化工学报 ›› 2024, Vol. 75 ›› Issue (11): 4188-4195.DOI: 10.11949/0438-1157.20240593

唐文娜1( ), 刘宏臣1(

), 刘宏臣1( ), 米晓天1, 秋列维1(

), 米晓天1, 秋列维1( ), 杨梅2, 陈光文2

), 杨梅2, 陈光文2

收稿日期:2024-05-31

修回日期:2024-07-09

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

刘宏臣,秋列维

作者简介:唐文娜(2000—),女,硕士研究生,632589947@qq.com

基金资助:

Wenna TANG1( ), Hongchen LIU1(

), Hongchen LIU1( ), Xiaotian MI1, Liewei QIU1(

), Xiaotian MI1, Liewei QIU1( ), Mei YANG2, Guangwen CHEN2

), Mei YANG2, Guangwen CHEN2

Received:2024-05-31

Revised:2024-07-09

Online:2024-11-25

Published:2024-12-26

Contact:

Hongchen LIU, Liewei QIU

摘要:

设计了一种具有嵌入式结构的筛孔微通道并研究了水-硅油体系的液滴生成过程。在不同的两相流量下观测到滴出流与喷射流两种流型,并考察了两相流量、界面张力对活化孔数量分布和液滴尺寸的影响。结果表明,随着分散相或连续相的毛细数Ca增加,筛孔活化数量增加;对于液滴尺寸,随着连续相流量的增加和界面张力的降低,液滴尺寸降低,而随着分散相流量的增加,液滴尺寸呈现波浪式增加。基于实验结果,建立了液滴尺寸预测模型,预测值与实验值吻合较好。此外,还考察了添加微孔膜阻件对活化孔数量分布和液滴尺寸的影响,发现微孔膜阻件能使分散相在更低流量下活化筛孔,生成尺寸更小的液滴。

中图分类号:

唐文娜, 刘宏臣, 米晓天, 秋列维, 杨梅, 陈光文. 嵌入式筛孔微通道内液滴生成规律研究[J]. 化工学报, 2024, 75(11): 4188-4195.

Wenna TANG, Hongchen LIU, Xiaotian MI, Liewei QIU, Mei YANG, Guangwen CHEN. Experimental investigation of droplet formation in microchannel device with an embedded microsieve[J]. CIESC Journal, 2024, 75(11): 4188-4195.

