化工学报 ›› 2025, Vol. 76 ›› Issue (3): 1156-1169.DOI: 10.11949/0438-1157.20241032

刘孟扬1( ), 孙雪剑1,2(

), 孙雪剑1,2( ), 毛文元1, 邓晰文2, 雷基林2(

), 毛文元1, 邓晰文2, 雷基林2( )

)

收稿日期:2024-09-13

修回日期:2024-10-09

出版日期:2025-03-25

发布日期:2025-03-28

通讯作者:

孙雪剑,雷基林

作者简介:刘孟扬(1998—),男,硕士研究生,aric2210@outlook.com

基金资助:

Mengyang LIU1( ), Xuejian SUN1,2(

), Xuejian SUN1,2( ), Wenyuan MAO1, Xiwen DENG2, Jilin LEI2(

), Wenyuan MAO1, Xiwen DENG2, Jilin LEI2( )

)

Received:2024-09-13

Revised:2024-10-09

Online:2025-03-25

Published:2025-03-28

Contact:

Xuejian SUN, Jilin LEI

摘要:

软硬配对的密封环广泛应用于旋转式动密封领域,然而动静环间的接触摩擦是引起密封失效的主要原因。分析密封环的接触特性对研究密封摩擦损伤现象乃至预测密封稳定运行具有重要意义。传统研究大多基于密封环微观表面微凸体满足高斯分布的单层特征假设,忽略其存在的分层特征。本研究以干气密封为工程背景,通过测量密封环表面形貌二维数据,利用间断分离法获取分层参数,结合双高斯表面仿真理论对密封环三维重构,使用确定性接触模型对密封环接触特性进行研究,并结合表面仿真分析相关长度、下高斯粗糙度、上高斯占比等对密封接触特性的影响。研究结果表明:经过抛光处理的成品碳石墨密封环分层特征明显。相关长度的增加会减少粗糙峰数量并增加粗糙峰平均曲率半径。上高斯占比的增加导致粗糙峰平均曲率半径略有增加。增加下高斯粗糙度会降低粗糙峰平均曲率半径,增加粗糙峰数量,显著降低接触性能。下高斯粗糙度对表面形貌、接触特性影响最大,而相关长度、上高斯占比对接触特性影响较小。

中图分类号:

刘孟扬, 孙雪剑, 毛文元, 邓晰文, 雷基林. 考虑微观表面分层特征密封环接触特性分析[J]. 化工学报, 2025, 76(3): 1156-1169.

Mengyang LIU, Xuejian SUN, Wenyuan MAO, Xiwen DENG, Jilin LEI. Contact characterization of sealing rings considering microscopic surface delamination features[J]. CIESC Journal, 2025, 76(3): 1156-1169.

