化工学报 ›› 2022, Vol. 73 ›› Issue (4): 1546-1556.DOI: 10.11949/0438-1157.20211574

刘宏斐1( ),李雪良1,钱钧弢2,刘金2,堵国成1,陈坚1(

),李雪良1,钱钧弢2,刘金2,堵国成1,陈坚1( )

)

收稿日期:2021-11-09

修回日期:2021-12-21

出版日期:2022-04-05

发布日期:2022-04-25

通讯作者:

陈坚

作者简介:刘宏斐(1996—),女,硕士研究生,基金资助:

Hongfei LIU1( ),Xueliang LI1,Juntao QIAN2,Jin LIU2,Guocheng DU1,Jian CHEN1(

),Xueliang LI1,Juntao QIAN2,Jin LIU2,Guocheng DU1,Jian CHEN1( )

)

Received:2021-11-09

Revised:2021-12-21

Online:2022-04-05

Published:2022-04-25

Contact:

Jian CHEN

摘要:

细胞培养技术是生物医药产业的支柱,以实现微小体积内的高密度、高通量细胞培养为目的,系统地研究了常用于单层静态培养的T25方瓶置于翘板摇床上在不同操作条件下的流体力学特性和传质性能。结果表明,振荡可以显著提高方瓶的传质速率并降低混合时间,使高密度培养成为可能,但瓶盖上的空气滤膜在高转速时成为传质速率的限制因素;培养瓶对称轴与摇床旋转轴平行时,其相对位置对混合和传质无明显影响,但当二者成45°角时,相同转速下混合时间显著缩短;使用自定义函数实现了基于动态网格的CFD模拟,对不同转速下方瓶内剪切应力和能量耗散在时间与空间上分布进行了分析,为基于T25培养瓶开发一次性高通量微型反应器提供了数据支持和理论基础。

中图分类号:

刘宏斐, 李雪良, 钱钧弢, 刘金, 堵国成, 陈坚. 摇床T25细胞培养瓶流体力学与传质特性研究[J]. 化工学报, 2022, 73(4): 1546-1556.

Hongfei LIU, Xueliang LI, Juntao QIAN, Jin LIU, Guocheng DU, Jian CHEN. Hydrodynamics and mass transfer in rocking T25 cell culture flasks[J]. CIESC Journal, 2022, 73(4): 1546-1556.

图3 不同振荡转速与换气方式组合下T25培养瓶中溶氧变化a—置换氮气,开口无瓶盖;b—置换氮气,刺穿瓶盖通空气;c—置换氮气,盖瓶盖,不通空气;d—未置换氮气,刺穿瓶盖通空气

Fig.3 Evolution of dissolved oxygen under different combinations of rocking speed and aeration method

