化工学报 ›› 2024, Vol. 75 ›› Issue (9): 3338-3347.DOI: 10.11949/0438-1157.20240274

收稿日期:2024-03-07

修回日期:2024-05-08

出版日期:2024-09-25

发布日期:2024-10-10

通讯作者:

范小明,张卫新

作者简介:王舒英(1999—),女,硕士研究生,2573533828@qq.com

基金资助:

Shuying WANG( ), Tao ZUO, Zhiwei SHI, Xiaoming FAN(

), Tao ZUO, Zhiwei SHI, Xiaoming FAN( ), Weixin ZHANG(

), Weixin ZHANG( )

)

Received:2024-03-07

Revised:2024-05-08

Online:2024-09-25

Published:2024-10-10

Contact:

Xiaoming FAN, Weixin ZHANG

摘要:

利用价格低廉的阳离子交换树脂作为碳源,基于离子交换策略引入铁离子,调控阳离子交换树脂热解过程的石墨化碳结构,并进一步酸刻蚀热解产物中的单质铁和碳化铁,制备了一种介孔石墨化碳,用于钠离子电池负极材料。阳离子交换树脂基介孔石墨化碳相比直接热解所得的树脂基硬碳具有更大的层间距、更少的缺陷结构以及由薄层石墨化碳构成的介孔孔道,可以显著提高碳负极材料在高倍率下的比容量及循环稳定性。将该材料应用于钠离子电池负极材料展示出优异的倍率性能和高倍率下的循环稳定性,在30 A·g-1的高电流密度下该材料的比容量可达100 mA·h·g-1,在0.5 A·g-1的电流密度下循环1000圈后比容量可保持在192 mA·h·g-1。

中图分类号:

王舒英, 左涛, 石志伟, 范小明, 张卫新. 阳离子交换树脂基介孔石墨化碳合成与储钠性能[J]. 化工学报, 2024, 75(9): 3338-3347.

Shuying WANG, Tao ZUO, Zhiwei SHI, Xiaoming FAN, Weixin ZHANG. Synthesis and sodium ion storage properties of cation exchange resin based mesoporous graphitic carbon[J]. CIESC Journal, 2024, 75(9): 3338-3347.

