化工学报 ›› 2023, Vol. 74 ›› Issue (2): 796-806.DOI: 10.11949/0438-1157.20221352

袁海鸥1( ), 叶方俊1(

), 叶方俊1( ), 张硕1, 罗祎青1,2,3(

), 张硕1, 罗祎青1,2,3( ), 袁希钢1,2,3

), 袁希钢1,2,3

收稿日期:2022-10-12

修回日期:2022-12-07

出版日期:2023-02-05

发布日期:2023-03-21

通讯作者:

罗祎青

作者简介:袁海鸥(1997—),女,硕士研究生,haiou_yuan@tju.edu.cn基金资助:

Haiou YUAN1( ), Fangjun YE1(

), Fangjun YE1( ), Shuo ZHANG1, Yiqing LUO1,2,3(

), Shuo ZHANG1, Yiqing LUO1,2,3( ), Xigang YUAN1,2,3

), Xigang YUAN1,2,3

Received:2022-10-12

Revised:2022-12-07

Online:2023-02-05

Published:2023-03-21

Contact:

Yiqing LUO

摘要:

针对考虑中间换热器(IHE)的精馏序列合成问题,提出基于随机优化策略的能量集成非清晰精馏序列(IHE-HIDSs)合成方法。通过对精馏序列分离任务合并处引入二元0/1变量表示是否存在IHE,以精馏序列的年总成本(TAC)为优化目标,建立了该合成问题的隐式混合整数非线性规划模型(MINLP),通过模拟退火和粒子群优化(SA-PSO)混合随机优化算法进行求解。为验证在精馏序列合成中同时考虑IHE的必要性以及所提出合成方法的有效性,对五组分醇类混合物和五组分烷烃类混合物两个算例的精馏序列合成问题进行了研究。结果表明,相比同时考虑热耦合和能量集成的精馏序列,IHE-HIDS具有更低的TAC。此外,所提出的方法可以在合理的计算时间内以高概率获得多个分离序列方案。

中图分类号:

袁海鸥, 叶方俊, 张硕, 罗祎青, 袁希钢. 考虑中间换热器的能量集成精馏序列合成[J]. 化工学报, 2023, 74(2): 796-806.

Haiou YUAN, Fangjun YE, Shuo ZHANG, Yiqing LUO, Xigang YUAN. Synthesis of heat-integrated distillation sequences with intermediate heat exchangers[J]. CIESC Journal, 2023, 74(2): 796-806.

图1 五组分非清晰分离精馏序列及对应的N-1塔精馏序列

Fig.1 Example of a nonsharp-split distillation sequence for a five-component mixture and the corresponding distillation configuration with N-1 columns

