化工学报 ›› 2023, Vol. 74 ›› Issue (10): 4302-4310.DOI: 10.11949/0438-1157.20230641

贺巍1,3( ), 曹永娜2,3, 尚宏儒1, 李崯雪3, 郭超4, 于艳玲1,3(

), 曹永娜2,3, 尚宏儒1, 李崯雪3, 郭超4, 于艳玲1,3( )

)

收稿日期:2023-06-28

修回日期:2023-08-30

出版日期:2023-10-25

发布日期:2023-12-22

通讯作者:

于艳玲

作者简介:贺巍(2002—),男,硕士研究生,1074992253@qq.com

基金资助:

Wei HE1,3( ), Yongna CAO2,3, Hongru SHANG1, Yinxue LI3, Chao GUO4, Yanling YU1,3(

), Yongna CAO2,3, Hongru SHANG1, Yinxue LI3, Chao GUO4, Yanling YU1,3( )

)

Received:2023-06-28

Revised:2023-08-30

Online:2023-10-25

Published:2023-12-22

Contact:

Yanling YU

摘要:

为了解决生物质好氧发酵热能难以有效回收的问题,以玉米秸秆为主要原料,采用热交换法,搭建了100 L规模发酵装置和热回收系统,用于回收堆肥蒸汽中的显热和潜热。利用电加热方式模拟好氧发酵产热,从流体流量、设备保温、蓄水量和换热面积多个方面对余热回收工艺进行优化设计,并测试了优化后系统的产热和热回收效果。结果表明,流体流量、水箱保温和蓄水量对系统热回收性能影响较大。在模拟产热方式下,水箱温度能够从17℃升至40℃以上。最终,采用间歇性热回收方式,系统平衡热回收效率达到57%以上,平均热回收功率达到274 kJ/h以上,实现了发酵余热的高效回收。

中图分类号:

贺巍, 曹永娜, 尚宏儒, 李崯雪, 郭超, 于艳玲. 生物质发酵余热回收系统优化设计与性能分析[J]. 化工学报, 2023, 74(10): 4302-4310.

Wei HE, Yongna CAO, Hongru SHANG, Yinxue LI, Chao GUO, Yanling YU. Optimum design and performance analysis of waste heat recovery system for biomass fermentation[J]. CIESC Journal, 2023, 74(10): 4302-4310.

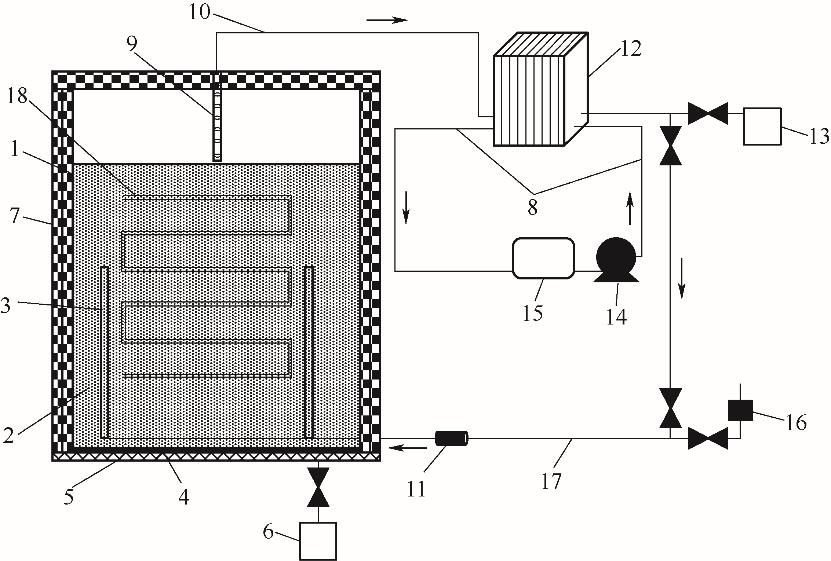

图1 好氧发酵余热回收装置示意图1—保温层;2—发酵堆;3—多孔通气管;4—多孔隔板;5—废水层;6—渗滤液收集器;7—发酵罐;8—水管;9—多孔吸气管;10—进气管道;11—管道抽气机;12—板式换热器;13—冷凝液收集器;14—水泵;15—蓄热水箱;16—空气泵;17—出气管道;18—电加热带