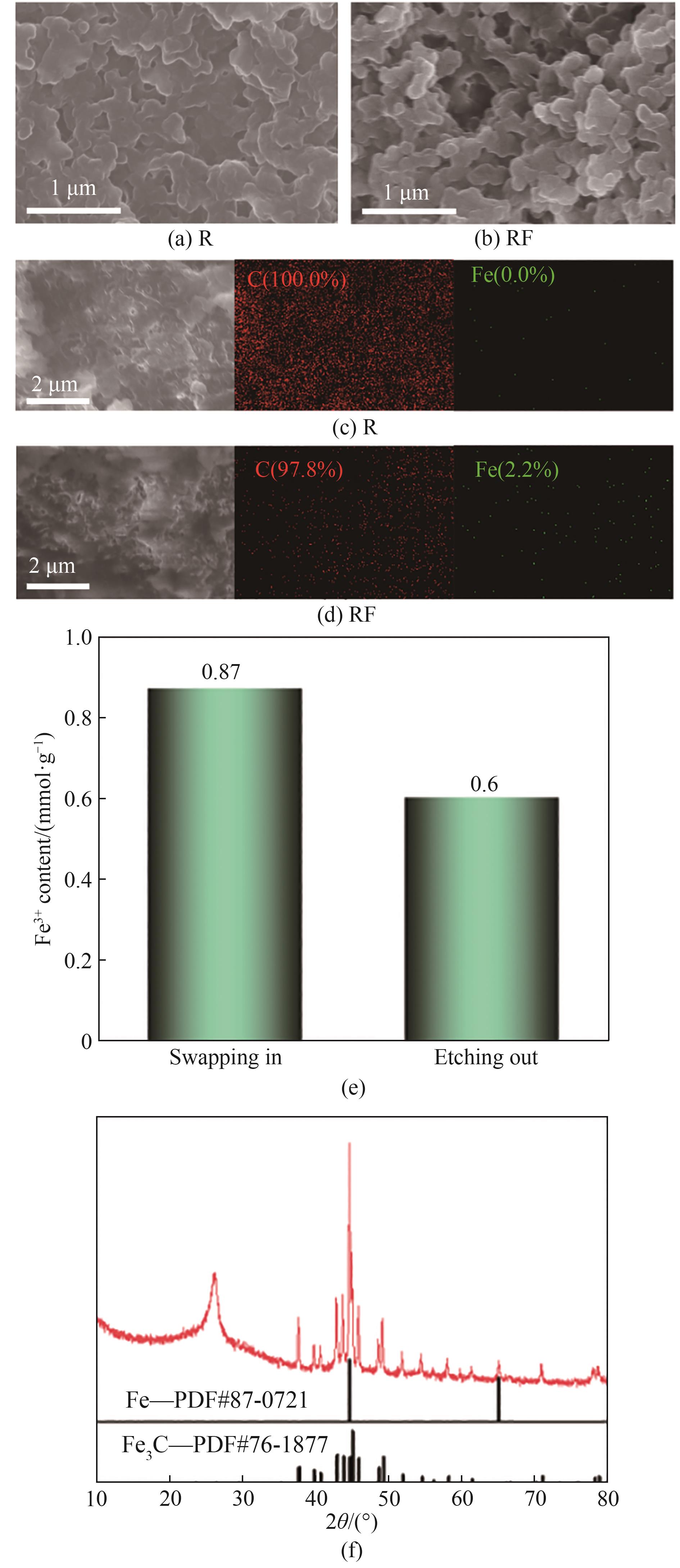

图2 不同样品的SEM照片[(a)、(b)];不同样品的EDS mapping图[(c)、(d)];树脂在0.5 mol·L-1溶液中交换进入及刻蚀出的Fe含量柱状图(e);样品HCF-700的XRD谱图(f)

Fig.2 SEM images of different samples [(a), (b)]; EDS mapping results of different samples [(c), (d)]; histogram of Fe content in ion-exchanged resin and acid-etched resin by thermal treatment (e);XRD patterns of the sample HCF-700 (f)