| 流体 | 密度 ρ/(kg/m3) | 黏度 μ/(mPa·s) | 界面张力 γ/(mN/m) |

|---|---|---|---|

| 硅油 | 955 | 540 | — |

| 去离子水 | 998 | 0.98 | 41.47 |

| 0.1%(质量分数)SDS | 998 | 0.98 | 11.83 |

| 1%(质量分数)SDS | 985 | 0.98 | 8.89 |

表1 两相体系的物性参数

Table 1 Physical properties of the two-phase system

| 流体 | 密度 ρ/(kg/m3) | 黏度 μ/(mPa·s) | 界面张力 γ/(mN/m) |

|---|---|---|---|

| 硅油 | 955 | 540 | — |

| 去离子水 | 998 | 0.98 | 41.47 |

| 0.1%(质量分数)SDS | 998 | 0.98 | 11.83 |

| 1%(质量分数)SDS | 985 | 0.98 | 8.89 |

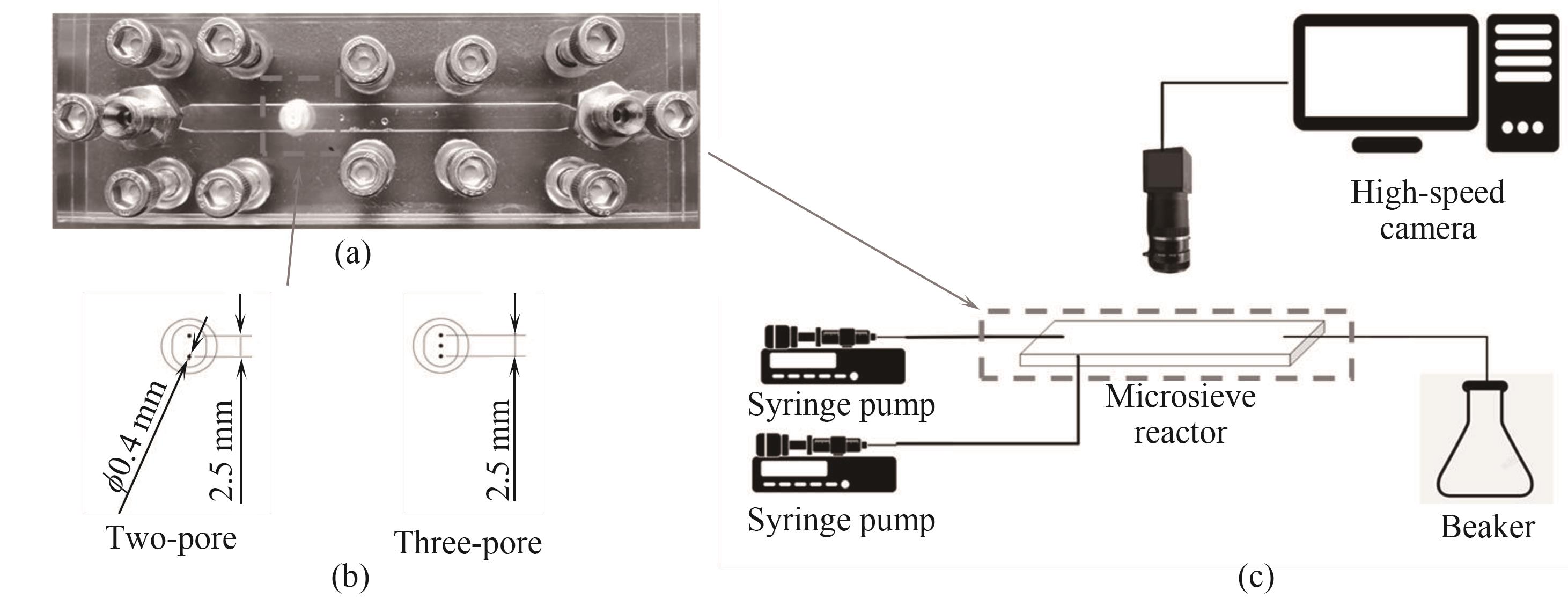

图1 (a)微筛孔反应器结构示意图;(b)筛孔结构;(c)实验装置流程图

Fig.1 (a) Schematic representation of the microsieve device; (b) Pore structure; (c) Sketch of the experimental setup

