化工学报 ›› 2022, Vol. 73 ›› Issue (4): 1534-1545.DOI: 10.11949/0438-1157.20211466

收稿日期:2021-10-13

修回日期:2022-03-01

出版日期:2022-04-05

发布日期:2022-04-25

通讯作者:

陈振乾

作者简介:许婉婷(1996—),女,硕士研究生,基金资助:

Wanting XU( ),Bo XU,Xin WANG,Zhenqian CHEN(

),Bo XU,Xin WANG,Zhenqian CHEN( )

)

Received:2021-10-13

Revised:2022-03-01

Online:2022-04-05

Published:2022-04-25

Contact:

Zhenqian CHEN

摘要:

采用SST k-ω湍流模型对加热条件下超临界CO2在方形微通道内的流动换热特性进行了数值模拟。通过对比三种壁面平均传热系数、浮升力参数和二次流强度的沿程变化研究了管型、热通量、质量流量和倾斜角度对微通道内流动换热性能的影响。结果表明:水平方形微通道的整体换热性能优于相同水力直径的半圆形微通道。流体域典型截面的温度分布、速度分布和湍动能分布等信息可以很好地解释水平方向流动时上、下壁面传热差异的现象。减小热通量、增大质量流量或减小流体流动方向与重力方向之间的夹角,可提高方形微通道的整体换热水平。该模拟结果对以超临界CO2为工质的微通道换热器的设计和优化具有一定的理论指导意义。

中图分类号:

许婉婷, 许波, 王鑫, 陈振乾. 方形微通道内超临界CO2流动换热特性研究[J]. 化工学报, 2022, 73(4): 1534-1545.

Wanting XU, Bo XU, Xin WANG, Zhenqian CHEN. Heat transfer characteristics of supercritical CO2 in square microchannels[J]. CIESC Journal, 2022, 73(4): 1534-1545.

| 入口温度Tin/K | 热通量q / (kW/m2) | 质量流量G / (kg/(m2·s)) | 倾斜角度α /(°) |

|---|---|---|---|

| 303.15 | 40,60,80 | 400 | 0 |

| 303.15 | 60 | 300,400,500 | 0 |

| 303.15 | 60 | 400 | 0,30,60,90,-30,-60,-90 |

表1 不同模拟工况的边界条件设置

Table 1 Boundary conditions under different simulated conditions

| 入口温度Tin/K | 热通量q / (kW/m2) | 质量流量G / (kg/(m2·s)) | 倾斜角度α /(°) |

|---|---|---|---|

| 303.15 | 40,60,80 | 400 | 0 |

| 303.15 | 60 | 300,400,500 | 0 |

| 303.15 | 60 | 400 | 0,30,60,90,-30,-60,-90 |

| 序号 | 网格数量 (径向)×横向 | 网格总数/万个 | 流体温度最大 相对误差/% | 平均传热系数最大相对误差/% |

|---|---|---|---|---|

| Grid1 | (48×48)×500 | 115.2 | 0.10 | 3.69 |

| Grid2 | (48×48)×1000 | 230.4 | 0.03 | 3.11 |

| Grid3 | (48×48)×2000 | 460.8 | 0.01 | 2.29 |

| Grid4 | (54×54)×500 | 145.8 | 0.09 | 1.98 |

| Grid5 | (54×54)×1000 | 291.6 | 0.02 | 0.86 |

| Grid6 | (54×54)×2000 | 583.2 | — | — |

表2 不同尺寸网格下的流体温度和平均传热系数偏差

Table 2 Deviations of bulk temperature and average heat transfer coefficient under different grid sizes