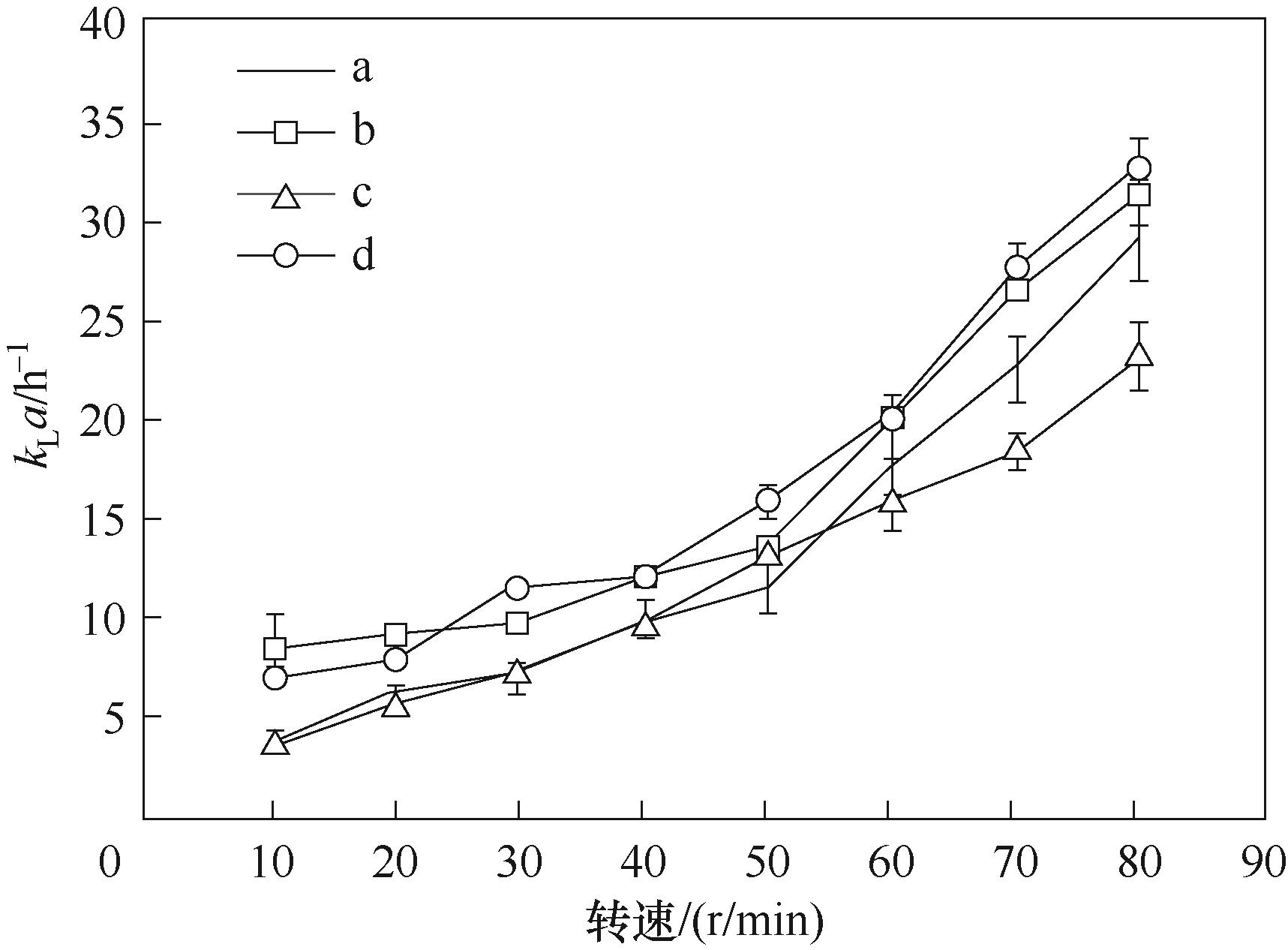

图4 振荡转速对T25培养瓶表观传质系数的影响a—置换氮气,开口无瓶盖;b—置换氮气,刺穿瓶盖通空气;c—置换氮气,盖瓶盖,不通空气;d—未置换氮气,刺穿瓶盖通空气

Fig.4 Effect of rocking speed on the apparent mass transfer coefficient

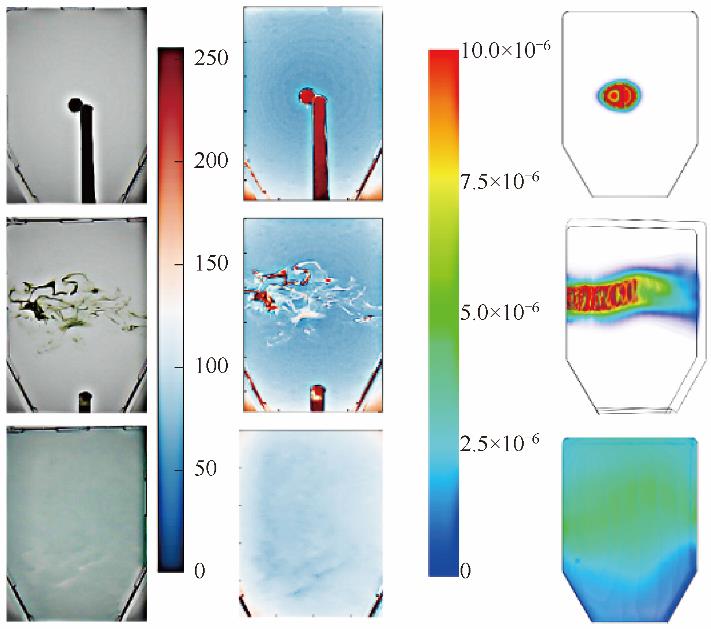

图5 70 r/min 时T25培养瓶混合情况及红色光吸收情况与CFD模拟结果的比较左—原始视频帧;中—红色光吸光度;右—CFD模拟结果

Fig.5 Red light absorbance after tracer addition under 70 r/min rocking compared with CFD simulation

