化工学报 ›› 2019, Vol. 70 ›› Issue (12): 4654-4663.DOI: 10.11949/0438-1157.20190851

收稿日期:2019-07-24

修回日期:2019-10-07

出版日期:2019-12-05

发布日期:2019-12-05

通讯作者:

梁红

作者简介:魏炜(1994—),男,硕士研究生,基金资助:

Wei WEI( ),Zhiwei QIAO,Shuhua LI,Menghan MIAO,Hong LIANG(

),Zhiwei QIAO,Shuhua LI,Menghan MIAO,Hong LIANG( ),Feng PENG

),Feng PENG

Received:2019-07-24

Revised:2019-10-07

Online:2019-12-05

Published:2019-12-05

Contact:

Hong LIANG

摘要:

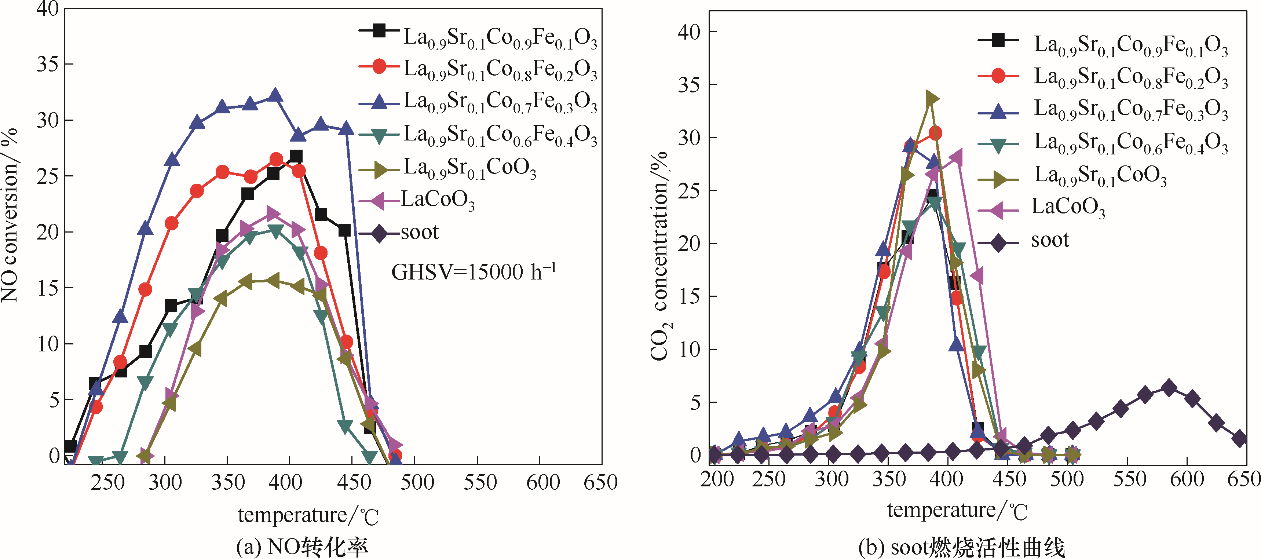

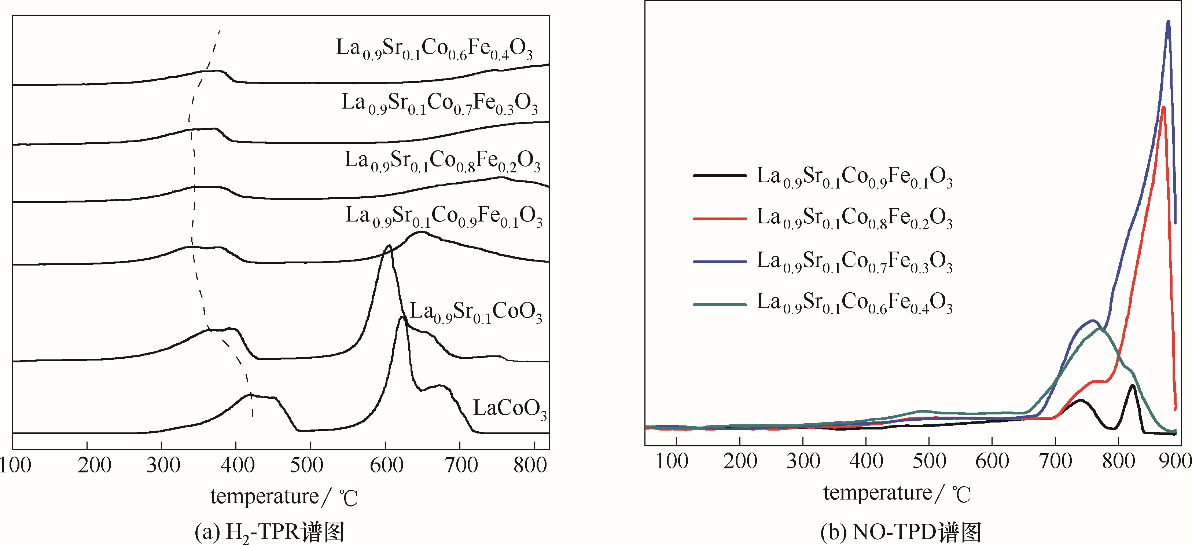

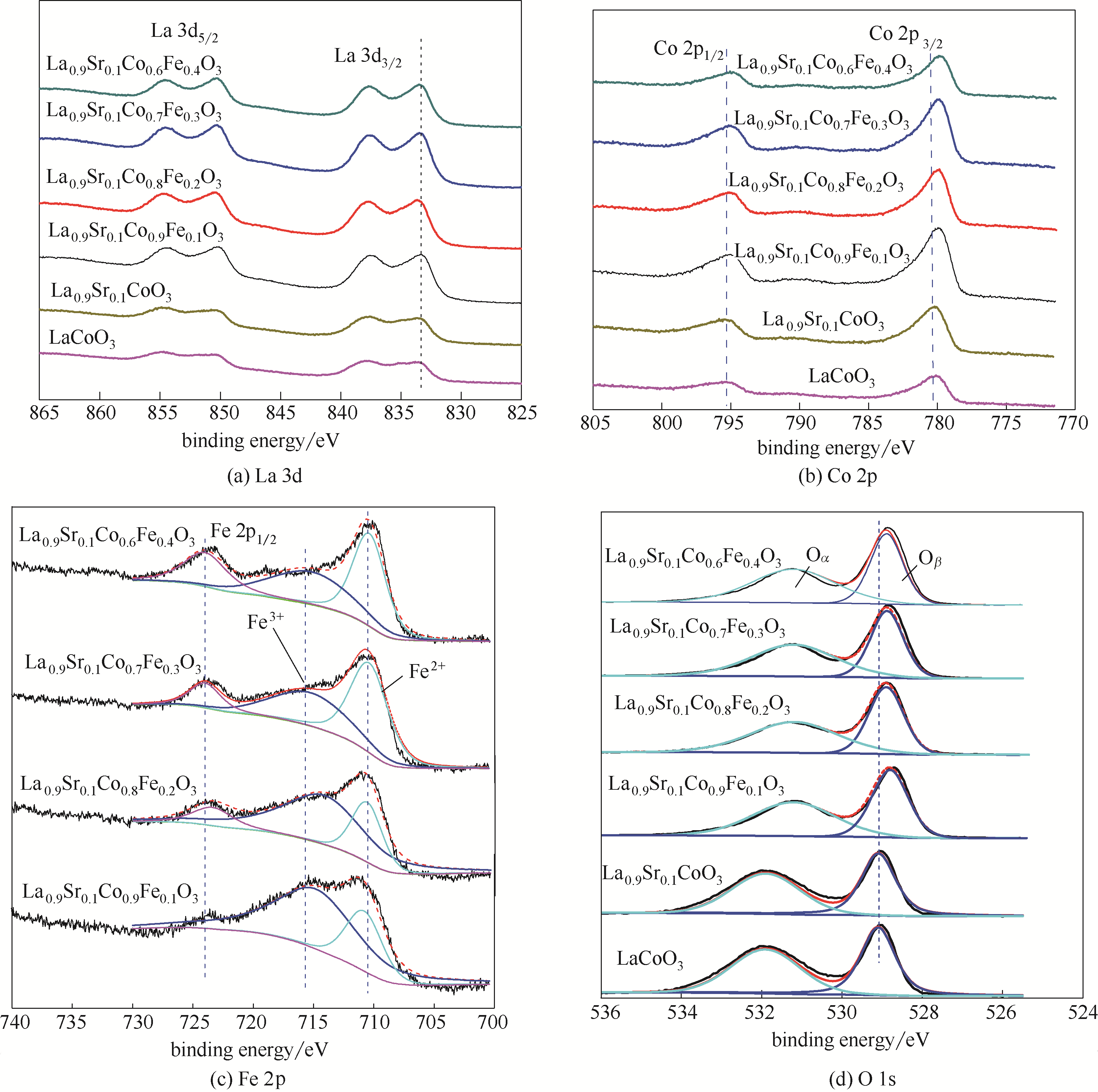

