化工学报 ›› 2024, Vol. 75 ›› Issue (1): 197-210.DOI: 10.11949/0438-1157.20230782

崔怡洲( ), 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英(

), 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英( )

)

收稿日期:2023-08-01

修回日期:2023-09-11

出版日期:2024-01-25

发布日期:2024-03-11

通讯作者:

蓝兴英

作者简介:崔怡洲(1994—),男,博士研究生,cuiyizhou_cup@163.com

基金资助:

Yizhou CUI( ), Chengxiang LI, Linxiao ZHAI, Shuyu LIU, Xiaogang SHI, Jinsen GAO, Xingying LAN(

), Chengxiang LI, Linxiao ZHAI, Shuyu LIU, Xiaogang SHI, Jinsen GAO, Xingying LAN( )

)

Received:2023-08-01

Revised:2023-09-11

Online:2024-01-25

Published:2024-03-11

Contact:

Xingying LAN

摘要:

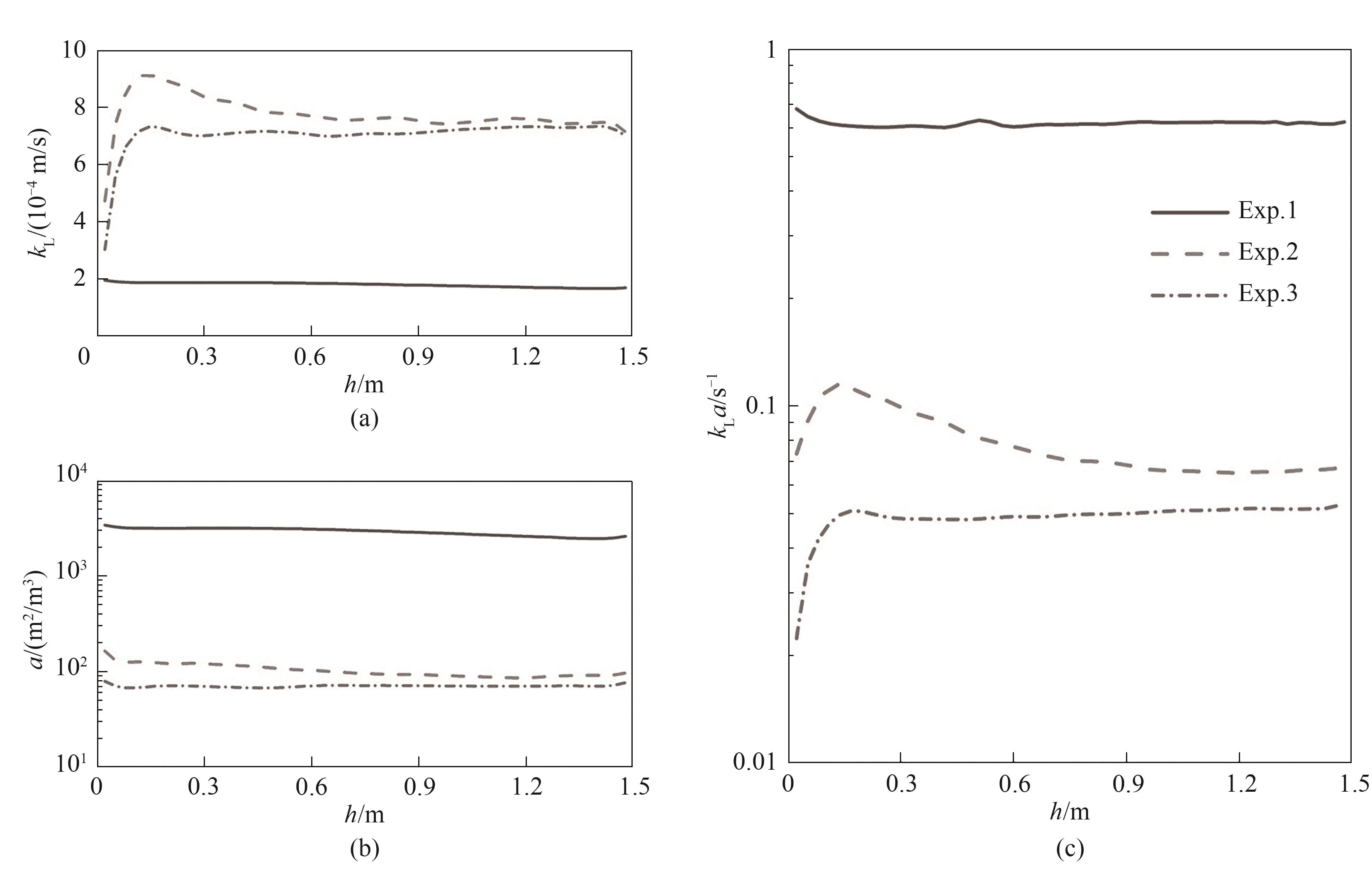

通过实验和数值模拟系统研究了亚毫米气泡鼓泡塔与常规鼓泡塔在流动和传质特性上的区别,并建立了适用于亚毫米气泡气液两相流流动和传质过程的数值模拟方法。研究结果表明,相比常规鼓泡塔,相同操作条件下亚毫米气泡鼓泡塔的气泡尺寸分布更窄,平均尺寸降至前者3%左右,气含率提高2倍以上,比表面积提高2个数量级。另外亚毫米气泡气液两相流中气液径向分布更均匀,轴向返混程度更小。亚毫米气泡鼓泡塔的相界面积是强化传质的关键控制因素,其液相传质系数虽低于常规鼓泡塔,但依靠巨大的相界面积,其体积传质系数是常规鼓泡塔的10倍左右。针对大规模鼓泡塔反应器的模拟结果也表明,亚毫米气泡可使反应器达到更均匀的气含率分布,受初始气液分布的影响小。

中图分类号:

崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210.

Yizhou CUI, Chengxiang LI, Linxiao ZHAI, Shuyu LIU, Xiaogang SHI, Jinsen GAO, Xingying LAN. Comparative study on the flow and mass transfer characteristics of sub-millimeter bubbles and conventional bubbles in gas-liquid two-phase flow[J]. CIESC Journal, 2024, 75(1): 197-210.

| 对比方式 | 实验编号 | 表观气速/(m/s) | 表观液速/(m/s) | 鼓泡塔入口处液相CO2浓度/(mol/L) | d32/mm |