图11 混合过程中培养瓶内不同位置示踪剂质量分数变化与红色吸收光标准差

Fig.11 Evolution of tracer mass fraction at five different points in the T-flask during mixing and the standard deviation of red light absorbance

| 1 | O'Flaherty R, Bergin A, Flampouri E, et al. Mammalian cell culture for production of recombinant proteins: a review of the critical steps in their biomanufacturing[J]. Biotechnology Advances, 2020, 43: 107552. |

| 2 | Zhang G Q, Zhao X R, Li X L, et al. Challenges and possibilities for bio-manufacturing cultured meat[J]. Trends in Food Science & Technology, 2020, 97: 443-450. |

| 3 | Pörtner R. Bioreactors for mammalian cells[M]//Cell Engineering. Cham: Springer International Publishing, 2014: 89-135. |

| 4 | Yang J, Guertin P, Jia G, et al. Large-scale microcarrier culture of HEK293T cells and Vero cells in single-use bioreactors[J]. AMB Express, 2019, 9(1): 70. |

| 5 | Verbruggen S, Luining D, Essen A, et al. Bovine myoblast cell production in a microcarriers-based system[J]. Cytotechnology, 2018, 70(2): 503-512. |

| 6 | 李雪良,张国强,赵鑫锐,等. 细胞培养肉规模化生产工艺及反应器展望[J]. 过程工程学报, 2020, 20(1): 3-11. |

| Li X L, Zhang G Q, Zhao X R, et al. Prospects of process and bioreactors for large scale cultured meat production[J]. The Chinese Journal of Process Engineering, 2020, 20(1): 3-11. | |

| 7 | Zhang J X, Li X L, Liu H F, et al. Hydrodynamics and mass transfer in spinner flasks: implications for large scale cultured meat production[J]. Biochemical Engineering Journal, 2021, 167: 107864. |

| 8 | 李雪良,钱钧弢,刘金,等. 微小型生物反应器及其在生物医药领域的应用展望[J]. 生物工程学报, 2020, 36(11): 2241-2249. |

| Li X L, Qian J T, Liu J, et al. Application of micro- and mini-bioreactors in biomedicine development and production[J]. Chinese Journal of Biotechnology, 2020, 36(11): 2241-2249. | |

| 9 | Fujii G, Kurashina Y, Terao Y, et al. Suspension culture in a T-flask with acoustic flow induced by ultrasonic irradiation[J]. Ultrasonics Sonochemistry, 2021, 73: 105488. |

| 10 | de Sá da Silva J, Mizukami A, Gil L V G, et al. Improving wave-induced motion bioreactor performance for human mesenchymal stromal cell expansion[J]. Process Biochemistry, 2019, 84: 143-152. |

| 11 | Ghasemi A, Bozorg A, Rahmati F, et al. Comprehensive study on wave bioreactor system to scale up the cultivation of and recombinant protein expression in baculovirus-infected insect cells[J]. Biochemical Engineering Journal, 2019, 143: 121-130. |

| 12 | Gradisnik L, Maver U, Bosnjak R, et al. Optimised isolation and characterisation of adult human astrocytes from neurotrauma patients[J]. Journal of Neuroscience Methods, 2020, 341: 108796. |

| 13 | Zhan C J, Hagrot E, Brandt L, et al. Study of hydrodynamics in wave bioreactors by computational fluid dynamics reveals a resonance phenomenon[J]. Chemical Engineering Science, 2019, 193: 53-65. |

| 14 | Dhaouadi H, Poncin S, Hornut J M, et al. Gas-liquid mass transfer in bubble column reactor: analytical solution and experimental confirmation[J]. Chemical Engineering and Processing: Process Intensification, 2008, 47(4): 548-556. |