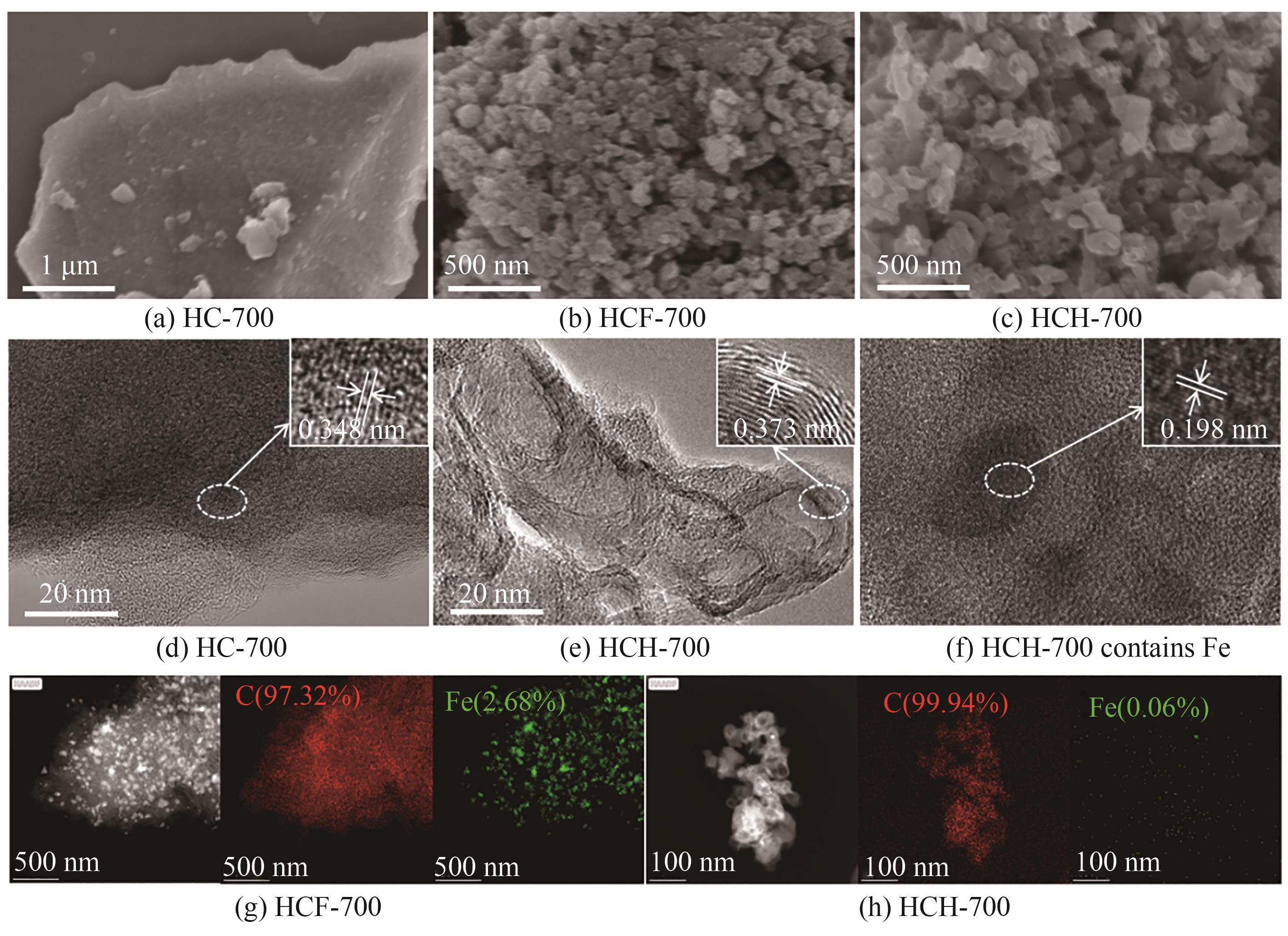

图3 不同样品的SEM照片[(a)~(c)]、TEM照片[(d)~(f)]和EDS mapping图[(g)、(h)]

Fig.3 SEM images [(a)-(c)], TEM images [(d)-(f)] and EDS mapping [(g),(h)] of different samples

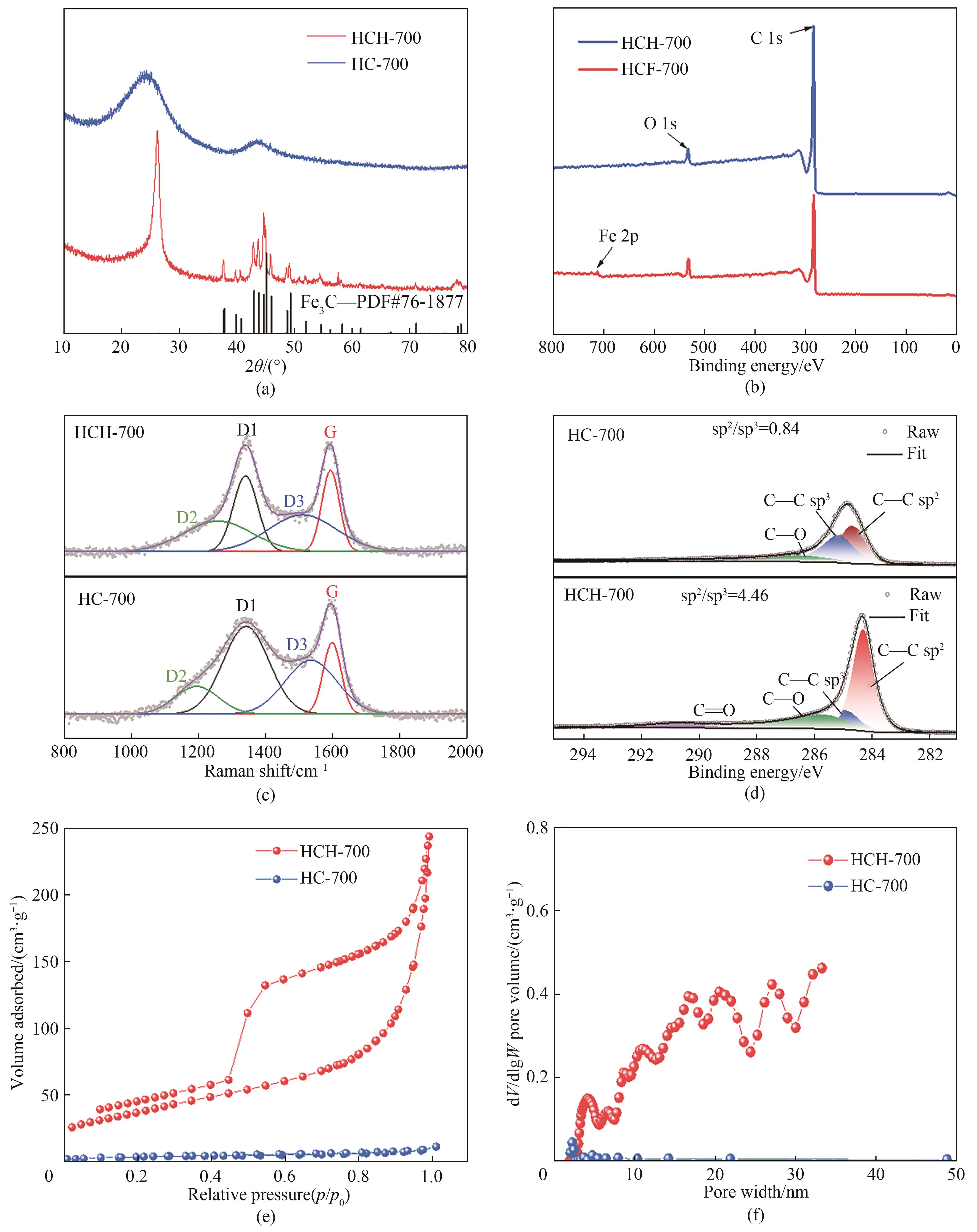

图4 不同样品的XRD谱图(a)、XPS全谱图(b)、拉曼光谱图(c)、C 1s XPS光谱图(d)、氮气吸脱附曲线(e)及孔径分布(f)

