化工学报 ›› 2022, Vol. 73 ›› Issue (11): 4957-4973.DOI: 10.11949/0438-1157.20221006

林志敏1,2( ), 王崇兆1,2, 强国智1,2, 刘树山1,2, 王良璧1,2

), 王崇兆1,2, 强国智1,2, 刘树山1,2, 王良璧1,2

收稿日期:2022-07-19

修回日期:2022-08-27

出版日期:2022-11-05

发布日期:2022-12-06

通讯作者:

林志敏

作者简介:林志敏(1982—),男,博士,教授,linzhimin@mail.lzjtu.cn

基金资助:

Zhimin LIN1,2( ), Chongzhao WANG1,2, Guozhi QIANG1,2, Shushan LIU1,2, Liangbi WANG1,2

), Chongzhao WANG1,2, Guozhi QIANG1,2, Shushan LIU1,2, Liangbi WANG1,2

Received:2022-07-19

Revised:2022-08-27

Online:2022-11-05

Published:2022-12-06

Contact:

Zhimin LIN

摘要:

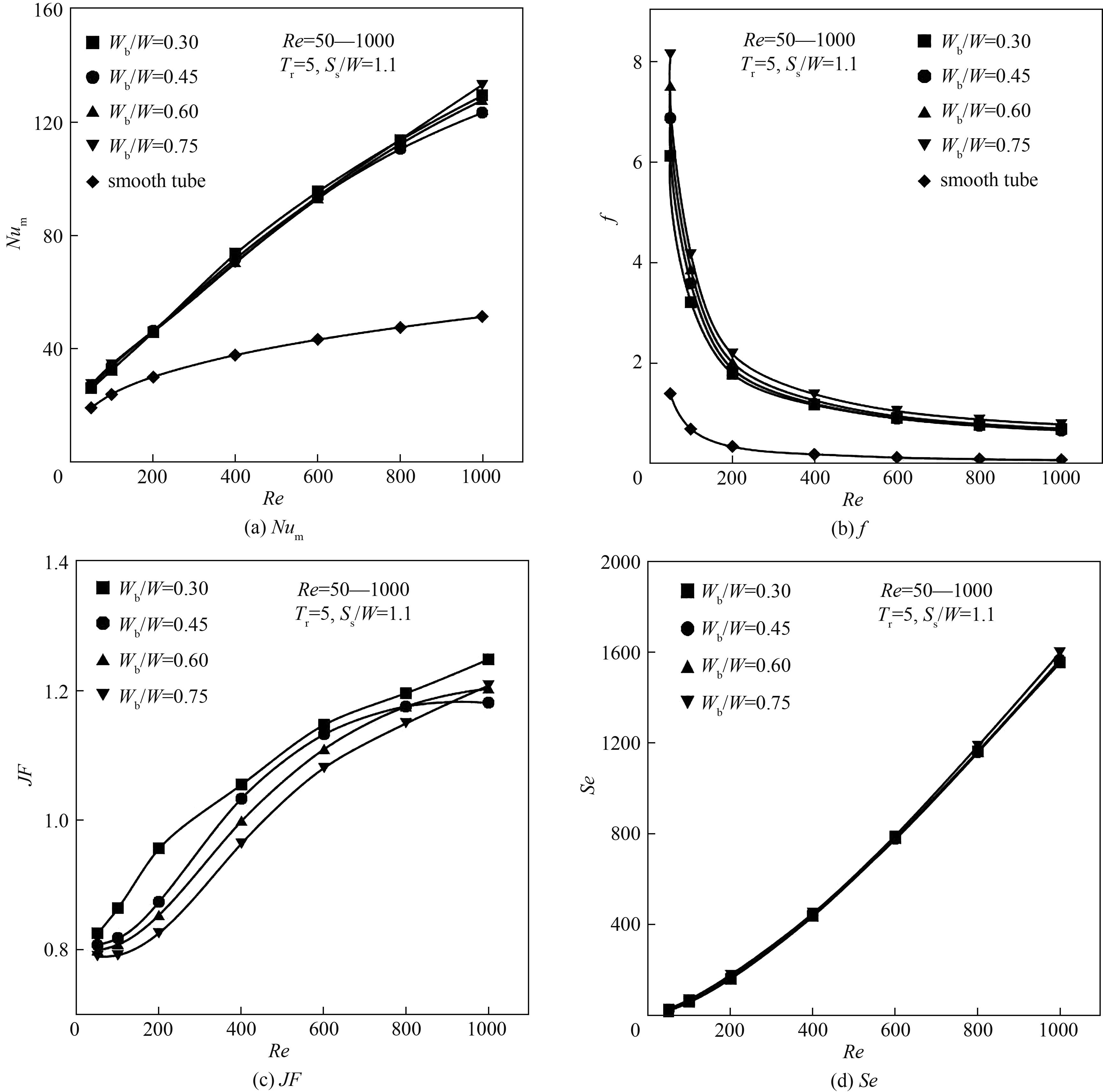