Fig.1 Schematic diagram of the waste heat recovery device for aerobic fermentation1—insulation layer; 2—fermentation heap; 3—porous vent pipe; 4—porous clapboard; 5—wastewater layer; 6—leachate collector; 7—fermenter; 8—water pipe; 9—porous suction pipe; 10—intake pipe; 11—pipeline air pump; 12—plate heat exchanger; 13—condensate collector; 14—pump; 15—heat storage tank; 16—air pump; 17—outlet pipe; 18—electric heating belt

| 部位 | 保温材料 | 热阻/(m2·℃/W) |

|---|---|---|

| 吸气管道和水管 | 橡塑管套 | 0.70 |

| 出气管道 | 铝箔气泡隔热膜 | 0.11 |

| 换热器 | 铝箔气泡隔热膜 | 0.32 |

| 水箱 | 铝箔气泡隔热膜 | 0.21 |

| 发酵罐 | 壁、底:橡塑板; 顶:高密度泡沫板 | 壁:1.77;底:0.88 顶:1.22 |

表1 热回收系统初始保温设计

Table 1 Initial thermal insulation design of the heat recovery system

| 部位 | 保温材料 | 热阻/(m2·℃/W) |

|---|---|---|

| 吸气管道和水管 | 橡塑管套 | 0.70 |

| 出气管道 | 铝箔气泡隔热膜 | 0.11 |

| 换热器 | 铝箔气泡隔热膜 | 0.32 |

| 水箱 | 铝箔气泡隔热膜 | 0.21 |

| 发酵罐 | 壁、底:橡塑板; 顶:高密度泡沫板 | 壁:1.77;底:0.88 顶:1.22 |

| 组别 | R1/(m2·℃/W) | R2/(m2·℃/W) | t1/min | Ts /℃ | |||

|---|---|---|---|---|---|---|---|

| 1 | 0.32 | 0.21 | 170±8 | 36.6±0.3 | 71.2±3.2 | 31.5±0.3 | 44.2±1.5 |

| 2 | 0.58 | 0.21 | 180±5 | 38.3±0.2 | 82.3±4.0 | 33.3±0.2 | 40.5±1.1 |

| 3 | 1.06 | 0.21 | 186±5 | 38.8±0.4 | 77.5±2.8 | 32.2±0.3 | 41.5±1.7 |

| 4 | 0.58 | 0.06 | 165±3 | 32.0±0.6 | 106.2±2.5 | 24.7±0.5 | 23.3±0.1 |

| 5 | 0.58 | 0.46 | 190±5 | 40.1±0.3 | 95.3±1.9 | 38.5±0.3 | 40.4±0.5 |

表2 不同热阻条件下热回收参数的统计及计算结果

Table 2 Statistics and calculation results of heat recovery parameters under different thermal resistance