Fig.4 XRD patterns (a), XPS survey spectra (b), Raman spectra (c), C 1s XPS spectra (d), N2 adsorption/desorption isotherms (e) and pore size distribution (f) of different samples

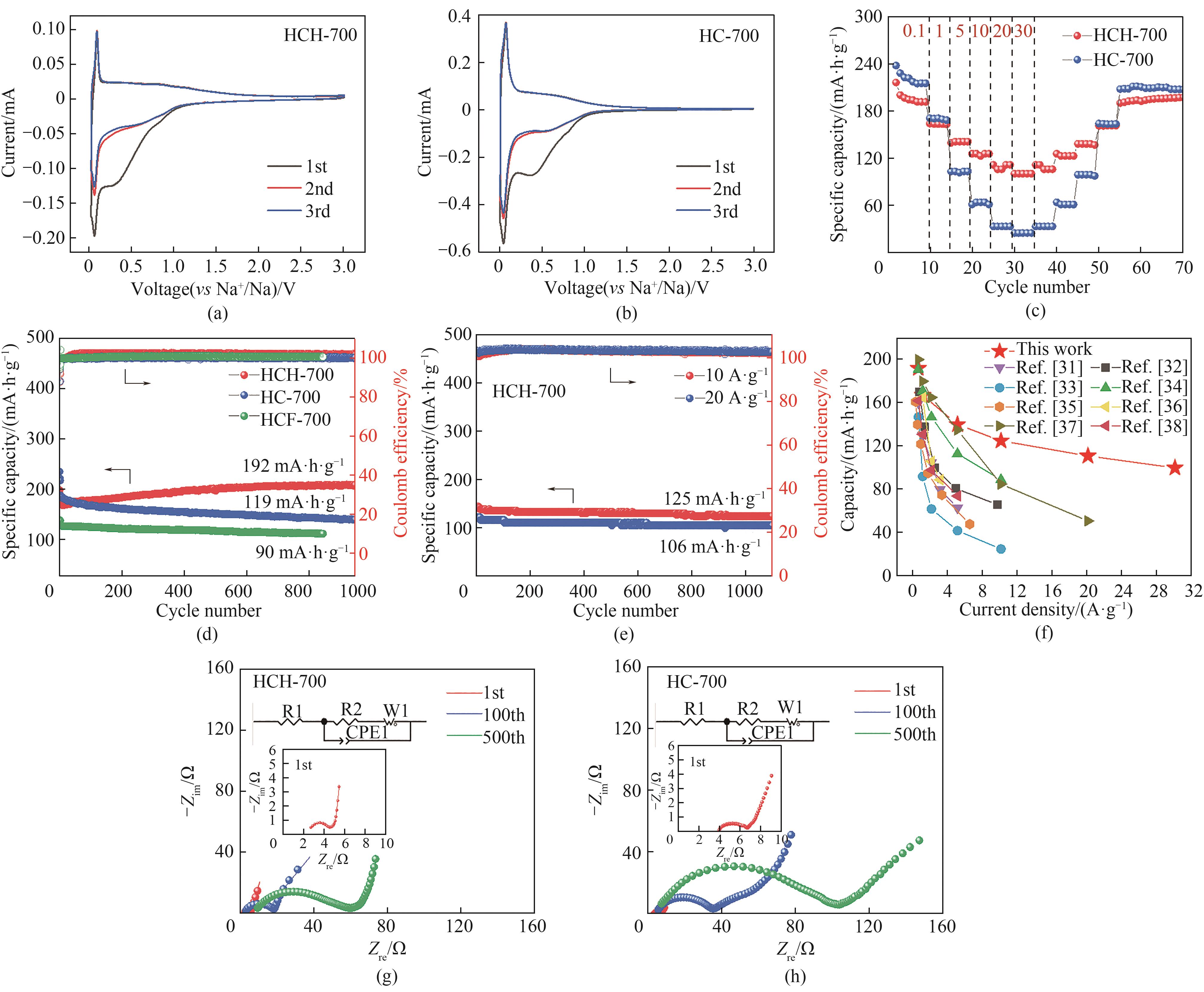

图5 HCH-700 (a) 和HC-700 (b) 前3圈的CV曲线;不同样品在电流密度为0.1~30 A·g-1下的倍率性能图 (c);不同样品在0.5 A·g-1下的长循环图 (d);HCH-700在10、20 A·g-1下的长循环图 (e);HCH-700与不同文献中的材料倍率性能对比图 (f);不同循环圈数下HCH-700 (g) 和HC-700 (h) 的EIS图