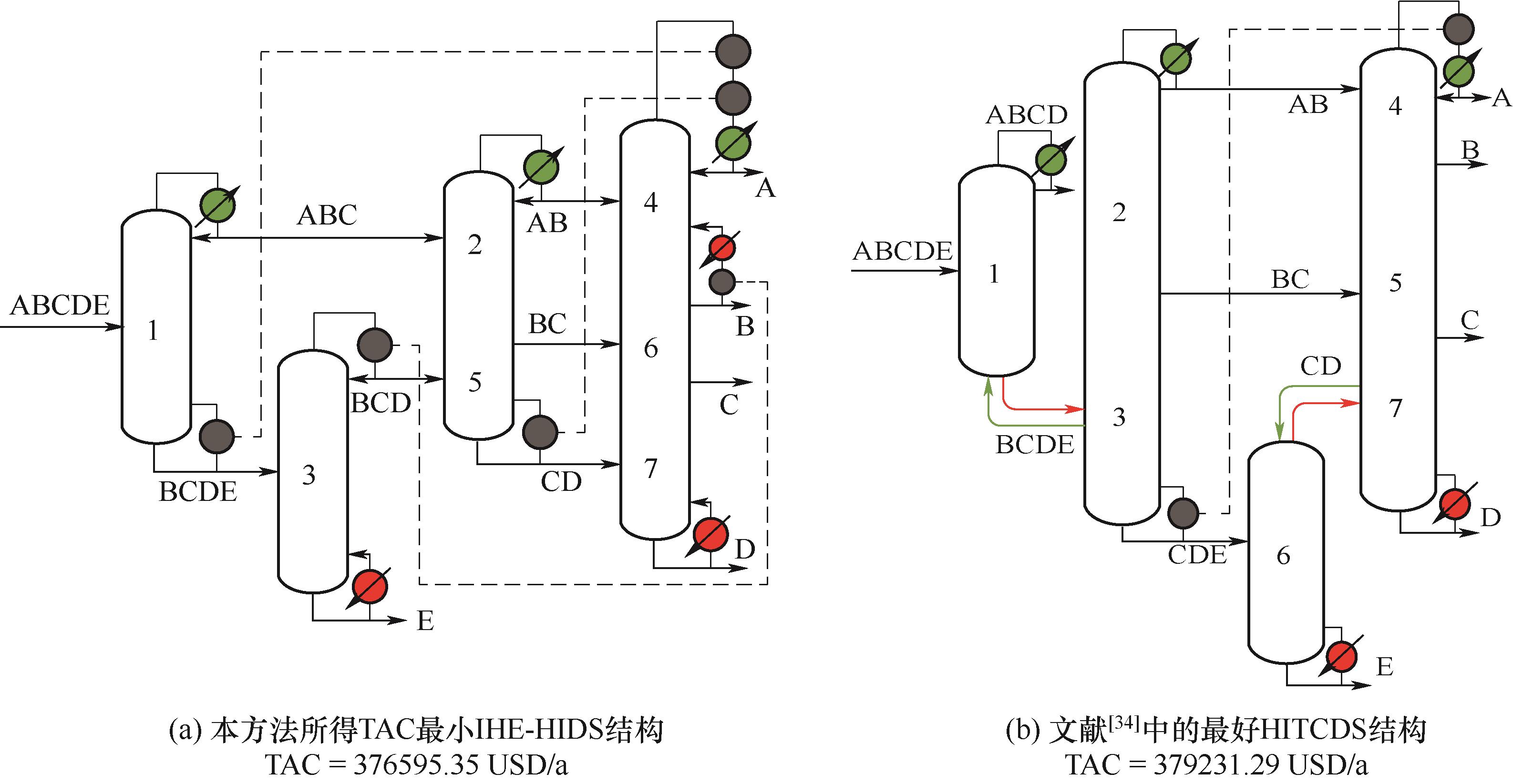

图4 算例1中SA-PSO算法优化得到的TAC最小IHE-HIDS和文献最好HITCDS

Fig.4 The TAC minimum IHE-HIDS and the best HITCDS in the literature obtained by the SA-PSO algorithm in case 1

| Separation task | p/MPa | R | ξLK | ξHK | V/(kmol/h) | TD/K | TB/K | Qc/(GJ/h) | Qr/(GJ/h) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ABC|BCDE | 0.10 | 1.10 | 0.980 | 0.020 | 486.15 | 355.52 | 379.05 | 19.320 | 20.346 |

| 2 | AB|BC | 0.10 | 1.26 | 0.980 | 0.020 | 375.51 | 352.58 | — | 14.670 | — |

| 3 | BCD|E | 0.40 | 1.56 | 0.9800 | 0.020 | 498.25 | 413.14 | 441.18 | 18.630 | 18.848 |

| 4 | A|B | 0.38 | 9.30 | 0.980 | 0.020 | 1221.85 | 389.07 | 403.11 | 42.964 | 30.007 |

| 5 | BC|CD | 0.10 | 5.65 | 0.997 | 0.005 | 375.51 | — | 377.45 | — | 15.610 |

| 6 | B|C | 0.38 | 8.52 | 0.980 | 0.020 | 343.49 | — | — | — | — |

| 7 | C|D | 0.38 | 2.90 | 0.980 | 0.020 | 343.49 | — | 428.15 | — | 12.755 |

{IHE}:{0, 1, 0}:2-5 (0)、4-6 (1)、6-7 (0) TAC:376595.35 USD/a | ||||||||||

| 年度设备费:81384.51 USD/a;年度操作费:295210.84 USD/a | ||||||||||

中间组分回收率:ABC|BCDE:ξB = 0.8154、ξC = 0.2653;AB|BC:ξB = 0.7351;BC|CD:ξC = 0.3102 能量匹配:20.346 GJ/h (4→1), 15.610 GJ/h (4→5), 18.630 GJ/h (3→4) | ||||||||||

