化工学报 ›› 2022, Vol. 73 ›› Issue (4): 1566-1574.DOI: 10.11949/0438-1157.20211715

收稿日期:2021-11-30

修回日期:2022-02-09

出版日期:2022-04-05

发布日期:2022-04-25

通讯作者:

李俊

作者简介:李俊(1986—),男,博士,讲师,基金资助:

Jun LI( ),Shihua LI,Zhigao SUN,Shibo SONG

),Shihua LI,Zhigao SUN,Shibo SONG

Received:2021-11-30

Revised:2022-02-09

Online:2022-04-05

Published:2022-04-25

Contact:

Jun LI

摘要:

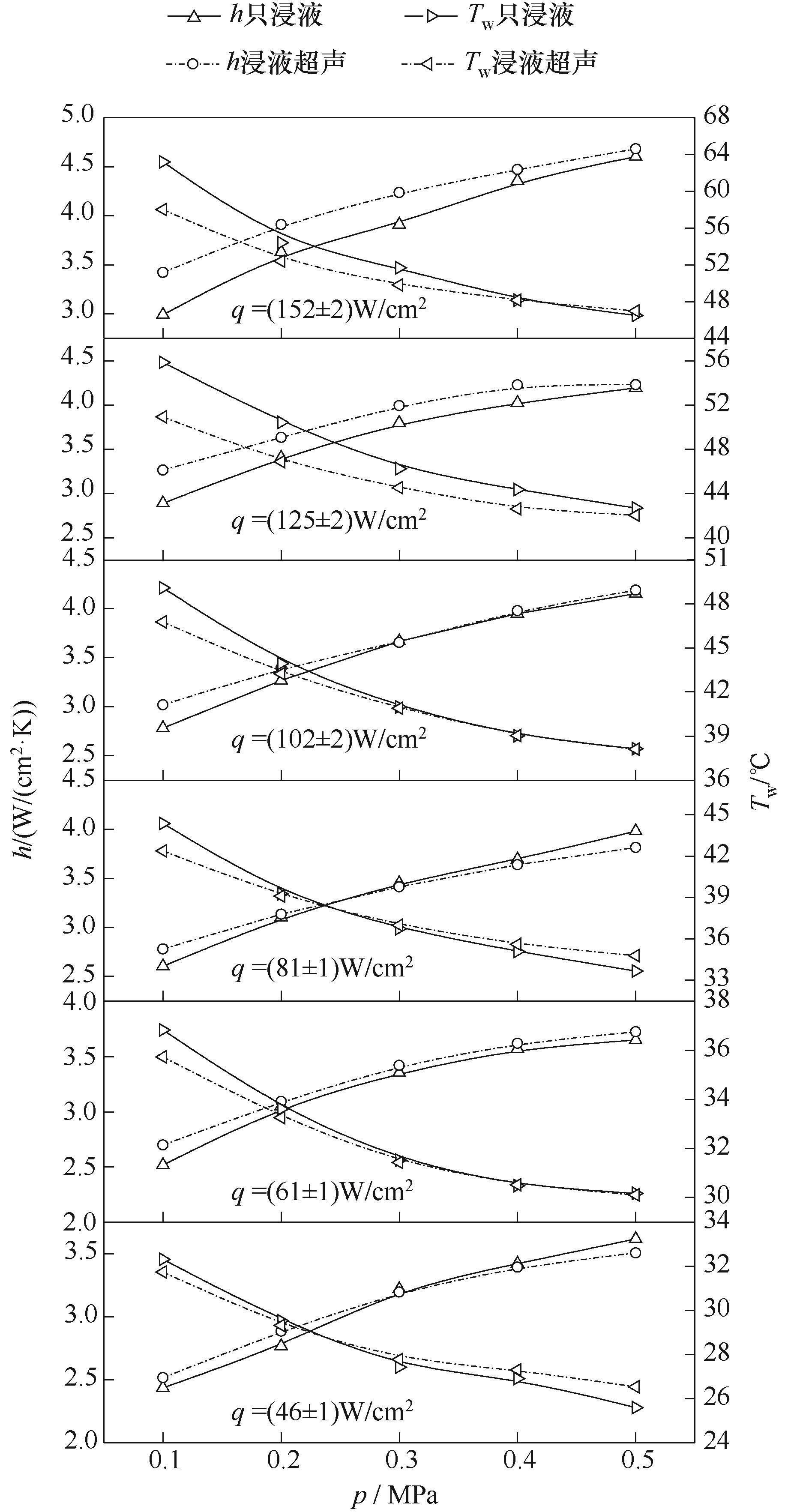

超声由于空化和声流机制可起到强化换热效果,为研究其在高热流下对喷雾冷却传热特性的影响,设计并搭建了以H2O为工质的浸液式喷雾冷却实验平台,在无沸腾区范围内考察了不同喷雾高度、压力和热通量下超声场对喷雾冷却换热性能的影响。研究表明:超声浸液喷雾冷却的换热效果要优于浸液式喷雾冷却,在高热通量152 W/cm2情况下更加明显;强化换热效果会随着喷雾压力的升高而减小,在最佳喷雾高度10 mm和喷雾压力0.1 MPa条件下,浸液超声式喷雾冷却相比浸液式换热效果最高提升14.4%;超声对换热的改善作用随着喷雾高度增加而提升,喷雾高度18 mm时最高强化比29.1%。

中图分类号:

李俊, 黎仕华, 孙志高, 宋士博. 超声对无沸腾区浸液式喷雾冷却的影响研究[J]. 化工学报, 2022, 73(4): 1566-1574.

Jun LI, Shihua LI, Zhigao SUN, Shibo SONG. Study on effect of ultrasound for immersed spray cooling in non-boiling regime[J]. CIESC Journal, 2022, 73(4): 1566-1574.

| 测量数据 | 测量仪器 | 量程 | 测量精度 |

|---|---|---|---|

| 冷却工质进口温度 | PT100铂电阻 | -50~150℃ | ±0.15℃ |

| 喷嘴出水温度 | PT100铂电阻 | -50~150℃ | ±0.15℃ |

| 喷雾腔内温度 | PT100铂电阻 | -50~150℃ | ±0.15℃ |

| 加热柱体温度 | K型针式热电偶 | 0~800℃ | ±1.5℃ |

| 喷嘴进口压力 | 压力传感器 | 0~1600 kPa | ±0.25%FS |

表1 测量仪器及其精度

Table 1 Measuring instrument and accuracy