Fig.5 CV curves for the first 3 cycles of HCH-700 (a) and HC-700 (b); rate performance of different samples at current densities of 0.1—30 A·g-1 (c); long-term stability test of different samples at 0.5 A·g-1 (d); long-term stability test of HCH-700 at 10 and 20 A·g-1 (e); comparison of rate performance of HCH-700 with materials in different references (f); EIS spectra of HCH-700 (g) and HC-700 (h) under different cycle numbers

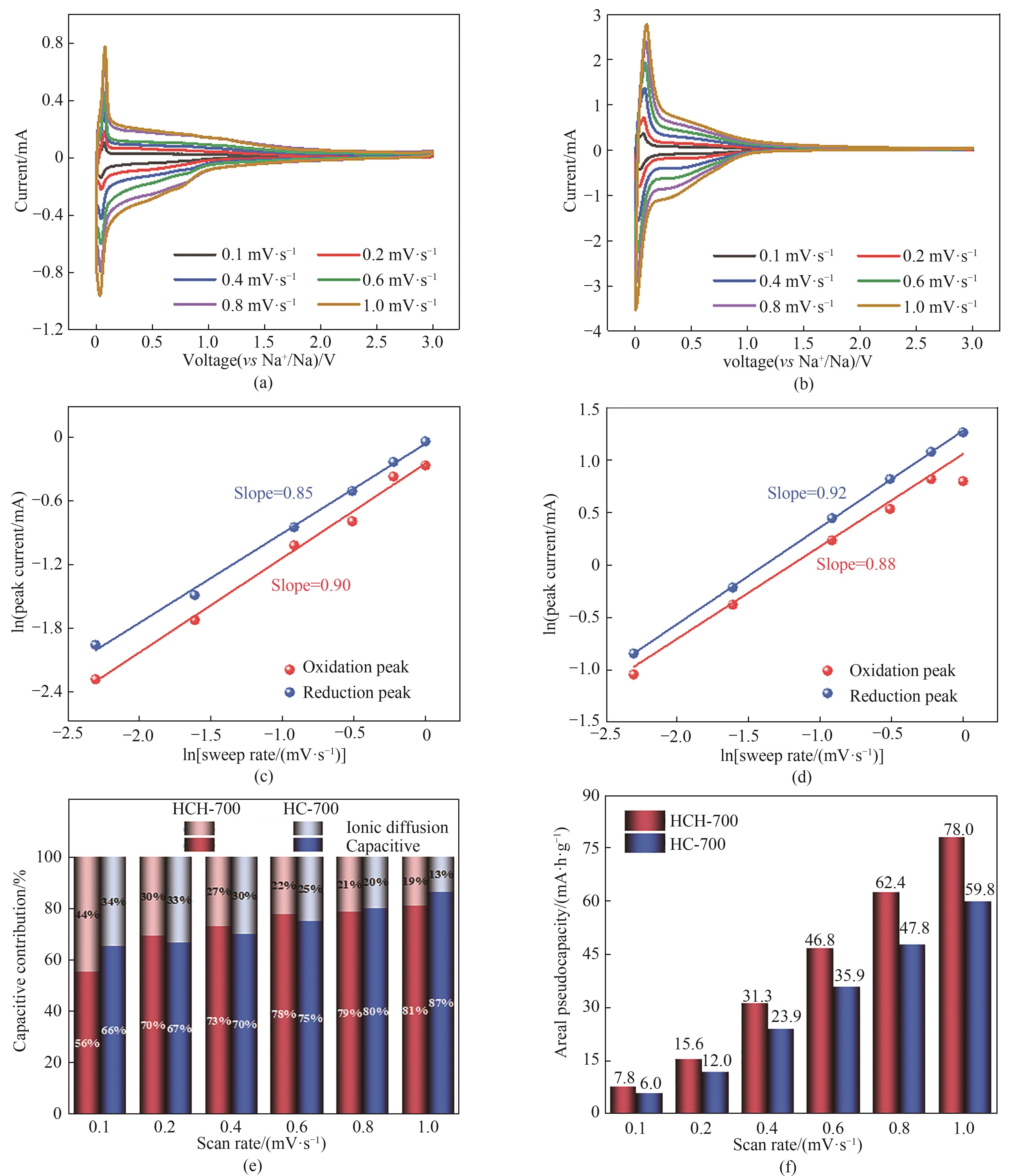

图6 不同扫描速率下HCH-700 (a) 和HC-700 (b) 的CV曲线;HCH-700 (c) 和HC-700 (d) 的CV峰值电流和扫速之间的线性关系;不同扫描速率下的赝电容占比 (e);HCH-700和HC-700在30 A·g-1下的实际赝电容 (f)