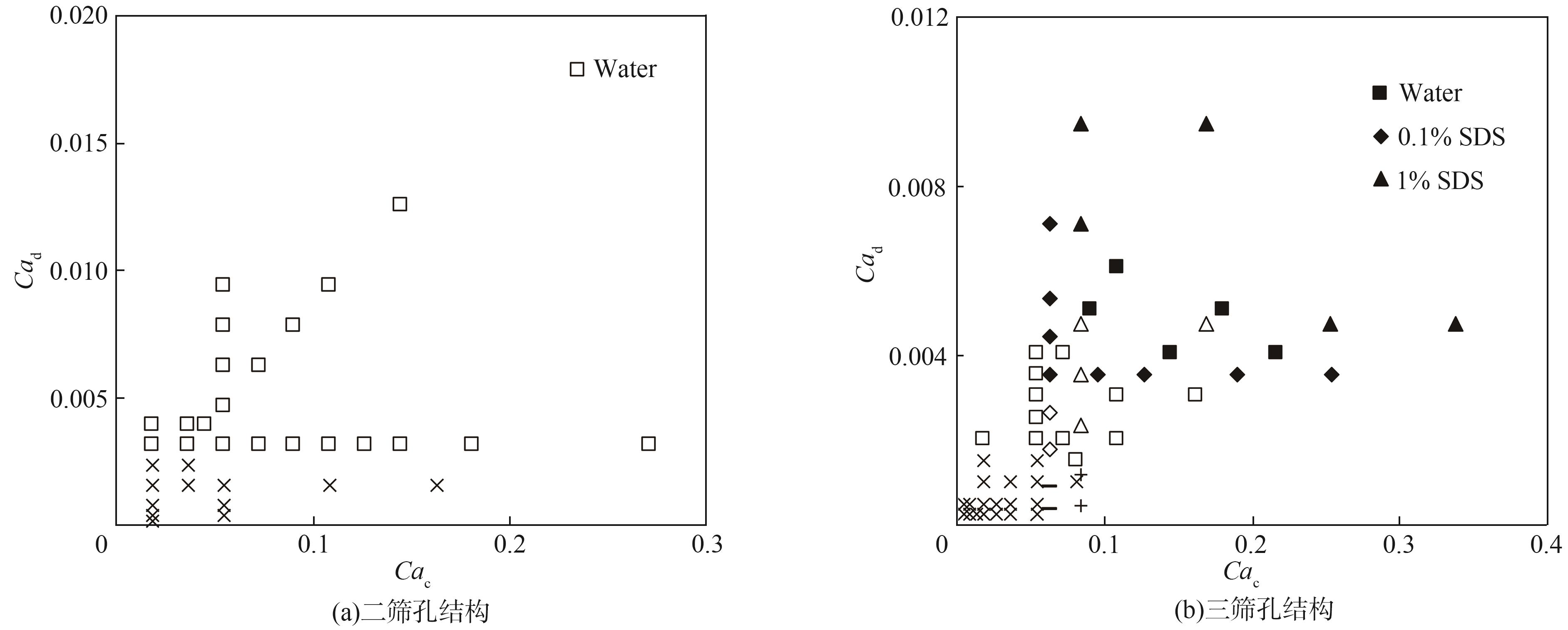

图3 以Cac和Cad表示的活化孔数量分布活化孔数量:×(water),-(0.1%SDS),+(1%SDS) —1;空心点—2;实心点—3

Fig.3 Diagram of the active pore number distribution characterized by Cac and CadNumber of active pore: ×(water),-(0.1%SDS),+(1%SDS) —1; hollow dot—2; solid dot—3

图4 硅油/水体系中连续相流量(a)和分散相流量(b)对液滴尺寸的影响

Fig.4 Effect of flow rates of continuous phase (a) and dispersed phase (b) on the droplet size for the silicone oil/water system