| 测量数据 | 测量仪器 | 量程 | 测量精度 |

|---|---|---|---|

| 冷却工质进口温度 | PT100铂电阻 | -50~150℃ | ±0.15℃ |

| 喷嘴出水温度 | PT100铂电阻 | -50~150℃ | ±0.15℃ |

| 喷雾腔内温度 | PT100铂电阻 | -50~150℃ | ±0.15℃ |

| 加热柱体温度 | K型针式热电偶 | 0~800℃ | ±1.5℃ |

| 喷嘴进口压力 | 压力传感器 | 0~1600 kPa | ±0.25%FS |

图3 不同热流下传热系数与热沉表面温度随喷雾压力的变化

Fig.3 Variation of surface heat transfer coefficient and surface temperature with spray pressure under different heat fluxes

| 1 | 谢宁宁. 喷雾冷却及其换热强化的实验与理论研究[D]. 北京: 中国科学院大学, 2012. |

| Xie N N. Experimental and theoretical study on spray cooling and enhancement[D]. Beijing: University of Chinese Academy of Sciences, 2012. | |

| 2 | Liang G T, Mudawar I. Review of spray cooling (1): Single-phase and nucleate boiling regimes, and critical heat flux[J]. International Journal of Heat and Mass Transfer, 2017, 115: 1174-1205. |

| 3 | Cheng W L, Zhang W W, Chen H, et al. Spray cooling and flash evaporation cooling: the current development and application[J]. Renewable and Sustainable Energy Reviews, 2016, 55: 614-628. |

| 4 | 钟泽民, 刘 妮, 黄千卫, 等. 喷雾冷却技术及其在电子冷却领域的应用[J]. 电子元件与材料, 2013, 32(10): 75-79. |

| Zhong Z M, Liu Ni, Huang Q W, et al. Spray cooling technology and its application in the field of electronic cooling[J]. Electronic Components and Materials, 2013, 32(10): 75-79. | |