| 分量 | 尺寸/(μm×μm) | 节点数 | σu,σl /μm | zmu,zml/μm | λxu,λxl/μm | λyu,λyl/μm |

|---|---|---|---|---|---|---|

| 上高斯 | 360×360 | 1024×1024 | 0.100 | -0.5000 | 10.200 | 10.200 |

| 下高斯 | 1.000 | 0.0000 | 10.200 | 10.200 |

表1 双高斯表面生成参数

Table 1 Bi-Gaussian surface generation parameters

| 分量 | 尺寸/(μm×μm) | 节点数 | σu,σl /μm | zmu,zml/μm | λxu,λxl/μm | λyu,λyl/μm |

|---|---|---|---|---|---|---|

| 上高斯 | 360×360 | 1024×1024 | 0.100 | -0.5000 | 10.200 | 10.200 |

| 下高斯 | 1.000 | 0.0000 | 10.200 | 10.200 |

| 参数 | 复现 | 文献值 | 参数 | 复现 | 文献值 |

|---|---|---|---|---|---|

| σ/μm | 0.411 | 0.429 | σl /μm | 0.979 | 1.060 |

| Ssk | -2.420 | -2.470 | zmu/μm | 0.1310 | 0.1310 |

| Sku | 9.880 | 10.100 | zml/μm | 0.6860 | 0.7670 |

| λx /μm | 8.100 | 8.800 | Smq | 0.7412 | 0.7536 |

| λy /μm | 8.450 | 8.450 | zk/μm | 0.005 | -0.013 |

| σu/μm | 0.120 | 0.125 |

表2 仿真表面双高斯参数

Table 2 Simulated surface Bi-Gaussian parameters

| 参数 | 复现 | 文献值 | 参数 | 复现 | 文献值 |

|---|---|---|---|---|---|

| σ/μm | 0.411 | 0.429 | σl /μm | 0.979 | 1.060 |

| Ssk | -2.420 | -2.470 | zmu/μm | 0.1310 | 0.1310 |

| Sku | 9.880 | 10.100 | zml/μm | 0.6860 | 0.7670 |

| λx /μm | 8.100 | 8.800 | Smq | 0.7412 | 0.7536 |

| λy /μm | 8.450 | 8.450 | zk/μm | 0.005 | -0.013 |

| σu/μm | 0.120 | 0.125 |

| 编号 | σ/μm | Ssk | Sku | λm/μm | σu/μm | σl /μm | zmu/μm | zml/μm | zk/μm | Smq |

|---|---|---|---|---|---|---|---|---|---|---|

| 1-1 | 0.064 | -1.016 | 7.772 | 9.766 | 0.059 | 0.162 | 0.0040 | 0.1560 | -0.083 | 0.9294 |

| 1-2 | 0.065 | -1.127 | 6.801 | 9.126 | 0.059 | 0.125 | 0.0030 | 0.0710 | -0.057 | 0.8472 |

| 2-1 | 0.064 | -1.035 | 6.789 | 11.047 | 0.058 | 0.159 | 0.0060 | 0.1510 | -0.077 | 0.9243 |

| 2-2 | 0.066 | -1.571 | 9.424 | 9.126 | 0.057 | 0.231 | 0.0010 | 0.2990 | -0.097 | 0.9563 |

| 3-1 | 0.063 | -0.894 | 7.165 | 10.247 | 0.062 | 0.166 | 0.0050 | 0.1740 | -0.095 | 0.9473 |

| 3-2 | 0.061 | -1.149 | 7.114 | 9.926 | 0.057 | 0.145 | 0.0050 | 0.1220 | -0.071 | 0.9088 |

| 平均值 | 0.064 | -1.132 | 7.511 | 9.873 | 0.059 | 0.165 | 0.0040 | 0.1620 | -0.080 | 0.9189 |

| 重构表面 | 0.069 | -1.254 | 6.799 | 8.970 | 0.056 | 0.164 | 0.0030 | 0.1420 | -0.007 | 0.8993 |

表3 碳石墨环表面参数

Table 3 Surface parameters of carbon graphite ring

| 编号 | σ/μm | Ssk | Sku | λm/μm | σu/μm | σl /μm | zmu/μm | zml/μm | zk/μm | Smq |

|---|---|---|---|---|---|---|---|---|---|---|

| 1-1 | 0.064 | -1.016 | 7.772 | 9.766 | 0.059 | 0.162 | 0.0040 | 0.1560 | -0.083 | 0.9294 |

| 1-2 | 0.065 | -1.127 | 6.801 | 9.126 | 0.059 | 0.125 | 0.0030 | 0.0710 | -0.057 | 0.8472 |

| 2-1 | 0.064 | -1.035 | 6.789 | 11.047 | 0.058 | 0.159 | 0.0060 | 0.1510 | -0.077 | 0.9243 |

| 2-2 | 0.066 | -1.571 | 9.424 | 9.126 | 0.057 | 0.231 | 0.0010 | 0.2990 | -0.097 | 0.9563 |

| 3-1 | 0.063 | -0.894 | 7.165 | 10.247 | 0.062 | 0.166 | 0.0050 | 0.1740 | -0.095 | 0.9473 |

| 3-2 | 0.061 | -1.149 | 7.114 | 9.926 | 0.057 | 0.145 | 0.0050 | 0.1220 | -0.071 | 0.9088 |

| 平均值 | 0.064 | -1.132 | 7.511 | 9.873 | 0.059 | 0.165 | 0.0040 | 0.1620 | -0.080 | 0.9189 |

| 重构表面 | 0.069 | -1.254 | 6.799 | 8.970 | 0.056 | 0.164 | 0.0030 | 0.1420 | -0.007 | 0.8993 |

