CIESC Journal ›› 2025, Vol. 76 ›› Issue (6): 3073-3083.DOI: 10.11949/0438-1157.20241441

• Material science and engineering, nanotechnology • Previous Articles Next Articles

Chang ZHANG( ), Qiang XIE(

), Qiang XIE( ), Yutong SHA, Bingjie WANG, Dingcheng LIANG, Jinchang LIU

), Yutong SHA, Bingjie WANG, Dingcheng LIANG, Jinchang LIU

Received:2024-12-12

Revised:2025-01-06

Online:2025-07-09

Published:2025-06-25

Contact:

Qiang XIE

张畅( ), 解强(

), 解强( ), 沙雨桐, 王炳杰, 梁鼎成, 刘金昌

), 沙雨桐, 王炳杰, 梁鼎成, 刘金昌

通讯作者:

解强

作者简介:张畅(2000—),女,硕士研究生,zc13763409978@163.com

基金资助:CLC Number:

Chang ZHANG, Qiang XIE, Yutong SHA, Bingjie WANG, Dingcheng LIANG, Jinchang LIU. Preparation of bamboo char with low ash and silicon content and electrochemical properties of its derived hard carbon[J]. CIESC Journal, 2025, 76(6): 3073-3083.

张畅, 解强, 沙雨桐, 王炳杰, 梁鼎成, 刘金昌. 低灰低硅竹炭的制备及衍生硬炭的电化学性能[J]. 化工学报, 2025, 76(6): 3073-3083.