采用柠檬酸-EDTA络合法制备了纳米钙钛矿催化剂La0.9Sr0.1Co1-xFexO3,催化剂具有较好的同时去除NO和碳烟(soot)催化活性,其中La0.9Sr0.1Co0.7Fe0.3O3展现出最佳的催化活性,其在380.0℃时NO转化率为32.5%,soot最大燃烧速率温度(Tm)为368.5℃。H2-程序升温还原(H2-TPR)和NO-程序升温脱附(NO-TPD)结果表明, Fe掺杂能显著提高催化剂低温还原性能、表面氧物种活性及NO吸附性能,这有利于其改善催化活性。X射线光电子能谱(XPS)结果表明,Fe掺杂能增加催化剂表面吸附氧浓度和高价离子(Co4+),这对提高催化氧化能力至关重要。采用颗粒物捕集器(DPF)作为载体涂覆CeO2涂层用于负载La0.9Sr0.1Co0.7Fe0.3O3催化剂进行柴油机台架实验,结果表明该催化剂具有较好的同时去除NOx和soot催化活性,最大NO转化率为23.0%,Tm为341.0℃,表明Fe掺杂对提高催化活性至关重要。

中图分类号:

魏炜, 乔智威, 李树华, 苗梦涵, 梁红, 彭峰. Fe掺杂对La0.9Sr0.1Co1-xFexO3催化剂同时净化NO和碳烟活性规律研究[J]. 化工学报, 2019, 70(12): 4654-4663.