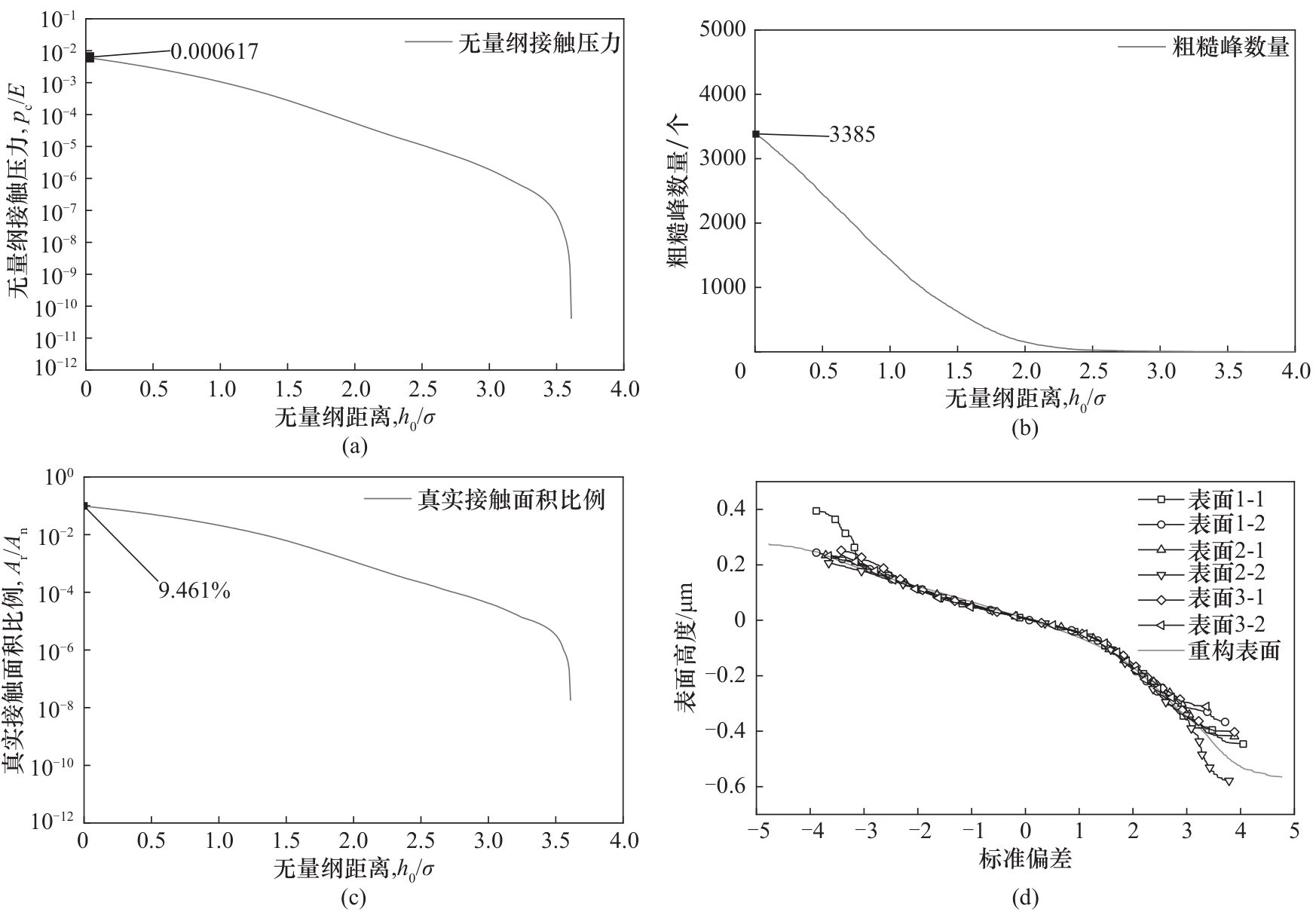

图7 碳石墨环的无量纲接触压力(a),粗糙峰数量(b),真实接触面积比例(c),PMRC(d)

Fig.7 Dimensionless contact pressure (a), number of rough peaks (b), proportion of true contact area (c), and PMRC (d) for carbon graphite rings