| 序号 | 网格数量 (径向)×横向 | 网格总数/万个 | 流体温度最大 相对误差/% | 平均传热系数最大相对误差/% |

|---|---|---|---|---|

| Grid1 | (48×48)×500 | 115.2 | 0.10 | 3.69 |

| Grid2 | (48×48)×1000 | 230.4 | 0.03 | 3.11 |

| Grid3 | (48×48)×2000 | 460.8 | 0.01 | 2.29 |

| Grid4 | (54×54)×500 | 145.8 | 0.09 | 1.98 |

| Grid5 | (54×54)×1000 | 291.6 | 0.02 | 0.86 |

| Grid6 | (54×54)×2000 | 583.2 | — | — |

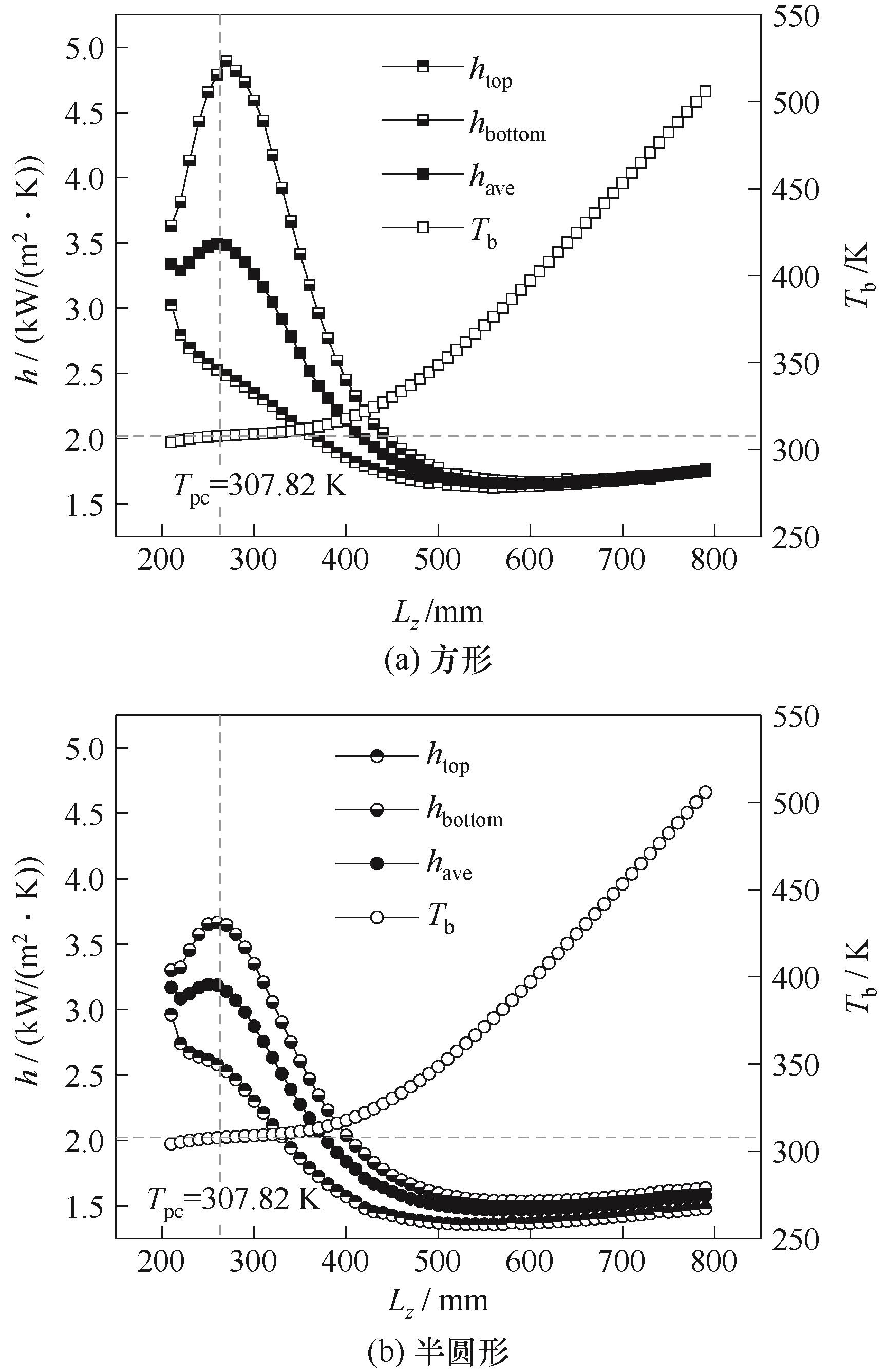

图4 方管和半圆管的壁面平均传热系数和流体温度(P=8.0 MPa, Tin=303.15 K,G=400 kg/(m2·s),q=60 kW/m2)

Fig.4 Heat transfer coefficient and local bulk temperature in square and semicircular tubes