Add to citation manager EndNote|Ris|BibTeX

| 样品 | 水分(Mad)/% | 灰分(Ad)/% | 挥发分(Vdaf)/% | 固定碳(FCdaf)/% |

|---|---|---|---|---|

| B | 6.76 | 1.30 | 83.87 | 16.13 |

| BC | 1.24 | 3.61 | 11.88 | 88.12 |

| HBC | 1.3 | 2.73 | 10.11 | 89.89 |

Table 1 Results of proximate analysis of bamboo and bamboo char samples

| 样品 | 水分(Mad)/% | 灰分(Ad)/% | 挥发分(Vdaf)/% | 固定碳(FCdaf)/% |

|---|---|---|---|---|

| B | 6.76 | 1.30 | 83.87 | 16.13 |

| BC | 1.24 | 3.61 | 11.88 | 88.12 |

| HBC | 1.3 | 2.73 | 10.11 | 89.89 |

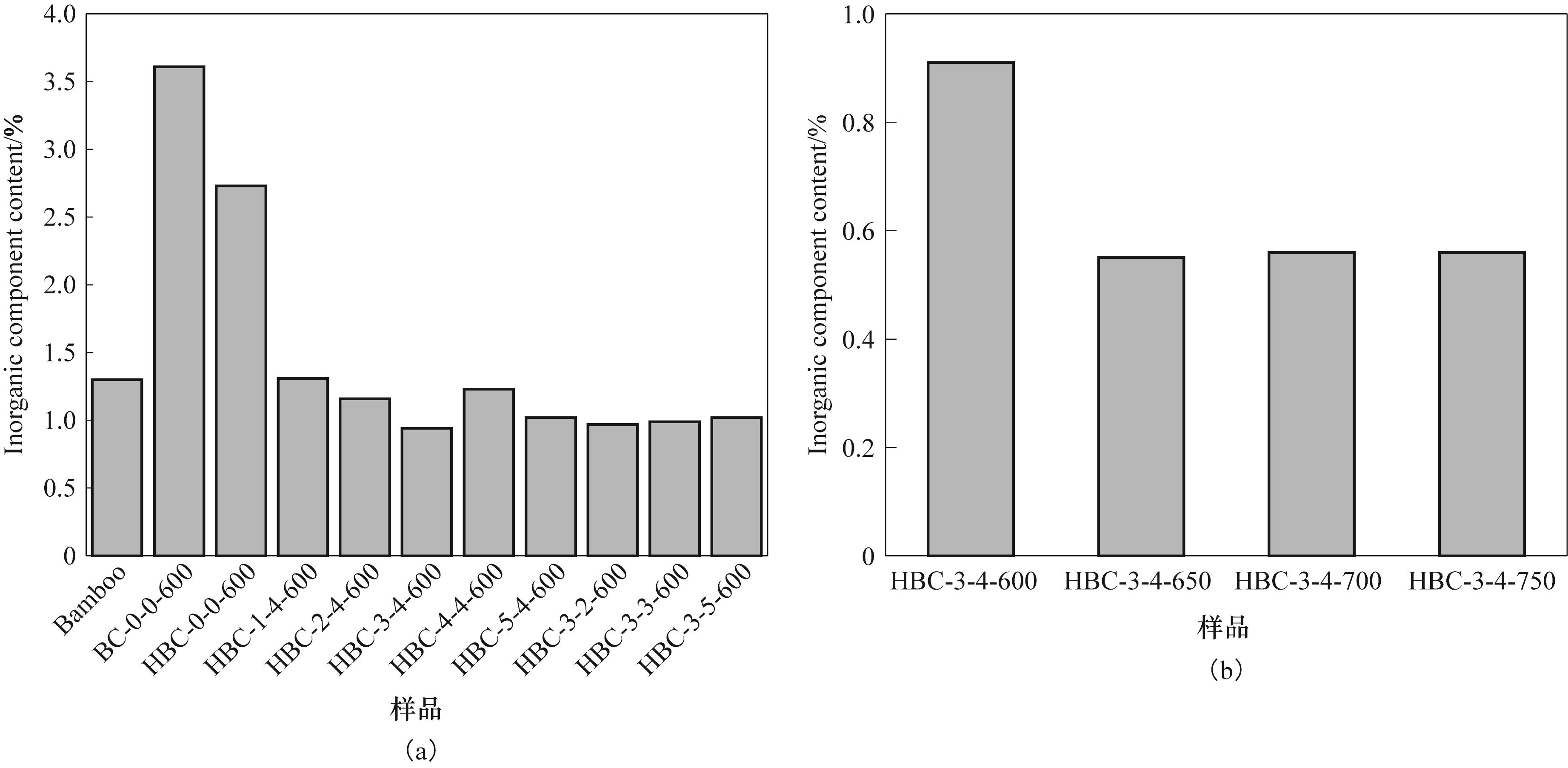

Fig.1 (a) The ash content of bamboo, bamboo char and bamboo char treated by alkali leaching, (b) The inorganic component content of bamboo char samples carbonized at different temperatures