| 5 | Sohel Murshed S M. Nieto de Castro C A. A critical review of traditional and emerging techniques and fluids for electronics cooling[J]. Renewable and Sustainable Energy Reviews, 2017, 78: 821-833. |

| 6 | Liu N, Wang N, Liu N, et al. Experimental study of the effects of structured surface geometry on water spray cooling performance in non-boiling regime[J]. Front. Energy, 2011, 5(1): 75-82. |

| 7 | 刘绍彦, 阮琳, 康玉慧. 喷雾冷却轴线处的雾化特性的实验研究与数值分析[J]. 科学技术与工程, 2018, 18(24): 225-229. |

| Liu S Y, Ruan L, Kang Y H. Experimental study and numerical analysis of atomization characteristics at spray cooling axis[J]. Science Technology and Engineering, 2018, 18(24): 225-229. | |

| 8 | Fabbri M, Jiang S J, Dhir V K, et al. Comparative study of spray and multiple micro jets cooling for high power density electronic applications[C]// ASME International Mechanical Engineering Congress & Exposition. Washington, D.C., USA, 2003:1-9. |

| 9 | Karwa N, Kale S R, Subbarao P M V. Experimental study of non-boiling heat transfer from a horizontal surface by water sprays[J]. Experimental Thermal and Fluid Science, 2007, 32(2): 571-579. |

| 10 | 周年勇, 冯浩, 许泓烨, 等. R134a闭式喷雾冷却传热性能实验研究[J]. 制冷学报, 2021, 42(3): 152-158. |

| Zhou N Y, Feng H, Xu H Y, et al. Experimental study on the heat transfer performance of R134a closed spray cooling [J]. Journal of Refrigeration, 2021, 42(3): 152-158. | |

| 11 | 黄龙, 蒋彦龙, 王瑜, 等. 以乙醇溶液为冷却工质的开式喷雾冷却系统实验研究[J]. 低温工程, 2017, 3: 28-33. |

| Huang L, Jiang Y L, Wang Y, et al. Experiment study on spray cooling of an open system with ethanol as coolant [J]. Cryogenics, 2017, 3: 28-33. | |

| 12 | 曹磊, 陈剑楠, 姜培学, 等. 基于制冷循环的闭式喷雾冷却系统实验研究[J]. 工程热物理学报, 2018, 39(2): 373-378. |

| Cao L, Chen J N, Jiang P X, et al. Experimental investigation of spray cooling system in a closed loop based on refrigeration cycle[J]. Journal of Engineering Thermophysics, 2018, 39(2): 373-378. | |

| 13 | Zhou N Y, Chen F J, Cao Y C, et al. Experimental investigation on the performance of a water spray cooling system[J]. Applied Thermal Engineering, 2017, 112: 1117-1128. |

| 14 | 王锐, 杨涛, 周致富, 等. 喷嘴类型对制冷剂喷雾雾化特性及表面传热的影响研究[J]. 工程热物理学报, 2017, 38(12): 2646-2650. |

| Wang R, Yang T, Zhou Z F, et al. Effects of nozzle type on spray characteristics and surface heat transfer in cryogen spray cooling[J]. Journal of Engineering Thermophysics, 2017, 38(12): 2646-2650. | |

| 15 | 侯燕. 多喷嘴喷雾冷却实验研究与数值模拟[D]. 北京: 中国科学院大学, 2014. |

| Hou Y. Experimental study and numerical simulation of multi-nozzle spray cooling [D]. Beijing: University of Chinese Academy of Sciences, 2014. | |

| 16 | Fukuda H, Nakata N, Kijima H, et al. Effects of surface conditions on spray cooling characteristics[J]. ISIJ International, 2016, 56(4): 628-636. |

| 17 | Wei Z, Wang Z, Xu M. Heat transfer characteristics in closed loop spray cooling of micro-structured surfaces[J]. High Power Laser & Particle Beams, 2012, 24(9): 2053-2058. |

