化工学报 ›› 2021, Vol. 72 ›› Issue (8): 4433-4443.DOI: 10.11949/0438-1157.20201604

• 过程安全 • 上一篇

收稿日期:2020-11-05

修回日期:2021-05-02

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

蒋军成

作者简介:李云浩(1990—),男,博士,讲师,基金资助:

Yunhao LI1( ),Juncheng JIANG1,2(

),Juncheng JIANG1,2( ),Yuan YU2,Zhirong WANG2,Qingwu ZHANG2

),Yuan YU2,Zhirong WANG2,Qingwu ZHANG2

Received:2020-11-05

Revised:2021-05-02

Online:2021-08-05

Published:2021-08-05

Contact:

Juncheng JIANG

摘要:

为获得大型钢制储罐在碎片冲击和池火热辐射耦合作用下的失效机理,采用Abaqus建立了高速碎片穿孔和热辐射耦合作用下固定拱顶钢储罐失效分析的有限元模型,分析了储罐在高速碎片冲击作用下的动力响应和穿孔储罐在热辐射作用下的热屈曲响应,研究了储罐壁面的应力变化过程。结果表明,在热辐射单一作用下,储罐由罐壁-罐顶连接处开始发生热屈曲,并出现褶皱变形;在高速碎片冲击与热辐射耦合作用下,高速碎片冲击导致储罐产生穿孔,储罐从穿孔两侧开始发生热屈曲,而且,穿孔导致塑性变形区及其附近区域产生应力集中,与未受冲击的储罐相比,穿孔储罐的罐壁处于更高的应力水平,更容易发生失稳。因此,穿孔储罐的抗火性能降低,热屈曲模式也发生改变。

中图分类号:

李云浩, 蒋军成, 喻源, 王志荣, 张庆武. 穿孔与热辐射耦合作用下固定拱顶钢储罐的失效机理[J]. 化工学报, 2021, 72(8): 4433-4443.

Yunhao LI, Juncheng JIANG, Yuan YU, Zhirong WANG, Qingwu ZHANG. Coupling effects of perforation and heat radiation on failure mechanism of fixed-roof steel tank[J]. CIESC Journal, 2021, 72(8): 4433-4443.

| 钢板参数 | 底板 | 第一层 | 第二层 | 第三层 | 第四层 | 第五层 | 第六层 | 第七至九层 | 第十层 | 顶盖 |

|---|---|---|---|---|---|---|---|---|---|---|

| 钢板厚度/mm | 10 | 13 | 12 | 11 | 10 | 9 | 7 | 6 | 6 | 5 |

| 钢板高度/m | — | 1.78 | 1.78 | 1.78 | 1.78 | 1.78 | 1.78 | 1.78 | 1.8 | — |

表1 5000 m3储罐的结构尺寸

Table 1 Structural dimensions of the 5000 m3 storage tank

| 钢板参数 | 底板 | 第一层 | 第二层 | 第三层 | 第四层 | 第五层 | 第六层 | 第七至九层 | 第十层 | 顶盖 |

|---|---|---|---|---|---|---|---|---|---|---|

| 钢板厚度/mm | 10 | 13 | 12 | 11 | 10 | 9 | 7 | 6 | 6 | 5 |

| 钢板高度/m | — | 1.78 | 1.78 | 1.78 | 1.78 | 1.78 | 1.78 | 1.78 | 1.8 | — |

| A/MPa | B/MPa | C | n | m | Tmelt/℃ | Ttrans/℃ |

|---|---|---|---|---|---|---|

| 374 | 795 | 0.01586 | 0.45451 | 0.88559 | 1500 | 20 |

表2 Q345钢的Johnson-Cook材料模型参数

Table 2 Johnson-Cook plasticity model parameters of the Q345 steel

| A/MPa | B/MPa | C | n | m | Tmelt/℃ | Ttrans/℃ |

|---|---|---|---|---|---|---|

| 374 | 795 | 0.01586 | 0.45451 | 0.88559 | 1500 | 20 |

| d1 | d2 | d3 | d4 | d5 | Tmelt/℃ | Ttrans/℃ | |

|---|---|---|---|---|---|---|---|

| 0.123 | 0.236 | 2.43 | 0.058 | 0 | 1500 | 20 | 1 |

表3 Q345钢的Johnson-Cook损伤失效准则参数

Table 3 Johnson-Cook damage model parameters of the Q345 steel

| d1 | d2 | d3 | d4 | d5 | Tmelt/℃ | Ttrans/℃ | |

|---|---|---|---|---|---|---|---|

| 0.123 | 0.236 | 2.43 | 0.058 | 0 | 1500 | 20 | 1 |

图3 Q345钢的热膨胀系数、弹性模量和应力-应变曲线

Fig.3 Thermal expansion coefficients, elastic modules, and stress-strain curves of a Q345 steel for different temperatures