Wei WEI, Zhiwei QIAO, Shuhua LI, Menghan MIAO, Hong LIANG, Feng PENG. Study on simultaneous removal of NO and soot by Fe-doped La0.9Sr0.1Co1-xFexO3 catalyst[J]. CIESC Journal, 2019, 70(12): 4654-4663.

图1 La0.9Sr0.1Co1-xFexO3 (x= 0、0.1、0.2、0.3、0.4) 催化剂同时去除NO和soot活性曲线

Fig.1 La0.9Sr0.1Co1-xFexO3 (x=0,0.1,0.2,0.3,0.4) catalyst simultaneously removes NO and soot activity curves

图5 La0.9Sr0.1Co1-xFexO3 (x = 0、0.1、0.2、0.3、0.4) 催化剂H2-TPR和NO-TPD谱图

Fig.5 H2-TPR and NO-TPD profiles of La0.9Sr0.1Co1-xFexO3(x = 0,0.1,0.2,0.3,0.4) catalysts

图6 La0.9Sr0.1Co1-xFexO3催化剂La 3d、Co 2p、Fe 2p及O 1s的XPS谱图

Fig.6 XPS spectra of La 3d, Co 2p, Fe 2p and O 1s core level for La0.9Sr0.1Co1-xFexO3 catalysts