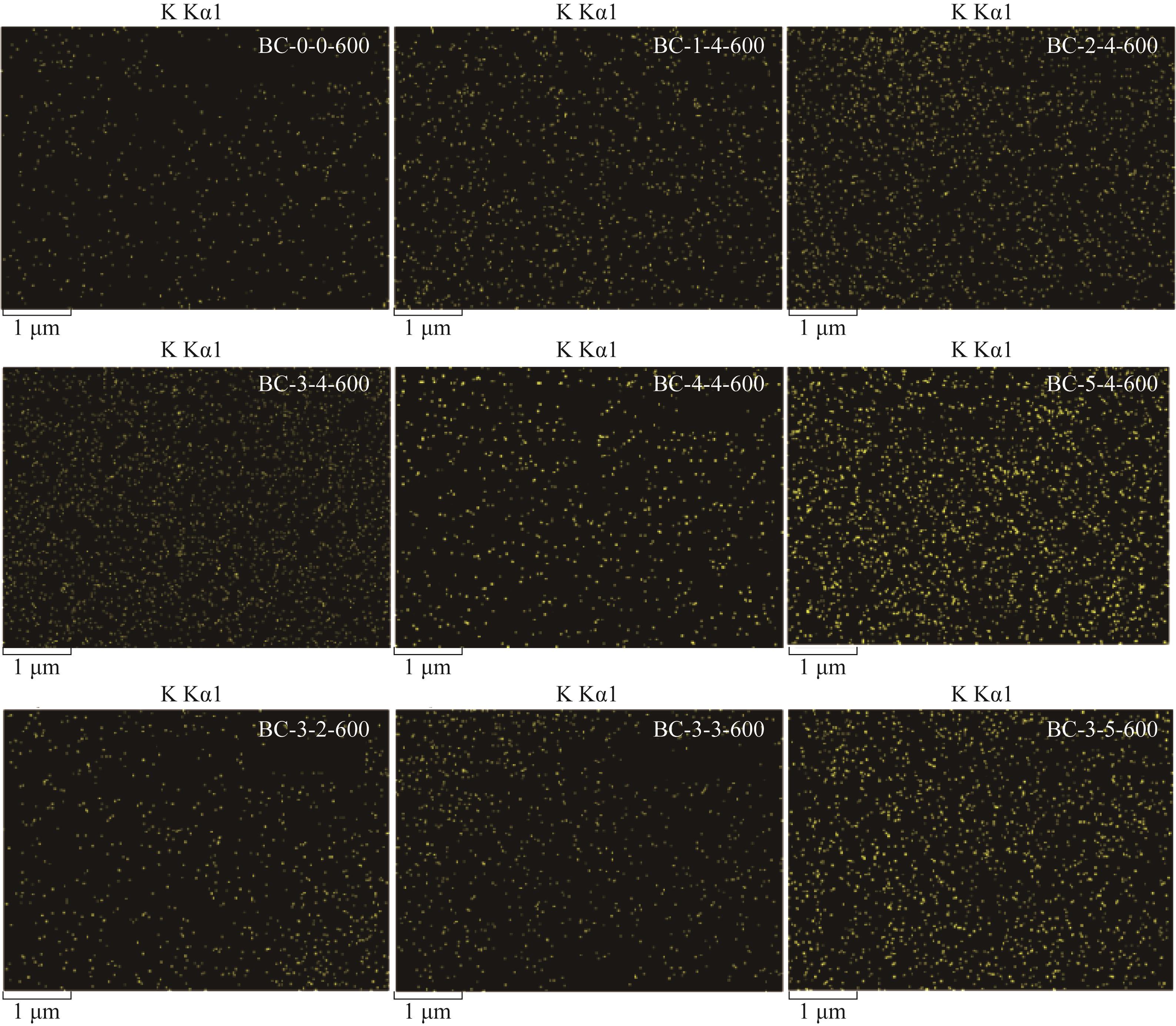

Fig.3 EDS diagrams of bamboo char, bamboo char impregnated by KOH with different concentrations for 4 h and bamboo char impregnated in 3 mol·L-1 KOH for different time