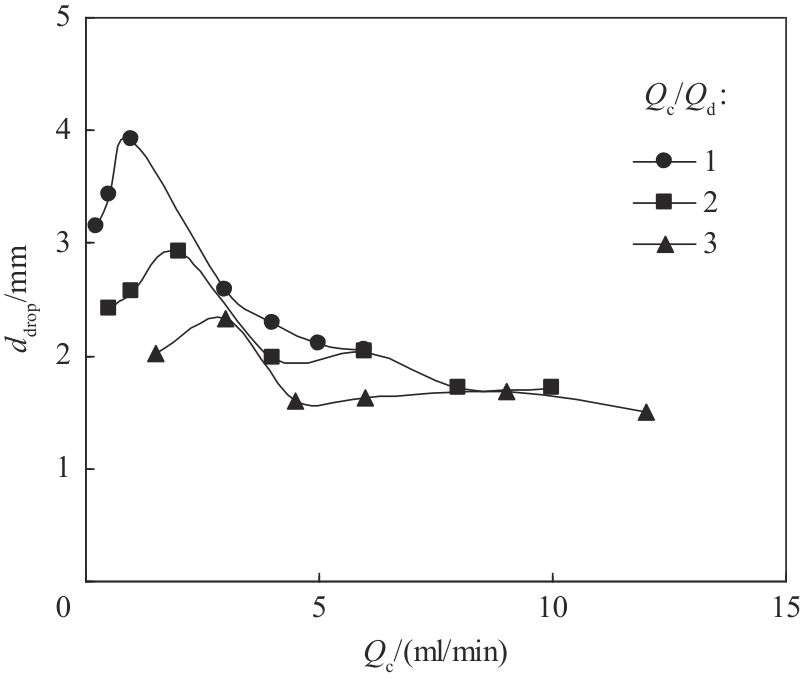

图5 三筛孔结构内硅油/水体系的连续相和分散相流量比Qc/Qd对液滴尺寸的影响

Fig.5 Effect of the ratio of continuous and dispersed phase flow rates on the droplet size for the silicone oil/water system in three-pore microsieve device

图6 三筛孔结构中界面张力对液滴尺寸的影响(Qc=1.0 ml/min)

Fig.6 Effect of interfacial tension on the droplet size as a function of Qd in three-pore microsieve device (Qc=1.0 ml/min)

图8 微孔膜阻件对活化孔数量分布的影响Number of active pore: ×(Device 1),+(Device 2) —1; hollow dot—2

Fig.8 Effect of the microporous membrane as a flow resistance on the active pore distribution in two-pore microsieve

| 1 | Moragues T, Arguijo D, Beneyton T, et al. Droplet-based microfluidics[J]. Nature Reviews Methods Primers, 2023, 3: 32. |

| 2 | Yang M, Luo L M, Chen G W. Microfluidic synthesis of ultrasmall Co nanoparticles over reduced graphene oxide and their catalytic properties[J]. AIChE Journal, 2020, 66(6): e16950. |

| 3 | Umbanhowar P B, Prasad V, Weitz D A. Monodisperse emulsion generation via drop break off in a coflowing stream[J]. Langmuir, 2000, 16(2): 347-351. |

| 4 | Zhu P G, Wang L Q. Microfluidics-enabled soft manufacture of materials with tailorable wettability[J]. Chemical Reviews, 2022, 122(7): 7010-7060. |

| 5 | Lathia R, Nampoothiri K N, Sagar N, et al. Advances in microscale droplet generation and manipulation[J]. Langmuir, 2023, 39(7): 2461-2482. |

| 6 | Wang K, Li L T, Xie P, et al. Liquid-liquid microflow reaction engineering[J]. Reaction Chemistry & Engineering, 2017, 2(5): 611-627. |

| 7 | Liu Z K, Yang M, Yao W, et al. Microfluidic ultrasonic cavitation enables versatile and scalable synthesis of monodisperse nanoparticles for biomedical application[J]. Chemical Engineering Science, 2023, 280: 119052. |

| 8 | Liu W W, Zhu Y. Development and application of analytical detection techniques for droplet-based microfluidics—a review[J]. Analytica Chimica Acta, 2020, 1113: 66-84. |

| 9 | Luo L M, Yang M, Chen G W. Continuous synthesis of TiO2-supported noble metal nanoparticles and their application in ammonia borane hydrolysis[J]. Chemical Engineering Science, 2022, 251: 117479. |

| 10 | Xu J H, Li S W, Tan J, et al. Preparation of highly monodisperse droplet in a T-junction microfluidic device[J]. AIChE Journal, 2006, 52(9): 3005-3010. |

| 11 | 宋仕容, 刘宏臣, 米晓天, 等. 同轴微通道内管结构对液滴生成的影响规律研究[J]. 化工学报, 2024, 75(2): 566-574. |

| Song S R, Liu H C, Mi X T, et al. Experimental investigation of droplet formation in coaxial microchannels with different geometries of inner channel[J]. CIESC Journal, 2024, 75(2): 566-574. | |

| 12 | Guerrero J, Chang Y W, Fragkopoulos A A, et al. Capillary-based microfluidics-coflow, flow-focusing, electro-coflow, drops, jets, and instabilities[J]. Small, 2020, 16(9): 1904344. |