Fig.6 CV curves of HCH-700 (a) and HC-700 (b) at different scan rates; linear relationship between peak current and scan rate in the CV curve of HCH-700 (c) and HC-700 (d); pseudocapacitance ratio at different scan rates (e); actual pseudocapacity of the HCH-700 and HC-700 under 30 A·g-1 (f)

| 1 | Li M, Lu J, Chen Z W, et al. 30 years of lithium-ion batteries[J]. Advanced Materials, 2018, 30(33): 1800561. |

| 2 | Liu C, Wang B W, Xu L Q, et al. Novel nonstoichiometric niobium oxide anode material with rich oxygen vacancies for advanced lithium-ion capacitors[J]. ACS Applied Materials & Interfaces, 2023, 15(4): 5387-5398. |

| 3 | 王晓波, 赵青山, 程智年, 等. 高性能碳基储能材料的设计、合成与应用[J]. 化工学报, 2020, 71(6): 2660-2677. |

| Wang X B, Zhao Q S, Cheng Z N, et al. Design, synthesis and application of high-performance carbon-based energy storage materials[J]. CIESC Journal, 2020, 71(6): 2660-2677. | |

| 4 | 郭行, 韩纹莉, 董晓玲, 等. 调控炭化过程优化煤基硬炭负极储钠性能[J]. 化工学报, 2022, 73(4): 1794-1806. |

| Guo H, Han W L, Dong X L, et al. Adjusting carbonization process to optimize sodium storage performance of coal-based hard carbon anode[J]. CIESC Journal, 2022, 73(4): 1794-1806. | |

| 5 | Xia S X, Yan Y H, Sun H, et al. Engineering unique vesicle structured tin phosphides@P/N co-doped carbon anode for high-performance sodium/lithium-ion batteries[J]. Rare Metals, 2022, 41(5): 1496-1503. |

| 6 | Fan C L, Zhang R S, Luo X H, et al. Epoxy phenol novolac resin: a novel precursor to construct high performance hard carbon anode toward enhanced sodium-ion batteries[J]. Carbon, 2023, 205: 353-364. |

| 7 | Wang P, Fan L P, Yan L, et al. Low-cost water caltrop shell-derived hard carbons with high initial coulombic efficiency for sodium-ion battery anodes[J]. Journal of Alloys and Compounds, 2019, 775: 1028-1035. |

| 8 | Li L, Zheng Y, Zhang S L, et al. Recent progress on sodium ion batteries: potential high-performance anodes[J]. Energy & Environmental Science, 2018, 11(9): 2310-2340. |

| 9 | Han X, Zhou S H, Liu H, et al. Noncrystalline carbon anodes for advanced sodium-ion storage[J]. Small Methods, 2023, 7(3): e2201508. |

| 10 | Zhu Y Y, Wang Y H, Wang Y T, et al. Research progress on carbon materials as negative electrodes in sodium- and potassium-ion batteries[J]. Carbon Energy, 2022, 4(6): 1182-1213. |

| 11 | Zhang M H, Li Y, Wu F, et al. Boost sodium-ion batteries to commercialization: strategies to enhance initial Coulombic efficiency of hard carbon anode[J]. Nano Energy, 2021, 82: 105738. |

| 12 | Yu Z L, Xin S, You Y, et al. Ion-catalyzed synthesis of microporous hard carbon embedded with expanded nanographite for enhanced lithium/sodium storage[J]. Journal of the American Chemical Society, 2016, 138(45): 14915-14922. |

| 13 | Ganesan V, Lee Y H, Jung H, et al. Porous polyhedral carbon matrix for high-performance Li/Na/K-ion battery anodes[J]. Carbon Letters, 2023, 33(7): 2189-2198. |

| 14 | Velez V, Ramos-Sánchez G, Lopez B, et al. Synthesis of novel hard mesoporous carbons and their applications as anodes for Li and Na ion batteries[J]. Carbon, 2019, 147: 214-226. |

| 15 | Xiao L F, Lu H Y, Fang Y J, et al. Low-defect and low-porosity hard carbon with high coulombic efficiency and high capacity for practical sodium ion battery anode[J]. Advanced Energy Materials, 2018, 8(20): 1703238. |

| 16 | Cai C C, Chen Y A, Hu P, et al. Regulating the interlayer spacings of hard carbon nanofibers enables enhanced pore filling sodium storage[J]. Small, 2022, 18(6): e2105303. |