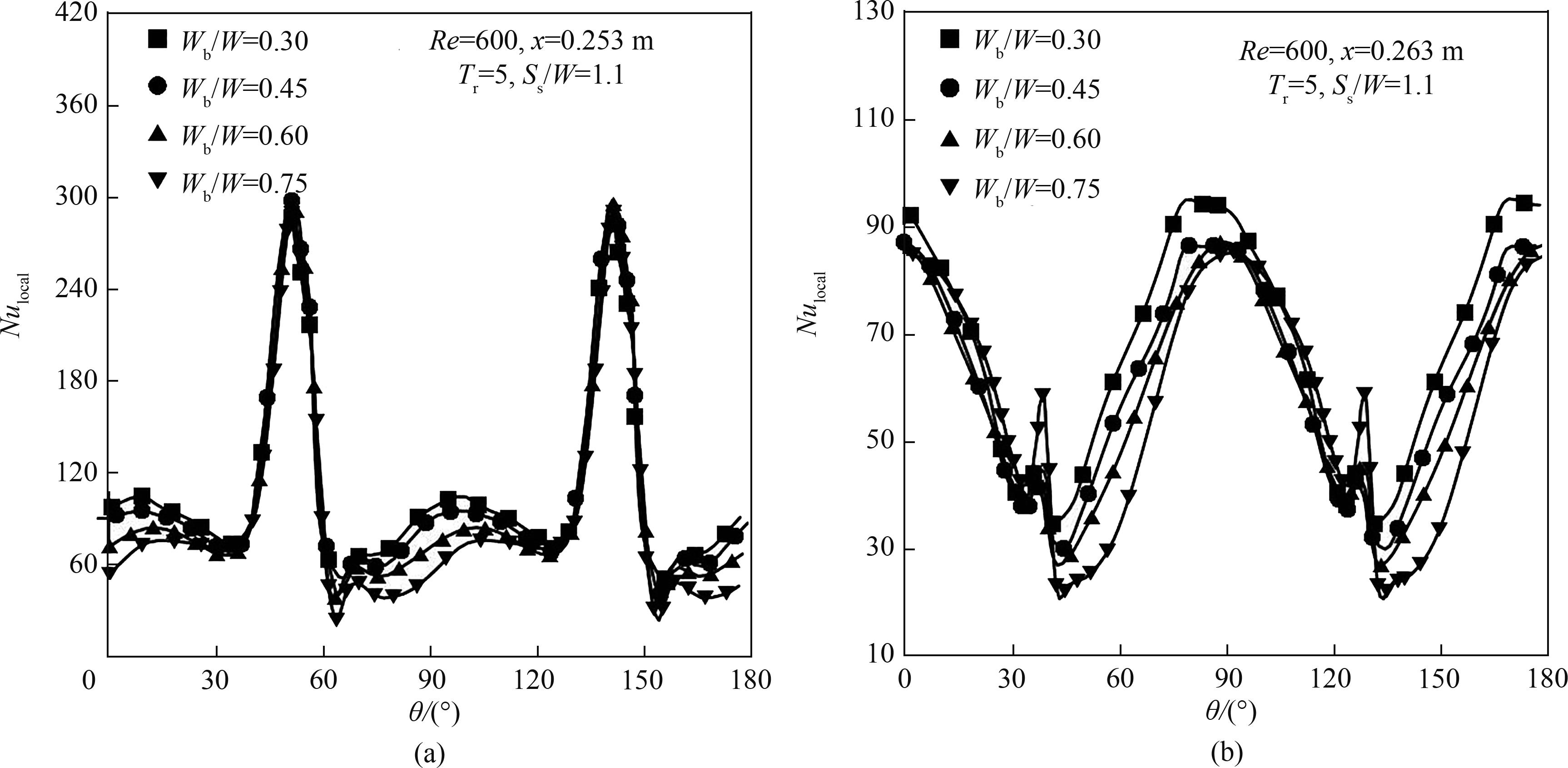

以润滑油为工质,采用数值方法对圆管内插同轴交叉等腰梯形涡产生器的管内流动与传热进行了数值模拟,分析了不同结构参数如扭率(Tr=3,4,5,6)、间距比(Ss/W=0.8,0.9,1.1,1.2)和基带宽度比(Wb/W=0.30,0.45,0.60,0.75)对圆管内插同轴交叉等腰梯形涡产生器的管内流动与传热特性的影响。结果表明:在相同Re下,平均Nusselt数Num、二次流强度Se、强化传热因子JF均随扭率和间距比的减小而增大,而其与基带宽度比的变化没有明显规律,阻力系数f随着扭率的减小和基带宽度比的增大而增大,间距比对f的影响甚微。在相同结构参数下,JF和Se均随Re的增大而增大。在Re=50~1000范围内,相比于光滑圆管,内插不同结构参数的同轴交叉涡产生器的Num增加了32.8%~208.6%,f增加了3.38~8.92倍,JF最大可达1.434。Num与Se呈幂函数相关,内插同轴交叉翼型涡产生器管内的二次流强度决定了其对流换热强度。

中图分类号:

林志敏, 王崇兆, 强国智, 刘树山, 王良璧. 润滑油在内插同轴交叉翼型涡产生器管内流动与传热特性分析[J]. 化工学报, 2022, 73(11): 4957-4973.