| 13 | Wang W, Xie R, Ju X J, et al. Controllable microfluidic production of multicomponent multiple emulsions[J]. Lab on a Chip, 2011, 11(9): 1587-1592. |

| 14 | Wang K, Lu Y C, Xu J H, et al. Generation of micromonodispersed droplets and bubbles in the capillary embedded T-junction microfluidic devices[J]. AIChE Journal, 2011, 57(2): 299-306. |

| 15 | Tian F, Cai L L, Liu C, et al. Microfluidic technologies for nanoparticle formation[J]. Lab on a Chip, 2022, 22(3): 512-529. |

| 16 | Yang S H, Ju X J, Deng C F, et al. Controllable fabrication of monodisperse poly(vinyl alcohol) microspheres with droplet microfluidics for embolization[J]. Industrial & Engineering Chemistry Research, 2022, 61(34): 12619-12631. |

| 17 | Sotowa K I, Sugiyama S, Nakagawa K. Flow uniformity in deep microchannel reactor under high throughput conditions[J]. Organic Process Research & Development, 2009, 13(5): 1026-1031. |

| 18 | 崔永晋, 李严凯, 王凯, 等. 微分散设备数量放大方式研究进展[J]. 化工学报, 2020, 71(10): 4350-4364. |

| Cui Y J, Li Y K, Wang K, et al. Recent advances of numbering-up technology of micro-dispersion devices[J]. CIESC Journal, 2020, 71(10): 4350-4364. | |

| 19 | Zhang J S, Wang K, Teixeira A R, et al. Design and scaling up of microchemical systems: a review[J]. Annual Review of Chemical and Biomolecular Engineering, 2017, 8: 285-305. |

| 20 | 邓传富, 汪伟, 谢锐, 等. 液滴微流控的集成化放大方法研究进展[J]. 化工学报, 2021, 72(12): 5965-5974. |

| Deng C F, Wang W, Xie R, et al. Recent progress in scale-up integration of microfluidic droplet generators[J]. CIESC Journal, 2021, 72(12): 5965-5974. | |

| 21 | Cui Y J, Li Y K, Wang K, et al. High-throughput preparation of uniform tiny droplets in multiple capillaries embedded stepwise microchannels[J]. Journal of Flow Chemistry, 2020, 10(1): 271-282. |

| 22 | 李光晓, 刘塞尔, 苏远海. 微尺度内液-液传质及反应过程强化的研究进展[J]. 化工学报, 2021, 72(1): 452-467. |

| Li G X, Liu S E, Su Y H. Research progress on micro-scale internal liquid-liquid mass transfer and reaction process enhancement[J]. CIESC Journal, 2021, 72(1): 452-467. | |

| 23 | Wang K, Lu Y C, Luo G S. Strategy for scaling-up of a microsieve dispersion reactor[J]. Chemical Engineering & Technology, 2014, 37(12): 2116-2122. |

| 24 | Zheng C, Zhao B C, Wang K, et al. Bubble generation rules in microfluidic devices with microsieve array as dispersion medium[J]. AIChE Journal, 2015, 61(5): 1663-1676. |

| 25 | Li S W, Xu J H, Wang Y J, et al. Liquid-liquid two-phase flow in pore array microstructured devices for scaling-up of nanoparticle preparation[J]. AIChE Journal, 2009, 55(12): 3041-3051. |

| 26 | Li W P, Xia F S, Zhao S C, et al. Characterization of liquid-liquid mass transfer performance in a novel pore-array intensified tube-in-tube microchannel[J]. AIChE Journal, 2020, 66(4): e16893. |

| 27 | Wang K, Lu Y C, Xu J H, et al. Droplet generation in micro-sieve dispersion device[J]. Microfluidics and Nanofluidics, 2011, 10(5): 1087-1095. |