| 研究对象 | λ/μm | σu/μm | σl /μm | zmu/μm | zml/μm |

|---|---|---|---|---|---|

| λ=3 μm | 3.000 | 0.064 | 0.165 | 0.0040 | 0.1620 |

| λ=10 μm | 10.000 | 0.064 | 0.165 | 0.0040 | 0.1620 |

| λ=20 μm | 20.000 | 0.064 | 0.165 | 0.0040 | 0.1620 |

| λ=30 μm | 30.000 | 0.064 | 0.165 | 0.0040 | 0.1620 |

| Smq=0.6 | 9.873 | 0.064 | 0.165 | 0.0040 | 0.0646 |

| Smq=0.7 | 9.873 | 0.064 | 0.165 | 0.0040 | 0.0747 |

| Smq=0.8 | 9.873 | 0.064 | 0.165 | 0.0040 | 0.0848 |

| Smq=0.9 | 9.873 | 0.064 | 0.165 | 0.0040 | 0.0949 |

| σl =0.3 μm | 9.873 | 0.064 | 0.300 | 0.0040 | 0.1620 |

| σl =0.5 μm | 9.873 | 0.064 | 0.500 | 0.0040 | 0.1620 |

| σl =0.7 μm | 9.873 | 0.064 | 0.700 | 0.0040 | 0.1620 |

| σl =0.9 μm | 9.873 | 0.064 | 0.900 | 0.0040 | 0.1620 |

表4 具有不同分层特征的表面仿真参数

Table 4 Simulation parameters of surfaces with different Stratified characteristics