表3 算例1中TAC最小IHE-HIDS的操作参数

Table 3 Operating parameters of the TAC minimum IHE-HIDS in case 1

| Separation task | p/MPa | R | ξLK | ξHK | V/(kmol/h) | TD/K | TB/K | Qc/(GJ/h) | Qr/(GJ/h) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ABC|BCDE | 0.10 | 1.10 | 0.980 | 0.020 | 486.15 | 355.52 | 379.05 | 19.320 | 20.346 |

| 2 | AB|BC | 0.10 | 1.26 | 0.980 | 0.020 | 375.51 | 352.58 | — | 14.670 | — |

| 3 | BCD|E | 0.40 | 1.56 | 0.9800 | 0.020 | 498.25 | 413.14 | 441.18 | 18.630 | 18.848 |

| 4 | A|B | 0.38 | 9.30 | 0.980 | 0.020 | 1221.85 | 389.07 | 403.11 | 42.964 | 30.007 |

| 5 | BC|CD | 0.10 | 5.65 | 0.997 | 0.005 | 375.51 | — | 377.45 | — | 15.610 |

| 6 | B|C | 0.38 | 8.52 | 0.980 | 0.020 | 343.49 | — | — | — | — |

| 7 | C|D | 0.38 | 2.90 | 0.980 | 0.020 | 343.49 | — | 428.15 | — | 12.755 |

{IHE}:{0, 1, 0}:2-5 (0)、4-6 (1)、6-7 (0) TAC:376595.35 USD/a | ||||||||||

| 年度设备费:81384.51 USD/a;年度操作费:295210.84 USD/a | ||||||||||

中间组分回收率:ABC|BCDE:ξB = 0.8154、ξC = 0.2653;AB|BC:ξB = 0.7351;BC|CD:ξC = 0.3102 能量匹配:20.346 GJ/h (4→1), 15.610 GJ/h (4→5), 18.630 GJ/h (3→4) | ||||||||||

| 合成方案 | TAC/(USD/a) | 设备费/(USD/a) | 操作费/(USD/a) |

|---|---|---|---|

| IHE-HIDS | 376595.35 | 81384.51 | 295210.84 |

| HITCDS | 379231.29 | 63343.43 | 315887.86 |

表4 算例1中TAC最小IHE-HIDS和HITCDS的TACs、年度设备费和操作费对比

Table 4 The comparison of TACs, capital costs and operate costs of the TAC minimum IHE-HIDS and HITCDS in case 1

| 合成方案 | TAC/(USD/a) | 设备费/(USD/a) | 操作费/(USD/a) |

|---|---|---|---|

| IHE-HIDS | 376595.35 | 81384.51 | 295210.84 |

| HITCDS | 379231.29 | 63343.43 | 315887.86 |

图6 算例2中SA-PSO算法优化得到的TAC最小IHE-HIDS和文献最好HITCDS

Fig.6 The TAC minimum IHE-HIDS and the best HITCDS in the literature obtained by the SA-PSO algorithm in case 2

| Separation task | p/MPa | R | ξLK | ξHK | V/(kmol/h) | TD/K | TB/K | Qc/(GJ/h) | Qr/(GJ/h) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ABCD|BCDE | 1.00 | 0.66 | 0.980 | 0.020 | 276.54 | 331.76 | 375.59 | 4.591 | 5.026 |