|---|---|---|---|---|---|

| 基准 | Exp.1 | 0.03226 | 0.04247 | 0.0384 | 0.312 |

| 对比方 | Exp.2 | 0.06717 | 0.04247 | 0 | 7.77 |

| 对比方 | Exp.3 | 0.03226 | 0.04247 | 0.0384 | 8.12 |

表1 传质实验操作条件总结

Table 1 Summary of the operating conditions of the mass transfer experiments

| 对比方式 | 实验编号 | 表观气速/(m/s) | 表观液速/(m/s) | 鼓泡塔入口处液相CO2浓度/(mol/L) | d32/mm |

|---|---|---|---|---|---|

| 基准 | Exp.1 | 0.03226 | 0.04247 | 0.0384 | 0.312 |

| 对比方 | Exp.2 | 0.06717 | 0.04247 | 0 | 7.77 |

| 对比方 | Exp.3 | 0.03226 | 0.04247 | 0.0384 | 8.12 |

图16 亚毫米气泡与毫米气泡液相传质系数、气相比表面积以及体积传质系数对比

Fig.16 Comparison of liquid side mass transfer coefficient, gas-liquid interfacial area, and volumetric mass transfer coefficient between sub-millimeter bubbles and millimeter bubbles

| 1 | Martín M, Galan M A, Cerro R L, et al. Shape oscillating bubbles: hydrodynamics and mass transfer—a review[J]. Bubble Science Engineering and Technology, 2011, 3(2): 48-63. |

| 2 | International Organization for Standardization. Fine bubble technology—general principles for usage and measurement of fine bubbles(part 1): Terminology: [S]. Switzerland, 2017. |

| 3 | 邓超, 杨丽, 陈海军, 等. 微纳米气泡发生装置及其应用的研究进展[J]. 石油化工, 2014, 43(10): 1206-1213. |

| Deng C, Yang L, Chen H J, et al. Progresses in research and application of micro-nano bubble generating device[J]. Petrochemical Technology, 2014, 43(10): 1206-1213. | |