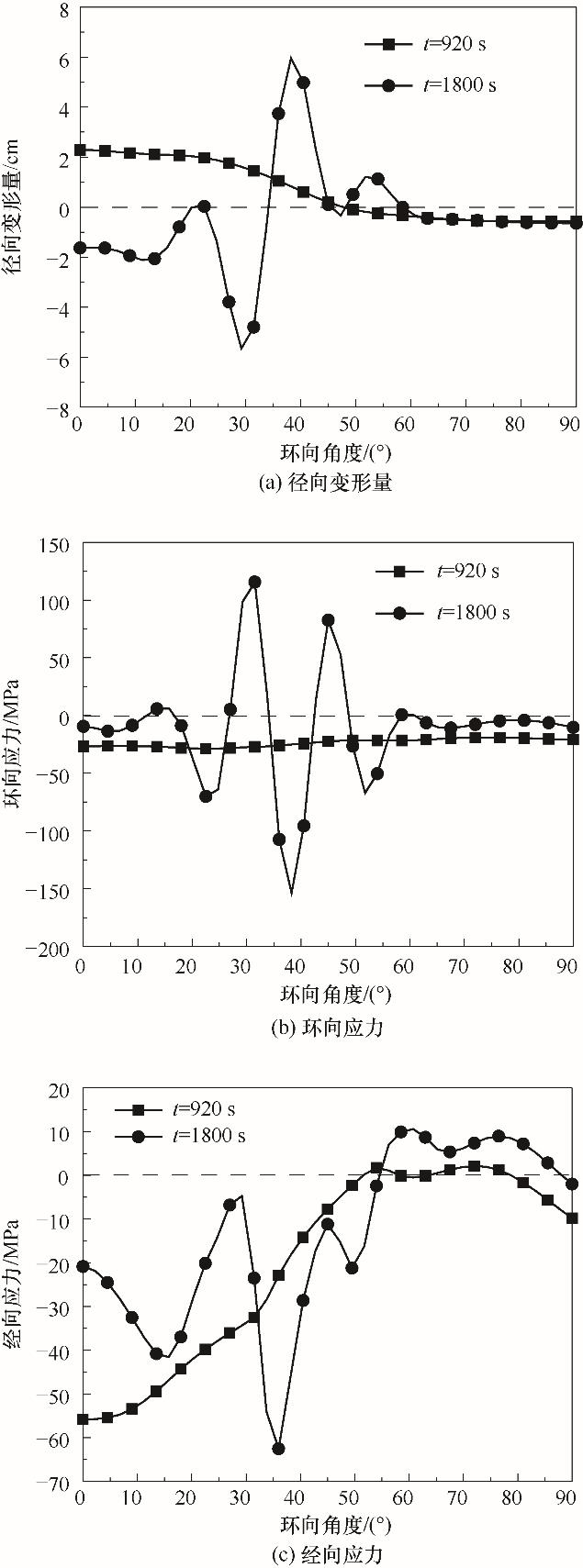

图8 屈曲和后屈曲状态下目标储罐环向(z=14 m,0°≤θ≤90°)的径向变形量和环向、经向应力分布

Fig. 8 Radial displacement, circumferential and meridional stresses around the circumference of the target tank (z=14 m, 0°≤θ≤90°) at buckling and post-buckling states

