescence coefficient

| Ug/(m/s) | Concentration/%(mass) | σ/σ0 | Ce | αexp | αsim | Error/% |

|---|---|---|---|---|---|---|

| 0.047 | 50 | 1.44 | 1.20 | 0.120 | 0.113 | -6.19 |

| 0.071 | 50 | 1.44 | 1.15 | 0.152 | 0.158 | 3.95 |

| 0.094 | 50 | 1.44 | 1.10 | 0.185 | 0.201 | 8.65 |

| 0.047 | 60 | 1.36 | 1.15 | 0.139 | 0.130 | -6.92 |

| 0.071 | 60 | 1.36 | 1.10 | 0.174 | 0.177 | 1.72 |

| 0.094 | 60 | 1.36 | 1.05 | 0.212 | 0.221 | 4.25 |

| 0.047 | 70 | 1.29 | 1.10 | 0.143 | 0.141 | -1.40 |

| 0.071 | 70 | 1.29 | 1.05 | 0.182 | 0.187 | 2.75 |

| 0.094 | 70 | 1.29 | 1.00 | 0.220 | 0.232 | 5.45 |

| 0.047 | 80 | 1.20 | 1.05 | 0.140 | 0.134 | -6.83 |

| 0.071 | 80 | 1.20 | 1.00 | 0.174 | 0.182 | 4.60 |

| 0.094 | 80 | 1.20 | 0.95 | 0.207 | 0.226 | 9.17 |

| 0.047 | 90 | 1.11 | 1.00 | 0.121 | 0.116 | -4.13 |

| 0.071 | 90 | 1.11 | 0.95 | 0.160 | 0.165 | 3.13 |

| 0.094 | 90 | 1.11 | 0.90 | 0.195 | 0.208 | 6.67 |

| 0.047 | 100 | 1.00 | 0.95 | 0.117 | 0.108 | -7.70 |

| 0.071 | 100 | 1.00 | 0.90 | 0.153 | 0.155 | 1.31 |

| 0.094 | 100 | 1.00 | 0.85 | 0.193 | 0.199 | 3.11 |

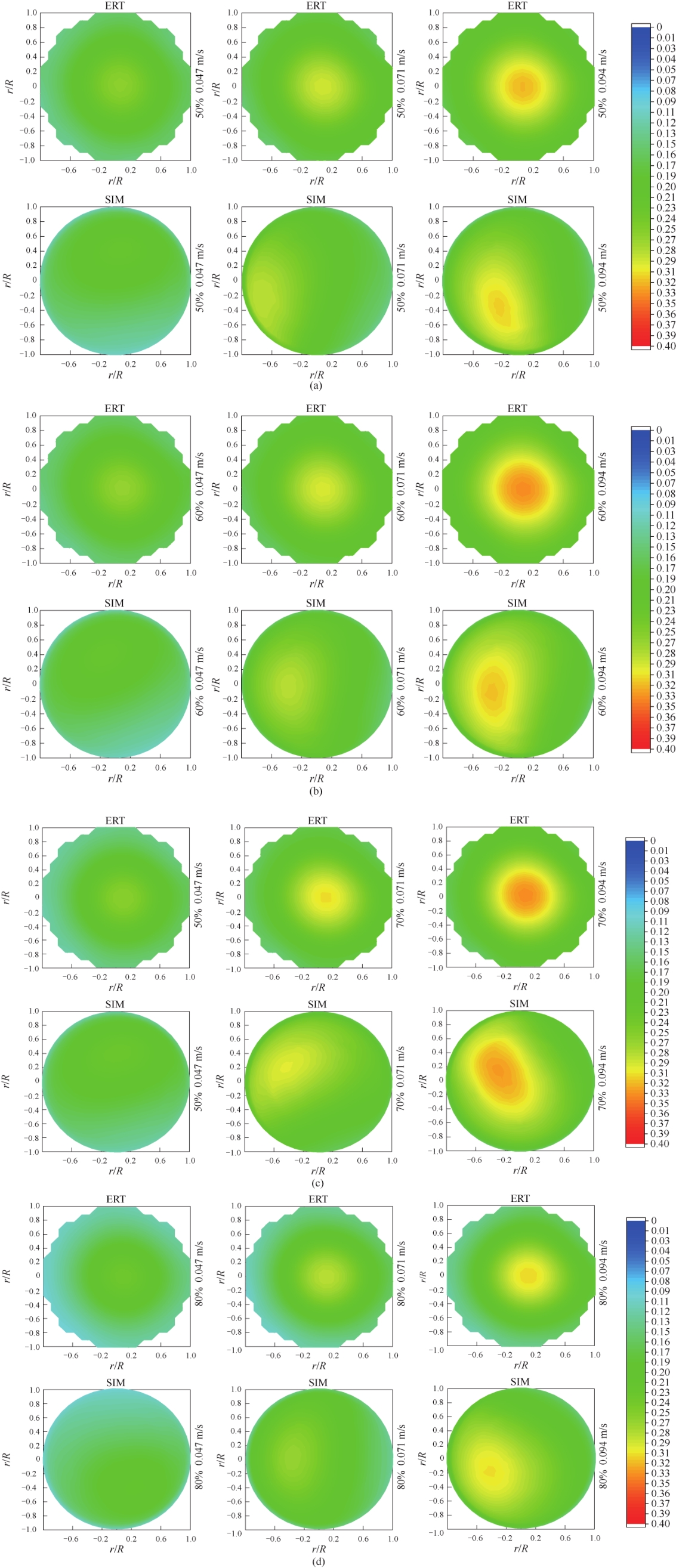

图10 不同表观气速下不同浓度醋酸横截面气含率云图分布(z = 0.86 m)

Fig.10 Cross-section contours of gas holdup distribution of different mass fractions of acetic acid under different superficial gas velocities(z = 0.86 m)