Zhimin LIN, Chongzhao WANG, Guozhi QIANG, Shushan LIU, Liangbi WANG. Analysis of flow and heat transfer characteristics of lubricating oil in circular tube with coaxial crossed vortex generators[J]. CIESC Journal, 2022, 73(11): 4957-4973.

| Case | Tr | Ss/W | Wb/W | β/(°) | γ/(°) | B/W | W/mm |

|---|---|---|---|---|---|---|---|

| VG1 | 3 | 1.1 | 0.30 | 60 | 60 | 0.578 | 18 |

| VG2 | 4 | 1.1 | 0.30 | 60 | 60 | 0.578 | 18 |

| VG3 | 5 | 1.1 | 0.30 | 60 | 60 | 0.578 | 18 |

| VG4 | 6 | 1.1 | 0.30 | 60 | 60 | 0.578 | 18 |

| VG5 | 5 | 0.8 | 0.60 | 60 | 60 | 0.578 | 18 |

| VG6 | 5 | 0.9 | 0.60 | 60 | 60 | 0.578 | 18 |

| VG7 | 5 | 1.1 | 0.60 | 60 | 60 | 0.578 | 18 |

| VG8 | 5 | 1.2 | 0.60 | 60 | 60 | 0.578 | 18 |

| VG9 | 5 | 1.1 | 0.45 | 60 | 60 | 0.578 | 18 |

| VG10 | 5 | 1.1 | 0.75 | 60 | 60 | 0.578 | 18 |

表1 同轴交叉涡产生器的结构参数

Table 1 Geometrical parameters of the coaxial crossed vortex generators

| Case | Tr | Ss/W | Wb/W | β/(°) | γ/(°) | B/W | W/mm |

|---|---|---|---|---|---|---|---|

| VG1 | 3 | 1.1 | 0.30 | 60 | 60 | 0.578 | 18 |

| VG2 | 4 | 1.1 | 0.30 | 60 | 60 | 0.578 | 18 |

| VG3 | 5 | 1.1 | 0.30 | 60 | 60 | 0.578 | 18 |

| VG4 | 6 | 1.1 | 0.30 | 60 | 60 | 0.578 | 18 |

| VG5 | 5 | 0.8 | 0.60 | 60 | 60 | 0.578 | 18 |

| VG6 | 5 | 0.9 | 0.60 | 60 | 60 | 0.578 | 18 |

| VG7 | 5 | 1.1 | 0.60 | 60 | 60 | 0.578 | 18 |

| VG8 | 5 | 1.2 | 0.60 | 60 | 60 | 0.578 | 18 |

| VG9 | 5 | 1.1 | 0.45 | 60 | 60 | 0.578 | 18 |

| VG10 | 5 | 1.1 | 0.75 | 60 | 60 | 0.578 | 18 |

| 序号 | 网格数量/个 | Num | f |

|---|---|---|---|

| 网格1 | 1426409 | 72.250 | 1.128 |

| 网格2 | 1889992 | 72.324 | 1.114 |

| 网格3 | 2752435 | 72.316 | 1.111 |

| 网格4 | 3810313 | 72.321 | 1.113 |

表2 网格独立性验证结果

Table 2 Results of grid independence test

| 序号 | 网格数量/个 | Num | f |

|---|---|---|---|

| 网格1 | 1426409 | 72.250 | 1.128 |

| 网格2 | 1889992 | 72.324 | 1.114 |

| 网格3 | 2752435 | 72.316 | 1.111 |

| 网格4 | 3810313 | 72.321 | 1.113 |

图7 管内插不同扭率Tr的同轴交叉涡产生器对平均流动与传热特性的影响

Fig.7 Effects of coaxial crossed vortex generators with four different twisted ratios on averaged flow and heat transfer characteristics

图8 内插不同扭率Tr的同轴交叉涡产生器对横截面上平均Nusselt数Nux 的影响

Fig.8 Effects of coaxial crossed vortex generators with four different twisted ratios on cross-averaged Nusselt number Nux