| 2 | A|BCD | 0.82 | 2.33 | 0.980 | 0.020 | 148.57 | 293.69 | — | 2.242 | — |

| 3 | BCD|CDE | 0.82 | 1.25 | 0.980 | 0.020 | 498.86 | 341.94 | 380.63 | 6.155 | 9.686 |

| 4 | B|CD | 0.61 | 6.96 | 0.980 | 0.020 | 1081.12 | 319.10 | 342.73 | 19.070 | 10.909 |

| 5 | CD|DE | 0.61 | 4.32 | 0.999 | 0.020 | 477.92 | — | 374.03 | — | 9.910 |

| 6 | C|D | 1.00 | 1.33 | 0.980 | 0.020 | 522.23 | 353.86 | — | 8.782 | — |

| 7 | D|E | 1.00 | 13.97 | 0.980 | 0.020 | 2000.57 | 391.05 | 405.00 | 26.789 | 36.626 |

{IHE}:{1, 1, 1}:2-3 (1)、4-5 (1)、6-7 (1) TAC:4924023.13 USD/a | ||||||||||

| 年度设备费:827841.36 USD/a;年度操作费:4096181.78 USD/a | ||||||||||

中间组分回收率:ABCD|BCDE:ξB = 0.3668、ξC = 0.2490、ξD = 0.0507;BCD|CDE:ξC = 0.6582、ξD = 0.1055;CD|DE:ξD = 0.1547 能量匹配:8.782 GJ/h (6→4), 5.026 GJ/h (7→1), 9.686 GJ/h (7→3) , 9.910 GJ/h (7→5) , 2.127 GJ/h (7→4) | ||||||||||

表6 算例2中TAC最小IHE-HIDS的操作参数

Table 6 Operating parameters of the TAC minimum IHE-HIDS in case 2

| Separation task | p/MPa | R | ξLK | ξHK | V/(kmol/h) | TD/K | TB/K | Qc/(GJ/h) | Qr/(GJ/h) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ABCD|BCDE | 1.00 | 0.66 | 0.980 | 0.020 | 276.54 | 331.76 | 375.59 | 4.591 | 5.026 |

| 2 | A|BCD | 0.82 | 2.33 | 0.980 | 0.020 | 148.57 | 293.69 | — | 2.242 | — |

| 3 | BCD|CDE | 0.82 | 1.25 | 0.980 | 0.020 | 498.86 | 341.94 | 380.63 | 6.155 | 9.686 |

| 4 | B|CD | 0.61 | 6.96 | 0.980 | 0.020 | 1081.12 | 319.10 | 342.73 | 19.070 | 10.909 |

| 5 | CD|DE | 0.61 | 4.32 | 0.999 | 0.020 | 477.92 | — | 374.03 | — | 9.910 |

| 6 | C|D | 1.00 | 1.33 | 0.980 | 0.020 | 522.23 | 353.86 | — | 8.782 | — |

| 7 | D|E | 1.00 | 13.97 | 0.980 | 0.020 | 2000.57 | 391.05 | 405.00 | 26.789 | 36.626 |

{IHE}:{1, 1, 1}:2-3 (1)、4-5 (1)、6-7 (1) TAC:4924023.13 USD/a | ||||||||||

| 年度设备费:827841.36 USD/a;年度操作费:4096181.78 USD/a | ||||||||||

中间组分回收率:ABCD|BCDE:ξB = 0.3668、ξC = 0.2490、ξD = 0.0507;BCD|CDE:ξC = 0.6582、ξD = 0.1055;CD|DE:ξD = 0.1547 能量匹配:8.782 GJ/h (6→4), 5.026 GJ/h (7→1), 9.686 GJ/h (7→3) , 9.910 GJ/h (7→5) , 2.127 GJ/h (7→4) | ||||||||||

| 合成方案 | TAC/(USD/a) | 设备费/(USD/a) | 操作费/(USD/a) |

|---|---|---|---|

| IHE-HIDS | 4924023.13 | 827841.36 | 4096181.78 |

| HITCDS | 5423006.58 | 683539.61 | 4739466.97 |

表7 算例2中TAC最小IHE-HIDS和HITCDS的TACs、年度设备费和操作费对比

Table 7 The comparison of TACs, capital costs and operate costs of the TAC minimum IHE-HIDS and HITCDS in case 2

| 合成方案 | TAC/(USD/a) | 设备费/(USD/a) | 操作费/(USD/a) |

|---|---|---|---|

| IHE-HIDS | 4924023.13 | 827841.36 | 4096181.78 |

| HITCDS | 5423006.58 | 683539.61 | 4739466.97 |

| 1 | Sholl D S, Lively R P. Seven chemical separations to change the world[J]. Nature, 2016, 532(7600): 435-437. |