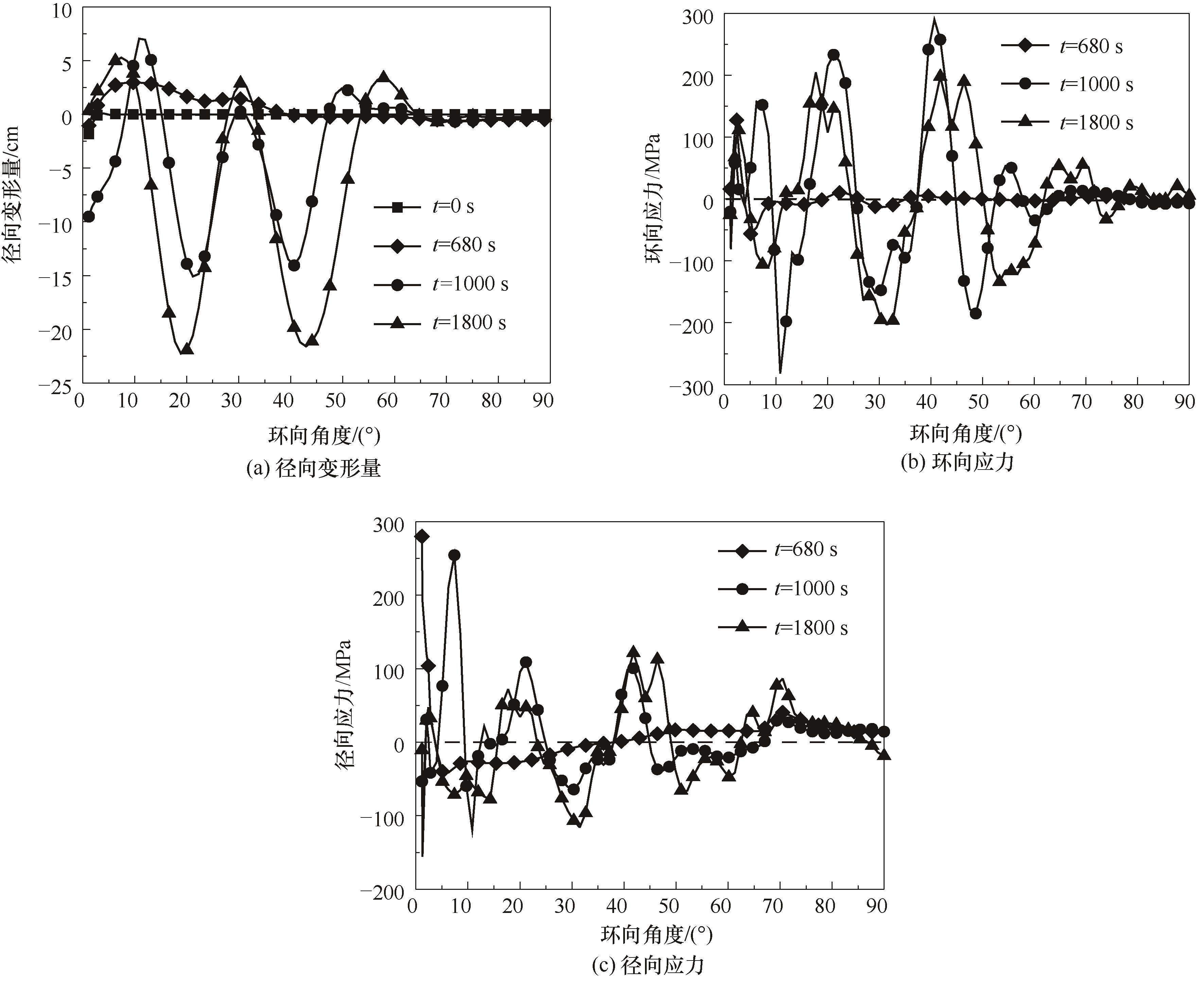

图13 屈曲和后屈曲状态下穿孔目标储罐环向(z=14 m,0°≤θ≤90°)的径向变形量和环向、径向应力分布

Fig. 13 Radial displacement, circumferential and meridional stresses around the circumference of the perforated target tank (z=14 m, 0°≤θ≤90°) at buckling and post-buckling states

| 1 | Gubinelli G, Cozzani V. Assessment of missile hazards: identification of reference fragmentation patterns[J]. Journal of Hazardous Materials, 2009, 163(2/3): 1008-1018. |

| 2 | Tugnoli A, Milazzo M F, Landucci G, et al. Assessment of the hazard due to fragment projection: a case study[J]. Journal of Loss Prevention in the Process Industries, 2014, 28: 36-46. |