| 18 | Rybicki J R, Mudawar I, et al. Single-phase and two-phase cooling characteristics of upward-facing and downward-facing sprays[J]. International Journal of Heat and Mass Transfer, 2006, 49(1-2): 5-16. |

| 19 | 吴正人, 甄猛, 刘梅, 等. 雾化压力对喷雾冷却效果影响的数值模拟 [J]. 中国科技论文, 2018, 13(11): 1309-1314. |

| Wu Z R, Zhen M, Liu M, et al. Numerical simulation of the effect of atomization pressure on spray cooling effect [J]. China Science Paper, 2018, 13(11): 1309-1314. | |

| 20 | Pautsch A G, Shedd T A, Nellis G F. Thickness measurements of the thin film in spray evaporative cooling[C]// Thermal and Thermomechanical Phenomena in Electronic Systems. Las Vegas, NV, USA, 2004: 70-76. |

| 21 | 谢宁宁, 陈东芳, 胡学功, 等. 压力与流量对喷雾冷却换热特性的影响[J]. 工程热物理学报, 2009, 30(12): 2059-2061. |

| Xie N N, Chen D F, Hu X G, et al. Influence of pressure and flow rate on spray cooling heat transfer characteristics[J]. Journal of Engineering Thermophysics, 2009, 30(12): 2059-2061. | |

| 22 | Cheng W L, Han F Y, Liu Q N, et al. Spray characteristics and spray cooling heat transfer in the non- boiling regime[J]. Energy, 2011, 36(5): 3399-3405. |

| 23 | Wang J X, Li Y Z, Li J X, et al. Enhanced heat transfer by an original immersed spray cooling system integrated with an ejector[J]. Energy, 2018, 158: 512-523. |

| 24 | Patrick B, Tarek G, Thomas F, et al. Water immersion cooling of high-power density electronics[J]. International Journal of Heat and Mass Transfer, 2020, 147: 118918-118930. |

| 25 | 陈伟中. 声空化物理 [M]. 北京: 科学出版社, 2014: 173-202. |

| Chen W Z. Acoustic Cavitation Physics[M]. Beijing: Science Press, 2014: 173-202. | |

| 26 | Wong S W, Chon W Y. Effects of ultrasonic vibrations on heat transfer to liquids by natural convection and by boiling[J]. AIChE Journal, 1969, 15(2): 281-288. |

| 27 | Legay M, Gondrexon N, Person S L, et al. Enhancement of heat transfer by ultrasound: review and recent advances[J]. International Journal of Chemical Engineering, 2011, 2011: 1-17. |

| 28 | 张东伟, 李凯华, 周俊杰, 等. 超声波强化传热的链式反应机理与模拟研究[J]. 工程热物理学报, 2017, 38(1): 145-148. |

| Zhang D W, Li K H, Zhou J J, et al. Research on the chain reaction mechanism and simulation of ultrasonic heat transfer enhancement[J]. Journal of Engineering Thermophysics, 2017, 38(1): 145-148. | |

| 29 | Kiani H, Sun D W, Zhang Z H. The effect of ultrasound irradiation on the convective heat transfer rate during immersion cooling of a stationary sphere[J]. Ultrasonics Sonochemistry, 2012, 19(6): 1238-1245. |

| 30 | Kim H Y, Kim Y G, Kang B H. Enhancement of natural convection and pool boiling heat transfer via ultrasonic vibration[J]. International Journal of Heat and Mass Transfer, 2004, 47(12/13): 2831-2840. |

| 31 | 周年勇, 徐慕豪, 冯浩, 等. 闭式喷雾冷却的瞬态传热过程研究[J]. 化工学报, 2020, 71(3): 1018-1025. |

| Zhou N Y, Xu M H, Feng H, et al. Study on transient heat transfer process of spray cooling with closed-loop[J]. CIESC Journal, 2020, 71(3): 1018-1025. | |

| 32 | Taylor J R. An Introduction to Error Analysis: The Study of Uncertainties in Physical Measurements[M]. Sausalito, California: University Science Books, 1997: 181-199. |

| [1] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [4] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [5] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [6] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [7] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [8] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [9] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [10] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [11] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [12] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [13] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [14] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [15] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号