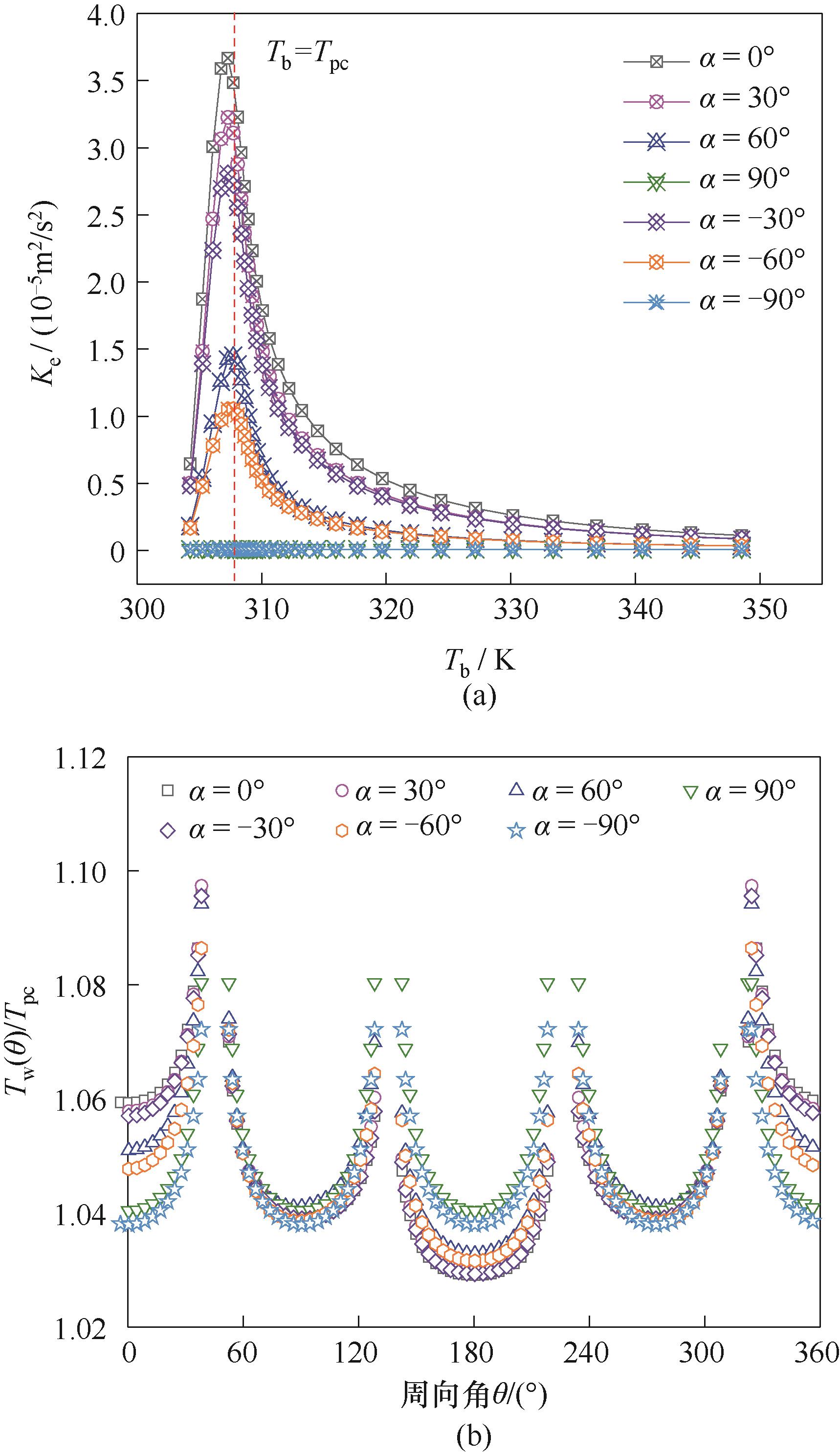

图14 倾斜角度对二次流强度和壁面温度的影响(P=8.0 MPa, Tin=303.15 K,q=60 kW/m2,G=400 kg/(m2·s))