| Sample | Binding energy/eV | Fe2+/(Fe2++ Fe3+) | Oα/(Oα+Oβ) | O/%(at) | ||

|---|---|---|---|---|---|---|

| La 3d3/2 | Co 2p3/2 | O 1s | ||||

| LaCoO3 | 833.80 | 780.10 | 529.05 | — | 52.3 | 18.81 |

| La0.9Sr0.1CoO3 | 833.75 | 780.20 | 528.90 | — | 53.5 | 18.09 |

| La0.9Sr0.1Co0.9Fe0.1O3 | 833.40 | 779.95 | 528.70 | 26.1 | 53.1 | 45.72 |

| La0.9Sr0.1Co0.8Fe0.2O3 | 833.65 | 779.85 | 528.90 | 26.5 | 54.0 | 45.84 |

| La0.9Sr0.1Co0.7Fe0.3O3 | 833.45 | 779.85 | 528.85 | 57.5 | 55.1 | 46.05 |

| La0.9Sr0.1Co0.6Fe0.4O3 | 833.50 | 779.90 | 528.80 | 54.0 | 45.7 | 45.17 |

表1 催化剂La 3d、Co 2p和O 1s的XPS结合能及表面吸附氧、Fe2+的相对含量

Table 1 Binding energy of catalyst La 3d, Co 2p and O 1s and relative content of surface adsorption oxygen and Fe2+

| Sample | Binding energy/eV | Fe2+/(Fe2++ Fe3+) | Oα/(Oα+Oβ) | O/%(at) | ||

|---|---|---|---|---|---|---|

| La 3d3/2 | Co 2p3/2 | O 1s | ||||

| LaCoO3 | 833.80 | 780.10 | 529.05 | — | 52.3 | 18.81 |

| La0.9Sr0.1CoO3 | 833.75 | 780.20 | 528.90 | — | 53.5 | 18.09 |

| La0.9Sr0.1Co0.9Fe0.1O3 | 833.40 | 779.95 | 528.70 | 26.1 | 53.1 | 45.72 |

| La0.9Sr0.1Co0.8Fe0.2O3 | 833.65 | 779.85 | 528.90 | 26.5 | 54.0 | 45.84 |

| La0.9Sr0.1Co0.7Fe0.3O3 | 833.45 | 779.85 | 528.85 | 57.5 | 55.1 | 46.05 |

| La0.9Sr0.1Co0.6Fe0.4O3 | 833.50 | 779.90 | 528.80 | 54.0 | 45.7 | 45.17 |

| 1 | Guo X, Meng M, Dai F F, et al. NOx-assisted soot combustion over dually substituted perovskite catalysts La1-xKxCo1-yPdyO3-σ[J]. Applied Catalysis B: Environmental, 2013, 142/143: 278-289. |

| 2 | Wang X X, Shi Y, Li S J, et al. Promotional synergistic effect of Cu and Nb doping on a novel Cu/Ti-Nb ternary oxide catalyst for the selective catalytic reduction of NOx with NH3[J]. Applied Catalysis B: Environmental, 2018, 220: 234-250. |

| 3 | 汪宗御, 邝海浪, 张继锋, 等. 基于DOC+SCR的船用柴油机尾气污染物脱除实验[J]. 化工学报, 2018, 69(7): 452-459. |

| Wang Z Y, Kuang H L, Zhang J F, et al. Removal of marine diesel engine exhaust pollutants with DOC+SCR technologies[J]. CIESC Journal, 2018, 69(7): 452-459. | |

| 4 | van Setten B A A L, Makkee M, Moulijn J A. Science and technology of catalytic diesel particulate filters[J]. Catalysis Reviews-Science and Engineering, 2001, 43(4): 489-564. |

| 5 | Burtscher H. Physical characterization of particulate emissions from diesel engines: a review[J]. Journal of Aerosol Science, 2005, 36(7): 896-932. |

| 6 | Matarrese R, Castoldi L, Lietti L, et al. Simultaneous removal of NOx and soot over Pt-Ba/Al2O3 and Pt-K/Al2O3 DPNR catalysts[J]. Topics in Catalysis, 2009, 52(13-20): 2041-2046. |

| 7 | Reichert D, Bockhorn H, Kureti S. Study of the reaction of NOxand soot on Fe2O3 catalyst in excess of O2[J]. Applied Catalysis B: Environmental, 2008, 80(3/4): 248-259. |

| 8 | Ma Z, Gao X A, Yuan X L, et al. Simultaneous catalytic removal of NOx and diesel soot particulates over La2-xAxNi1-yByO4 perovskite-type oxides[J]. Catalysis Communications, 2011, 12(9): 817-821. |

| 9 | Zhang Z L, Zhang Y X, Wang Z P, et al. Catalytic performance and mechanism of potassium-promoted Mg-Al hydrotalcite mixed oxides for soot combustion with O2[J]. Journal of Catalysis, 2010, 271(1): 12-21. |