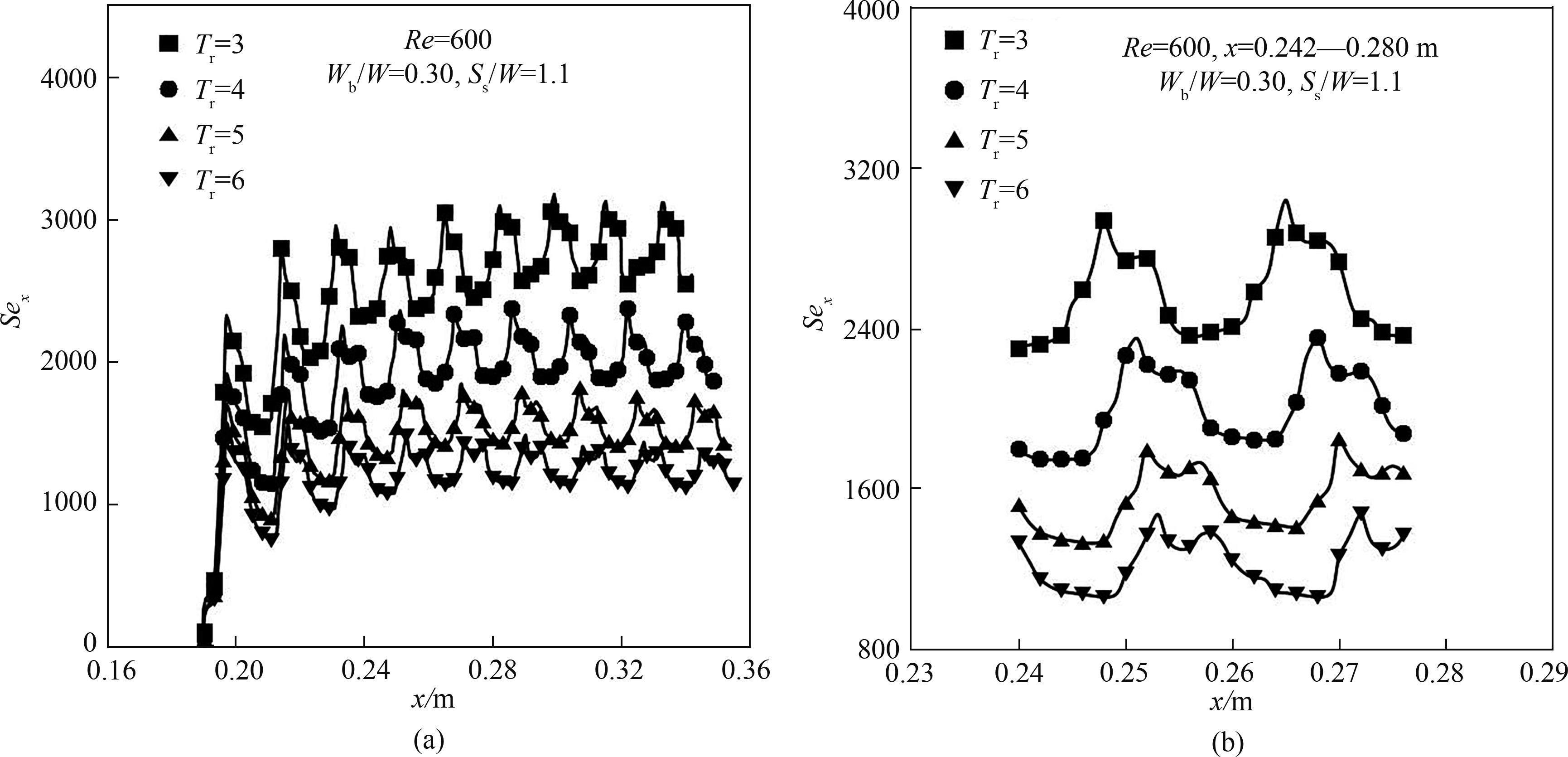

图9 内插不同扭率Tr的同轴交叉涡产生器对横截面上平均二次流强度Sex 的影响

Fig.9 Effects of coaxial crossed vortex generators with four different twisted ratios on cross-averaged secondary flow intensity Sex

图10 内插不同扭率Tr的同轴交叉涡产生器对管壁表面局部Nusselt数Nulocal的影响

Fig.10 Effects of coaxial crossed vortex generators with four different twisted ratios on local Nusselt number Nulocal