| 研究对象 | λ/μm | σu/μm | σl /μm | zmu/μm | zml/μm |

|---|---|---|---|---|---|

| λ=3 μm | 3.000 | 0.064 | 0.165 | 0.0040 | 0.1620 |

| λ=10 μm | 10.000 | 0.064 | 0.165 | 0.0040 | 0.1620 |

| λ=20 μm | 20.000 | 0.064 | 0.165 | 0.0040 | 0.1620 |

| λ=30 μm | 30.000 | 0.064 | 0.165 | 0.0040 | 0.1620 |

| Smq=0.6 | 9.873 | 0.064 | 0.165 | 0.0040 | 0.0646 |

| Smq=0.7 | 9.873 | 0.064 | 0.165 | 0.0040 | 0.0747 |

| Smq=0.8 | 9.873 | 0.064 | 0.165 | 0.0040 | 0.0848 |

| Smq=0.9 | 9.873 | 0.064 | 0.165 | 0.0040 | 0.0949 |

| σl =0.3 μm | 9.873 | 0.064 | 0.300 | 0.0040 | 0.1620 |

| σl =0.5 μm | 9.873 | 0.064 | 0.500 | 0.0040 | 0.1620 |

| σl =0.7 μm | 9.873 | 0.064 | 0.700 | 0.0040 | 0.1620 |

| σl =0.9 μm | 9.873 | 0.064 | 0.900 | 0.0040 | 0.1620 |

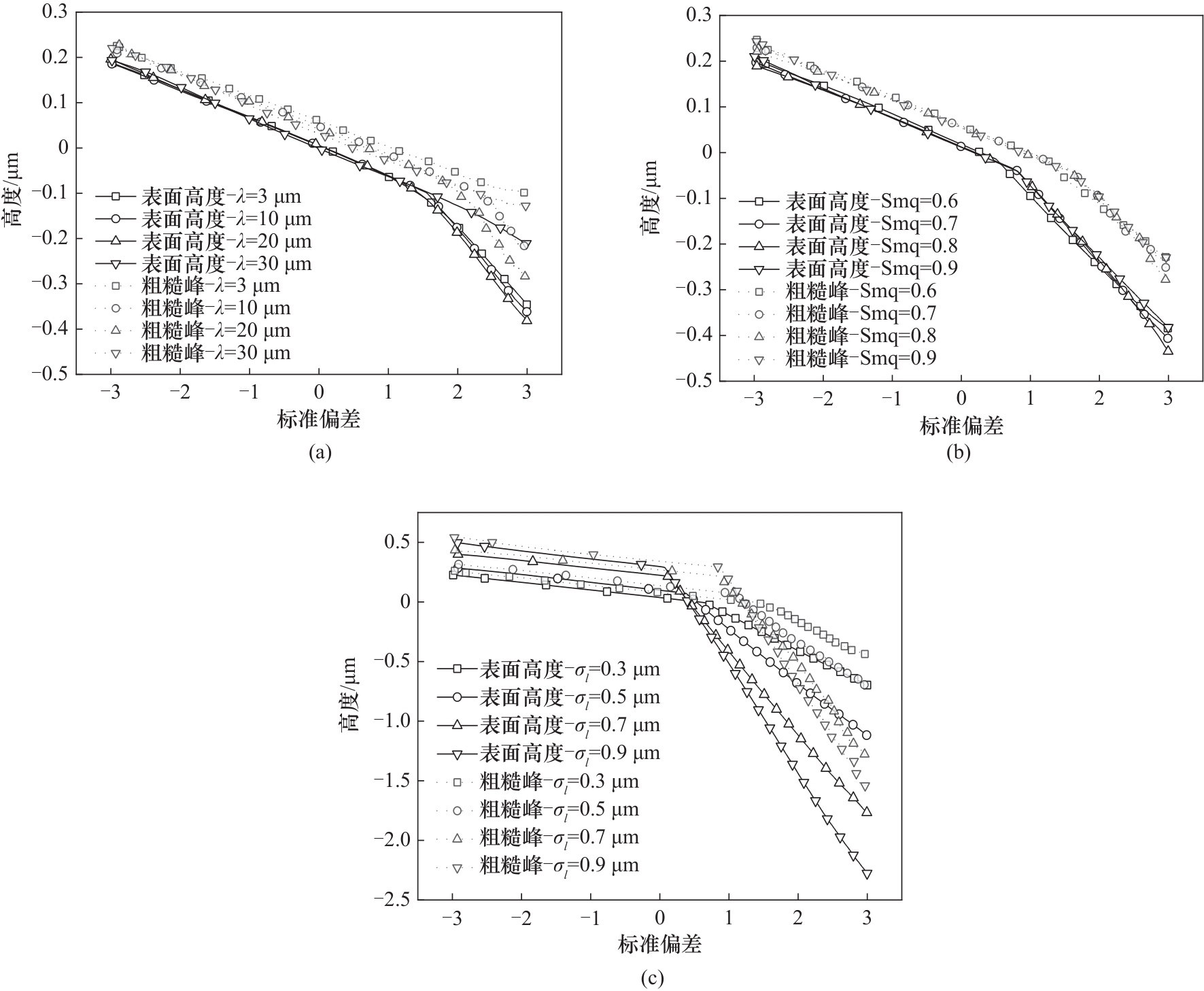

图10 具有不同λ(a)、Smq(b)、σl (c)参数的表面形貌(实线)以及粗糙峰(虚线)形貌的PMRC曲线

Fig.10 PMRC curves with different λ (a), Smq (b) and σl (c) parameters for surface morphology (solid line) and rough peaks (dashed line)