| 28 | Shao H W, Lu Y C, Wang K, et al. Liquid-liquid microflows in micro-sieve dispersion devices with dual pore size[J]. Microfluidics and Nanofluidics, 2012, 12(5): 705-714. |

| 29 | Hu Y P, Wang K, Han C L, et al. Liquid-liquid microdispersion method for the synthesis of TS-1 free of extra-framework Ti species[J]. Industrial & Engineering Chemistry Research, 2019, 58(27): 12010-12017. |

| 30 | Yuan Q C, Aryanti N, Gutiérrez G, et al. Enhancing the throughput of membrane emulsification techniques to manufacture functional particles[J]. Industrial & Engineering Chemistry Research, 2009, 48(19): 8872-8880. |

| 31 | Darvishzadeh T, Tarabara V V, Priezjev N V. Oil droplet behavior at a pore entrance in the presence of crossflow: implications for microfiltration of oil-water dispersions[J]. Journal of Membrane Science, 2013, 447: 442-451. |

| 32 | Guo M Z, Bai S Q, Wang Y J, et al. Novel microfabricated nozzle array with grooves for microdroplet generation[J]. Chemical Engineering Journal, 2021, 416: 129103. |

| 33 | Pathak M. Numerical simulation of membrane emulsification: effect of flow properties in the transition from dripping to jetting[J]. Journal of Membrane Science, 2011, 382(1/2): 166-176. |

| [1] | 赵振刚, 周梦瑶, 金典, 张大骋. 基于泡沫碳扩散层的直接甲醇燃料电池改性研究[J]. 化工学报, 2024, 75(S1): 259-266. |

| [2] | 徐英宇, 杨国强, 彭璟, 孙海宁, 张志炳. 微界面高级氧化处理煤化工废水的研究[J]. 化工学报, 2024, 75(S1): 283-291. |

| [3] | 李雨霜, 王兴成, 温伯尧, 骆政园, 白博峰. 多孔介质中乳状液驱油的两相流动过程及其影响因素[J]. 化工学报, 2024, 75(S1): 56-66. |

| [4] | 刘律, 刘洁茹, 范亮亮, 赵亮. 基于层流效应的被动式颗粒分离微流控方法研究[J]. 化工学报, 2024, 75(S1): 67-75. |

| [5] | 杜得辉, 冯威, 张江辉, 项燕龙, 乔高攀, 李蔚. 微型翅片疏水复合强化管管内流动沸腾换热预测模型[J]. 化工学报, 2024, 75(S1): 95-107. |

| [6] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [7] | 陈超伟, 柳洋, 杜文静, 李金波, 史大阔, 辛公明. 局部热点下微肋通道流动传热特性[J]. 化工学报, 2024, 75(9): 3113-3121. |

| [8] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [9] | 唐昊, 胡定华, 李强, 张轩畅, 韩俊杰. 抗加速度双切线弧流道内气泡动力学行为数值与可视化研究[J]. 化工学报, 2024, 75(9): 3074-3082. |

| [10] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [11] | 王皓宇, 杨杨, 荆文婕, 杨斌, 唐雨, 刘毅. 不同旋流器作用下气液螺旋环状流动特性研究[J]. 化工学报, 2024, 75(8): 2744-2755. |

| [12] | 赵亮, 李雨桥, 张德, 沈胜强. 螺旋喷嘴内外流场特性的实验研究[J]. 化工学报, 2024, 75(8): 2777-2786. |

| [13] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [14] | 曲玖哲, 杨鹏, 杨绪飞, 张伟, 宇波, 孙东亮, 王晓东. 硅基微柱簇阵列微通道流动沸腾实验研究[J]. 化工学报, 2024, 75(8): 2840-2851. |

| [15] | 李彦熹, 王晔春, 谢向东, 王进芝, 王江, 周煜, 潘盈秀, 丁文涛, 郭烈锦. 蜗壳式多通道气液旋流分离器结构优化及分离特性研究[J]. 化工学报, 2024, 75(8): 2875-2885. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号