| 组别 | R1/(m2·℃/W) | R2/(m2·℃/W) | t1/min | Ts /℃ | |||

|---|---|---|---|---|---|---|---|

| 1 | 0.32 | 0.21 | 170±8 | 36.6±0.3 | 71.2±3.2 | 31.5±0.3 | 44.2±1.5 |

| 2 | 0.58 | 0.21 | 180±5 | 38.3±0.2 | 82.3±4.0 | 33.3±0.2 | 40.5±1.1 |

| 3 | 1.06 | 0.21 | 186±5 | 38.8±0.4 | 77.5±2.8 | 32.2±0.3 | 41.5±1.7 |

| 4 | 0.58 | 0.06 | 165±3 | 32.0±0.6 | 106.2±2.5 | 24.7±0.5 | 23.3±0.1 |

| 5 | 0.58 | 0.46 | 190±5 | 40.1±0.3 | 95.3±1.9 | 38.5±0.3 | 40.4±0.5 |

| 组别 | m1/kg | S/m2 | t1/min | Ts/℃ | |||

|---|---|---|---|---|---|---|---|

| 5 | 4.5 | 1.44 | 190±5 | 40.1±0.3 | 95.3±1.9 | 38.5±0.3 | 40.4±0.5 |

| 6 | 7.5 | 1.44 | 240±5 | 33.7±0.2 | 123.6±2.6 | 31.6±0.2 | 25.6±0.4 |

| 7 | 10.5 | 1.44 | 280±5 | 31.6±0.5 | 139.2±3.2 | 32.3±0.5 | 23.2±0.2 |

| 8 | 4.5 | 2.16 | 140±8 | 38.1±0.9 | 93.9±3.1 | 44.7±1.1 | 47.6±0.4 |

表3 不同蓄水量、换热面积条件下热回收参数统计及计算结果

Table 3 Statistics and calculation results of heat recovery parameters under different water storage capacity and heat exchange area

| 组别 | m1/kg | S/m2 | t1/min | Ts/℃ | |||

|---|---|---|---|---|---|---|---|

| 5 | 4.5 | 1.44 | 190±5 | 40.1±0.3 | 95.3±1.9 | 38.5±0.3 | 40.4±0.5 |

| 6 | 7.5 | 1.44 | 240±5 | 33.7±0.2 | 123.6±2.6 | 31.6±0.2 | 25.6±0.4 |

| 7 | 10.5 | 1.44 | 280±5 | 31.6±0.5 | 139.2±3.2 | 32.3±0.5 | 23.2±0.2 |

| 8 | 4.5 | 2.16 | 140±8 | 38.1±0.9 | 93.9±3.1 | 44.7±1.1 | 47.6±0.4 |

| 产热方式 | 热回收方式 | 热流体进口温度/℃ | 热流体进口湿度/% | |||

|---|---|---|---|---|---|---|

| 电加热模拟 | 连续性 | 52降至48 | 100降至77 | 93.9±3.1 | 44.7±1.1 | 47.6±0.4 |

| 电加热模拟 | 间歇性 | 52降至50 | 100降至90 | 120.4±4.3 | 79.9±3.2 | 66.4±0.3 |

| 好氧发酵 | 间歇性 | 53降至45 | 100 | 133.2±3.4 | 77.0±0.9 | 57.8±0.8 |

表4 不同产热-热回收方式下系统热回收性能对比

Table 4 Comparison of system heat recovery performance under different heat production-heat recovery modes

| 产热方式 | 热回收方式 | 热流体进口温度/℃ | 热流体进口湿度/% | |||

|---|---|---|---|---|---|---|

| 电加热模拟 | 连续性 | 52降至48 | 100降至77 | 93.9±3.1 | 44.7±1.1 | 47.6±0.4 |

| 电加热模拟 | 间歇性 | 52降至50 | 100降至90 | 120.4±4.3 | 79.9±3.2 | 66.4±0.3 |

| 好氧发酵 | 间歇性 | 53降至45 | 100 | 133.2±3.4 | 77.0±0.9 | 57.8±0.8 |

| 1 | 李荆波, 丁攀, 兰明明, 等. 玉米秸秆复合菌兼氧预处理产热特性分析[J]. 热科学与技术, 2019, 18(2): 143-154. |

| Li J B, Ding P, Lan M M, et al. Analysis of heat production characteristics of corn straw compound microorganism and aerobic pretreatment[J]. Journal of Thermal Science and Technology, 2019, 18(2): 143-154. | |

| 2 | Fulford B. The composting greenhouse at new alchemy institute: a report on two years of operation and monitoring[R]. New Alchemy Institute, Research Report No.3, 1986. |

| 3 | Malesani R, Pivato A, Bocchi S, et al. Compost heat recovery systems: an alternative to produce renewable heat and promoting ecosystem services[J]. Environmental Challenges, 2021, 4: 100131. |

| 4 | Themelis N. Control of heat generation during composting[J]. Biocycle, 2005, 46: 28-30. |

| 5 | Chambers D. The design and development of heat extraction technologies for the utilisation of compost thermal energy[D]. Galway-Mayo: Galway-Mayo Institute of Technology, 2009. |

| 6 | Allain C. Cold weather operations: energy recovery at biosolids composting facility[J]. BioCycle: Journal of Composting & Recycling, 2007, 48(10): 50-53. |