| 17 | Song M H, Song Q, Zhang T, et al. Growing curly graphene layer boosts hard carbon with superior sodium-ion storage[J]. Nano Research, 2023, 16(7): 9299-9309. |

| 18 | Qi Y R, Lu Y X, Liu L L, et al. Retarding graphitization of soft carbon precursor: from fusion-state to solid-state carbonization[J]. Energy Storage Materials, 2020, 26: 577-584. |

| 19 | Matei Ghimbeu C, Górka J, Simone V, et al. Insights on the Na+ ion storage mechanism in hard carbon: discrimination between the porosity, surface functional groups and defects[J]. Nano Energy, 2018, 44: 327-335. |

| 20 | Krivchenkova E A, Panfilova L A, Chernova I A. An analysis of the range and quality of cation-exchange resins available in the Russian market and intended for use in thermal power plant water treatment installations[J]. Thermal Engineering, 2021, 68(10): 785-793. |

| 21 | Tran L B, Nguyen T T, Padungthon S, et al. Advanced natural hydrated iron-alum oxides cation exchange resin for simultaneous phosphate and hardness removal[J]. NPJ Clean Water, 2022, 5: 43. |

| 22 | Víctor-Ortega M D, Ochando-Pulido J M, Martínez-Ferez A. Iron removal and reuse from Fenton-like pretreated olive mill wastewater with novel strong-acid cation exchange resin fixed-bed column[J]. Journal of Industrial and Engineering Chemistry, 2016, 36: 298-305. |

| 23 | Riveros P A. The extraction of Fe(Ⅲ) using cation-exchange carboxylic resins[J]. Hydrometallurgy, 2004, 72(3/4): 279-290. |

| 24 | Kajjumba G W, Fischer D, Risso L, et al. Application of cerium and lanthanum coagulants in wastewater treatment—a comparative assessment to magnesium, aluminum, and iron coagulants[J]. Chemical Engineering Journal, 2021, 426: 131268. |

| 25 | 智研咨询发布:中国离子交换树脂行业市场研究报告(2023版)[EB/OL]. (2023-05-04)[2023-11-15]. . |

| Intelligence research: market research repot on China’s ion exchange resin industry (2023 edition)[EB/OL]. (2023-05-04)[2023-11-15]. . | |

| 26 | Shi W P, Zhang Y M, Tian Z Q, et al. Low temperature synthesis of polyhedral hollow porous carbon with high rate capability and long-term cycling stability as Li-ion and Na-ion battery anode material[J]. Journal of Power Sources, 2018, 398: 149-158. |

| 27 | Zhou K, Hu M X, He Y B, et al. Transition metal assisted synthesis of tunable pore structure carbon with high performance as sodium/lithium ion battery anode[J]. Carbon, 2018, 129: 667-673. |

| 28 | Zhao J H, He X X, Lai W H, et al. Catalytic defect-repairing using manganese ions for hard carbon anode with high-capacity and high-initial-coulombic-efficiency in sodium-ion batteries[J]. Advanced Energy Materials, 2023, 13(18): 2300444. |

| 29 | Wang X, Li X, Lu Z, et al. Constructing porous lignin-based carbon nanofiber anodes with flexibility for high-performance lithium/sodium-ion batteries[J]. Materials Today Sustainability, 2022, 20: 100234. |

| 30 | Niu S S, Wang Z Y, Yu M L, et al. MXene-based electrode with enhanced pseudocapacitance and volumetric capacity for power-type and ultra-long life lithium storage[J]. ACS Nano, 2018, 12(4): 3928-3937. |

| 31 | Huang S F, Li Z P, Wang B, et al. N-doping and defective nanographitic domain coupled hard carbon nanoshells for high performance lithium/sodium storage[J]. Advanced Functional Materials, 2018, 28(10): 1706294. |

| 32 | Lu P, Sun Y, Xiang H F, et al. 3D amorphous carbon with controlled porous and disordered structures as a high-rate anode material for sodium-ion batteries[J]. Advanced Energy Materials, 2018, 8(8): 1702434. |

| 33 | Zhu Z Y, Liang F, Zhou Z R, et al. Expanded biomass-derived hard carbon with ultra-stable performance in sodium-ion batteries[J]. Journal of Materials Chemistry A, 2018, 6(4): 1513-1522. |

| 34 | Wang X, Zhu F L, Xiao M J, et al. N-doped hollow porous carbon microspheres with highrate performance as anode for sodium-ion batteries[J]. Journal of Materials Science: Materials in Electronics, 2022, 33(10): 7913-7922. |

| 35 | Du L L, Wu W, Luo C, et al. Lignin-derived nitrogen-doped porous carbon as a high-rate anode material for sodium ion batteries[J]. Journal of the Electrochemical Society, 2019, 166(2): A423-A428. |