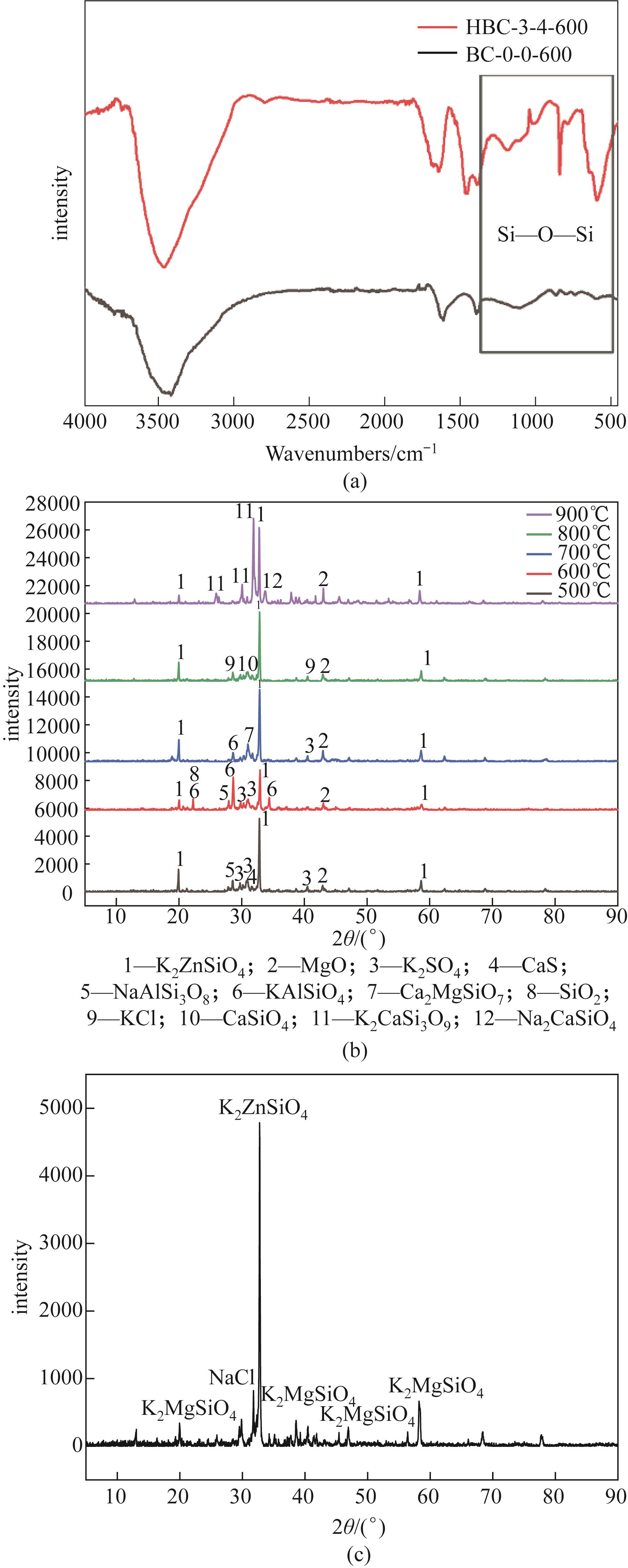

Fig.4 (a) Infrared spectra of bamboo char and treated samples, (b) XRD patterns of ash from bamboo char carbonized at different temperatures, (c) XRD patterns of ash from bamboo char carbonized at 650℃

炭化 温度/℃ | 元素含量/% | ||||||

|---|---|---|---|---|---|---|---|

| K | O | Si | Na | Al | Mg | Ca | |

| 600 | 79.89 | 17.52 | 0.49 | 0.38 | 0.13 | 0.27 | 0.20 |

| 650 | 79.96 | 17.49 | 0.43 | 0.40 | 0.10 | 0.25 | 0.18 |

| 700 | 80.01 | 17.43 | 0.39 | 0.45 | 0.09 | 0.24 | 0.17 |

| 750 | 78.10 | 18.02 | 1.43 | 0.51 | 0.23 | 0.20 | 0.22 |

| 800 | 73.41 | 20.51 | 3.82 | 0.63 | 0.48 | 0.14 | 0.39 |

Table 2 XRF analysis results of ashes of bamboo char samples obtained by carbonization of bamboo treated with 3 mol·L-1 KOH for 4 h at different temperatures