Fig.14 Effect of inclination angle on secondary flow intensity and wall temperature

| 1 | Wu P, Ma Y D, Gao C T, et al. A review of research and development of supercritical carbon dioxide Brayton cycle technology in nuclear engineering applications[J]. Nuclear Engineering and Design, 2020, 368: 110767. |

| 2 | Jiang P X, Zhang F Z, Xu R N. Thermodynamic analysis of a solar-enhanced geothermal hybrid power plant using CO2 as working fluid[J]. Applied Thermal Engineering, 2017, 116: 463-472. |

| 3 | Ma Y T, Liu Z Y, Tian H. A review of transcritical carbon dioxide heat pump and refrigeration cycles[J]. Energy, 2013, 55: 156-172. |

| 4 | Ehsan M M, Guan Z Q, Klimenko A Y. A comprehensive review on heat transfer and pressure drop characteristics and correlations with supercritical CO2 under heating and cooling applications[J]. Renewable and Sustainable Energy Reviews, 2018, 92: 658-675. |

| 5 | Gkountas A A, Stamatelos A M, Kalfas A I. Recuperators investigation for high temperature supercritical carbon dioxide power generation cycles[J]. Applied Thermal Engineering, 2017, 125: 1094-1102. |

| 6 | Zhao P H, Wan T, Jin Y X, et al. Direct numerical simulation analysis of heat transfer deterioration of supercritical fluids in a vertical tube at a high ratio of heat flux to mass flowrate[J]. Physics of Fluids, 2021, 33(5): 055114. |

| 7 | Zhu B G, Zhu X J, Xie J, et al. Heat transfer prediction of supercritical carbon dioxide in vertical tube based on artificial neural networks[J]. Journal of Thermal Science, 2021, 30(5): 1751-1767. |

| 8 | Zhang S J, Xu X X, Liu C, et al. Experimental investigation on the heat transfer characteristics of supercritical CO2 at various mass flow rates in heated vertical-flow tube[J]. Applied Thermal Engineering, 2019, 157: 113687. |

| 9 | Yan C S, Xu J L, Zhu B G, et al. Numerical analysis on heat transfer characteristics of supercritical CO2 in heated vertical up-flow tube[J]. Materials (Basel, Switzerland), 2020, 13(3): 723. |

| 10 | Liao S M, Zhao T S. Measurements of heat transfer coefficients from supercritical carbon dioxide flowing in horizontal mini/micro channels[J]. Journal of Heat Transfer, 2002, 124(3): 413-420. |

| 11 | Kim T H, Kwon J G, Kim M H, et al. Experimental investigation on validity of buoyancy parameters to heat transfer of CO2 at supercritical pressures in a horizontal tube[J]. Experimental Thermal and Fluid Science, 2018, 92: 222-230. |

| 12 | Wang J Y, Guan Z Q, Gurgenci H, et al. Computational investigations of heat transfer to supercritical CO2 in a large horizontal tube[J]. Energy Conversion and Management, 2018, 157: 536-548. |

| 13 | Kumar N, Basu D N. Computational appraisal of the thermalhydraulic characteristics of supercritical carbon dioxide in heated mini-channel for HVAC applications[J]. IOP Conference Series: Earth and Environmental Science, 2020, 463(1): 012048. |

| 14 | Xiang M R, Guo J F, Huai X L, et al. Thermal analysis of supercritical pressure CO2 in horizontal tubes under cooling condition[J]. The Journal of Supercritical Fluids, 2017, 130: 389-398. |

| 15 | 杨传勇, 徐进良, 王晓东, 等. 超临界参数CO2在倾斜管内对流换热数值模拟[J]. 热力发电, 2013, 42(1): 26-35. |

| Yang C Y, Xu J L, Wang X D, et al. Numerical simulation of convective heat transfer for supercritical CO2 in inclined tubes[J]. Thermal Power Generation, 2013, 42(1): 26-35. | |

| 16 | 闫晨帅, 朱兵国, 尹少军, 等. 倾斜圆管内超临界压力CO2流动换热数值分析[J]. 中国科学: 技术科学, 2020, 50(5): 571-581. |

| Yan C S, Zhu B G, Yin S J, et al. Numerical analysis on flow and heat transfer characteristics of supercritical pressure CO2 in inclined tube[J]. Scientia Sinica (Technologica), 2020, 50(5): 571-581. | |

| 17 | Zhang L N, Liu M S, Dong Q W, et al. Numerical research of heat transfer of supercritical COR2R in channels[J]. Energy and Power Engineering, 2011, 3(2): 167-173. |

| 18 | Guo J F, Huai X L. Coordination analysis of cross-flow heat exchanger under high variations in thermodynamic properties[J]. International Journal of Heat and Mass Transfer, 2017, 113: 935-942. |

| 19 | Li H Z, Zhang Y F, Zhang L X, et al. PDF-based modeling on the turbulent convection heat transfer of supercritical CO2 in the printed circuit heat exchangers for the supercritical CO2 Brayton cycle[J]. International Journal of Heat and Mass Transfer, 2016, 98: 204-218. |