| 10 | Wang H, Zhao Z, Liang P, et al. Highly active La1-xKxCoO3 perovskite-type complex oxide catalysts for the simultaneous removal of diesel soot and nitrogen oxides under loose contact conditions[J]. Catalysis Letters, 2008, 124(1/2): 91-99. |

| 11 | Russo N, Furfori S, Fino D, et al. Lanthanum cobaltite catalysts for diesel soot combustion[J]. Applied Catalysis B: Environmental, 2008, 83(1/2): 85-95. |

| 12 | 王虹, 赵震, 徐春明, 等. LaBO3钙钛矿型复合氧化物同时消除柴油机尾气炭颗粒和NO[J]. 催化学报, 2008, 29(7): 649-654. |

| Wang H, Zhao Z, Xu C M, et al. Simultaneous removal of soot particles and NO from diesel engines over LaBO3 perovskite-type oxides[J]. Chinese Journal of Catalysis, 2008, 29(7): 649-654. | |

| 13 | Wu S H, Song C L, Bin F, et al. La1-xCexMn1-yCoyO3 perovskite oxides: preparation, physico-chemical properties and catalytic activity for the reduction of diesel soot[J]. Materials Chemistry and Physics, 2014, 148(1/2): 181-189. |

| 14 | Wu Y H, Li G Y, Chu B X, et al. NO reduction by CO over highly active and stable perovskite oxide catalysts La0.8Ce0.2M0.25Co0.75O3 (M = Cu, Mn, Fe): effect of the role in B site[J]. Industrial & Engineering Chemistry Research, 2018, 57(46): 15670-15682. |

| 15 | An S R, Song K H, Lee K Y, et al. Fe-doped LaCoO3 perovskite catalyst for NO oxidation in the post-treatment of marine diesel engine s exhaust emissions[J]. Korean Journal of Chemical Engineering, 2018, 35(9): 1807-1814. |

| 16 | Li Z Q, Meng M, Li Q A, et al. Fe-substituted nanometric La0.9K0.1Co1-xFexO3-δ perovskite catalysts used for soot combustion, NOxstorage and simultaneous catalytic removal of soot and NOx[J]. Chemical Engineering Journal, 2010, 164(1): 98-105. |

| 17 | Zhang S B, Zhao Y C, Yang J P, et al. Fe-modified MnOx/TiO2 as the SCR catalyst for simultaneous removal of NO and mercury from coal combustion flue gas[J]. Chemical Engineering Journal, 2018, 348: 618-629. |

| 18 | Liu F D, He H, Zhang C B, et al. Mechanism of the selective catalytic reduction of NOx with NH3 over environmental-friendly iron titanate catalyst[J]. Catalysis Today, 2011, 175(1): 18-25. |

| 19 | Cao F, Su S, Xiang J, et al. The activity and mechanism study of Fe-Mn-Ce/gamma-Al2O3 catalyst for low temperature selective catalytic reduction of NO with NH3[J]. Fuel, 2015, 139: 232-239. |

| 20 | Chen L, Wang X X, Cong Q L, et al. Design of a hierarchical Fe-ZSM-5@CeO2 catalyst and the enhanced performances for the selective catalytic reduction of NO with NH3[J]. Chemical Engineering Journal, 2019, 369: 957-967. |

| 21 | Liu F D, Shan W P, Lian Z H, et al. The smart surface modification of Fe2O3 by WOx for significantly promoting the selective catalytic reduction of NOx with NH3[J]. Applied Catalysis B: Environmental, 2018, 230: 165-176. |

| 22 | Merino N A, Barbero B P, Grange P, et al. La1-xCaxCoO3 perovskite-type oxides: preparation, characterisation, stability, and catalytic potentiality for the total oxidation of propane[J]. Journal of Catalysis, 2005, 231(1): 232-244. |

| 23 | Kostoglou M, Housiada P, Konstandopoulos A G. Multichannel simulation of regeneration in honeycomb monolithic diesel particulate filters[J]. Chemical Engineering Science, 2003, 58(14): 3273-3283. |