| 3 | Reniers G, Cozzani V. Domino Effects in the Process Industries[M]. Amsterdam: Elsevier, 2013: 116-153. |

| 4 | 黄维秋, 方洁, 吕成, 等. 内浮顶罐组油气泄漏扩散叠加效应的数值模拟与风洞实验研究[J]. 化工学报, 2019, 70(11): 4504-4516. |

| Huang W Q, Fang J, Lyu C, et al. Numerical simulation of oil vapor leakage and diffusion superposition effect of internal floating-roof tank group and experimental investigation on wind-tunnel[J]. CIESC Journal, 2019, 70(11): 4504-4516. | |

| 5 | Schneider P, Buchar F, Zápeca F. Structural response to thin steel shell structures due to aircraft impact[J]. Journal of Loss Prevention in the Process Industries, 1999, 12(4): 325-329. |

| 6 | Lecysyn N, Dandrieux A, Heymes F, et al. Preliminary study of ballistic impact on an industrial tank: projectile velocity decay[J]. Journal of Loss Prevention in the Process Industries, 2008, 21(6): 627-634. |

| 7 | Ren P, Zhou J Q, Tian A, et al. Experimental investigation on dynamic failure of water-filled vessel subjected to projectile impact[J]. International Journal of Impact Engineering, 2018, 117: 153-163. |

| 8 | 潘旭海, 徐进, 蒋军成, 等. 爆炸碎片撞击圆柱薄壁储罐的有限元模拟分析[J]. 南京工业大学学报(自然科学版), 2008, 30(3): 15-20. |

| Pan X H, Xu J, Jiang J C, et al. Finite element simulation analysis on explosion debris impacting thin-wall cylindrical tanks[J]. Journal of Nanjing University of Technology (Natural Science Edition), 2008, 30(3): 15-20. | |

| 9 | 曹源, 金先龙, 李政. 冲击载荷下柔性储液罐动态响应数值模拟及规律分析[J]. 爆炸与冲击, 2011, 31(5): 469-474. |

| Cao Y, Jin X L, Li Z. Dynamic analysis of flexible containers under impact[J]. Explosion and Shock Waves, 2011, 31(5): 469-474. | |

| 10 | 张涛, 方秦, 吴昊, 等. 商用客机撞击储油罐破坏效应的数值模拟[J]. 振动与冲击, 2015, 34(23): 18-24. |

| Zhang T, Fang Q, Wu H, et al. Numerical simulation for damage effects of a fuel tank under commercial aircraft impact[J]. Journal of Vibration and Shock, 2015, 34(23): 18-24. | |

| 11 | 陈国华, 胡昆, 周池楼, 等. 尖头碎片撞击小尺寸储罐的模拟实验[J]. 爆炸与冲击, 2018, 38(6): 1295-1302. |

| Chen G H, Hu K, Zhou C L, et al. Simulation experiment on small-size tank impacted by conical projectiles[J]. Explosion and Shock Waves, 2018, 38(6): 1295-1302. | |

| 12 | Salahshour S, Fallah F. Elastic collapse of thin long cylindrical shells under external pressure[J]. Thin-Walled Structures, 2018, 124: 81-87. |

| 13 | Liu Y. Thermal buckling of metal oil tanks subject to an adjacent fire[D]. Edinburgh: The University of Edinburgh, 2011. |

| 14 | Godoy L A, Batista-Abreu J C. Buckling of fixed-roof aboveground oil storage tanks under heat induced by an external fire[J]. Thin-Walled Structures, 2012, 52: 90-101. |

| 15 | Pantousa D, Godoy L A. On the mechanics of thermal buckling of oil storage tanks[J]. Thin-Walled Structures, 2019, 145: 106432. |

| 16 | 李玉, 徐春明, 韩帅, 等. 火灾条件下拱顶油罐弱连接结构的失效分析[J]. 化工学报, 2020, 71(7): 3372-3378. |

| Li Y, Xu C M, Han S, et al. Failure analysis of weak connection structure of vaulted oil tank under fire condition[J]. CIESC Journal, 2020, 71(7): 3372-3378. | |

| 17 | Santos F D S, Landesmann A. Thermal performance-based analysis of minimum safe distances between fuel storage tanks exposed to fire[J]. Fire Safety Journal, 2014, 69: 57-68. |