炭化 温度/℃ | 元素含量/% | ||||||

|---|---|---|---|---|---|---|---|

| K | O | Si | Na | Al | Mg | Ca | |

| 600 | 79.89 | 17.52 | 0.49 | 0.38 | 0.13 | 0.27 | 0.20 |

| 650 | 79.96 | 17.49 | 0.43 | 0.40 | 0.10 | 0.25 | 0.18 |

| 700 | 80.01 | 17.43 | 0.39 | 0.45 | 0.09 | 0.24 | 0.17 |

| 750 | 78.10 | 18.02 | 1.43 | 0.51 | 0.23 | 0.20 | 0.22 |

| 800 | 73.41 | 20.51 | 3.82 | 0.63 | 0.48 | 0.14 | 0.39 |

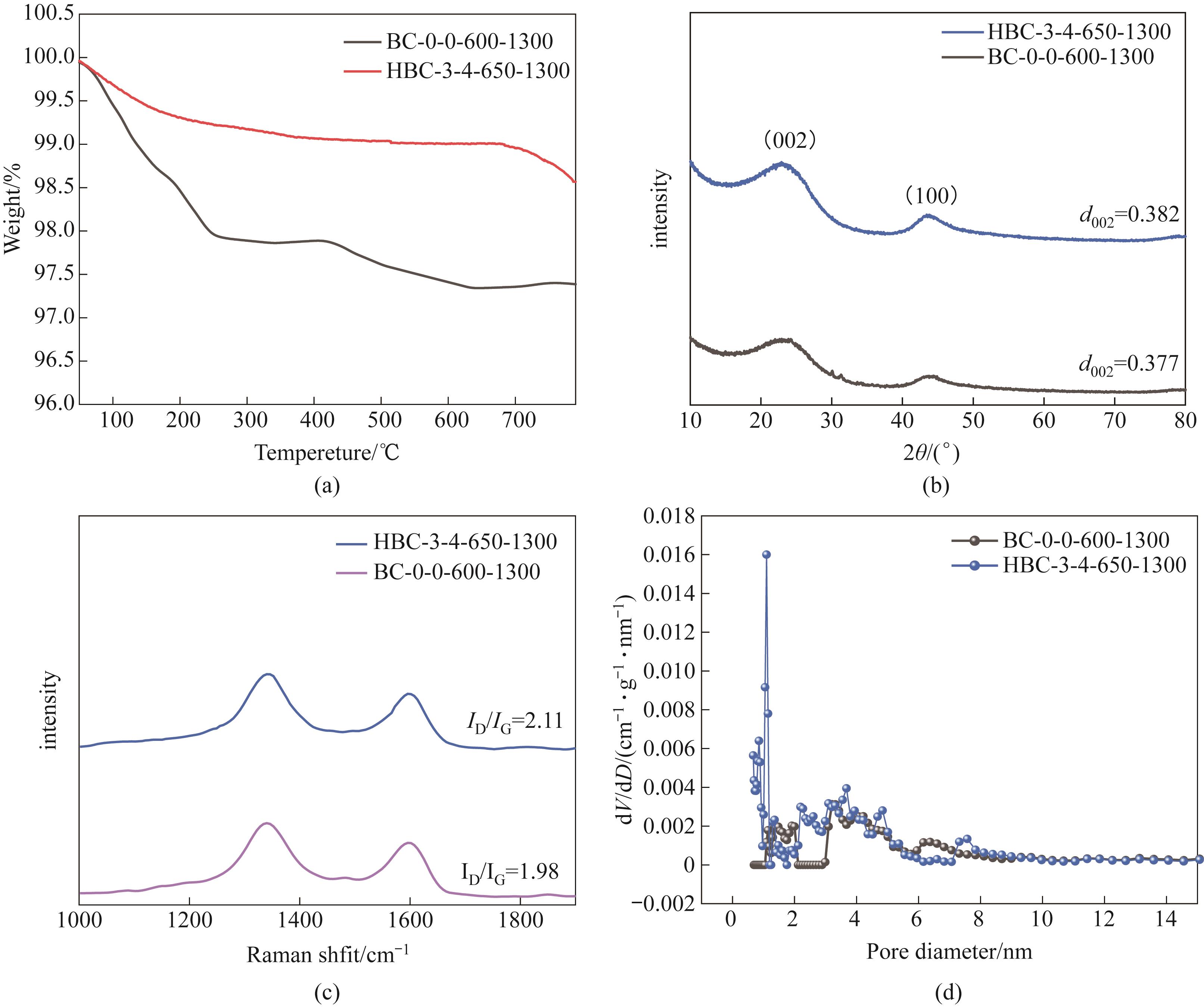

Fig.5 BC-0-0-600-1300 and HBC-3-4-650-1300 Thermogravimetric diagram (a), XRD spectrum (b), Raman spectrum (c), and pore size distribution diagram (d)

Fig.7 BC-0-0-600-1300 and HBC-3-4-650-1300 the initial galvanostatic charge-discharge profiles[(a), (b)]; AC impedance diagram[(c), (d)]; rate diagram[(e), (f)]

| 样品 | 可逆比容量/(mAh·g -1) | 首次库仑 效率/% | 孔结构 |

|---|---|---|---|

| 低灰竹基硬炭 | 365 | 70.67 | ≤1 |

| 未脱硅竹炭衍生硬炭[ | 348.5 | 84.1 | 2~4 nm |

Table 3 Comparison of bamboo-based hard carbon and low ash bamboo-based hard carbon

| 样品 | 可逆比容量/(mAh·g -1) | 首次库仑 效率/% | 孔结构 |

|---|---|---|---|

| 低灰竹基硬炭 | 365 | 70.67 | ≤1 |

| 未脱硅竹炭衍生硬炭[ | 348.5 | 84.1 | 2~4 nm |

| 样品或文献 | 首次库伦 效率/% | 首次放电比 容量/(mAh·g -1) | 充放电循环 性能/(mAh·g -1) |

|---|---|---|---|

| HBC-3-4-650-1300 | 70.67 | 536.9 | 348.5 |

| [ | 84.1 | 414.3 | 295.9 |

| [ | 83.7 | 363.2 | 272.8 |

| [ | 84.4 | 378.8 | 283.9 |

Table 4 The electrochemical performances of HBC-3-4-650-1300 compare with other bamboo-based hard carbons