| 24 | Wang H, Shang H C, Zhang J H, et al. Niuhuang Jiangya preparation for treatment of essential hypertension: a systematic review [J]. Chinese Journal of Catalysis, 2008, 35: 649-652. |

| 25 | Yao X J, Chen L, Cao J, et al. Enhancing the deNOx performance of MnOx/CeO2-ZrO2 nanorod catalyst for low-temperature NH3-SCR by TiO2 modification[J]. Chemical Engineering Journal, 2019, 369: 46-56. |

| 26 | He X X, He J J, Meng M. Perovskite-based lean-burn NOx trap catalysts without using platinum group metals: K/LaCoO3/Ce1-x ZrxO2[J]. Catalysis Letters, 2011, 141(9): 1364-1370. |

| 27 | Liang H, Hong Y X, Zhu C Q, et al. Influence of partial Mn-substitution on surface oxygen species of LaCoO3 catalysts[J]. Catalysis Today, 2013, 201(201): 98-102. |

| 28 | Ma S B, Zhao X Y, Li Y S, et al. Effect of W on the acidity and redox performance of the Cu0.02Fe0.2WaTiOx (a=0.01, 0.02, 0.03) catalysts for NH3-SCR of NO[J]. Applied Catalysis B: Environmental, 2019, 248: 226-238. |

| 29 | Cao J L, Wang Y, Yu X L, et al. Mesoporous CuO-Fe2O3 composite catalysts for low-temperature carbon monoxide oxidation[J]. Applied Catalysis B: Environmental, 2008, 79(1/2): 26-34. |

| 30 | Ali S, Li Y S, Zhang T R, et al. Promotional effects of Nb on selective catalytic reduction of NO with NH3 over FexNb0.5-xCe0.5 (x=0.45, 0.4, 0.35) oxides catalysts[J]. Molecular Catalysis, 2018, 461: 97-107. |

| 31 | Lian Z H, Liu F D, He H, et al. Manganese-niobium mixed oxide catalyst for the selective catalytic reduction of NOx with NH3 at low temperatures[J]. Chemical Engineering Journal, 2014, 250: 390-398. |

| 32 | Dunn J P, Koppula P R, Stenger H G, et al. Oxidation of sulfur dioxide to sulfur trioxide over supported vanadia catalysts[J]. Applied Catalysis B: Environmental, 1998, 19(2): 103-117. |

| 33 | Li Z Q, Meng M, Zha Y Q, et al. Highly efficient multifunctional dually-substituted perovskite catalysts La1-xKxCo1-yCuyO3-σ used for soot combustion, NOx storage and simultaneous NOx-soot removal[J]. Applied Catalysis B: Environmental, 2012, 121: 65-74. |

| 34 | Lin K A, Chen Y C, Lin Y F. LaMO3 perovskites (M=Co, Cu, Fe and Ni) as heterogeneous catalysts for activating peroxymonosulfate in water[J]. Chemical Engineering Science, 2017, 160: 96-105. |

| 35 | Liu Z M, Hao J M, Fu L X, et al. Study of Ag/La0.6Ce0.4CoO3 catalysts for direct decomposition and reduction of nitrogen oxides with propene in the presence of oxygen[J]. Applied Catalysis B: Environmental, 2003, 44(4): 355-370. |

| 36 | Ali S, Chen L Q, Li Z B, et al. CuxNb1.1-x(x=0.45, 0.35, 0.25, 0.15) bimetal oxides catalysts for the low temperature selective catalytic reduction of NO with NH3[J]. Applied Catalysis B: Environmental, 2018, 236: 25-35. |

| 37 | Zha K W, Cai S X, Hu H, et al. In situ DRIFTs investigation of promotional effects of tungsten on MnOx-CeO2/meso-TiO2 catalysts for NOx reduction [J]. Journal of Physical Chemistry C, 2017, 121(45): 25243-25254. |

| [1] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [2] | 胡超, 董玉明, 张伟, 张红玲, 周鹏, 徐红彬. 浓硫酸活化五氧化二钒制备高浓度全钒液流电池正极电解液[J]. 化工学报, 2023, 74(S1): 338-345. |

| [3] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [4] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [5] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [6] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [7] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [8] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [9] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [10] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [11] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| [12] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [13] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [14] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [15] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号