| 18 | Pantousa D. Numerical study on thermal buckling of empty thin-walled steel tanks under multiple pool-fire scenarios[J]. Thin-Walled Structures, 2018, 131: 577-594. |

| 19 | Li Y H, Jiang J C, Zhang Q W, et al. Static and dynamic flame model effects on thermal buckling: fixed-roof tanks adjacent to an ethanol pool-fire[J]. Process Safety and Environmental Protection, 2019, 127: 23-35. |

| 20 | Quiel S E, Marjanishvili S M. Fire resistance of a damaged steel building frame designed to resist progressive collapse[J]. Journal of Performance of Constructed Facilities, 2012, 26(4): 402-409. |

| 21 | Yu W J, Zhao J C, Luo H X, et al. Experimental study on mechanical behavior of an impacted steel tubular T-joint in fire[J]. Journal of Constructional Steel Research, 2011, 67(9): 1376-1385. |

| 22 | Xi F, Li Q M, Tan Y H. Dynamic response and critical temperature of a steel beam subjected to fire and subsequent impulsive loading[J]. Computers & Structures, 2014, 135: 100-108. |

| 23 | Li Y H, Jiang J C, Bian H T, et al. Coupling effects of the fragment impact and adjacent pool-fire on the thermal buckling of a fixed-roof tank[J]. Thin-Walled Structures, 2019, 144: 106309. |

| 24 | 中华人民共和国住房和城乡建设部. 立式圆筒形钢制焊接油罐设计规范: [S]. 北京: 中国计划出版社, 2015. |

| Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of vertical cylindrical welded steel oil tanks: [S]. Beijing: China Planning Press, 2015. | |

| 25 | 胡可. 钢储罐结构爆炸冲击荷载与动力响应的数值模拟研究[D]. 杭州: 浙江大学, 2016. |

| Hu K. Numerical simulation of explosion loading and dynamic response of steel tanks[D]. Hangzhou: Zhejiang University, 2016. | |

| 26 | Yang G D, Wang G H, Lu W B, et al. Numerical modeling of surface explosion effects on shallow-buried box culvert behavior during the water diversion[J]. Thin-Walled Structures, 2018, 133: 153-168. |

| 27 | 孔祥韶. 爆炸载荷及复合多层防护结构响应特性研究[D]. 武汉: 武汉理工大学, 2013. |

| Kong X S. Research on the blast loadings and the response of multi-layer protective structure[D]. Wuhan: WuhanUniversity of Technology, 2013. | |

| 28 | Yao S J, Zhang D, Lu Z J, et al. Experimental and numerical investigation on the dynamic response of steel chamber under internal blast[J]. Engineering Structures, 2018, 168: 877-888. |

| 29 | Mudan K S. Thermal radiation hazards from hydrocarbon pool fires[J]. Progress in Energy and Combustion Science, 1984, 10(1): 59-80. |

| 30 | Hurley M J, Gottuk D, Hall J R, et al. SFPE Handbook of Fire Protection Engineering[M]. New York: Springer, 2016. |

| 31 | Maynard T. Fire interactions and pulsation—theoretical and physical modeling[D]. Riverside: University of California, Riverside, 2013. |

| 32 | Muñoz M, Arnaldos J, Casal J, et al. Analysis of the geometric and radiative characteristics of hydrocarbon pool fires[J]. Combustion and Flame, 2004, 139(3): 263-277. |

| 33 | Zukoski E E, Cetegen B M, Kubota T. Visible structure of buoyant diffusion flames[J]. Symposium (International) on Combustion, 1985, 20(1): 361-366. |

| 34 | 周魁斌, 蒋军成, 张旭. 基于火焰脉动的池火灾辐射热流预测模型[J]. 南京工业大学学报(自然科学版), 2016, 38(4): 114-118. |

| Zhou K B, Jiang J C, Zhang X. Flame pulsation-based model for predicting radiant heat flux of pool fire[J]. Journal of Nanjing Tech University (Natural Science Edition), 2016, 38(4): 114-118. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [9] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [10] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [11] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [12] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [13] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [14] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [15] | 刘晓洋, 喻健良, 侯玉洁, 闫兴清, 张振华, 吕先舒. 螺旋微通道对掺氢甲烷爆轰传播的影响[J]. 化工学报, 2023, 74(7): 3139-3148. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号