| 7 | Hirakazu S, Mass Tomoaki K., energy and exergy balances for heat recovery operation from compost[J]. Environment Control in Biology, 2010, 31(4): 205-215. |

| 8 | Hirakazu S. Fermentation heat utilization system and fermentation heat utilization method: JP2013013376[P]. 2013-01-24. |

| 9 | Smith M M, Aber J D. Energy recovery from commercial-scale composting as a novel waste management strategy[J]. Applied Energy, 2018, 211: 194-199. |

| 10 | Bajko J, Fišer J, Jícha M. Condenser-type heat exchanger for compost heat recovery systems[J]. Energies, 2019, 12(8): 1583. |

| 11 | Zeng G M, Huang H L, Huang D L, et al. Effect of inoculating white-rot fungus during different phases on the compost maturity of agricultural wastes[J]. Process Biochemistry, 2009, 44(4): 396-400. |

| 12 | Gou C L, Wang Y Q, Zhang X Q, et al. Inoculation with a psychrotrophic-thermophilic complex microbial agent accelerates onset and promotes maturity of dairy manure-rice straw composting under cold climate conditions[J]. Bioresource Technology, 2017, 243: 339-346. |

| 13 | 詹亚斌, 魏雨泉, 陶兴玲, 等. 餐厨垃圾生物干化研究进展[C]//中国环境科学学会2021年科学技术年会. 天津:《工业建筑》杂志社有限公司, 2021: 272-276. |

| Zhan Y B, Wei Y Q, Tao X L, et al. Research progress of biological drying of food kitchen waste[C]//Proceedings of Science and Technology 2021 of Chinese Society of Environmental Sciences. Tianjin: Industrial Building Magazine Co., Ltd., 2021: 272-276. | |

| 14 | 袁京, 张地方, 李赟, 等. 外加碳源对厨余垃圾生物干化效果的影响[J]. 中国环境科学, 2017, 37(2): 628-635. |

| Yuan J, Zhang D F, Li Y, et al. Effect of external carbon sources on biodrying of kitchen waste[J]. China Environmental Science, 2017, 37(2): 628-635. | |

| 15 | 李清飞, 何新生, 孙震宇, 等. 农村生活垃圾好氧堆肥技术探讨[J]. 农机化研究, 2011, 33(6): 186-189. |

| Li Q F, He X S, Sun Z Y, et al. Aerobic composting technology for rural domestic waste[J]. Journal of Agricultural Mechanization Research, 2011, 33(6): 186-189. | |

| 16 | 白海涛, 柴哲, 柴博, 等. 一种低能耗污泥干燥和好氧发酵装置: 210457913U[P]. 2020-05-05. |

| Bai H T, Chai Z, Chai B, et al. Low-energy-consumption sludge drying and aerobic fermentation device: 210457913U[P]. 2020-05-05. | |

| 17 | 孔馨. 污泥生物干化处理过程强化及特性研究[D]. 昆明: 昆明理工大学, 2022. |

| Kong X. Study on strengthening and characteristics of sludge biological drying treatment process[D]. Kunming: Kunming University of Science and Technology, 2022. | |

| 18 | 石贵振, 王永江. 内循环式浆料好氧发酵反应器的流场与传热分析及其参数优化[J]. 华中农业大学学报, 2021, 40(6): 203-210. |

| Shi G Z, Wang Y J. Flow field and heat transfer and parameter optimization of an internal circulation slurry aerobic fermentation reactor[J]. Journal of Huazhong Agricultural University, 2021, 40(6): 203-210. | |

| 19 | 李一凡, 裴凯, 王永江. 堆肥余热辅热养殖水体的仿真与试验[J]. 华中农业大学学报, 2022, 41(4): 73-78. |

| Li Y F, Pei K, Wang Y J. Experiment and simulation of aquaculture water with compost waste heat and auxiliary heat[J]. Journal of Huazhong Agricultural University, 2022, 41(4): 73-78. | |

| 20 | 王一豪. 动态曝气对好氧堆肥效果及传热特性影响研究[D]. 哈尔滨: 东北农业大学, 2022. |

| Wang Y H. Study on the effect of dynamic aeration on aerobic composting and heat transfer characteristics[D]. Harbin: Northeast Agricultural University, 2022. | |