| 样品或文献 | 首次库伦 效率/% | 首次放电比 容量/(mAh·g -1) | 充放电循环 性能/(mAh·g -1) |

|---|---|---|---|

| HBC-3-4-650-1300 | 70.67 | 536.9 | 348.5 |

| [ | 84.1 | 414.3 | 295.9 |

| [ | 83.7 | 363.2 | 272.8 |

| [ | 84.4 | 378.8 | 283.9 |

| [1] | Kressman R, Long S. GCB‐Bioenergy reaches a new high in impact factor and goes open access[J]. GCB Bioenergy, 2016, 8(1): 936-953. |

| [2] | Park S, Song J J, Lee W C, et al. Advances in biomass-derived electrode materials for energy storage and circular carbon economy[J]. Chemical Engineering Journal, 2023, 470: 144234. |

| [3] | Yang X M, He H H, Lv T, et al. Fabrication of biomass-based functional carbon materials for energy conversion and storage[J]. Materials Science and Engineering R: Reports, 2023, 154: 100736. |

| [4] | Ashok Kumar S S, Bashir S, Pershaanaa M, et al. A review on the recent progress of the plant-based porous carbon materials as electrodes for high-performance supercapacitors[J]. Journal of Materials Science, 2023, 58(15): 6516-6555. |

| [5] | Zhang G X, Chen Y M, Chen Y G, et al. Activated biomass carbon made from bamboo as electrode material for supercapacitors[J]. Materials Research Bulletin, 2018, 102: 391-398. |

| [6] | Chai Y L, Wan C C, Cheng W J, et al. Biomass-derived carbon for dye-sensitized solar cells: a review[J]. Journal of Materials Science, 2023, 58(14): 6057-6075. |

| [7] | Du B X, Xing J W, Ran Z Y, et al. Dielectric and energy storage properties of polypropylene by deashing method for DC polymer film capacitors[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2021, 28(6): 1917-1924. |

| [8] | Liou T H, Wu S J. Characteristics of microporous/mesoporous carbons prepared from rice husk under base- and acid-treated conditions[J]. Journal of Hazardous Materials, 2009, 171(1/2/3): 693-703. |

| [9] | Zhou S Y, Li X H, Wang Z X, et al. Effect of activated carbon and electrolyte on properties of supercapacitor[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1328-1333. |

| [10] | Zhang Y F, Zhang C X, Huang G X, et al. Tailoring the textural properties of hierarchical porous carbons for supercapacitors[J]. Materials Letters, 2015, 159: 377-380. |

| [11] | Yang X M, Lv T, Qiu J S. High mass‐loading biomass‐based porous carbon electrodes for supercapacitors: review and perspectives[J]. Small, 2023, 19(22): 2300336. |

| [12] | Gou L, Jing W F, Li Y, et al. Lattice-coupled Si/MXene confined by hard carbon for fast sodium-ion conduction[J]. ACS Applied Energy Materials, 2021, 4(7): 7268-7277. |

| [13] | Dong D, Xiao Y. Recent progress and challenges in coal-derived porous carbon for supercapacitor applications[J]. Chemical Engineering Journal, 2023, 470: 144441. |

| [14] | Kharrazi S M, Soleimani M, Jokar M, et al. Pretreatment of lignocellulosic waste as a precursor for synthesis of high porous activated carbon and its application for Pb (Ⅱ) and Cr (Ⅵ) adsorption from aqueous solutions[J]. International Journal of Biological Macromolecules, 2021, 180: 299-310. |

| [15] | Chen D Y, Zhuang X Z, Gan Z Y, et al. Co-pyrolysis of light bio-oil leached bamboo and heavy bio-oil: effects of mass ratio, pyrolysis temperature, and residence time on the biochar[J]. Chemical Engineering Journal, 2022, 437: 135253. |

| [16] | 张振, 杨胜杰, 张晓丽, 等. 超级电容器用竹基活性炭原料脱灰工艺的研究[J]. 电池工业, 2013, 18(1): 55-57. |

| Zhang Z, Yang S J, Zhang X L,et al. Research on the deashing technology for super capacitor using bamboo-based activated carbon material[J]. Chinese Battery Industry, 2013, 18(1): 55-57. | |