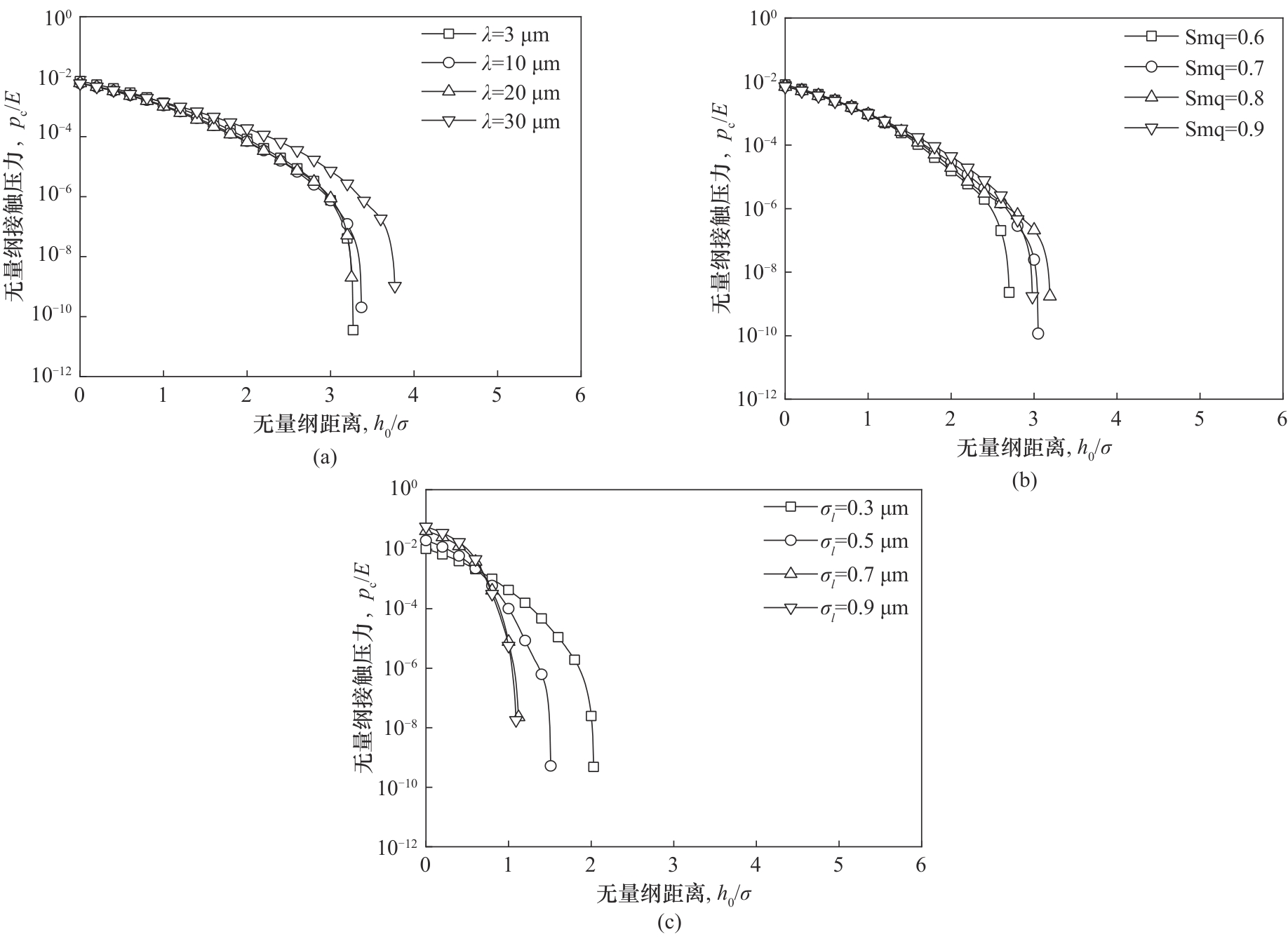

图14 具有不同λ(a)、Smq(b)、σl (c)的无量纲接触压力与无量纲距离之间的关系

Fig.14 Relationship between dimensionless contact pressure and dimensionless distance with different λ (a), Smq (b) and σl (c)

| 1 | Xu H J, Yue Y G, Song P Y, et al. Analysis on the dynamic characteristics of spiral groove dry gas seal based on the gas film adaptive adjustment model[J]. Industrial Lubrication and Tribology, 2023, 75(4): 406-414. |

| 2 | Park Y, Hahn M, Jang G. Effect of laminar, turbulent and slip conditions on the dynamic coefficients of a dry gas seal[J]. Lubricants, 2023, 11(3): 98. |

| 3 | 王世鹏, 丁雪兴, 丁俊华, 等. 微孔几何轮廓对浮环气膜密封动压润滑特性的影响[J]. 表面技术, 2024, 53(13): 139-150. |

| Wang S P, Ding X X, Ding J H, et al. Effect of micro-pore geometric configuration on dynamic lubrication performance of floating ring gas seal[J]. Surface Technology, 2024, 53(13): 139-150. | |

| 4 | 赵欢, 姜金裕, 孙丹, 等. 浅槽动压整体式浮环密封静力与动力特性数值研究[J]. 航空动力学报, 2024, 39(9): 91-101. |

| Zhao H, Jiang J Y, Sun D, et al. Numerical study on static and dynamic characteristics of an integral floating ring seal with shallow groove dynamic pressure[J]. Journal of Aerospace Power, 2024, 39(9): 91-101. | |

| 5 | Zhang W Z, Han D M. Study of the sealing performance of a high-speed deep groove mechanical seal thermodynamic lubrication model[J]. Industrial Lubrication and Tribology, 2024: DOI:10.1108/ILT-05-2024-0184. |

| 6 | 陆俊杰, 刘柱, 丁俊华, 等. 机械密封界面摩擦声发射信号的特征提取与分析[J]. 振动工程学报, 2025, 38(02): 411-419. |

| Lu J J, Liu Z, Ding J H, et al. Feature extraction and analysis of friction acoustic emission signal at mechanical seal interface[J]. Journal of Vibration Engineering, 2025, 38(02): 411-419. | |

| 7 | Hu F M, He Q, Huang W F, et al. Face grooves for state monitoring in dry gas seals[J]. Tribology International, 2023, 189: 108950. |

| 8 | 侯耀春, 周昶清, 武鹏, 等. 基于最大李雅普诺夫指数异常感知和CatBoost识别的机械密封失效模式层次化诊断框架[J]. 工程热物理学报, 2024, 45(1): 93-100. |