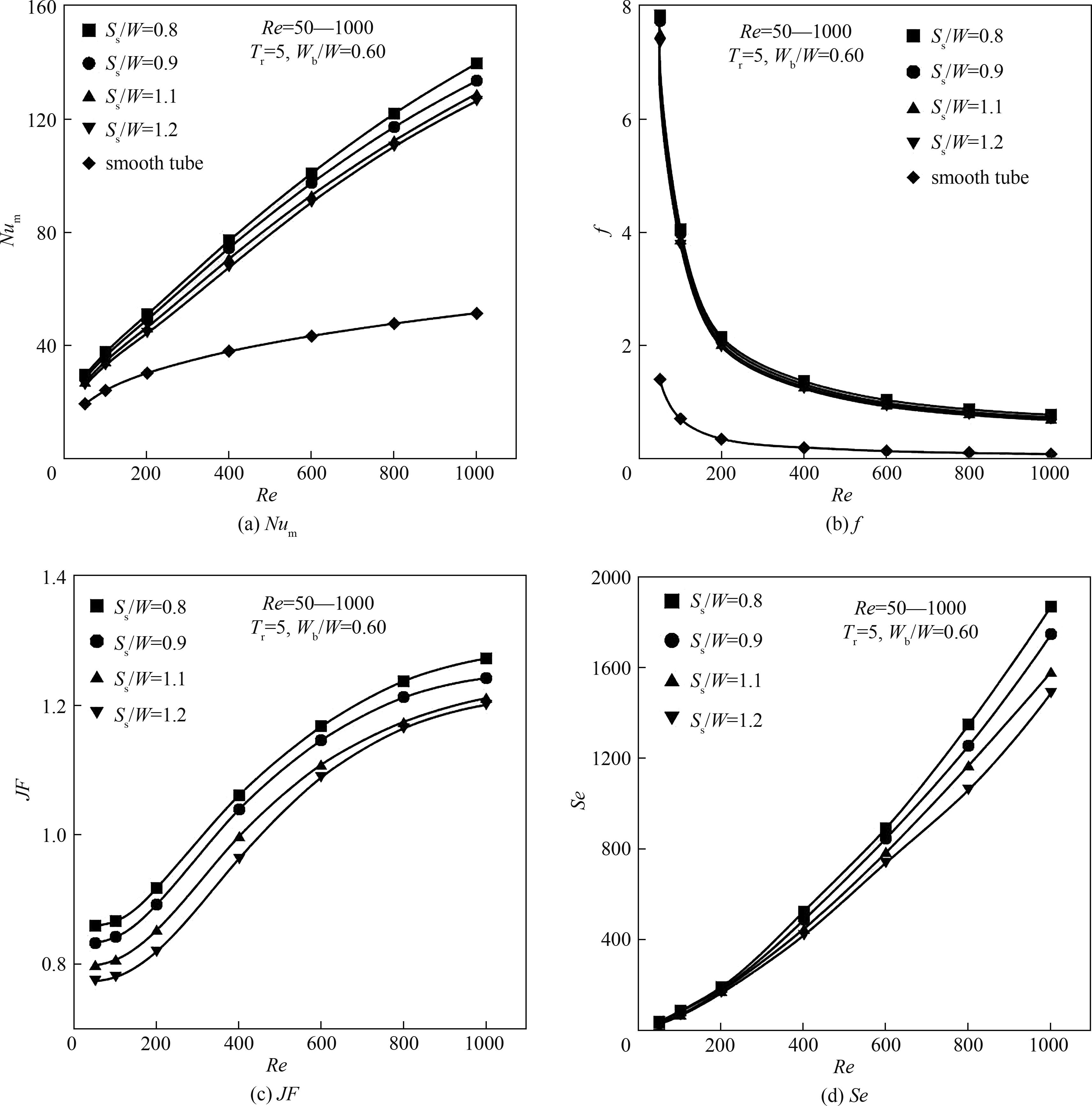

图11 管内插不同间距比Ss/W的同轴交叉涡产生器对平均流动与传热特性的影响

Fig.11 Effects of coaxial crossed vortex generators with four different spacing ratios on averaged flow and heat transfer characteristics

图12 内插不同间距比Ss/W的同轴交叉涡产生器对横截面上平均Nusselt数Nux 的影响

Fig.12 Effects of coaxial crossed vortex generators with four different spacing ratios on cross-averaged Nusselt number Nux

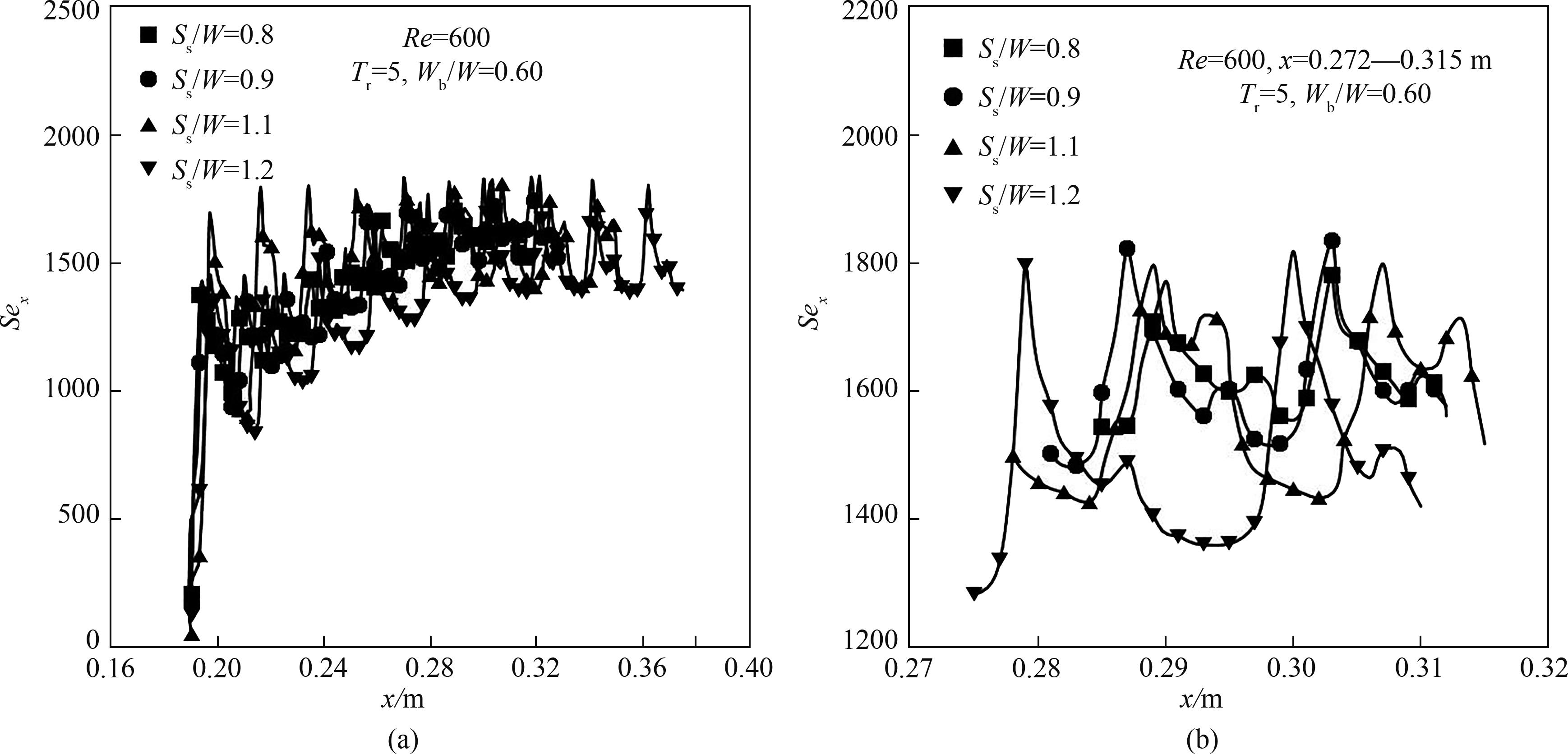

图13 内插不同间距比Ss/W的同轴交叉涡产生器对横截面上平均二次流强度Sex 的影响

Fig.13 Effects of coaxial crossed vortex generators with four different spacing ratios on cross-averaged secondary flow intensity Sex