| [17] | Yang J F, Feng Z X, Gao Q, et al. Ash thermochemical behaviors of bamboo lignin from kraft pulping: influence of washing process[J]. Renewable Energy, 2021, 174: 178-187. |

| [18] | Liu X, Tang X, Ran H, et al. Si supply could alter N uptake and assimilation of saplings—A 15N tracer study of four subtropical species[J] Forests, 2023, 14: 1353. |

| [19] | Yang W T, Gong X X, Ji H B, et al. Qualitative and quantitative characterization of nutrient content and morphology in seeds of bamboo, rice, and wheat[J]. Journal of Cereal Science, 2021, 101: 103273. |

| [20] | Rusch F, Wastowski A D, De Lira T S, et al. Description of the component properties of species of bamboo: a review[J]. Yordsre, 2023, 13(3): 2487-2495. |

| [21] | Gao Q, Ni L M, He Y Y, et al. Effect of hydrothermal pretreatment on deashing and pyrolysis characteristics of bamboo shoot shells[J]. Energy, 2022, 247: 123510. |

| [22] | Zhang J B, Zhong Z P, Shen D K, et al. Preparation of bamboo-based activated carbon and its application in direct carbon fuel cells[J]. Energy & Fuels, 2011, 25(5): 2187-2193. |

| [23] | Ellerbrock R, Stein M, Schaller J. Comparing amorphous silica, short-range-ordered silicates and silicic acid species by FTIR[J]. Scientific Reports, 2022, 12(1): 11708. |

| [24] | Su M F, Ni L M, Rong S W, et al. The ash-forming element migration and mineral transformation during the bamboo combustion process[J]. ACS Omega, 2024, 9(20): 21974-21982. |

| [25] | Zheng H, Wang Z Y, Deng X, et al. Characteristics and nutrient values of biochars produced from giant reed at different temperatures[J]. Bioresource Technology, 2013, 130: 463-471. |

| [26] | Liu L, Tan Z, Gong H, et al. Migration and transformation mechanisms of nutrient elements (N, P, K) within biochar in straw-biochar-soil-plant systems: a review[J]. 2019, 7: 22-32. |

| [27] | Zhang X W, Deng H K, Yang J, et al. Isoconversional kinetics of pyrolysis of vaporthermally carbonized bamboo[J]. Renewable Energy, 2020, 149: 701-707. |

| [28] | Pothaya S, Poochai C, Tammanoon N, et al. Bamboo-derived hard carbon/carbon nanotube composites as anode material for long-life sodium-ion batteries with high charge/discharge capacities[J]. Rare Metals, 2024, 43(1): 124-137. |

| [29] |

Chen L, Bai L, Yeo J, et al. Wood-derived carbon with selectively introduced C O groups toward stable and high capacity anodes for sodium storage[J]. ACS Appl. Mater. Interfaces, 2020, 12: 27499-27507. O groups toward stable and high capacity anodes for sodium storage[J]. ACS Appl. Mater. Interfaces, 2020, 12: 27499-27507.

|

| [30] | Sun D, Zhao L, Sun P, et al. Rationally regulating closed pore structures by pitch coating to boost sodium storage performance of hard carbon in low‐voltage platforms[J]. Advanced Functional Materials, 2024, 34(40): 2403642. |

| [31] | Kuai J, Xie J, Wang J D, et al. Comparison and optimization of biomass-derived hard carbon as anode materials for sodium-ion batteries[J]. Chemical Physics Letters, 2024, 842: 141214. |

| [32] | Xu T Y, Qiu X, Zhang X, et al. Regulation of surface oxygen functional groups and pore structure of bamboo-derived hard carbon for enhanced sodium storage performance[J]. Chemical Engineering Journal, 2023, 452: 139514. |

| [33] | Kuai J, Xie J, Wang J D, et al. Optimizing hard carbon materials for sodium-ion batteries: insights from particle size and soft carbon-coating strategy[J]. Journal of Power Sources, 2025, 627: 235792. |