| Hou Y C, Zhou C Q, Wu P, et al. Hierarchical diagnostic framework of mechanical seal failure modes based on maximum Lyapunov exponent anomaly sensing and CatBoost model recognition[J]. Journal of Engineering Thermophysics, 2024, 45(1): 93-100. | |

| 9 | Deng Q G, Sun X J, Xu H J, et al. Thermal characteristics of dry gas seal in startup process considering microscale effects[J]. Lubricants, 2023, 11(12): 503. |

| 10 | Ghaednia H, Wang X Z, Saha S, et al. A review of elastic-plastic contact mechanics[J]. Applied Mechanics Reviews, 2017, 69(6): 060804. |

| 11 | 刘勇, 夏天, 陈志英, 等. 粗糙表面统计接触模型的提出与发展[J]. 摩擦学学报, 2020, 40(3): 395-406. |

| Liu Y, Xia T, Chen Z Y, et al. The development of statistical contact model for rough surface[J]. Tribology, 2020, 40(3): 395-406. | |

| 12 | Greenwood J A, Williamson J B P. Contact of nominally flat surfaces[J]. Proceedings of the Royal Society of London Series A. Mathematical and Physical Sciences, 1966, 295(1442): 300-319. |

| 13 | Whitehouse David J. The properties of random surfaces of significance in their contact[D]. Leicester, East Midlands, UK: University of Leicester, 1971. |

| 14 | Onions R A, Archard J F. The contact of surfaces having a random structure[J]. Journal of Physics D: Applied Physics, 1973, 6(3): 289-304. |

| 15 | Chang W R, Etsion I, Bogy D B. An elastic-plastic model for the contact of rough surfaces[J]. Journal of Tribology, 1987, 109(2): 257-263. |

| 16 | 孙雪剑, 宋鹏云, 毛文元, 等. 考虑密封环材料属性和表面形貌干气密封启停阶段的动态接触特性分析[J]. 化工学报, 2021, 72(8): 4279-4291. |

| Sun X J, Song P Y, Mao W Y, et al. Dynamic contact analysis of dry gas seal during start-stop process considering material properties and surface topography of seal rings[J]. CIESC Journal, 2021, 72(8): 4279-4291. | |

| 17 | Minet C, Brunetiere N, Tournerie B, et al. Analysis and modeling of the topography of mechanical seal faces[J]. Tribology Transactions, 2010, 53(6): 799-815. |

| 18 | Minet C, Brunetière N, Tournerie B. A deterministic mixed lubrication model for mechanical seals[J]. Journal of Tribology, 2011, 133(4): 1. |

| 19 | 孙宝财, 丁雪兴, 陈金林, 等. 干气密封摩擦界面法向接触刚度分形模型[J]. 振动与冲击, 2019, 38(18): 248-255. |

| Sun B C, Ding X X, Chen J L, et al. Fractal model for the normal contact stiffness of frictional interface in dry gas seals[J]. Journal of Vibration and Shock, 2019, 38(18): 248-255. | |

| 20 | 孙宝财, 丁雪兴, 陈金林, 等. 干气密封滑动摩擦界面切向接触刚度分形模型[J]. 摩擦学学报, 2019, 39(1): 65-72. |

| Sun B C, Ding X X, Chen J L, et al. Fractal model for tangential contact stiffness of sliding frictional interface in dry gas seals[J]. Tribology, 2019, 39(1): 65-72. | |

| 21 | Whitehouse D J. Handbook of Surface and Nanometrology[M]. Boca Raton: CRC Press, 2010. |

| 22 | 胡松涛, 黄伟峰, 史熙, 等. 基于双高斯分层表面理论的机械密封研究综述[J]. 机械工程学报, 2019, 55(1): 91-105. |

| Hu S T, Huang W F, Shi X, et al. Review on mechanical seals using a Bi-Gaussian stratified surface theory[J]. Journal of Mechanical Engineering, 2019, 55(1): 91-105. | |

| 23 | Ken S. How smooth is smooth? A visual examination of surface roughness[J]. Production Engineer, 1980, 59(5): 31. |

| 24 | Hu S T, Brunetiere N, Huang W F, et al. Evolution of bi-Gaussian surface parameters of silicon-carbide and carbon-graphite discs in a dry sliding wear process[J]. Tribology International, 2017, 112: 75-85. |