| 20 | Zhang Y D, Peng M J, Xia G L, et al. Numerical investigation on local heat transfer characteristics of S-CO2 in horizontal semicircular microtube[J]. Applied Thermal Engineering, 2019, 154: 380-392. |

| 21 | Wen Z X, Lv Y G, Li Q, et al. Numerical study on heat transfer behavior of wavy channel supercritical CO2 printed circuit heat exchangers with different amplitude and wavelength parameters[J]. International Journal of Heat and Mass Transfer, 2020, 147: 118922. |

| 22 | Li Y, Sun F, Xie G N, et al. Numerical investigation on flow and thermal performance of supercritical CO2 in horizontal cylindrically concaved tubes[J]. Applied Thermal Engineering, 2019, 153: 655-668. |

| 23 | Zhang S J, Xu X X, Liu C, et al. The buoyancy force and flow acceleration effects of supercritical CO2 on the turbulent heat transfer characteristics in heated vertical helically coiled tube[J]. International Journal of Heat and Mass Transfer, 2018, 125: 274-289. |

| 24 | Chen W, Yang Z N, Yang L, et al. Numerical investigation of heat transfer and flow characteristics of supercritical CO2 in U-duct[J]. Applied Thermal Engineering, 2018, 144: 532-539. |

| 25 | Kim J K, Jeon H K, Lee J S. Wall temperature measurements with turbulent flow in heated vertical circular/non-circular channels of supercritical pressure carbon-dioxide[J]. International Journal of Heat and Mass Transfer, 2007, 50(23/24): 4908-4911. |

| 26 | Hasan M I, Rageb A A, Yaghoubi M, et al. Influence of channel geometry on the performance of a counter flow microchannel heat exchanger[J]. International Journal of Thermal Sciences, 2009, 48(8): 1607-1618. |

| 27 | Besarati S M, Yogi Goswami D, Stefanakos E K. Development of a solar receiver based on compact heat exchanger technology for supercritical carbon dioxide power cycles[J]. Journal of Solar Energy Engineering, 2015, 137(3): 031018. |

| 28 | Zhang H Y, Guo J F, Huai X L, et al. Thermodynamic performance analysis of supercritical pressure CO2 in tubes[J]. International Journal of Thermal Sciences, 2019, 146: 106102. |

| 29 | Lei Y C, Chen Z Q. Numerical study on cooling heat transfer and pressure drop of supercritical CO2 in wavy microchannels[J]. International Journal of Refrigeration, 2018, 90: 46-57. |

| 30 | Khalesi J, Sarunac N. Numerical analysis of flow and conjugate heat transfer for supercritical CO2 and liquid sodium in square microchannels[J]. International Journal of Heat and Mass Transfer, 2019, 132: 1187-1199. |

| 31 | Yang Z N, Chen W, Chyu M K. Numerical study on the heat transfer enhancement of supercritical CO2 in vertical ribbed tubes[J]. Applied Thermal Engineering, 2018, 145: 705-715. |

| 32 | Menter F R. Two-equation eddy-viscosity turbulence models for engineering applications[J]. AIAA Journal, 1994, 32(8): 1598-1605. |

| 33 | Liao S M, Zhao T S. An experimental investigation of convection heat transfer to supercritical carbon dioxide in miniature tubes[J]. International Journal of Heat and Mass Transfer, 2002, 45(25): 5025-5034. |

| 34 | Wang L, Pan Y C, Lee J D, et al. Experimental investigation in the local heat transfer of supercritical carbon dioxide in the uniformly heated horizontal miniature tubes[J]. International Journal of Heat and Mass Transfer, 2020, 159: 120136. |

| 35 | Yang C Y, Xu J L, Wang X D, et al. Mixed convective flow and heat transfer of supercritical CO2 in circular tubes at various inclination angles[J]. International Journal of Heat and Mass Transfer, 2013, 64: 212-223. |

| 36 | Wang X C, Xiang M J, Huo H J, et al. Numerical study on nonuniform heat transfer of supercritical pressure carbon dioxide during cooling in horizontal circular tube[J]. Applied Thermal Engineering, 2018, 141: 775-787. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [5] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [6] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [7] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [8] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [9] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [10] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [11] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [12] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [13] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [14] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [15] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号