| [1] | Jiawei HU, Cong WANG, Meijing LIU. Utility model relates to double - layer anti - scale and hydrophobic coating that inhibits crystal formation in tunnel drainage pipe [J]. CIESC Journal, 2025, 76(6): 3053-3072. |

| [2] | Haiyan JI, Jiayin LIU, Haijun WU, Jinglin HE, Ziheng JIN, Dianhang WEI, Xia JIANG. Research progress on the application of low-temperature plasma in biomass gasification to produce hydrogen [J]. CIESC Journal, 2025, 76(6): 2419-2433. |

| [3] | Jia KANG, Huan LIU, Haiyan LI, Maoliang LUO, Hong YAO. Corrosion behavior and coating performance of carbon steel in HCl/NaOH thermal medium in wide temperature zone [J]. CIESC Journal, 2025, 76(6): 2872-2885. |

| [4] | Di WU, Shipeng LIU, Wenwei WANG, Jiuchun JIANG, Xiaoguang YANG. Recent advances in the influence of mechanical pressure on the performance of lithium metal batteries [J]. CIESC Journal, 2025, 76(4): 1422-1431. |

| [5] | Kun LI, Rui HUANG, Jun CONG, Haitao MA, Longjiao CHANG, Shaohua LUO. Simultaneous evolution of structural morphology and lithium storage properties in NCM622 cathode material [J]. CIESC Journal, 2025, 76(4): 1831-1840. |

| [6] | Wei LIN, Jian DU, Chen YAO, Jiahao ZHU, Wei WANG, Xiaotao ZHENG, Jianmin XU, Jiuyang YU. Study on ion transport and nucleation mechanism in electrochemical water softening process [J]. CIESC Journal, 2025, 76(4): 1788-1799. |

| [7] | Wenzhi DAI, Xiongjian SHEN, Xiaobo SONG, Xinle YANG. Environmental analysis of biomass double-stage evaporation double-regenerative organic Rankine cycle system [J]. CIESC Journal, 2025, 76(3): 1230-1242. |

| [8] | Zhihua XIAO, Haonan FANG, Fangzhi ZHENG, Dong SUN, Lida TAO, Yongfeng LI, Chunming XU, Xinlong MA. NaCl assisted constructing high-performance pitch-based hard carbon anode material [J]. CIESC Journal, 2025, 76(2): 846-857. |

| [9] | Jiayi YAO, Donghui ZHANG, Zhongli TANG, Wenbin LI. Research on carbon capture by pressure swing adsorption based on two-stage dual reflux [J]. CIESC Journal, 2025, 76(2): 744-754. |

| [10] | Zihang ZHAI, Jie JIANG, Jinjin LI, Ling ZHAO, Zhenhao XI. Synthesis and properties of ternary random copolyester PBSF based on 2,5-furandicarboxylic acid [J]. CIESC Journal, 2025, 76(2): 868-878. |

| [11] | Wenbao LI, Jinpeng HU, Miao DU, Pengju PAN, Guorong SHAN. High strength and toughness P(SBMA-co-AAc)/SiO2 composite hydrogel marine antifouling and drag-reducing coating [J]. CIESC Journal, 2025, 76(2): 787-796. |

| [12] | Zhijiao JI, Xiaofang ZHANG, Wen GAN, Yunpeng XUE. Influence of support on the performance of single atom electrocatalyst for ammonia synthesis and the control strategy [J]. CIESC Journal, 2025, 76(1): 18-39. |

| [13] | Shan GUO, Yu TIAN, Yongbin XU, Peng WANG, Zhiming LIU. Synthesis of a high-efficacy medium-entropy alloy catalyst via the recycling of spent batteries and its subsequent performance evaluation [J]. CIESC Journal, 2025, 76(1): 231-240. |

| [14] | Ziyi XU, Yang XI, Zewen SONG, Haijun ZHOU. Advances in the application of carbon nanomaterials for zinc ion batteries [J]. CIESC Journal, 2025, 76(1): 40-52. |

| [15] | Dewei WU, Zhengpeng WANG, Yue ZHOU, Xiaoning LI, Zhao CHEN, Zhuo LI, Chengwei LIU, Xuegang LI, Wende XIAO. Preparation of silicon carbon anode for lithium-ion batteries by fixed bed and lithium storage properties [J]. CIESC Journal, 2024, 75(S1): 300-308. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||