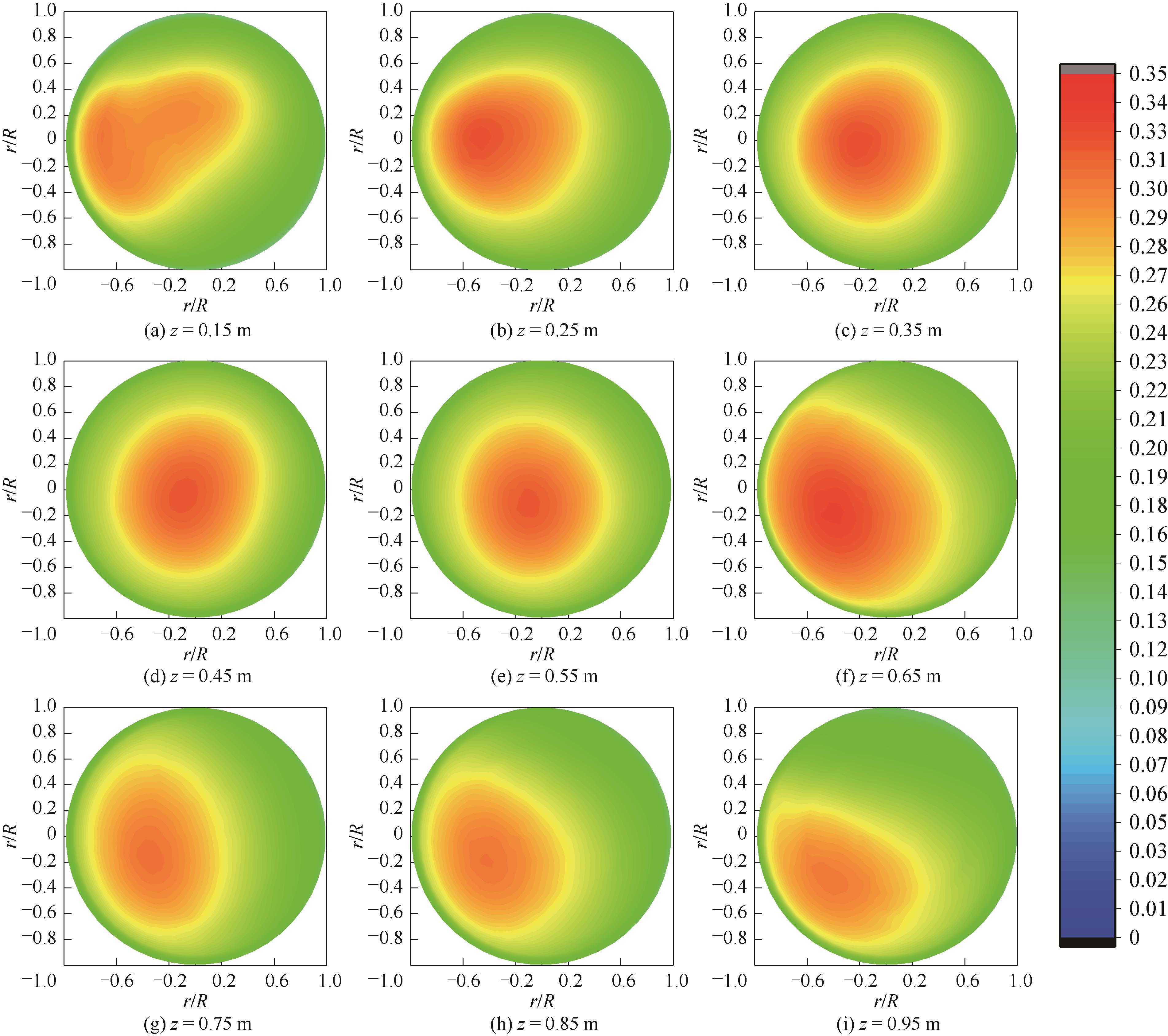

图13 不同浓度醋酸不同轴向高度处径向截面气含率云图分布

Fig.13 Radial-section contour distribution of gas holdup at different axial heights of different mass fractions of acetic acid solution

| 1 | Guo K Y, Wang T F, Yang G Y, et al. Distinctly different bubble behaviors in a bubble column with pure liquids and alcohol solutions[J]. Journal of Chemical Technology & Biotechnology, 2017, 92(2): 432-441. |

| 2 | Montoya G, Lucas D, Baglietto E, et al. A review on mechanisms and models for the churn-turbulent flow regime[J]. Chemical Engineering Science, 2016, 141: 86-103. |

| 3 | 李光. 鼓泡塔反应器气液两相流数值模拟模型及应用[D]. 上海: 华东理工大学, 2010. |

| Li G. Two-phase flow dynamical simulations and modelling of bubble column reactors[D]. Shanghai: East China University of Science and Technology, 2010. | |

| 4 | Jin H, Yang S, Zhang T, et al. Bubble behavior of a large-scale bubble column with elevated pressure[J]. Chemical Engineering & Technology, 2004, 27(9): 1007-1013. |

| 5 | Tran B V, Nguyen D D, Ngo S I, et al. Hydrodynamics and simulation of air–water homogeneous bubble column under elevated pressure[J]. AIChE Journal, 2019, 65(10): e16685. |

| 6 | Zhang X B, Luo Z H. Effects of bubble coalescence and breakup models on the simulation of bubble columns[J]. Chemical Engineering Science, 2020, 226: 115850. |

| 7 | Zhang X B, Zheng R Q, Luo Z H. CFD-PBM simulation of bubble columns: effect of parameters in the class method for solving PBEs[J]. Chemical Engineering Science, 2020, 226: 115853. |