| 15 | Gourich B, Vial C, El Azher N, et al. Improvement of oxygen mass transfer estimation from oxygen concentration measurements in bubble column reactors[J]. Chemical Engineering Science, 2006, 61(18): 6218-6222. |

| 16 | Cerri M O, Nordi Esperança M, Colli Badino A, et al. A new approach for kL a determination by gassing-out method in pneumatic bioreactors[J]. Journal of Chemical Technology & Biotechnology, 2016, 91(12): 3061-3069. |

| 17 | Heidi N. Transport Processes in the Environment[Z/OL]. . |

| 18 | Shih T H, Liou W W, Shabbir A, et al. A new k-ϵ eddy viscosity model for high Reynolds number turbulent flows[J]. Computers & Fluids, 1995, 24(3): 227-238. |

| 19 | Yakhot V, Orszag S A. Renormalization group analysis of turbulence (I): Basic theory[J]. Journal of Scientific Computing, 1986, 1(1): 3-51. |

| 20 | Danckwerts P V. Significance of liquid-film coefficients in gas absorption[J]. Industrial & Engineering Chemistry, 1951, 43(6): 1460-1467. |

| 21 | Whitman Walter G. The two film theory of gas absorption[J]. Chemical and Metallurgical Engineering, 1962,29: 429-433. |

| 22 | Nienow A W, Rielly C D, Brosnan K, et al. The physical characterisation of a microscale parallel bioreactor platform with an industrial CHO cell line expressing an IgG4[J]. Biochemical Engineering Journal, 2013, 76: 25-36. |

| 23 | Menter F R, Langtry R, Völker S. Transition modelling for general purpose CFD codes[J]. Flow, Turbulence and Combustion, 2006, 77(1/2/3/4): 277-303. |

| 24 | Hermann R, Lehmann M, Büchs J. Characterization of gas-liquid mass transfer phenomena in microtiter plates[J]. Biotechnology and Bioengineering, 2003, 81(2): 178-186. |

| 25 | Kensy F, Zimmermann H F, Knabben I, et al. Oxygen transfer phenomena in 48-well microtiter plates: determination by optical monitoring of sulfite oxidation and verification by real-time measurement during microbial growth[J]. Biotechnology and Bioengineering, 2005, 89(6): 698-708. |

| 26 | Ghasemian M, Layton C, Nampe D, et al. Hydrodynamic characterization within a spinner flask and a rotary wall vessel for stem cell culture[J]. Biochemical Engineering Journal, 2020, 157: 107533. |

| 27 | Li X R, Yang Y K, Wang R B, et al. A scale-down model of 4000-L cell culture process for inactivated foot-and-mouth disease vaccine production[J]. Vaccine, 2019, 37(43): 6380-6389. |

| 28 | 焦鹏. 一种基于微小生物反应器的新型菌株复筛和前期发酵工艺开发平台[J]. 生物产业技术, 2015(1): 17-23. |

| Jiao P. A new type of micro-bioreactor-based re-screening of new strains and a development platform for pre-fermentation technology[J]. Biotechnology & Business, 2015(1): 17-23. | |

| 29 | Nienow A W. Hydrodynamics of stirred bioreactors[J]. Applied Mechanics Reviews, 1998, 51(1): 3-32. |

| 30 | Furukawa H, Kato Y, Inoue Y, et al. Correlation of power consumption for several kinds of mixing impellers[J]. International Journal of Chemical Engineering, 2012, 2012: 1-6. |

| [1] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [2] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [3] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [4] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [5] | 谈莹莹, 刘晓庆, 王林, 黄鲤生, 李修真, 王占伟. R1150/R600a自复叠制冷循环开机动态特性实验研究[J]. 化工学报, 2023, 74(S1): 213-222. |

| [6] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [7] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [8] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [9] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [10] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [11] | 汪尔奇, 彭书舟, 杨震, 段远源. 含HFO混合体系气液相平衡的理论模型评价[J]. 化工学报, 2023, 74(8): 3216-3225. |

| [12] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [13] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [14] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [15] | 何晓崐, 刘锐, 薛园, 左然. MOCVD生长AlN单晶薄膜的气相和表面化学反应综述[J]. 化工学报, 2023, 74(7): 2800-2813. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号