| 2 | Humphrey J L, Siebert A F. Separation technologies: an opportunity for energy savings[J]. Chemical Engineering Progress, 1992, 88(3): 32-41. |

| 3 | Jana A K. Heat integrated distillation operation[J]. Applied Energy, 2010, 87(5): 1477-1494. |

| 4 | Kiss A A. Towards energy efficient distillation technologies — making the right choice[J]. Energy, 2012, 47(1): 531-542. |

| 5 | Yeomans H, Grossmann I E. Disjunctive programming models for the optimal design of distillation columns and separation sequences[J]. Industrial & Engineering Chemistry Research, 2000, 39(6): 1637-1648. |

| 6 | Zhang L B, Linninger A A. Towards computer-aided separation synthesis[J]. AIChE Journal, 2006, 52(4): 1392-1409. |

| 7 | Wang F, Luo Y Q, Yuan X G. A formulation methodology for multicomponent distillation sequences based on stochastic optimization[J]. Chinese Journal of Chemical Engineering, 2016, 24(9): 1229-1235. |

| 8 | Leeson D. Simultaneous design of separation sequences and whole process energy integration[J]. Chemical Engineering Research and Design, 2017, 125: 166-180. |

| 9 | Zhang S. Simultaneous optimization of nonsharp distillation sequences and heat integration networks by simulated annealing algorithm[J]. Energy, 2018, 162: 1139-1157. |

| 10 | Caballero J A, Grossmann I E. Optimal synthesis of thermally coupled distillation sequences using a novel MILP approach[J]. Computers & Chemical Engineering, 2014, 61: 118-135. |

| 11 | Caballero J A, Grossmann I E. Structural considerations and modeling in the synthesis of heat-integrated-thermally coupled distillation sequences[J]. Industrial & Engineering Chemistry Research, 2006, 45(25): 8454-8474. |

| 12 | 陆恩锡, 李小玲, 吴震. 蒸馏过程中间再沸器与中间冷凝器[J]. 化学工程, 2008, 36(11): 74-78. |

| Lu E X, Li X L, Wu Z. Inter-reboiler and inter-condenser in distillation[J]. Chemical Engineering (China), 2008, 36(11): 74-78. | |

| 13 | Alcántara-Avila J R, Tanaka M, Márquez C R, et al. Design of a multitask reactive distillation with intermediate heat exchangers for the production of silane and chlorosilane derivates[J]. Industrial & Engineering Chemistry Research, 2016, 55(41): 10968-10977. |

| 14 | Li Y D, Ye Q, Wang N G, et al. Energy-efficient extractive distillation combined with heat-integrated and intermediate reboilers for separating acetonitrile/isopropanol/water mixture[J]. Separation and Purification Technology, 2021, 262: 118343. |

| 15 | Agrawal R, Herron D M. Efficient use of an intermediate reboiler or condenser in a binary distillation[J]. AIChE Journal, 1998, 44(6): 1303-1315. |

| 16 | Agrawal R, Herron D M. Intermediate reboiler and condenser arrangement for binary distillation columns[J]. AIChE Journal, 1998, 44(6): 1316-1324. |

| 17 | Björn I N. Simulation and experimental study of intermediate heat exchange in a sieve tray distillation column[J]. Computers & Chemical Engineering, 2002, 26(4/5): 499-505. |

| 18 | 许良华, 陈大为, 罗祎青, 等. 带有中间热集成的精馏塔序列及其性能[J]. 化工学报, 2013, 64(7): 2503-2510. |

| Xu L H, Chen D W, Luo Y Q, et al. Intermediate heat-integrated sequence of distillation columns and its energy-saving property[J]. CIESC Journal, 2013, 64(7): 2503-2510. | |

| 19 | An W Z, Yu F J, Dong F L, et al. Simulated annealing approach to the optimal synthesis of distillation column with intermediate heat exchangers[J]. Chinese Journal of Chemical Engineering, 2008, 16(1): 30-35. |

| 20 | Thompson R W, King C J. Systematic synthesis of separation schemes[J]. AIChE Journal, 1972, 18(5): 941-948. |

