化工学报 ›› 2021, Vol. 72 ›› Issue (5): 2506-2513.DOI: 10.11949/0438-1157.20201269

沈超1( ),刘玉娟1,王竹萱1,张东伟2(

),刘玉娟1,王竹萱1,张东伟2( ),杨建中1,魏新利2

),杨建中1,魏新利2

收稿日期:2020-09-07

修回日期:2020-12-08

出版日期:2021-05-05

发布日期:2021-05-05

通讯作者:

张东伟

作者简介:沈超(1980—),男,博士研究生,副教授,基金资助:

SHEN Chao1( ),LIU Yujuan1,WANG Zhuxuan1,ZHANG Dongwei2(

),LIU Yujuan1,WANG Zhuxuan1,ZHANG Dongwei2( ),YANG Jianzhong1,WEI Xinli2

),YANG Jianzhong1,WEI Xinli2

Received:2020-09-07

Revised:2020-12-08

Online:2021-05-05

Published:2021-05-05

Contact:

ZHANG Dongwei

摘要:

平行流热管换热器综合热管轴向高效换热和平行流换热器管外高效换热的优点,是一种新型的热管换热器。为了研究平行流热管工作机理及管内流动过程,搭建了平行流热管可视化实验台并对不同结构参数、不同加热功率和不同充注工质下的启动特性和传热传质规律进行了实验研究。实验结果表明:平行流热管工作机理复杂,并联管路内气柱和液柱在重力和不平衡压力的共同作用下进行互激振荡流动,并且管内出现泡状流、弹状流、环状流等多种流型,同时较高的加热功率和较大的管径会加剧工质在并联各管路之间的往复振荡,增加工质在蒸发段和冷凝段的扰动,提高热管的换热性能。

中图分类号:

沈超, 刘玉娟, 王竹萱, 张东伟, 杨建中, 魏新利. 平行流热管管内两相流动可视化实验研究[J]. 化工学报, 2021, 72(5): 2506-2513.

SHEN Chao, LIU Yujuan, WANG Zhuxuan, ZHANG Dongwei, YANG Jianzhong, WEI Xinli. Visualization experiment of two-phase flow in parallel flow heat pipe[J]. CIESC Journal, 2021, 72(5): 2506-2513.

实验 样品 | 平行流热管参数 | |||||

|---|---|---|---|---|---|---|

| 管长/mm | 管径/mm | 集液管和均压管管径/mm | 工质 | 管间距/mm | 充液率 | |

| 1 | 300 | 4 | 8 | 丙酮 | 4 | 0.258 |

| 2 | 300 | 2 | 6 | 丙酮 | 6 | 0.26 |

| 3 | 300 | 4 | 8 | 甲醇 | 4 | 0.258 |

表1 平行流热管样品参数

Table 1 Sample parameters of parallel flow heat pipe

实验 样品 | 平行流热管参数 | |||||

|---|---|---|---|---|---|---|

| 管长/mm | 管径/mm | 集液管和均压管管径/mm | 工质 | 管间距/mm | 充液率 | |

| 1 | 300 | 4 | 8 | 丙酮 | 4 | 0.258 |

| 2 | 300 | 2 | 6 | 丙酮 | 6 | 0.26 |

| 3 | 300 | 4 | 8 | 甲醇 | 4 | 0.258 |

| 工质 | 沸点Ts/℃ | 密度ρl(20℃)/ (kg/m3) | 比热容Cpl(20℃)/ (kJ/(kg·℃)) | 热导率λl(20℃)/ (W/(m·℃)) | 汽化潜热Hfg(20℃)/ (kJ/kg) | (dP/dT)sat(60℃)/ (kPa/℃) | 动力黏度υl(20℃)/ (mPa·s) |

|---|---|---|---|---|---|---|---|

| 丙酮 | 56.5 | 790.4 | 2.13 | 0.157 | 539 | 3.83 | 0.32 |

| 甲醇 | 64.7 | 790.9 | 2.48 | 0.212 | 1101 | 3.43 | 0.58 |

表2 标准大气压下不同工质的热物性参数

Table 2 Thermophysical parameters of different working fluids at standard atmospheric pressure