| 4 | Parmar R, Majumder S K. Microbubble generation and microbubble-aided transport process intensification—a state-of-the-art report[J]. Chemical Engineering and Processing-Process Intensification, 2013, 64: 79-97. |

| 5 | Muroyama K, Imai K, Oka Y, et al. Mass transfer properties in a bubble column associated with micro-bubble dispersions[J]. Chemical Engineering Science, 2013, 100: 464-473. |

| 6 | Muroyama K, Oka Y, Fujiki R. Transport properties of micro-bubbles in a bubble column[J]. Journal of Chemical Engineering of Japan, 2012, 45(9): 666-671. |

| 7 | Kalaga D V, Ansari M, Turney D E, et al. Scale-up of a downflow bubble column: experimental investigations[J]. Chemical Engineering Journal, 2020, 386: 121447. |

| 8 | 张志炳. 微界面传质强化技术[M]. 北京: 化学工业出版社, 2020: 379-426. |

| Zhang Z B. Microinterfacial Mass Transfer Intensification[M]. Beijing: Chemical Industry Press, 2020: 379-426. | |

| 9 | Li J J, Song Y C, Yin J L, et al. Investigation on the effect of geometrical parameters on the performance of a Venturi type bubble generator[J]. Nuclear Engineering and Design, 2017, 325: 90-96. |

| 10 | Tsuge H. Fundamental of microbubbles and nanobubbles[J]. Bulletin of the Society of Sea Water Science Japan, 2010, 64: 4-10. |

| 11 | Kim Y B, Lee H S, Francis L, et al. Innovative swirling flow-type microbubble generator for multi-stage DCMD desalination system: focus on the two-phase flow pattern, bubble size distribution, and its effect on MD performance[J]. Journal of Membrane Science, 2019, 588: 117197. |

| 12 | Rehman F, Medley G J D, Bandulasena H, et al. Fluidic oscillator-mediated microbubble generation to provide cost effective mass transfer and mixing efficiency to the wastewater treatment plants[J]. Environmental Research, 2015, 137: 32-39. |

| 13 | Tian H Z, Pi S F, Feng Y C, et al. One-dimensional drift-flux model of gas holdup in fine-bubble jet reactor[J]. Chemical Engineering Journal, 2020, 386: 121222. |

| 14 | Weber J, Agblevor F A. Microbubble fermentation of Trichoderma reesei for cellulase production[J]. Process Biochemistry, 2005, 40(2): 669-676. |

| 15 | Wang X Y, Shuai Y, Zhou X R, et al. Performance comparison of swirl-Venturi bubble generator and conventional Venturi bubble generator[J]. Chemical Engineering and Processing-Process Intensification, 2020, 154: 108022. |

| 16 | 丁国栋, 陈家庆, 王春升, 等. 轴向旋流式微气泡发生器的结构设计与数值模拟[J]. 过程工程学报, 2018, 18(5): 934-941. |

| Ding G D, Chen J Q, Wang C S, et al. Structural design and numerical simulation of axial-swirling type micro-bubble generator[J]. Chinese Journal of Process Engineering, 2018, 18(5): 934-941. | |

| 17 | Han Y, Liu Y F, Hong J, et al. Large scale preparation of microbubbles by multi-channel ceramic membranes: hydrodynamics and mass transfer characteristics[J]. The Canadian Journal of Chemical Engineering, 2017, 95(11): 2176-2185. |

| 18 | Liu Y, Han Y, Li X L, et al. Controlling microbubbles in alcohol solutions by using a multi-channel ceramic membrane distributor[J]. Journal of Chemical Technology & Biotechnology, 2018, 93: 2456-2463. |

| 19 | Liu Y, Han Y, Li X L, et al. Efficient control of microbubble properties by alcohol shear flows in ceramic membrane channels[J]. Chemical Engineering & Technology, 2018, 41(1): 168-174. |

| 20 | Wang Z C, Guo K, Liu H, et al. Effects of bubble size on the gas-liquid mass transfer of bubble swarms with Sauter mean diameters of 0.38—4.88 mm in a co-current upflow bubble column[J]. Journal of Chemical Technology and Biotechnology, 2020, 95(11): 2853-2867. |