| 21 | Stephanopoulos G, Westerberg A W. Studies in process synthesis(Ⅱ): Evolutionary synthesis of optimal process flowsheets[J]. Chemical Engineering Science, 1976, 31(3): 195-204. |

| 22 | Qian Y, Lien K M. Rule based synthesis of separation systems by predictive best first search with rules represented as trapezoidal numbers[J]. Computers & Chemical Engineering, 1995, 19(11): 1185-1205. |

| 23 | Gooty R T. An MINLP formulation for the optimization of multicomponent distillation configurations[J]. Computers & Chemical Engineering, 2019, 125: 13-30. |

| 24 | Yeomans H. A systematic modeling framework of superstructure optimization in process synthesis[J]. Computers & Chemical Engineering, 1999, 23(6): 709-731. |

| 25 | Caballero J A. Design of distillation sequences: from conventional to fully thermally coupled distillation systems[J]. Computers & Chemical Engineering, 2004, 28(11): 2307-2329. |

| 26 | Caballero J A, Grossmann I E. Synthesis of complex thermally coupled distillation systems including divided wall columns[J]. AIChE Journal, 2013, 59(4): 1139-1159. |

| 27 | Biegler L T. Retrospective on optimization[J]. Computers & Chemical Engineering, 2004, 28(8): 1169-1192. |

| 28 | Shah V H, Agrawal R. A matrix method for multicomponent distillation sequences[J]. AIChE Journal, 2010, 56(7): 1759-1775. |

| 29 | Wang X H, Li Y G. Synthesis of multicomponent products separation sequences via stochastic GP method[J]. Industrial & Engineering Chemistry Research, 2008, 47(22): 8815-8822. |

| 30 | Jain S, Smith R, Kim J K. Synthesis of heat-integrated distillation sequence systems[J]. Journal of the Taiwan Institute of Chemical Engineers, 2012, 43(4): 525-534. |

| 31 | Yuan X G, An W Z. Synthesis of heat integrated complex distillation systems via stochastic optimization approaches[J]. Chinese Journal of Chemical Engineering, 2002, 10(5): 495-507. |

| 32 | An W Z. A simulated annealing-based approach to the optimal synthesis of heat-integrated distillation sequences[J]. Computers & Chemical Engineering, 2009, 33(1): 199-212. |

| 33 | Zhang S. Synthesis of simultaneously heat integrated and thermally coupled nonsharp distillation sequences based on stochastic optimization[J]. Computers & Chemical Engineering, 2019, 127: 158-174. |

| 34 | Zhang S, Luo Y Q, Yuan X G. A novel stochastic optimization method to efficiently synthesize large-scale nonsharp distillation systems[J]. AIChE Journal, 2021, 67(9): e17328. |

| 35 | Giridhar A. Synthesis of distillation configurations ( Ⅰ ) : Characteristics of a good search space[J]. Computers & Chemical Engineering, 2010, 34(1): 73-83. |

| 36 | 安维中. 基于随机优化的复杂精馏系统综合研究[D]. 天津: 天津大学, 2003. |

| An W Z. Synthesis of complex distillation systems based on stochastic optimization[D]. Tianjin: Tianjin University, 2003. | |

| 37 | Metropolis N, Rosenbluth A W, Rosenbluth M N, et al. Equation of state calculations by fast computing machines[J]. The Journal of Chemical Physics, 1953, 21(6): 1087-1092. |

| 38 | Turton R, Bailie R C, Whiting W B, et al. Analysis, Synthesis and Design of Chemical Processes[M]. New York: Pearson Education, 2008: 231-266. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [3] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [4] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [5] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [6] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [7] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [8] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [9] | 尹刚, 李伊惠, 何飞, 曹文琦, 王民, 颜非亚, 向禹, 卢剑, 罗斌, 卢润廷. 基于KPCA和SVM的铝电解槽漏槽事故预警方法[J]. 化工学报, 2023, 74(8): 3419-3428. |

| [10] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [11] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [12] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [13] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [14] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [15] | 李贵贤, 曹阿波, 孟文亮, 王东亮, 杨勇, 周怀荣. 耦合固体氧化物电解槽的CO2制甲醇过程设计与评价研究[J]. 化工学报, 2023, 74(7): 2999-3009. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号