| 25 | Williamson J B P. Paper 17: microtopography of surfaces[C]//Proceedings of the Institution of Mechanical Engineers, Conference Proceedings. 1967, 182(11): 21-30. |

| 26 | Bain L J, Engelhardt M. Introduction to probability and mathematical statistics[J]. Biometrics, 1993, 49(2): 673. |

| 27 | Hu S T, Huang W F, Brunetiere N, et al. Stratified effect of continuous bi-Gaussian rough surface on lubrication and asperity contact[J]. Tribology International, 2016, 104: 328-341. |

| 28 | 陈辉, 胡元中, 王慧, 等. 粗糙表面计算机模拟[J]. 润滑与密封, 2006, 31(10): 52-55, 59. |

| Chen H, Hu Y Z, Wang H, et al. Computer simulation of rough surfaces[J]. Lubrication Engineering, 2006, 31(10): 52-55, 59. | |

| 29 | Pawlus P. Simulation of stratified surface topographies[J]. Wear, 2008, 264(5/6): 457-463. |

| 30 | 司佳鑫, 杨小成, 翁泽文, 等. 干气密封两种典型螺旋槽摩擦振动试验分析[J]. 流体机械, 2020, 48(12): 1-6, 21. |

| Si J X, Yang X C, Weng Z W, et al. Experimental analysis of friction and vibration of two typical spiral grooves for dry gas seal[J]. Fluid Machinery, 2020, 48(12): 1-6, 21. | |

| 31 | Hu S T, Brunetiere N, Huang W F, et al. Stratified revised asperity contact model for worn surfaces[J]. Journal of Tribology, 2017, 139(2): 021403. |

| 32 | 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 产品几何技术规范: [S]. 北京: 中国标准出版社, 2009. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Geometrical product specifications(GPS): [S]. Beijing: Standards Press of China, 2009. | |

| 33 | Hu S T, Brunetiere N, Huang W F, et al. The bi-Gaussian theory to understand sliding wear and friction[J]. Tribology International, 2017, 114: 186-191. |

| [1] | 魏攀攀, 刘怿楠, 朱春英, 付涛涛, 高习群, 马友光. 改进的T型微通道内双水相液滴的制备[J]. 化工学报, 2025, 76(2): 576-583. |

| [2] | 张恒, 魁殿禄, 常虹, 詹志刚. 机械应力对气体扩散层界面传输特性影响[J]. 化工学报, 2025, 76(2): 637-644. |

| [3] | 洪奥越, 徐强, 蒋帅之, 李翔宇, 马小俊, 郭烈锦. 蒸汽射流直接接触凝结诱导振动特性研究[J]. 化工学报, 2024, 75(8): 2723-2733. |

| [4] | 朱子良, 王爽, 姜宇昂, 林梅, 王秋旺. 欧拉-拉格朗日迭代固-液相变算法[J]. 化工学报, 2024, 75(8): 2763-2776. |

| [5] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [6] | 董可豪, 周敬之, 周峰, 陈海家, 淮秀兰, 李栋. 超薄空间复杂边界条件下气体流动压降实验[J]. 化工学报, 2024, 75(7): 2505-2521. |

| [7] | 徐嘉宇, 陈飞国, 徐骥, 葛蔚. 颗粒体系的多尺度混合指数[J]. 化工学报, 2024, 75(6): 2214-2221. |

| [8] | 宋璟, 王玉军, 邓建, 陈光文, 骆广生. 微反应器内芳烃硝化反应研究进展[J]. 化工学报, 2024, 75(11): 3911-3922. |

| [9] | 王法军, 陈安, 徐建鸿. 微反应器内颜料红57连续化合成工艺[J]. 化工学报, 2024, 75(10): 3600-3609. |

| [10] | 王禹丹, 徐晨, 阮达, 春江, 马学虎. V形沟槽纳米线团簇表面的毛细抽吸-补液蒸发传热特性研究[J]. 化工学报, 2024, 75(10): 3424-3436. |

| [11] | 李亚婷, 王忠东, 董艳鹏, 朱春英, 马友光, 付涛涛. 微通道中毛细流动及其工程应用的研究进展[J]. 化工学报, 2024, 75(1): 159-170. |

| [12] | 苏伟, 马东旭, 金旭, 刘忠彦, 张小松. 表面润湿性对霜层传递特性影响可视化实验研究[J]. 化工学报, 2023, 74(S1): 122-131. |

| [13] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [14] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [15] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号