| 工质 | 沸点Ts/℃ | 密度ρl(20℃)/ (kg/m3) | 比热容Cpl(20℃)/ (kJ/(kg·℃)) | 热导率λl(20℃)/ (W/(m·℃)) | 汽化潜热Hfg(20℃)/ (kJ/kg) | (dP/dT)sat(60℃)/ (kPa/℃) | 动力黏度υl(20℃)/ (mPa·s) |

|---|---|---|---|---|---|---|---|

| 丙酮 | 56.5 | 790.4 | 2.13 | 0.157 | 539 | 3.83 | 0.32 |

| 甲醇 | 64.7 | 790.9 | 2.48 | 0.212 | 1101 | 3.43 | 0.58 |

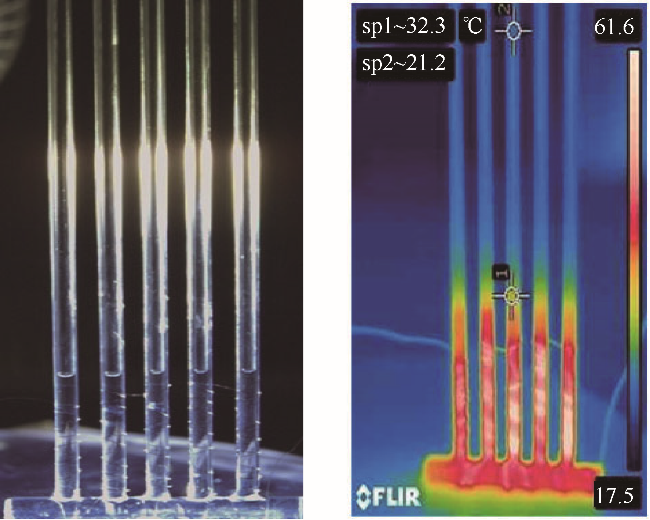

图3 平行流热管蒸发段工质流动情况和热管表面温度分布(4 mm,丙酮,10 W)

Fig.3 Working fluid flow and surface temperature distribution of parallel flow heat pipe evaporation section (4 mm, acetone, 10 W)

图9 平行流热管在不同管径下启动后的表面温度分布(丙酮,50 W)

Fig.9 Surface temperature distribution of parallel flow heat pipe after startup under different pipe diameters (acetone, 50 W)

| 1 | Abreu S L, Colle S. An experimental study of two-phase closed thermosyphons for compact solar domestic hot-water systems[J]. Solar Energy, 2004, 76(1/2/3): 141-145. |

| 2 | Ramos-Alvarado B, Li P W, Liu H, et al. CFD study of liquid-cooled heat sinks with microchannel flow field configurations for electronics, fuel cells, and concentrated solar cells[J]. Applied Thermal Engineering, 2011, 31(14/15): 2494-2507. |

| 3 | Lamaison N, Ong C L, Marcinichen J B, et al. Two-phase mini-thermosyphon electronics cooling: dynamic modeling, experimental validation and application to 2U servers[J]. Applied Thermal Engineering, 2017, 110: 481-494. |

| 4 | Chang Y W, Cheng C H, Wang J C, et al. Heat pipe for cooling of electronic equipment[J]. Energy Conversion and Management, 2008, 49(11): 3398-3404. |

| 5 | Krishna J, Kishore P S, Solomon A B. Heat pipe with nano enhanced-PCM for electronic cooling application[J]. Experimental Thermal and Fluid Science, 2017, 81: 84-92. |

| 6 | Weng Y C, Cho H P, Chang C C, et al. Heat pipe with PCM for electronic cooling[J]. Applied Energy, 2011, 88(5): 1825-1833. |

| 7 | Sundaram A S, Bhaskaran A. Thermal modeling of thermosyphon integrated heat sink for CPU cooling[J]. Journal of Electronics Cooling and Thermal Control, 2011, 1(2): 15-21. |