| 21 | Zeng W, Jia C, Luo H X, et al. Microbubble-dominated mass transfer intensification in the process of ammonia-based flue gas desulfurization[J]. Industrial & Engineering Chemistry Research, 2020, 59(44): 19781-19792. |

| 22 | Li C X, Cui Y Z, Shi X G, et al. Numerical simulation on the terminal rise velocity and mass transfer rate of single sub-millimeter bubbles[J]. Chemical Engineering Science, 2021, 246: 116963. |

| 23 | 李成祥, 崔怡洲, 石孝刚, 等. 表面活性物质影响下单个自由上升微气泡传质过程的直接数值模拟[J]. 过程工程学报, 2021, 21(8): 877-886. |

| Li C X, Cui Y Z, Shi X G, et al. Direct numerical simulation of mass transfer process of single free rising microbubbles under the influence of surface active materials[J]. Chinese Journal of Process Engineering, 2021, 21(8): 877-886. | |

| 24 | Cui Y Z, Li C X, Zhang W L, et al. A deep learning-based image processing method for bubble detection, segmentation, and shape reconstruction in high gas holdup sub-millimeter bubbly flows[J]. Chemical Engineering Journal, 2022, 449: 137859. |

| 25 | Ansari M, Turney D E, Yakobov R, et al. Chemical hydrodynamics of a downward microbubble flow for intensification of gas-fed bioreactors[J]. AIChE Journal, 2018, 64(4): 1399-1411. |

| 26 | 安钢, 孙波, 安以弘, 等. 不同类型鼓泡塔气液并流时液相轴向扩散系数[J]. 过程工程学报, 2010, 10(6): 1048-1053. |

| An G, Sun B, An Y H, et al. Liquid phase axial diffusion coefficients of gas-liquid concurrent flow in different types of bubbling column[J]. Chinese Journal of Process Engineering, 2010, 10(6): 1048-1053. | |

| 27 | Li C X, Cui Y Z, Zhai L X, et al. Study on drag coefficient for sub-millimeter bubbles in gas-liquid bubbly flow: experiments and CFD simulations[J]. Chemical Engineering Journal, DOI: 10.1016/j.cej.2023.147236 . |

| 28 | Tomiyama A. Struggle with computational bubble dynamics[J]. Multiphase Science and Technology, 1998, 10: 369-405. |

| 29 | Jajuee B, Margaritis A, Karamanev D, et al. Application of surface-renewal-stretch model for interface mass transfer[J]. Chemical Engineering Science, 2006, 61: 3917-3929. |

| 30 | Chen J Q, Brooks C S. Experiments and CFD simulation of mass transfer and hydrodynamics in a cylindrical bubble column[J]. Chemical Engineering Science, 2021, 234: 116435. |

| 31 | 黄子宾. 鼓泡塔内液相多尺度循环流动结构的研究[D]. 上海: 华东理工大学, 2011. |

| Huang Z B. Study on liquid multiscale circulation structure in a bubble column[D]. Shanghai: East China University of Science and Technology, 2011. |

| [1] | 王俊男, 何呈祥, 王忠东, 朱春英, 马友光, 付涛涛. T型微混合器内均相混合的数值模拟[J]. 化工学报, 2024, 75(1): 242-254. |

| [2] | 赵若晗, 黄蒙蒙, 朱春英, 付涛涛, 高习群, 马友光. 缩口T型微通道内纳米流体吸收CO2的流动与传质研究[J]. 化工学报, 2024, 75(1): 221-230. |

| [3] | 赵碧丹, 代伊杨, 王军武, 张永民. CFD-DEM-IBM方法探究流化床倾斜挡板内构件受力特性[J]. 化工学报, 2024, 75(1): 255-267. |

| [4] | 周尧, 杨小平, 倪一程, 刘继平, 魏进家, 严俊杰. 应用于新型环路热管的两相引射器数值模拟[J]. 化工学报, 2024, 75(1): 268-278. |

| [5] | 王义江, 孙莉, 刘梦涵, 杨金宏, 王国元. 基于响应面法的矿用翅片管空冷器参数优化[J]. 化工学报, 2024, 75(1): 279-291. |

| [6] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [7] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [8] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [9] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [10] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [11] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [12] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [13] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [14] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [15] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号