| 21 | 李明. 有机固体废弃物好氧分解能量回收技术研究[D]. 南京: 南京理工大学, 2015. |

| Li M. Study on energy recovery technology of aerobic decomposition of organic solid waste[D]. Nanjing: Nanjing University of Science and Technology, 2015. | |

| 22 | 王永江, 黄光群, 韩鲁佳. 猪粪好氧堆肥过程有机质降解和热量平衡模型[J]. 农业机械学报, 2011, 42(10): 121-124, 115. |

| Wang Y J, Huang G Q, Han L J. Modeling of organic matter degradation and thermal balance during pig slurry aerobic composting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(10): 121-124, 115. | |

| 23 | 王顺. 猪粪好氧堆肥产热特征及热能回收产电的研究[D]. 济南: 山东大学, 2020. |

| Wang S. Study on heat production characteristics of aerobic composting of pig manure and heat energy recovery to generate electricity[D]. Jinan: Shandong University, 2020. | |

| 24 | 展长虹, 李光皓. 一种农林有机固体废物静态堆肥热回收利用系统: 111393203A[P]. 2020-07-10. |

| Zhan C H, Li G H. Agriculture and forestry organic solid waste static compost heat recycling system: 111393203A[P]. 2020-07-10. | |

| 25 | 于艳玲, 刘净伊, 曹永娜, 等. 一种玉米秸秆好氧堆肥的快速产热菌剂及其应用: 113122483A[P]. 2021-07-16. |

| Yu Y L, Liu J Y, Cao Y N, et al. Rapid heat generation bacterium agent for aerobic composting of corn stalks and application of rapid heat generation bacterium agent: 113122483A[P]. 2021-07-16. | |

| 26 | 耿云灿. EM菌和蚯蚓对玉米秸秆分解的作用[D]. 长春: 长春师范大学, 2022. |

| Geng Y C. Effect of EM bacteria and earthworm on decomposition of corn stalk[D]. Changchun: Changchun Normal University, 2022. | |

| 27 | Tiquia S M, Tam N F Y, Hodgkiss I J. Effects of bacterial inoculum and moisture adjustment on composting of pig manure[J]. Environmental Pollution, 1997, 96(2): 161-171. |

| 28 | Haug R. The Practical Handbook of Compost Engineering[M]. USA: CRC Press, 1993. |

| 29 | 吕黄珍. 猪粪麦秸好氧堆肥工艺参数优化及过程模拟[D]. 北京: 中国农业大学, 2007. |

| Lyu H Z. Optimization of process parameters and process simulation of aerobic composting of pig manure and wheat straw[D]. Beijing: China Agricultural University, 2007. | |

| 30 | 周海瑛, 邱慧珍, 杨慧珍, 等. C/N比对好氧堆肥中NH3挥发损失和含氮有机物转化的影响[J]. 干旱地区农业研究, 2020, 38(2): 69-77. |

| Zhou H Y, Qiu H Z, Yang H Z, et al. Effects of C/N ratio on NH3 volatilization loss and nitrogen-containing organic compounds conversion in aerobic composting[J]. Agricultural Research in the Arid Areas, 2020, 38(2): 69-77. | |

| 31 | 胡菊. VT菌剂在好氧堆肥中的作用机理及肥效研究[D]. 北京: 中国农业大学, 2005. |

| Hu J. Study on the mechanism and fertilizer efficiency of VT microbial inoculum in aerobic composting[D]. Beijing: China Agricultural University, 2005. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [4] | 张龙, 宋孟杰, 邵苛苛, 张旋, 沈俊, 高润淼, 甄泽康, 江正勇. 管翅式换热器迎风侧翅片末端霜层生长模拟研究[J]. 化工学报, 2023, 74(S1): 179-182. |

| [5] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [6] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [7] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [8] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [9] | 邹启宏, 李乾, 葛天舒. 基于多目标下的两级并联除湿热泵系统实验研究[J]. 化工学报, 2023, 74(S1): 265-271. |

| [10] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [11] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [12] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [13] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [14] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [15] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号