| 8 | Yu X, Zhou H, Jing S, et al. CFD-PBM simulation of two-phase flow in a pulsed disc and doughnut column with directly measured breakup kernel functions[J]. Chemical Engineering Science, 2019, 201: 349-361. |

| 9 | Yang N, Xiao Q. A mesoscale approach for population balance modeling of bubble size distribution in bubble column reactors[J]. Chemical Engineering Science, 2017, 170: 241-250. |

| 10 | 张佳宝, 崔丽杰, 杨宁. 曳力模型和湍流模型对内环流反应器数值模拟的影响[J]. 化工学报, 2018, 69(1): 389-395. |

| Zhang J B, Cui L J, Yang N. Effects of drag model and turbulence model on simulation of air-lift internal-loop reactor[J]. CIESC Journal, 2018, 69(1): 389-395. | |

| 11 | Gong S G, Gao N N, Han L C, et al. A theoretical model for bubble coalescence by coupling film drainage with approach processes[J]. Chemical Engineering Science, 2020, 213: 115387. |

| 12 | Wang T F, Wang J F, Jin Y. A novel theoretical breakup kernel function for bubbles/droplets in a turbulent flow[J]. Chemical Engineering Science, 2003, 58(20): 4629-4637. |

| 13 | Wang T F, Wang J F, Jin Y. A CFD-PBM coupled model for gas-liquid flows[J]. AIChE Journal, 2006, 52(1): 125-140. |

| 14 | 王铁峰. 气液(浆)反应器流体力学行为的实验研究和数值模拟[D]. 北京: 清华大学, 2004. |

| Wang T F. Experimental study and numerical simulation on the hydrodynamics in gas-liquid (slurry) reactors[D]. Beijing: Tsinghua University, 2004. | |

| 15 | Prince M J, Blanch H W. Bubble coalescence and break-up in air-sparged bubble columns[J]. AIChE Journal, 1990, 36(10): 1485-1499. |

| 16 | Luo H, Svendsen H F. Modeling and simulation of binary approach by energy conservation analysis[J]. Chemical Engineering Communications, 1996, 145(1): 145-153. |

| 17 | Lehr F, Millies M, Mewes D. Bubble-size distributions and flow fields in bubble columns[J]. AIChE Journal, 2002, 48(11): 2426-2443. |

| 18 | Luo H A, Svendsen H F. Theoretical model for drop and bubble breakup in turbulent dispersions[J]. AIChE Journal, 1996, 42(5): 1225-1233. |

| 19 | Shi W B, Yang J, Li G, et al. Modelling of breakage rate and bubble size distribution in bubble columns accounting for bubble shape variations[J]. Chemical Engineering Science, 2018, 187: 391-405. |

| 20 | Hinze J O. Fundamentals of the hydrodynamic mechanism of splitting in dispersion processes[J]. AIChE Journal, 1955, 1(3): 289-295. |

| 21 | Tikhomirov V M. On the breakage of drops in a turbulent flow[M]//Selected Works of A. N. Kolmogorov. Dordrecht: Springer Netherlands, 1991: 339-343. |

| 22 | Yan P, Jin H B, Gao X, et al. Numerical analysis of bubble characteristics in a pressurized bubble column using CFD coupled with a population balance model[J]. Chemical Engineering Science, 2021, 234: 116427. |

| 23 | Yan P, Jin H B, He G X, et al. Numerical simulation of bubble characteristics in bubble columns with different liquid viscosities and surface tensions using a CFD-PBM coupled model[J]. Chemical Engineering Research and Design, 2020, 154: 47-59. |

| 24 | Yan P, Jin H B, He G X, et al. CFD simulation of hydrodynamics in a high-pressure bubble column using three optimized drag models of bubble swarm[J]. Chemical Engineering Science, 2019, 199: 137-155. |

| 25 | Zhang B, Kong L T, Jin H B, et al. CFD simulation of gas-liquid flow in a high-pressure bubble column with a modified population balance model[J]. Chinese Journal of Chemical Engineering, 2018, 26(6): 1350-1358. |