| 8 | Zhang M Y, Lai Y M, Zhang J M, et al. Numerical study on cooling characteristics of two-phase closed thermosyphon embankment in permafrost regions[J]. Cold Regions Science and Technology, 2011, 65(2): 203-210. |

| 9 | 杨永平, 魏庆朝, 周顺华, 等. 热管技术及其在多年冻土工程中的应用研究[J]. 岩土工程学报, 2005, 27(6): 698-706. |

| Yang Y P, Wei Q C, Zhou S H, et al. Thermosyphon technology and its application in permafrost[J]. Chinese Journal of Geotechnical Engineering, 2005, 27(6): 698-706. | |

| 10 | Tundee S, Srihajong N, Charmongkolpradit S. Electric power generation from solar pond using combination of thermosyphon and thermoelectric modules[J]. Energy Procedia, 2014, 48: 453-463. |

| 11 | Yau Y H. Experimental thermal performance study of an inclined heat pipe heat exchanger operating in high humid tropical HVAC systems[J]. International Journal of Refrigeration, 2007, 30(7): 1143-1152. |

| 12 | Yau Y H. Application of a heat pipe heat exchanger to dehumidification enhancement in a HVAC system for tropical climates—a baseline performance characteristics study[J]. International Journal of Thermal Sciences, 2007, 46(2): 164-171. |

| 13 | Yau Y H. The use of a double heat pipe heat exchanger system for reducing energy consumption of treating ventilation air in an operating theatre—a full year energy consumption model simulation[J]. Energy and Buildings, 2008, 40(5): 917-925. |

| 14 | Gedik E, Yılmaz M, Kurt H. Experimental investigation on the thermal performance of heat recovery system with gravity assisted heat pipe charged with R134a and R410A[J]. Applied Thermal Engineering, 2016, 99: 334-342. |

| 15 | 张海松, 谢国威, 战洪仁, 等. 两相闭式热虹吸管内部过程可视化及其强化传热研究进展[J]. 化工进展, 2017, 36(3): 791-801. |

| Zhang H S, Xie G W, Zhan H R, et al. Progress of research on visualization of internal procedure of two-phase closed thermosyphon and its heat transfer enhancement[J]. Chemical Industry and Engineering Progress, 2017, 36(3): 791-801. | |

| 16 | Yu F W, Yu C, Cao J G, et al. Experimental analysis of the evaporation regimes of an axially grooved heat pipe at small tilt angles[J]. International Journal of Heat and Mass Transfer, 2018, 126: 334-341. |

| 17 | 黄廉民, 孙曾闰, 张有衡. 垂直封闭两相热虹吸管内部流动的可视化实验研究[J]. 南京工业大学学报(自然科学版), 1986, 8(4): 92-103. |

| Huang L M, Sun Z R, Zhang Y H. Visualization experimental study on the flow in a vertical closed two-phase thermosyphon [J]. Journal of Nanjing University of Technology (Natural Science Edition), 1986, 8(4): 92-103. | |

| 18 | 陈岗, 辛明道, 陈远国. 两相闭式热虹吸管内的流动和传热[J]. 工程热物理学报, 1987, 8(2): 149-152. |

| Chen G, Xin M D, Chen Y G. Flow and heat transfer in two-phase closed thermosyphons[J]. Journal of Engineering Thermophysics, 1987, 8(2): 149-152. | |

| 19 | Emami M R S, Noie S H, Khoshnoodi M. Effect of aspect ratio and filling ratio on thermal performance of an inclined two-phase closed thermosyphon[J]. Iranian Journal of Science and Technology Transaction B-Engineering, 2008, 32(B1): 39-51. |

| 20 | 韩振兴, 王冬骁, 王飞, 等. 重力热管冷凝段运行特征的可视化实验研究[J]. 化工学报, 2014, 65(8): 2934-2939. |

| Han Z X, Wang D X, Wang F, et al. Visual experimental study on operation characteristics of condensation segment of gravity-assisted heat pipe[J]. CIESC Journal, 2014, 65(8): 2934-2939. | |