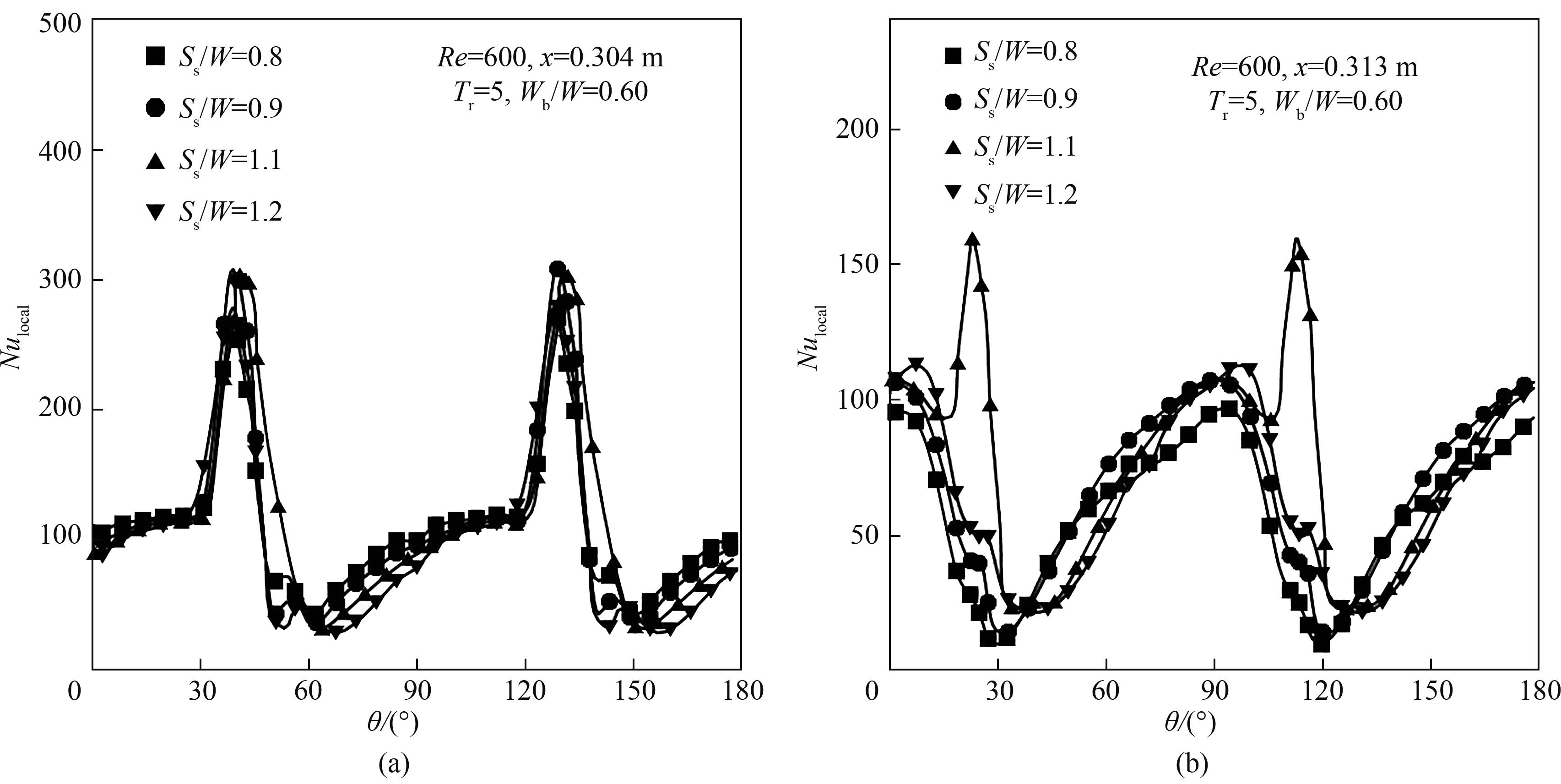

图14 内插不同间距比Ss/W的同轴交叉涡产生器对管壁表面局部Nusselt数Nulocal的影响

Fig.14 Effects of coaxial crossed vortex generators with four different spacing ratios on local Nusselt number Nulocal

图15 管内插不同基带宽度比Wb/W的同轴交叉涡产生器对平均流动与传热特性的影响

Fig.15 Effects of coaxial crossed vortex generators with four different base tape width ratios on averaged flow and heat transfer characteristics

图16 内插不同基带宽度比Wb/W的同轴交叉涡产生器对横截面上平均Nusselt数Nux 的影响

Fig.16 Effects of coaxial crossed vortex generators with four different base tape width ratios on cross-averaged Nusselt number Nux

图17 内插不同基带宽度比Wb/W的同轴交叉涡产生器对横截面上平均二次流强度Sex 的影响

Fig.17 Effects of coaxial crossed vortex generators with four different base tape width ratios on cross-averaged secondary flow intensity Sex