| 36 | Gao Y P, Piao S Y, Jiang C H, et al. Navel orange peel-derived hard carbons as high performance anode materials of Na and Li-ion batteries[J]. Diamond and Related Materials, 2022, 129: 109329. |

| 37 | Jeon I, Yang D C, Yadav D, et al. Sodium storage behavior and long cycle stability of boron-doped carbon nanofibers for sodium-ion battery anodes[J]. Electrochimica Acta, 2023, 439: 141730. |

| 38 | Su L, Kong L N, Hao S G, et al. Honeycomb-like porous carbon with nanographitic domains, supported on graphene layers: applicability for lithium/sodium storage[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(12): 10986-10994. |

| 39 | Xiong T Z, Gao Y X, Huang P, et al. Actual pseudocapacity for Li ion storage in tunable core-shell electrode architectures[J]. EcoMat, 2022, 4(5): e12217. |

| [1] | 吴学红, 韦新, 侯加文, 吕财, 刘勇, 刘鹤, 常志娟. 热解法制备碳纳米管及其在散热涂层中的应用研究[J]. 化工学报, 2024, 75(9): 3360-3368. |

| [2] | 罗欣怡, 徐强, 佘永璐, 聂腾飞, 郭烈锦. 光电分解水制氢气泡动力学特性及其传质机理研究[J]. 化工学报, 2024, 75(9): 3083-3093. |

| [3] | 黄正梁, 冯铭瑞, 宋琦, 任聪静, 杨遥, 孙婧元, 王靖岱, 阳永荣. 预混进料对废树脂流化裂解反应中颗粒团聚的抑制作用[J]. 化工学报, 2024, 75(9): 3094-3102. |

| [4] | 彭丹, 卢俊杰, 倪文静, 杨媛, 汪靖伦. 高电压钴酸锂电池电解液研究进展[J]. 化工学报, 2024, 75(9): 3028-3040. |

| [5] | 丁湧, 李文建, 陈昭宇, 曹立辉, 刘轩铭, 任强强, 胡松, 向军. 废旧晶体硅光伏组件EVA有氧热解动力学与产物特性[J]. 化工学报, 2024, 75(9): 3310-3319. |

| [6] | 姚宏哲, 黄飞宇, 杨松, 钟梅, 代正华. 重质油高温快速热解自动反应网络的动力学建模[J]. 化工学报, 2024, 75(7): 2644-2655. |

| [7] | 江洋, 彭长宏, 陈伟, 周豪, 马忠彬, 李洪博, 邱在容, 张国鹏, 周康根. 废旧磷酸铁锂粉料综合回收中试研究[J]. 化工学报, 2024, 75(6): 2353-2361. |

| [8] | 王天闻, 闫肃, 赵梦园, 杨天让, 刘建国. 固体氧化物电池空气电极铬中毒机理及抗铬性能研究进展[J]. 化工学报, 2024, 75(6): 2091-2108. |

| [9] | 晁惠雨, 白振敏, 侯汉青, 田立志, 李洪, 房晓权, 石晓华. 液相法合成三聚氰酸体系热力学分析[J]. 化工学报, 2024, 75(6): 2157-2165. |

| [10] | 裴欣哲, 孙朱行, 林钰翔, 张朝阳, 钱勇, 吕兴才. 电催化分解液氨阳极材料的研究[J]. 化工学报, 2024, 75(5): 1843-1854. |

| [11] | 李昂, 赵振宇, 李洪, 高鑫. 微波诱导高分散Pd/FeP催化剂构筑及其电催化性能研究[J]. 化工学报, 2024, 75(4): 1594-1606. |

| [12] | 李云璇, 刘新悦, 陈熙, 刘文, 周明月, 蓝兴英. 基于固液氧化还原靶向反应的能量存储技术:材料、器件及动力学[J]. 化工学报, 2024, 75(4): 1222-1240. |

| [13] | 贾旭东, 杨博龙, 程前, 李雪丽, 向中华. 分步负载金属法制备铁钴双金属位点高效氧还原电催化剂[J]. 化工学报, 2024, 75(4): 1578-1593. |

| [14] | 严孝清, 赵瑛, 张宇哲, 欧鸿辉, 黄起中, 胡华贵, 杨贵东. 五重孪晶铜纳米线@聚吡咯制备及其电催化硝酸盐还原制氨[J]. 化工学报, 2024, 75(4): 1519-1532. |

| [15] | 孙铭泽, 黄鹤来, 牛志强. 铂基氧还原催化剂:从单晶电极到拓展表面纳米材料[J]. 化工学报, 2024, 75(4): 1256-1269. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号