| 21 | 于程, 刘向东, 张孟臣, 等. 平板热管内气液两相流动与传热的可视化实验研究[J]. 工程热物理学报, 2017, 38(4): 807-810. |

| Yu C, Liu X D, Zhang M C, et al. Visualization study of vapor-liquid two phase flow and heat transfer in flat plate heat pipe[J]. Journal of Engineering Thermophysics, 2017, 38(4): 807-810. | |

| 22 | Smith K, Robinson A J, Kempers R. Confinement and vapour production rate influences in closed two-phase reflux thermosyphons Part B: Heat transfer[J]. International Journal of Heat and Mass Transfer, 2018, 120: 1241-1254. |

| 23 | Smith K, Kempers R, Robinson A J. Confinement and vapour production rate influences in closed two-phase reflux thermosyphons Part A: Flow regimes[J]. International Journal of Heat and Mass Transfer, 2018, 119: 907-921. |

| 24 | Kim I G, Kim K M, Jeong Y S, et al. Flow visualization and heat transfer performance of annular thermosyphon heat pipe[J]. Applied Thermal Engineering, 2017, 125: 1456-1468. |

| 25 | 孙芹, 屈健, 袁建平. 等截面和变截面通道硅基微型脉动热管传热特性比较[J]. 化工学报, 2017, 68(5): 1803-1810. |

| Sun Q, Qu J, Yuan J P. Heat transfer performance comparison of silicon-based micro oscillating heat pipes with and without expanding channels[J]. CIESC Journal, 2017, 68(5): 1803-1810. | |

| 26 | 刘向东, 王超, 陈永平. 基于红外热成像的脉动热管运行及传热特性分析[J]. 化工学报, 2016, 67(4): 1129-1135. |

| Liu X D, Wang C, Chen Y P. Analysis of operation and heat transfer characteristics in pulsating heat pipe based on infrared thermal imaging technology[J]. CIESC Journal, 2016, 67(4): 1129-1135. | |

| 27 | 冼海珍, 刘晓敏, 杨勇平, 等. 振荡流热管可视化实验[J]. 工程热物理学报, 2011, 32(9): 1583-1585. |

| Xian H Z, Liu X M, Yang Y P, et al. Visualization experiment for oscillating heat pipe[J]. Journal of Engineering Thermophysics, 2011, 32(9): 1583-1585. | |

| 28 | 冼海珍, 王川川, 杨勇平, 等. 工质为戊醇-水溶液的振荡流热管可视化实验[J]. 工程热物理学报, 2013, 34(7): 1343-1346. |

| Xian H Z, Wang C C, Yang Y P, et al. Visualization experiment for pentanol-water solution oscillating heat pipe[J]. Journal of Engineering Thermophysics, 2013, 34(7): 1343-1346. | |

| 29 | Zou Y, Tuo H F, Hrnjak P S. Modeling refrigerant maldistribution in microchannel heat exchangers with vertical headers based on experimentally developed distribution results[J]. Applied Thermal Engineering, 2014, 64(1/2): 172-181. |

| 30 | 沈超, 余鹏, 张东伟, 等. 平行流热管换热器传热传质特性的数值模拟研究[J]. 工程热物理学报, 2017, 38(6): 1309-1312. |

| Shen C, Yu P, Zhang D W, et al. Numerical simulation of heat and mass transfer in a parallel flow heat exchanger[J]. Journal of Engineering Thermophysics, 2017, 38(6): 1309-1312. | |

| 31 | 沈超, 杨绍伦, 张东伟, 等. 平行流热管换热器传热性能实验研究[J]. 工程热物理学报, 2018, 39(6): 1339-1343. |

| Shen C, Yang S L, Zhang D W, et al. Experimental research on heat transfer performance of parallel flow heat pipe exchangers[J]. Journal of Engineering Thermophysics, 2018, 39(6): 1339-1343. |

| [1] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [2] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [5] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [6] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [7] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [8] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [9] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [10] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [11] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [12] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [13] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [14] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [15] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号