图18 内插不同基带宽度比Wb/W的同轴交叉涡产生器对管壁表面局部Nusselt数Nulocal的影响

Fig.18 Effects of coaxial crossed vortex generators with four different base tape width ratios on local Nusselt number Nulocal

| 1 | Yu C L, Zhang H Q, Wang Y Q, et al. Numerical study on turbulent heat transfer performance of twisted oval tube with different cross sectioned wire coil[J]. Case Studies in Thermal Engineering, 2020, 22: 100759. |

| 2 | Dang W, Wang L B. Convective heat transfer enhancement mechanisms in circular tube inserted with a type of twined coil[J]. International Journal of Heat and Mass Transfer, 2021, 169: 120960. |

| 3 | Chang S W, Yu K C. Heat transfer enhancement by spirally coiled spring inserts with and without segmental solid cords[J]. Experimental Thermal and Fluid Science, 2018, 97: 119-132. |

| 4 | Meng H B, Zhu G X, Yu Y F, et al. The effect of symmetrical perforated holes on the turbulent heat transfer in the static mixer with modified Kenics segments[J]. International Journal of Heat and Mass Transfer, 2016, 99: 647-659. |

| 5 | Liu S, Sakr M. A comprehensive review on passive heat transfer enhancements in pipe exchangers[J]. Renewable and Sustainable Energy Reviews, 2013, 19: 64-81. |

| 6 | Hasanpour A, Farhadi M, Sedighi K. A review study on twisted tape inserts on turbulent flow heat exchangers: the overall enhancement ratio criteria[J]. International Communications in Heat and Mass Transfer, 2014, 55: 53-62. |

| 7 | Varun, Garg M O, Nautiyal H, et al. Heat transfer augmentation using twisted tape inserts: a review[J]. Renewable and Sustainable Energy Reviews, 2016, 63: 193-225. |

| 8 | Eiamsa-ard P, Piriyarungroj N, Thianpong C, et al. A case study on thermal performance assessment of a heat exchanger tube equipped with regularly-spaced twisted tapes as swirl generators[J]. Case Studies in Thermal Engineering, 2014, 3: 86-102. |

| 9 | Guo J, Fan A W, Zhang X Y, et al. A numerical study on heat transfer and friction factor characteristics of laminar flow in a circular tube fitted with center-cleared twisted tape[J]. International Journal of Thermal Sciences, 2011, 50(7): 1263-1270. |

| 10 | Singh Suri A R, Kumar A, Maithani R. Effect of square wings in multiple square perforated twisted tapes on fluid flow and heat transfer of heat exchanger tube[J]. Case Studies in Thermal Engineering, 2017, 10: 28-43. |

| 11 | Wongcharee K, Eiamsa-ard S. Heat transfer enhancement by twisted tapes with alternate-axes and triangular, rectangular and trapezoidal wings[J]. Chemical Engineering and Processing: Process Intensification, 2011, 50(2): 211-219. |

| 12 | Saysroy A, Eiamsa-ard S. Periodically fully-developed heat and fluid flow behaviors in a turbulent tube flow with square-cut twisted tape inserts[J]. Applied Thermal Engineering, 2017, 112: 895-910. |

| 13 | Ruengpayungsak K, Kumar M, Chuwattanakul V, et al. Experimental study of the effects of inclusion of rectangular-cut twisted tapes on heat transfer and pressure drop in a round tube[J]. Arabian Journal for Science and Engineering, 2019, 44(12): 10303-10312. |

| 14 | Chang S W, Huang B J. Thermal performances of tubular flows enhanced by ribbed spiky twist tapes with and without edge notches[J]. International Journal of Heat and Mass Transfer, 2014, 73: 645-663. |

| 15 | Kumar B, Patil A K, Jain S, et al. Effects of double V cuts in perforated twisted tape insert: an experimental study[J]. Heat Transfer Engineering, 2020, 41(17): 1473-1484. |

| 16 | Liu X Y, Ding M, Bian H Z, et al. Numerical study on heat transfer and resistance of a tube fitted with new twisted tapes for lubricating oil[C]//Proceedings of 2017 25th International Conference on Nuclear Engineering. Shanghai, 2017. |

| 17 | Liu X Y, Li C, Cao X X, et al. Numerical analysis on enhanced performance of new coaxial cross twisted tapes for laminar convective heat transfer[J]. International Journal of Heat and Mass Transfer, 2018, 121: 1125-1136. |

| 18 | Lin Z M, Wang L B, Lin M, et al. Numerical study of the laminar flow and heat transfer characteristics in a tube inserting a twisted tape having parallelogram winglet vortex generators[J]. Applied Thermal Engineering, 2017, 115: 644-658. |

| 19 | 武永和, 林志敏, 刘树山, 等. 内插不同形状涡产生器管内层流流动与传热特性的对比分析[J]. 化工学报, 2020, 71(S2): 176-186. |

| Wu Y H, Lin Z M, Liu S S, et al. Comparative analysis of laminar flow and heat transfer characteristics in a circular tube with different shape vortex generators[J]. CIESC Journal, 2020, 71(S2): 176-186. | |

| 20 | Lei Y G, Zheng F, Song C F, et al. Improving the thermal hydraulic performance of a circular tube by using punched delta-winglet vortex generators[J]. International Journal of Heat and Mass Transfer, 2017, 111: 299-311. |