| 26 | 张文龙, 侯燕, 靳海波, 等. 加温加压下CFD-PBM耦合模型空气-水两相流数值模拟研究[J]. 化工学报, 2021, 72(9): 4594-4606. |

| Zhang W L, Hou Y, Jin H B, et al. Numerical simulation of air-water two-phase flow under elevated pressures and temperatures using CFD-PBM coupled model[J]. CIESC Journal, 2021, 72(9): 4594-4606. | |

| 27 | Tabib M V, Roy S A, Joshi J B. CFD simulation of bubble column—an analysis of interphase forces and turbulence models[J]. Chemical Engineering Journal, 2008, 139(3): 589-614. |

| 28 | Li J H, Cheng C L, Zhang Z D, et al. The EMMS model—its application, development and updated concepts[J]. Chemical Engineering Science, 1999, 54(22): 5409-5425. |

| 29 | 张煜. 湍动鼓泡塔充分发展段的流体力学与内构件技术研究[D]. 杭州: 浙江大学, 2011. |

| Zhang Y. Hydrodynamics of turbulent bubble column with and without internals in well-developed flow region[D]. Hangzhou: Zhejiang University, 2011. | |

| 30 | Frank T, Zwart P J, Krepper E, et al. Validation of CFD models for mono- and polydisperse air-water two-phase flows in pipes[J]. Nuclear Engineering and Design, 2008, 238(3): 647-659. |

| 31 | de Bertodano M L, Lahey R T, Jones O C. Turbulent bubbly two-phase flow data in a triangular duct[J]. Nuclear Engineering and Design, 1994, 146(1/2/3): 43-52. |

| 32 | Ning S L, Jin H B, He G X, et al. Effects of the microbubble generation mode on hydrodynamic parameters in gas–liquid bubble columns[J]. Processes, 2020, 8(6): 663. |

| 33 | 王珏, 杨宁. 基于EMMS方法的鼓泡塔反应器CFD及群平衡模拟[J]. 化工学报, 2017, 68(7): 2667-2677. |

| Wang J, Yang N. CFD-PBM simulation with EMMS correctors for bubble column reactors[J]. CIESC Journal, 2017, 68(7): 2667-2677. | |

| 34 | 李兆奇. 列管型鼓泡塔中流动发展规律的研究[D]. 杭州: 浙江大学, 2015. |

| Li Z Q. Flow development in bubble columns with pipe bundle internals[D]. Hangzhou: Zhejiang University, 2015. | |

| 35 | Ruzicka M C, Drahoš J, Mena P C, et al. Effect of viscosity on homogeneous-heterogeneous flow regime transition in bubble columns[J]. Chemical Engineering Journal, 2003, 96(1/2/3): 15-22. |

| 36 | 黄娟, 戴干策. 升温鼓泡塔内有机溶液的气含率[J]. 过程工程学报, 2008, 8(2): 209-216. |

| Huang J, Dai G C. Gas holdup in a bubble column at elevated temperature with organic liquid solutions[J]. The Chinese Journal of Process Engineering, 2008, 8(2): 209-216. | |

| 37 | Krishna R, Swart D J W A, Ellenberger J, et al. Gas holdup in slurry bubble columns[J]. AIChE Journal, 1997, 43(2): 311-316. |

| [1] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [2] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [3] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [4] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [5] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [6] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [7] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [8] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [9] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [10] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [11] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [12] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [13] | 郭雨莹, 敬加强, 黄婉妮, 张平, 孙杰, 朱宇, 冯君炫, 陆洪江. 稠油管道水润滑减阻及压降预测模型修正[J]. 化工学报, 2023, 74(7): 2898-2907. |

| [14] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [15] | 何宣志, 何永清, 闻桂叶, 焦凤. 磁液液滴颈部自相似破裂行为[J]. 化工学报, 2023, 74(7): 2889-2897. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号