| 21 | Khoshvaght-Aliabadi M, Zanganeh A, Akbari M H, et al. Experimental investigation on thermal-hydraulic characteristics of a tube equipped with modified vortex-generator inserts[J]. Experimental Heat Transfer, 2017, 30(1): 11-24. |

| 22 | Wang Y F, Liu P, Shan F, et al. Effect of longitudinal vortex generator on the heat transfer enhancement of a circular tube[J]. Applied Thermal Engineering, 2019, 148: 1018-1028. |

| 23 | Abdelmaksoud W A, Mahfouz A E, Khalil E E. Thermal performance enhancement for heat exchanger tube fitted with vortex generator inserts[J]. Heat Transfer Engineering, 2021, 42(21): 1861-1875. |

| 24 | 林志敏, 武永和, 王良璧, 等. 管内置矩形翼涡产生器二次流特性及其与换热的关系[J]. 热科学与技术, 2020, 19(3): 205-213. |

| Lin Z M, Wu Y H, Wang L B, et al. The characteristic of secondary flow in a circular tube with twisted rectangular winglet vortex generators and its relationship with conrective heat transfer[J]. Journal of Thermal Science and Technology, 2020, 19(3): 205-213. | |

| 25 | 李凡, 陆高锋, 马光柏, 等. 纵向涡强化圆管内换热的数值模拟及性能分析[J]. 化工学报, 2021, 72(S1): 120-126. |

| Li F, Lu G F, Ma G B, et al. Numerical simulation and performance analysis of heat transfer enhancement in tube by longitudinal vortex[J]. CIESC Journal, 2021, 72(S1): 120-126. | |

| 26 | Deshmukh P W, Prabhu S V, Vedula R P. Heat transfer augmentation for turbulent flow in circular tubes using inserts with multiple curved vortex generator elements[J]. International Journal of Thermal Sciences, 2022, 171: 107203. |

| 27 | Deshmukh P W, Prabhu S V, Vedula R P. Heat transfer enhancement for laminar flow in tubes using curved delta wing vortex generator inserts[J]. Applied Thermal Engineering, 2016, 106: 1415-1426. |

| 28 | Manjunath M S, Fernandes D V. Numerical investigation of heat transfer and friction factor characteristics of circular tube fitted with an array of semi-elliptical vortex generator inserts[J]. Cogent Engineering, 2021, 8(1): 1968742. |

| 29 | Rambhad K S, Kalbande V P, Kumbhalkar M A, et al. Heat transfer and fluid flow analysis for turbulent flow in circular pipe with vortex generator[J]. SN Applied Sciences, 2021, 3(7): 1-21. |

| 30 | Khoshvaght-Aliabadi M, Sartipzadeh O, Alizadeh A. An experimental study on vortex-generator insert with different arrangements of delta-winglets[J]. Energy, 2015, 82: 629-639. |

| 31 | Chamoli S, Lu R X, Xie J, et al. Numerical study on flow structure and heat transfer in a circular tube integrated with novel anchor shaped inserts[J]. Applied Thermal Engineering, 2018, 135: 304-324. |

| 32 | 唐凌虹, 谭思超, 高璞珍. 纵向涡发生器作用下矩形通道内流动换热性能研究[J]. 原子能科学技术, 2014, 48(5): 812-817. |

| Tang L H, Tan S C, Gao P Z. Study on flow and heat transfer characteristic in rectangular channel with longitudinal vortex generator[J]. Atomic Energy Science and Technology, 2014, 48(5): 812-817. | |

| 33 | Wijayanta A T, Yaningsih I, Aziz M, et al. Double-sided delta-wing tape inserts to enhance convective heat transfer and fluid flow characteristics of a double-pipe heat exchanger[J]. Applied Thermal Engineering, 2018, 145: 27-37. |

| 34 | Fiebig M. Vortex generators for compact heat exchangers[J]. Journal of Enhanced Heat Transfer, 1995, 2(1/2): 43-61. |

| 35 | Jacobi A M, Shah R K. Heat transfer surface enhancement through the use of longitudinal vortices: a review of recent progress[J]. Experimental Thermal and Fluid Science, 1995, 11(3): 295-309. |

| 36 | Fiebig M. Vortices, generators and heat transfer[J]. Chemical Engineering Research and Design, 1998, 76(2): 108-123. |

| 37 | Agarwal S K, Rao M R. Heat transfer augmentation for the flow of a viscous liquid in circular tubes using twisted tape inserts[J]. International Journal of Heat and Mass Transfer, 1996, 39(17): 3547-3557. |

| 38 | 林志敏. 扭带及涡产生器在管内诱导的二次流强度及其强化传热特性研究[D]. 兰州: 兰州交通大学, 2011. |

| Lin Z M. The characteristics of secondary flow and heat transfer enhancement in circular tube with twisted tape or vortex generators[D]. Lanzhou: Lanzhou Jiaotong University, 2011. | |

| 39 | Manglik R M, Bergles A E. Heat transfer and pressure drop correlations for twisted-tape inserts in isothermal tubes (part Ⅰ):Laminar flows[J]. Journal of Heat Transfer, 1993, 115(4): 881-889. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [4] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [5] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [6] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [7] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [8] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [9] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [10] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [11] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [12] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [13] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [14] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [15] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号